Summary of Contents for YASKAWA PVI 60TL

- Page 1 PVI 50TL PVI 60TL INSTALLATION AND OPERATION MANUAL Revision E ©2017, Yaskawa - Solectria Solar...

- Page 2 PVI 50/60 TL Installation and Operation Manual (Rev E) IMPORTANT REGISTRATION AND WARRANTY INFORMATION For warranty to become active, this inverter must be registered. To activate warranty and register inverter, please visit the link below. www.solectria.com/registration DOCR-070645-E Page 2 of 102...

-

Page 3: Before You Start

PVI 50/60TL. Be sure to read this manual carefully before using the inverter. Thank you for choosing a Yaskawa – Solectria Solar grid-tied PV Inverter. This PV Inverter is a high performance and highly reliable product specifically designed for the North American Solar market. -

Page 4: Important Safety Instructions

IMPORTANT Safety Instructions SAVE THESE INSTRUCTIONS Please read this user manual carefully before product installation. Yaskawa - Solectria Solar reserves the right to refuse warranty claims for equipment damage if the user fails to install the equipment according to the instructions in this manual. - Page 5 PVI 50/60 TL Installation and Operation Manual (Rev E) Markings on the Product HIGH VOLTAGE: This inverter works with high voltages. All work on the product must only be performed as described in this document. HOT SURFACE: The equipment is designed to meet international safety standards, but surfaces can become hot during operation.

- Page 6 PVI 50/60 TL Installation and Operation Manual (Rev E) For continued protection against risk of fire, replace only with same type and ratings of fuse. Pour une protection continuelle contre tout risque d'incendie, remplacez les fuses uniquement avec le même type et calibre." DANGER: Please disconnect the inverter from AC grid and PV modules before opening the equipment.

-

Page 7: Table Of Contents

PVI 50/60 TL Installation and Operation Manual (Rev E) BEFORE YOU START… ................. 3 PLEASE KEEP THIS USER MANUAL ON HAND FOR QUICK REFERENCE. ALWAYS CHECK ONLINE FOR AN UPDATED VERSION OF THIS PRODUCT MANUAL. THE CONTENTS OF THIS DOCUMENT ARE SUBJECT TO CHANGE WITHOUT NOTICE. - Page 8 PVI 50/60 TL Installation and Operation Manual (Rev E) 3.1.1 Mechanical Installation ...............55 3.1.2 Cable Connections ...............55 3.1.3 Electrical Check ................55 3.2 C ..............55 OMMISSIONING TEPS 4.0: USER INTERFACE ................58 4.1 D ............. 58 ESCRIPTION OF THE NTERFACE 4.2 O ................

- Page 9 PVI 50/60 TL Installation and Operation Manual (Rev E) 6.2.4 Replace the Inverter ..............92 6.3 U ............94 NINSTALLING THE NVERTER 7.0: PRODUCT WARRANTY AND RMA POLICY .......... 94 8.0: TECHNICAL DATA ................95 9.0: ACCESSORY OPTIONS ..............100 ..............100 YPASS ..............

-

Page 10: Overview

PVI 50/60 TL Installation and Operation Manual (Rev C) 1.0: Overview 1.1 Inverter for Grid-Tied PV Systems The PVI 50/60TL inverter is suitable for use on commercial and utility-scale rooftop, carport and ground mount grid-tied PV systems. A system is generally made up of PV modules, DC power distribution equipment, PV inverter and AC power distribution equipment (Figure 1.1). -

Page 11: Product Protection Functions

PVI 50/60 TL Installation and Operation Manual (Rev C) 1.3 Product Protection Functions Reverse polarity protection on the DC inputs Short circuit protection Arc-Fault Circuit Interruption Anti-islanding protection Input and output over-voltage protection Input over-current protection ... -

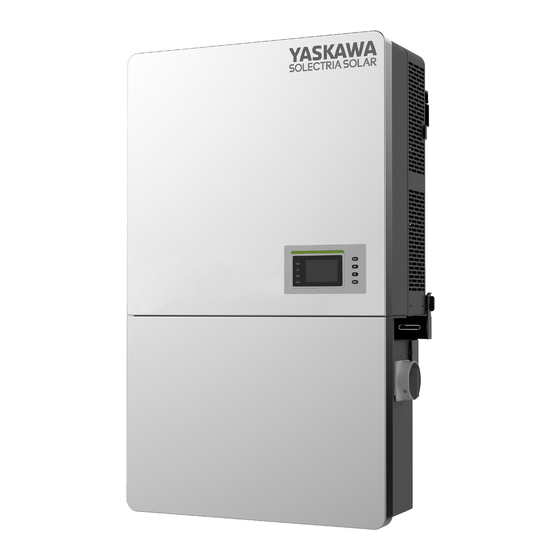

Page 12: Appearance Description

PVI 50/60 TL Installation and Operation Manual (Rev C) 1.5 Appearance Description Figure 1.3 - Sketch of PVI 50/60TL Inverter Main Items of the Inverter: 1) Main inverter section 2) Wiring box of the inverter 3) Mounting bracket 4) External cooling fans 5) LED indication lights 6) LCD 7) Key buttons... -

Page 13: Dc Ground Fault Protection

PVI 50/60 TL Installation and Operation Manual (Rev C) these small variations will have negligible effects on system voltage and frequency. However, in an islanded condition the small amount of reactive power changes will force the system voltage or frequency to change significantly, which will trigger the inverter to shut down. - Page 14 PVI 50/60 TL Installation and Operation Manual (Rev C) Upon which inverter is hung and Mounting bracket mounted onto a wall User manual Installation and operation manual Accessory kit Contains all necessary accessories The (5) Accessory kit contains items listed below, in Table 2.2: Table 2.2 –...

- Page 15 PVI 50/60 TL Installation and Operation Manual (Rev C) Table 2.3 – Accessory Kit Components (H4 wiring box) Q’ty Item Note M8 Expansion tubes For mounting bracket M8×25 assembling bolts For mounting bracket 4 for wiring box and main housing; M6 X18 screw 6 for inverter and mounting bracket;...

-

Page 16: Recommendations Before Installation

PVI 50/60 TL Installation and Operation Manual (Rev C) 2.1 Recommendations Before Installation Check that the product environmental specifications (protection degree, operating temperature range, humidity and altitude, etc.) meet the requirements of the specific project location. Make sure that the AC grid voltage is within the normal range. ... -

Page 17: Mechanical Installation

PVI 50/60 TL Installation and Operation Manual (Rev C) 2.2 Mechanical Installation 1) Dimensions Figure 2.1 - PVI 50/60TL Inverter Dimensions 2) Installation Method (see Figure 2.2): Make sure that the mounting structure (wall, rack, etc.) is suitable to support the inverter weight. - Page 18 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.2 - Inverter Mounting WARNING: Shade cover accessory required for installation angles of 75° or less. DOCR-070645-E Page 18 of 102...

- Page 19 PVI 50/60 TL Installation and Operation Manual (Rev C) 3) Installation Space Requirement (see Figure 2.3): The distances between the inverters or the surrounding objects should meet the following conditions: NOTICE: The spacing between two adjacently mounted inverters should be ≥500mm (19.7 in.).

- Page 20 PVI 50/60 TL Installation and Operation Manual (Rev C) La distance d'installation entre deux onduleurs doivent être élargie quand é é ℃ la temp rature ambiante est sup rieure à 45 Figure 2.4 - Inverter Pillar Mounting Specifications INSTRUCTION: If the inverter is installed on Unistrut or the array racking (instead of solid wall), the space from the bottom of one inverter to the top of the inverter below may be as small as 4in.

- Page 21 PVI 50/60 TL Installation and Operation Manual (Rev C) 4) Mounting the Inverter onto the Bracket (1) Mark the 8 holes on the bearing surface for mounting the bracket as shown in Figure 2.5; 4.5” Figure 2.5 - Holes on the Bearing Surface Dimensions (2) Drill holes at the marked positions with a 10mm (0.4in.) drill and put the M8 expansion tubes ①...

- Page 22 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.7 - Securing the Mounting Bracket (3) Hang the inverter onto the mounting bracket as shown in Figure 2.8 and Figure 2.9; Lift mounting: Take out the lifting eye nut M10 (2pcs) from the accessory kit, and screw them onto the studs at the top of the inverter.

- Page 23 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.8 - Mounting the Main Inverter Section on the Bracket Figure 2.9 - Grab Handle Position (4) Installing the wiring box ① Remove the cover plate at the bottom of the main section. (see Figure 2.10) Tool: No.2 Phillips head screwdriver DOCR-070645-E Page 23 of 102...

- Page 24 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.10 – Main Section Cover Plate ② Remove the cover at the top of the wiring box (see Figure 2.11) Figure 2.11 - Wiring Box Cover ③ Connect the wiring box to the main section, using M6x18 screws (4pcs) to secure the wiring box.

- Page 25 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.12 - Wiring Box Installation CAUTION: The total weight of the PVI 50/60TL inverter is 156 pounds (71kg). Please ensure the mounting is properly installed before hanging the inverter on the bracket. Le poids total de la PVI 50/60TL onduleur est d'environ 71 kg (156 livres).Veuillez vous assurer que le support est correctement installé...

- Page 26 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.13 - Secure the Main Section and Wiring Box to the Bracket (6) Optional - Install an anti-theft padlock when the installation is complete. The anti-theft padlock is used to help prevent the inverter from being stolen when the equipment is installed outdoors.

- Page 27 PVI 50/60 TL Installation and Operation Manual (Rev C) The anti-theft padlock should meet the requirement of the dimensions shown in Figure 2.15: Recommended lock size: A: Ф3~6mm B: 20~50mm C: 20~50mm Figure 2.15 - Dimensions of Anti-Theft Padlock (7) Attach the cover board as shown in Figure 2-10 to the left side of the wiring box.

- Page 28 PVI 50/60 TL Installation and Operation Manual (Rev C) 5) Removing/Replacing the Wiring Box Cover: (1) Use a #3 Phillips screwdriver to remove the 4 screws on the wiring box and pull cover straight off the box. Do not twist or slide the cover while removing. (see Figure 2.17) Figure 2.17 –...

-

Page 29: Electrical Installation

PVI 50/60 TL Installation and Operation Manual (Rev C) 2.3 Electrical Installation There are two options for wiring box, please confirm which one you have: Figure 2.18 – (a) Standard wiring box (b) H4 quick connect wiring box The connection interface of the PVI 50/60TL inverter with Standard wiring box: Figure 2.19 - Full View of Standard Wiring Box with Options DOCR-070645-E Page 29 of 102... - Page 30 PVI 50/60 TL Installation and Operation Manual (Rev C) 20.5in(520mm) 19.0in(483mm) 17.5in(445mm) 13.2in(336mm) 10.2in(258mm) 7.1in (180mm) DC INPUT COMM. PORT DC INPUT DC INPUT AC OUTPUT For more details please see the user manual. WARNING: High touch current . Earth connection essential before connecting supply.

- Page 31 PVI 50/60 TL Installation and Operation Manual (Rev C) 7. Internal ground connection point and grounding studs 8. AC output terminal block The connection interface of the PVI 50/60TL inverter with H4 wiring box: 9.4 in. (237mm) 3.9 in. (99mm) COMM.

- Page 32 PVI 50/60 TL Installation and Operation Manual (Rev C) Choose the cables for inverters according to the following configuration table: Table 2.5 - Cable Specifications Position Cable #10-8AWG (Copper only) using fuse holders DC input (﹢/﹣) Up to #2AWG (Copper or Aluminum) using bypass terminal kit #3-2/0 AWG (Copper) #2-2/0 AWG Aluminum...

-

Page 33: Dc Connection

In Independent mode each PV input section works with an independent MPP Tracker. 2) DC Fuse Configuration Table 2.6 - DC Input Power Specification (Independent mode – PVI 50/60TL per zone - DEFAULT) PVI 50TL PVI 60TL Rated DC power 17.5kW (36A) 20.5kW (38A) Max DC power allowed 25kW 30kW... - Page 34 PVI 50/60 TL Installation and Operation Manual (Rev C) The PVI 50/60TL inverters are equipped with standard 15A DC fuses. Customers must verify that the appropriate fuses are installed depending on the PV system design. (a) Each independent PV DC input string needs fuse protection. (b) The rated voltage of fuses should be 1000V (c) The rated current of fuses is generally 1.56 ×...

- Page 35 PVI 50/60 TL Installation and Operation Manual (Rev C) WARNING: Working with live voltage is dangerous. It is recommended to have all live circuits disabled prior to performing connections. Table 2.8 - DC Input Configuration Configuration for DC Wire Conductors each MPPT zone Connect to: Inputs...

-

Page 36: Dc Connection For Standard Wiring Box

PVI 50/60 TL Installation and Operation Manual (Rev C) positive, the polarity of the strings is correct. ii. The positive (+) end of the PV string conductor should match the positive (+) terminal of inverter’s DC input. iii. The negative (-) end of the PV string conductor should match the negative (-) terminal of inverter’s DC input. - Page 37 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2.27- DC Input Cable Connection (standard wiring box) (c) If you prefer to route all DC cables thru a single hole inside the wiring box please refer to Figure 2.28 Figure 2.28- DC Input Cable Connection ①...

-

Page 38: Dc Connection For H4 Wiring Box

PVI 50/60 TL Installation and Operation Manual (Rev C) 2.3.1.2 DC Connection for H4 Wiring Box (a) Check the polarity of the DC input cables to avoid any risk of reverse polarity. (b) Put the positive (negative) DC cable through the gland and cable fastener, and then crimp the cable with the cord end terminals shown in Table 2-9. -

Page 39: Individual Maximum Power Point Tracking

PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2-31 Plug DC cable connectors 2.3.1.3 Individual Maximum Power Point Tracking The inverter is designed with three separate MPP Trackers (MPPT), which operate independently. IN1+ PV1+ IN1- PV1- IN2+ PV2+ Inverter IN2- PV2-... -

Page 40: Ac And Ground Connections

PVI 50/60 TL Installation and Operation Manual (Rev C) NOTE: Connecting all of the inputs at zone “PV1” will result in only utilizing 33% of the inverter power WARNING: Strings must be balanced for optimum performance and AC output. When doing DC/AC ratio sizing, perform calculations at the zone level. - Page 41 PVI 50/60 TL Installation and Operation Manual (Rev C) Tools Where used #3 Phillips screwdriver Remove cover, external grounding 1/4” flat head bit Internal grounding bar 14mm hex socket wrench AC terminal block Torque wrench AC terminal block Diagonal pliers Cut cables Wire stripping pliers Remove insulation of wires...

- Page 42 PVI 50/60 TL Installation and Operation Manual (Rev C) AC Output: Use 90¡ã C wire, either 3~2/0AWG copper or AC Output: Use 90¡ã C wire, either 3~2/0AWG copper or 2~2/0AWG aluminum, torque 110 in-lbs. 2~2/0AWG aluminum, torque 110 in-lbs. AC Ground: Use 90¡ã...

- Page 43 PVI 50/60 TL Installation and Operation Manual (Rev C) OT type terminal,4pcs Pre-insulated end ferrule 1pcs Core wire Pre-insulated end ferrule Core wire OT type terminal Figure 2.36 - AC Output and Ground Cable setup NOTICE: Please connect the Ground cable before any AC cable. It is required to use the AL9CU OT type terminal or equivalent if you chose the aluminum cable for AC output.

- Page 44 Inverter AC breaker rated current(A) PVI 50TL PVI 60TL NOTE: If you are using aluminum wires you need to follow the following steps to prep each cable prior to connecting to the AC terminal block: a) Using a utility knife, gently strip the top layer of the aluminum conductors...

- Page 45 PVI 50/60 TL Installation and Operation Manual (Rev C) Table 2.13 – Transformer configurations When interfacing with a Wye-grounded transformer winding, a neutral is required. Since the neutral is used by the inverter for voltage sensing only, the neutral does not carry current.

-

Page 46: Inverter Communication Connections

In addition to SolrenView and/or third party monitoring, these inverters are also able to send data to an online portal which is used for remote diagnostic purposes. This capability can be used by Yaskawa-Solectria Solar for remote diagnostics, remote firmware upgrades and remote troubleshooting. - Page 47 PVI 50/60 TL Installation and Operation Manual (Rev C) Below is a brief description of the communication board: Table 2.14 – Communication Board Connections and Configuration Switches Item Picture Configuration Description 1. USB port S200 Firmware upgrade via USB drive 1 -----12V+ 2 -----12VGND 2.

- Page 48 PVI 50/60 TL Installation and Operation Manual (Rev C) 2.4.2 Ethernet Network Card: A maximum of 32 inverters can be connected to this device. When provided with an internet connection, it can send data to an online portal which Solectria can use for troubleshooting and remote diagnostic purposes.

- Page 49 PVI 50/60 TL Installation and Operation Manual (Rev C) Table 2.15 – Overview of Ethernet Card Item Configuration Description and Function Ethernet Port For connecting to the internet USB Port Firmware upgrade via USB drive 1.RS485+ 2. RS485- External RS485 3 .Ground For RS485 communication with other inverters For RS485 communication with the inverter...

- Page 50 RS485 daisy chain. The Inverter Modbus IDs are configurable from 1 to 128. Yaskawa - Solectria Solar recommends limiting the RS485 daisy chain for PVI 50/60TL inverters to a maximum length of 3000 ft. (914m). Additionally, no individual run should be longer than 300 ft. (91.4m).

- Page 51 PVI 50/60 TL Installation and Operation Manual (Rev C) Figure 2-44 Correct and incorrect topologies It is important to daisy chain the inverter RS485 connections to minimize noise and bus reflections. Any network topologies shown in the left column in figure 2.44 should be avoided.

-

Page 52: Preparing The Inverter For Modbus Communications

PVI 50/60 TL Installation and Operation Manual (Rev C) 4. If the inverter is the last Modbus device in the daisy chain and the inverter without the Ethernet Network Card, make sure the Modbus termination switch S1 is in the ON position, enabling Modbus termination. -

Page 53: Installing The Ethernet Network Card

PVI 50/60 TL Installation and Operation Manual (Rev C) 2.4.2 Installing the Ethernet Network Card Figure 2-46 Communication card and location for Ethernet Network card The Ethernet Network Card will be installed in the first or last inverter of the daisy chain. 1. -

Page 54: Connecting The Ethernet Network Card To Other Inverters

PVI 50/60 TL Installation and Operation Manual (Rev C) 2.4.3 Connecting the Ethernet Network Card to other inverters. 1. The connector in the upper left corner of the Ethernet Network Card allows for a connection of the inverter daisy chain on the Communication Card. 2. -

Page 55: Commissioning

PVI 50/60 TL Installation and Operation Manual (Rev C) 3.0: Commissioning WARNING: Please follow the guidelines below before on-grid operation to eliminate possible dangers and to ensure safety. Veuillez suivre les directives ci-dessous avant l'opération on-grid pour éliminer les dangers possibles pour assurer la sécurité. 3.1 Commissioning Checklist 3.1.1 Mechanical Installation Make sure that the mounting bracket is secure and all the screws have been tightened... - Page 56 PVI 50/60 TL Installation and Operation Manual (Rev C) When the inverter completes “sys checking”, the LCD shows the screen as Figure 3.1 below. Press ENTER to the standard selection interface, as shown in Figure 3.1. The default grid standard is IEEE 1547. If a different standard is needed please go to “Menu Functions”...

- Page 57 PVI 50/60 TL Installation and Operation Manual (Rev C) 8.) Time Setting: The date and time can be set as in Figure 3.3: Time setting Date: 2016–05 - 21 Time: 12 :21 :03 P1/1 Figure 3-3 Time Setting 9.) When the LCD screen shows the normal operation status (Figure 3.4) and the “RUN” light on the LED panel lights up, it indicates that the grid connection and power generation are successful.

-

Page 58: User Interface

4.0: User Interface 4.1 Description of the Interface The inverter’s user interface screen mainly consists of LCD, LED indicator lights, buzzer and 4 keys, as shown in Figure 4.1. POWER GRID FAULT Figure 4.1 - LCD Interpretation for the indicator lights is shown in Table 4.1 and function of the keys is shown in Table 4.2. -

Page 59: Operation State

Light Indicates a Fault Slow Indicates Alarm (light on 0.5s, light off Fault status flash FAULT indication Fast Protective action (light on 0.5s, light off light flash 0.5s) Light No fault or power supply not working Table 4.2 - Definition of the Keys Description Definition of function Escape key... -

Page 60: Interface Types

Users can perform the corresponding operations with the 4 function keys according to the indications of the LCD. (1) The LCD interface starts with the company logo once the system is energized, as shown in Figure 4.2. Yaskawa Solectria Solar Initialization Figure 4.2 - Logo Screen (2) Indication of inverter operation mode:... -

Page 61: Menu Functions

daily generated power and time information under normal operation. The fault information of the most recent / currently present fault will be shown on the LCD when the inverter is in fault mode. 4.4 Menu Functions LCD displays “Main user interface” when the inverter is in operation mode. Press ESC in this interface to escape the default interface and to enter the main operation interface. - Page 62 PV Information Independent PV Input Mode PdcTotal(kW) Vdc(V) Idc(A) P1/4 AC Output L1-N L3-N L2-N V(V) I(A) Main Menu F(Hz) Measurement Data Pac(Kw) Setting P Ref 100.0% Power On/Off PF Ref 1.000 History Record P2/4 Device Information Energy E-Today(kWh) E-Month(kWh) E-Total(kWh) P3/4 Others...

-

Page 63: Setting

4.4.2 Setting Move the cursor to “Settings” in the main interface. Press ENT, you will be asked for a password. Enter the password: “1111”as shown Figure 4.7. Change the password digits by pressing . Then press ENT to input the next digit and Press ENT to confirm the password or Press ESC return back to setting. -

Page 64: System Parameters

4.4.2.1 System Parameters (1) “Language Setting” One language, i.e. English is available in “Language” menu. (2) “Grid Rule”: There are four grid standards. Selecting the corresponding grid standard and press ENT confirm the selection as shown in Figure 4-9. Grid Connection Rule IEEE1547 Rule-21 HECO-HM... - Page 65 automatically if alarm or protection faults occur. This function will not respond when the inverter is in operation mode and a “FaultOperated” alarm interface is indicated. (2) “Factory Default” menu: The manufacturer’s default parameters value can be restored when the inverter is not in operation mode. If you try to change the parameters while the unit is operational “Fault Operated”...

-

Page 66: Protect Parameters

4.4.2.3 Protect Parameters In this interface you can change the Protect parameters of grid voltage, frequency and recovery, etc., as shown in Figure 4-10. But you can’t enable/disable the function. The protect parameters are shown in Table 4.3. Grid Over Voltage Protection Grid Low Voltage Protection 110.00% 88.00%... - Page 67 Table 4.3 Protection Parameters (IEEE1547) REMARK: Please contact Applications Engineering if you need to change any of the voltage settings. Grid Over Voltage Protection Setup range (lower limit, Parameter name Description default & upper limit) Threshold value of Level 1 Max. {100.00%, 110.00%, GridVoltMax1 grid voltage...

- Page 68 Protection threshold value of GridFrqMin2 {54, 57, 60} Level 2 Min. grid frequency Trip time of Level 2 Min. grid FrqMinTripT2(s) {0, 0.16, 655} frequency Protection threshold value of GridFrqMin3 {54, 57, 60} Level 3 Min. grid frequency Trip time of Level 3 Min. grid FrqMinTripT3(s) {0, 0.16, 655} frequency...

-

Page 69: L/Hvrt Parameters

Setup range (lower limit, Parameter name Description default & upper limit) Threshold value of grid voltage GridVolBalance (0.01%,10%,10%) unbalance 4.4.2.4 L/HVRT Parameters “L/HVRT” is for setting the Low Voltage Ride-Through (LVRT) and High Voltage Ride-Through (HVRT) parameters. Move the cursor to this item, and press ENT to set the parameters. - Page 70 1.25 Through 1.15 5,6,7,8 Trip 1.05 Time/S 2 4 6 8 10 12 14 16 18 20 22 Figure 4.13 HVRT graph Table 4.4 LVRT and HVRT parameters LVRT Setup range (lower limit, Parameter name Description default & upper limit) Threshold value of Low voltage ride {0%, 0%, 100%} LVRTVolt (1,2)

- Page 71 through(first or second point) {100%, 125%, 135%} Time of Level high voltage ride {0, 0, 655} HVRTTime (1,2) through(t first or second point) {0, 0.8, 655} Threshold value of high voltage ride {100%, 124%, 135%} HVRTVolt(3,4) through(third or fourth point) {100%, 124%, 135%} Time of Level high voltage ride {0, 0.8, 655}...

-

Page 72: Power Derating Setting

4.4.2.5 Power Derating Setting “Power Derating Setting” menu is to set the active power derating parameters include active power derating, over frequency derating, low frequency derating and high temperature frequency derating, etc. The parameters are shown in Table 4.5. Power vs Friquency 60.4 OvrFrqMin(Hz) OvrFrqMax(Hz) -

Page 73: Reactive Derating Setting

Recovery time of grid over voltage OvrVoltFilterT(s) {1,60,90} derating Grid Over Frequency Derating Setup range (lower limit, Parameter name Description default & upper limit) Min Threshold value of grid over OvrFrqMin(Hz) {60,60.2,72} Frequencyderatingstarted Max Threshold value of grid over OvrFrqMax(Hz) {60,61.4,72} Frequencyderating over Slop of grid over... - Page 74 (1) CtrMode: Set the control mode of reactive power 0: Disable dispatch mode 1: Remote dispatch mode 2: Local control, by Q 3: Local control, by PF 4: PF(P) curve 5: Q(U) curve (2) PF Set: Set the PF value NOTE: You can change the reactive power by adjusting the power factor (3) PF(P) Curve:PF curve mode NOTE: The power factor changes according to the power change, as shown in Figure...

- Page 75 Q(%) (QuCurveU2i,QuCurveQ2i) Inductive (QuCurveU1, QuCurveQ1) (QuCurveU1i, U(V) QuCurveQ1i) Capacitive (QuCurveU2,QuCurveQ2) Figure 4.17 Q(U) Curve Mode The Table 4.6 lists the parameters of PF Set, PF(P) Curve and Q(U) Curve modes. After you setup the parameters, press ENT to activate the modes. Table 4.6 - Parameters of Reactive Power Control (IEEE-1547) Grid Reactive Power Derating Setup range (lower limit,...

-

Page 76: Arc Parameters

Figure 4-15 QuCurveU1i(V) {432,441.4,456} Figure 4-15 QuCurveQ1i {-1,0,1} Figure 4-15 QuCurveU2i(V) {384,432,441.4} Figure 4-15 QuCurveQ2i {-1,0.5,1} QuCurveTriPower {0.05,0.2,1} Qu curve trip power Qu curve revocation QuCurveUndoPower {0.05,0.05,1} power 4.4.2.7 Arc Parameters The ARC Parameters submenu is to enable/disable the ARC detection function and set the ARC parameters. - Page 77 Others Others Others FaultPowerT(C) Islang Protect PowerOnDelay(s) 95.0 Enable PVSlowStartSlope 10.00% Disable FaultEnvT(C) Fan Detect 83.0 Enable ErrSoftStartP 0.16% Enable NormSoftStopP 6.00% Setting Others Parameters NormSoftStartP 4.00% 6.00% NormalDeratingStep P1/5 P2/5 P5/5 Others Others GFCIStaticValue(mA) PVStarupVolt(V) Enable MPPTScanPeriod(s) GFCIStaticT(s) 3600 Enable GFCIDynProFactor ISOProtection...

-

Page 78: Power On/Off

4.4.3 Power ON/OFF A manual power cycle ON/OFF is required after any parameter change, after getting an error message or updating the software. The unit will automatically go into the OFF state. Press ESC or ENT to enter into the Main Menu, then press ENT and go to the submenu “Power On/OFF”. -

Page 79: Device Information

4.4.5 Device Information Move the cursor to the main operation interface “Main Menu”. Press ENT and go to sub menu “Device Information” and press ENT to check the device information as shown in Figure 4-21. Inverter information Device Model: SCA60KTL-DO/US- PVI-50/60TL Device SN: 0 0000 0000 0000 DSP Ver:... -

Page 80: Operation

5.0: Operation 5.1 Start-Up Manual Start-up: Manual start-up is required after regulation setting change or manual (fault) shut-down. Move the cursor from the main operation interface to “Setting”. Press ENT and go to submenu “1 ON/OFF”. Then move the cursor to “ON” and press ENT to start the inverter. - Page 81 E-total: E-Today: Running Status Cycle Display Status Addr:000 2015-10-22 10:00:00 Figure 5.2 - Default Indication Interface for Normal Operation In this mode, the inverter converts the power generated by PV modules to AC continuously and feeds into the power grid. (3) Standby mode, as shown in Figure 5.3: The inverter will enter standby mode when the output voltage and power of PV modules do not meet the startup conditions or PV voltage and input power are lower...

-

Page 82: Grid-Tied Power Generation

Current Error Date Time Error 2015/10/22 12:20:08 ArcboardErr 2015/10/22 12:20:08 Fault0040 Fault0040 2015/10/22 12:20:08 Fault0040 2015/10/22 12:20:08 Fault0040 2015/10/22 12:20:08 P1/1 Figure 5.4 - Fault Indication Interface WARNING: All installation and wiring connections should be performed by qualified technical personnel. Disconnect the inverter from PV modules and the AC supply before performing maintenance. -

Page 83: Maintenance And Removal Of Inverter

6.0: Maintenance and Removal of Inverter 6.1 Fault Shutdown and Troubleshooting 6.1.1 LED Fault and Troubleshooting When contacting Solectria for support please provide the serial number of the inverter and the fault message. If the fault is regarding a voltage issue, please measure the AC and DC voltage at the inverter prior to calling. - Page 84 Table 6.2 - LCD Troubleshooting Table Definition: Communication inside inverter failed Possible causes: Terminal block connecters of internal communication wires have poor contact 1.CommErr Recommended solutions: 1.Observe for 5 minutes and see whether the alarm will be eliminated automatically; 2.Turn off both AC and DC disconnect for 2 minutes and reset the inverter;...

- Page 85 Definition: Internal alarm Recommended solutions: Warn0030 1.Observe for 5 minutes and see whether the alarm will (EepromErr) be eliminated automatically; 2. Contact after-sales service personnel if the error persists Recommended solutions: 1. Visually check the DC SPD device to see if its indicator is red.

- Page 86 2. Contact after-sales service personnel if the error persists 1.Confirm that external ambient temperature is within the specified range of operating temperature; 2.Check whether air inlet is blocked; TempOver 3.Check whether fan is blocked; (Over-temperature 4.Check whether the location of installation is protection) appropriate or not;...

- Page 87 (Mini MCU Fault) Wait for 1 minute between OFF and ON for all energy to discharge. 2. Contact after-sales service personnel if the error persists 1. Restart inverter by recycle both AC and DC switches. Protect0110 Wait for 1 minute between OFF and ON for all energy to (BUS over voltage discharge.

- Page 88 persists 1. Restart inverter by recycle both AC and DC switches. Fault0130 Wait for 1 minute between OFF and ON for all energy to (Bus over total discharge. voltage) 2. Contact after-sales service personnel if the error persists Fault0110 1. Contact after-sales service personnel if the error (Bus imbalance) persists 1.

- Page 89 1. Restart inverter by recycle both AC and DC switches. Fault0020 Wait for 1 minute between OFF and ON for all energy to (Bus over volt discharge. Hardware) 2. Contact after-sales service personnel if the error persists 1. Restart inverter by recycle both AC and DC switches. Fault0150 Wait for 1 minute between OFF and ON for all energy to (Open-loop self-check...

-

Page 90: Product Maintenance

6.2 Product Maintenance 6.2.1 Check the Electrical Connection Check all the cable connections as a regular maintenance inspection every 6 months or every year. 1.) Check the cable connections. If loose, tighten all the cables according to “2.3 Electrical Installation”. 2.) Check for cable damage, especially whether the cable surface is scratched or smooth. - Page 91 50~60mm Figure 6.1 - Replace Cooling Fans DOCR-070645-E Page 91 of 102...

-

Page 92: Replace The Inverter

6.2.4 Replace the Inverter Please confirm the following before replacing the inverter: (1) The inverter is turned off. (2) The DC switch of the inverter is turned to OFF position. Afterwards replace the inverter according to the following steps: a.) Unlock the padlock if it is installed on the inverter. Figure 6.2 - Unlock the Padlock b.) Use a No. - Page 93 Figure 6.3 - Remove the Screws on Both Sides c.) Use a No. 10 Hex wrench to remove the 4 screws between the main section and the wiring box. Lift up the main section and disconnect from the wiring box. Figure 6.4 - Disconnect the Main Section from the Wiring Box d.) Use a No.2 Phillips head screwdriver to remove the 2 screws on the left side of the wiring box, and take off the cover board.

-

Page 94: Uninstalling The Inverter

6.3 Uninstalling the Inverter Uninstall the inverter according to the following steps when the service is due or for other reasons: DANGER: Please disconnect the electrical connection in strict accordance with the following steps. Otherwise, the inverter will be damaged and the service personnel’s life will be endangered. -

Page 95: Technical Data

8.0: Technical Data Model Name PVI 50TL PVI 60TL DC Input Max. PV Power 75kW (25kW/MPPT) 90kW (30kW/MPPT) Nominal DC Input Power 51.5kW 61.5kW Max. DC Input Voltage 1000Vdc Operating DC Input 200-950Vdc Voltage Range Start-up DC Input Voltage 330V/80W... - Page 96 Max. Efficiency 99.0% CEC Efficiency 98.5% Stand-by / Night <30W / <2W Consumption Environment Protection Degree TYPE 4X Cooling Variable speed cooling fans Operating Temperature -22°F to +140°F / -30°C to +60°C (derating from +122°F Range / +50°C) Operating Humidity 0-95%, non-condensing Operating Altitude 13123.4ft / 4000m (derating from 9842.5ft / 3000m)

- Page 97 NOTE 1: When the DC input voltage is lower than 540V (for PVI 60TL) and 480V (for PVI 50TL) or higher than 850V, the inverter begins derating, as shown in Figure 7.1 and Figure 7.2. 110% 100% 0.8%/V 100 200 300 400 500 600...

- Page 98 NOTE 2: When the ambient temperature is higher than 113°F (45°C), the output power may begin derating. For DC voltage as shown in Figure 7.3: Output Power Celsius Figure 7.3 - PVI 50/60TL Derating Curve with High Temperature Note: At 60 degrees C the inverter is likely to shutoff. Depending on various factors like angle of installation, air flow and others, the thermal shutdown may occur at higher temperature like 61-63 degrees C.

- Page 99 NOTE 3: When the altitude is higher than 9843ft (3000m), the power of the inverter will start derating, as shown in Figure 7.3: Po/Pn Pin/Pn 100% -30%/km 3000 4000 Altitude(m) Figure 7.4 - PVI 50/60TL Derating Curve with High Altitude NOTE 4: The inverter can output the AC power with full loads within 100%~110% of the rated grid voltage.

-

Page 100: Accessory Options

PVI 50-60TL Installation and Operation Manual PVI Series Inverters 9.0: Accessory Options The PVI 50/60TL has several orderable options that allow the inverter to support a wide range of real life applications. Fuse Bypass OPT-FUSEBYPASS-PVI-50-60TL allows customers to combine the DC inputs outside of the inverter and enter with only one or two combined inputs. -

Page 101: Shade Cover

PVI 50-60TL Installation and Operation Manual PVI Series Inverters Shade Cover OPT-SHADECOVER-PVI-50-60TL is specifically designed for inverters mounted at a 30-degree tilt angle or lower. It protects the inverter from harsh weather and direct sunlight/extremely hot temperatures while reducing thermal gain on the inverter and increasing energy production. - Page 102 PVI 50-60TL Installation and Operation Manual PVI Series Inverters Install top bracket as shown. Nuts M10- 2 pcs. Torque to 50 in-lbs (5.6 N.m). Install bottom bracket as shown. Screws M6x16- 4 pcs. Torque to 25 in-lbs (2.8 N.m). Figure 8.4 –Shade Cover Installation; Steps 3 and 4 DOCR-070645-E Page 102 of 102...

-

Page 103: Ppendixa - Pvi 50/60Tl Datasheet

PVI 50-60TL Installation and Operation Manual PVI Series Inverters Appendix A – PVI 50/60TL Datasheet https://solectria.com/support/documentation/inverter-datasheets/pvi-50tl-pvi-60tl- transformerless-3-ph-string-inverters-datasheet/ Appendix B – String Sizing Tool http://solectria.com/support/string-sizing-tool/ Appendix C – Contact Information Yaskawa – Solectria Solar 360 Merrimack Street Lawrence, Massachusetts 01843 Tel: 978.683.9700 Fax: 978.683.9702 Sales/General Info: inverters@solectria.com... -

Page 104: Appendixe - Ul 1741 / Ul 1699B/ Ieee 1547 / Csa 22.2#107.1

PVI 50-60TL Installation and Operation Manual PVI Series Inverters Appendix E – UL 1741 / UL 1699B/ IEEE 1547 / CSA 22.2#107.1 DOCR-070645-E Page 104 of 102...