Datamax A-Class A-4212 Operator's Manual

A-class series

Hide thumbs

Also See for A-Class A-4212:

- Installation information (2 pages) ,

- Programmer's manual (302 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Datamax A-Class A-4212

- Page 1 Operator’s Manual...

- Page 3 Information in this document is subject to change without notice and does not represent a commitment on the part of Datamax Barcode Products Corporation. No part of this manual may be reproduced or transmitted in any form or by any means, for any purpose other than the purchaser's personal use, without the expressed written permission of Datamax Corporation.

- Page 4 Agency Compliance and Approvals: UL60950 Information Technology Equipment C22.2 No. 950-M93 Listed EN60950 For 230 Volt Operation (Europe): Use a cord set, marked “HAR,” consisting of a min H05VV-F cord which has a minimum 0.75 square mm diameter conductors, provided with an IEC 320 receptacle and a male plug for the country of installation rated 6A, 250V Für 230 Volt (Europa): Benützen Sie ein Kabel, das mit “HAR”...

-

Page 7: Important Safety Instructions

Important Safety Instructions: Throughout the literature accompanying this unit, the exclamation point within an equilateral triangle is intended to alert the user to the presence of important operating and maintenance instructions. This unit has been carefully designed to provide years of safe, reliable performance. However, as with all electrical equipment, there are some basic precautions that you should follow to avoid personal injury or damage to the printer: Before using the print engine, carefully read all the installation and operating... -

Page 9: Table Of Contents

Contents 1 Overview....................1 1.1 About the Printer ................1 1.1.1 Standard Features ..............2 1.1.2 Optional Features ..............3 1.2 Index to Features and Controls............5 1.2.1 Right Hand Models..............6 1.2.2 Left Hand Models..............7 2 Getting Started ..................9 2.1 Unpacking .................. - Page 10 3.3 Loading Ribbon ................26 3.3.1 Right Hand Models..............26 3.3.2 Left Hand Models..............28 3.3.3 Removing Ribbon ..............29 3.4 Quick Calibration ................30 3.5 Print Quality Controls ............... 30 4 Using the Control Panel................. 31 4.1 Layout ................... 31 4.1.1 Ready Mode................

- Page 11 5 Operating, Adjusting and Maintaining the Printer ......... 71 5.1 Displayed Messages ................. 71 5.1.1 Prompts and Condition Messages ..........71 5.2 Calibration..................74 5.2.1 Standard Method ..............74 5.2.2 Advanced Entry ..............76 5.3 Printhead Adjustments ..............83 5.3.1 Leveling Cam Adjustment ............83 5.3.2 Burn Line Adjustment..............

- Page 12 6 Troubleshooting .................. 103 6.1 Problem Resolution .................103 6.1.1 General Resolutions ...............103 6.1.2 Warning and Fault Messages ...........106 6.2 Hex Dump Mode................112 7 Specifications..................115 7.1 Printer Specifications ..............115 7.2 Approved Media and Ribbon .............120 Appendix A....................123 Module Assignments ................123 File Handling Messages ................123 Cut Behind Setup ..................125 Appendix B....................

- Page 13 Multi-Language Menu................139 Appendix F ....................143 Saving a Configuration File ..............143 Appendix G....................145 Ribbon Saver Overview ................145 Warranty Information ................147 Glossary ....................149...

-

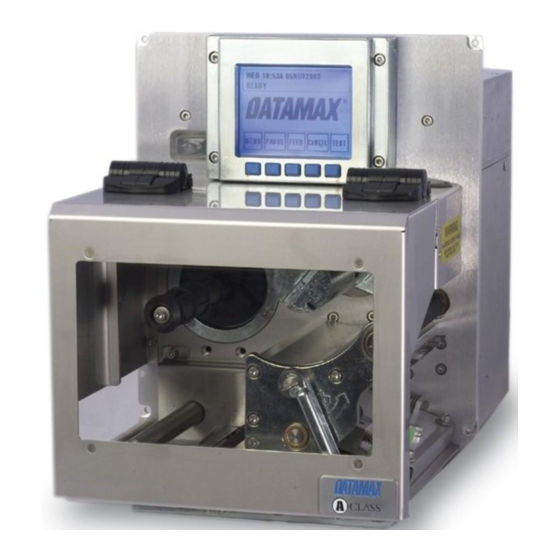

Page 15: Overview

Overview 1.1 About the Printer Congratulations on your purchase of an A-Class printer. This print engine (hereafter referred to as “the printer” and, when necessary, by model) is designed for professional integration into an industrial applicator system. This manual provides all the information necessary for installation, setup and operation of the printer. -

Page 16: Standard Features

1.1.1 Standard Features This printer offers the following standard features: Right-handed or left-handed configurations • Electronics card cage • 4 MB Flash downloadable program memory • 16 MB DRAM memory • Host computer accessible memory for object temporary storage • Two RS-232 serial interfaces (one of which is also RS-422/RS-485 capable) •... -

Page 17: Optional Features

1.1.2 Optional Features (available except as noted) The following optional features are available: DMXNetII and DMXrfNetII • An internal wired or wireless Network Interface Controller for Ethernet connectivity with multiple operating system and protocol support, including trap functions. Expanded Flash Main Logic CCA •... - Page 18 Installing Printer Options The table below lists competency level recommendations for the installation of the various options. For detailed information regarding an option, contact a dealer or Datamax Technical Support. Experience Level Option Installer DMXNetII DMX Certified Technician DMXrfNetII DMX Certified Technician...

-

Page 19: Index To Features And Controls

1.2 Index to Features and Controls Important printer parts are highlighted in the table and drawings below: Item Number Description Control Panel Power Switch Access Cover Power Receptacle GPI/O Port A Serial Port USB Port Parallel Port GPI/O Port B Ribbon Take-Up Hub* Ribbon Supply Hub* Upper Media Post... -

Page 20: Right Hand Models

1.2.1 Right Hand Models A-Class... -

Page 21: Left Hand Models

1.2.2 Left Hand Models A-Class... - Page 22 A-Class...

-

Page 23: Getting Started

Getting Started 2.1 Unpacking The printer is carefully packaged for transit. Upon arrival, inspect the shipping carton(s) for damage; if evident, immediately report the damage to the freight company. In order to operate the printer, remove all packaging material: 1. With the Shipping Carton arrows pointing upward, open the Shipping Carton and remove the Accessories Box and the Top Foams. -

Page 24: Contents

2.1.1 Contents Check the contents of the carton for the following items: Printer • Power cord • Accessories CD-ROM • Any additionally purchased items or options. • 2.1.2 Additional Requirements Other items can also be needed for operation: Media (and ribbon, if necessary); see Section 7.2. •... - Page 25 Attach the printer to the support structure using a #10 screw inserted at each Mounting Hole position (see note below). Mounting Holes The following drawings detail additional mounting considerations: A-Class...

- Page 26 A-4xxx models 9.67” (246 11.81” Front View, Peel Assembly lowered: (300 2.25” 7.68” (195 Side View: 10.45” (266 15.35” (390 12.51” 7.66” (318 (195 Side View, Cover raised: 20.17” (512 A-Class...

- Page 27 A-6xxx models 9.67” (246 11.81” Front View, Peel Assembly lowered: (300 2.25” 9.68” (246 Side View: 10.45” (266 17.35” (441 7.66” 14.51” (195 (369 Side View, Cover raised: 22.17” (563 A-Class...

-

Page 28: Interfacing A Host

Peel Point Dimension Peel Bar See Appendix C for the PE printer’s dimension. 2.2.2 Interfacing a Host Ensure that the Power Switch is OFF when making printer connections. The printer can be interfaced to a host via the parallel, serial, and USB ports. (Ethernet users, consult the documentation that accompanied the option.) Following power-up (or after a period of inactivity), interface port selection occurs automatically upon detection of valid data. -

Page 29: Parallel Port Connections

2.2.2.1 Parallel Port Connections ® The parallel interface requires a Centronics IEEE 1284 cable with a 36 pin male connector. Bi-directional mode is IEEE 1284 compliant, allowing data to be returned to the host. 2.2.2.2 Serial Port Connections Serial Port A supports RS-232C and RS-422/RS-485 communications; COM C and COM D support RS-232 (see Appendix D for exceptions). - Page 30 For proper data exchange, the serial interface requires specific cable pin-outs. Serial cable part numbers and wiring diagrams are shown below. RS-232 Cables* Part # 32-2301-01 Part # 32-2300-01 *Printer serial ports A & C require a DB9 male connector (e.g., Startech C9PSM). RS-422/485 Communications To use RS-422/485 communications (Port A, only), the main logic card must be reconfigured:...

- Page 31 The Main Logic Card location varies depending upon the model of printer. 3. On the Main Logic Card, move the jumpers JMP1, JMP2, JMP3, JMP4, JMP5, and JMP6 from their positions across pins 1 & 2, and place them across pins 2 & 3, respectively.

-

Page 32: Usb Port Connections

COM D RS-232 Cable Host DB-9S Printer RJ45P +5 VDC +5 VDC GROUND GROUND Part # 32-2603-00 2.2.2.3 USB Port Connections The Universal Serial Bus port requires a standard USB cable. This USB Port is a device-end only connection. Never attach a keyboard, mouse, modem, etc. -

Page 33: Connecting An Applicator

2.2.3 Connecting an Applicator Setup the GPIO Port using the information in Appendix D and then connect the applicator cable to port(s) on the Applicator Interface Card. Failure to properly configure the GPIO Port(s) may result in damage to the printer and / or the applicator. - Page 34 Power Switch 3. Connect the AC Power Cord to the printer and then to a properly grounded outlet. 4. Turn ON (in the following order) the host computer, the applicator system, and then the printer. A-Class...

-

Page 35: Setting Up The Printer

Setting up the Printer 3.1 Loading Media Load media according to its type and desired output: 1. Open the Access Cover and raise the Head Lift Lever. 2. Route the Media between the Media Posts, through the Media Sensor, over the Peel Bar, and out of the printer, as shown below. - Page 36 Peel Assembly Release Lever Media Peel Assembly 4. Remove the labels from 12 inches (30 cm) of the Media Liner. Route the Media Liner down to the Peel Assembly, over the Latch Roller, and through the Slot as shown below. Media Media Liner Peel Assembly...

- Page 37 Latch Roller Slot Peel Assembly 5. Pull the Media Liner through the Slot in the Peel Assembly until all slack is removed. Lifting from the center, raise the Peel Assembly until it locks into place. Head Lift Lever Media Guide Peel Assembly A-Class...

- Page 38 6. Position the Media Guide lightly against the side of the media. Media Guide Head Lift Lever Locking Post 7. Adjust the Media Sensor over the labels (see Section 3.2). 8. If printing on thermal transfer media, load ribbon (see Section 3.3); otherwise go to Step 9.

-

Page 39: Adjusting The Media Sensor

3.2 Adjusting the Media Sensor Position the Media Sensor to detect labels as follows: 1. Ensure that media is routed through the Media Sensor; see Section 3.1. Media Media Sensor Media Eye Mark Media Sensor Adjustment Knob 2. Depending on the type of media being used, rotate the Media Sensor Adjustment Knob until the Eye Mark on the Media Sensor is positioned according to the table below. -

Page 40: Loading Ribbon

3.3 Loading Ribbon Load ribbon (for thermal transfer media) according to its coated side and the printer model. Using a ribbon slightly wider than the media (and liner) is recommended for added protection against abrasive wear. 3.3.1 Right Hand Models Load ribbon as follows: 1. - Page 41 2. With the Head Lift Lever raised, route the Ribbon under the Lower Idler, over the Ribbon Shield and Upper Idler, and then clockwise around to the Ribbon Take-Up Hub. 3. Rotate the Ribbon Take-Up Hub clockwise several times to secure the Ribbon. 4.

-

Page 42: Left Hand Models

3.3.2 Left Hand Models Load ribbon as follows: 1. Orient the unwind position of the Ribbon according to the coated side (CSI or CSO) and then slide the Ribbon Roll completely onto the Ribbon Supply Hub, as shown below: Ribbon Ribbon Supply Hub Supply Hub... -

Page 43: Removing Ribbon

4. Lower and lock the Head Lift Lever then close the access cover. Ribbon Ribbon Take-Up Hub Take-Up Hub Head Head Lift Lever Lift Lever Upper Idler Upper Idler CSO Ribbon CSI Ribbon Roll Roll Ribbon Shield Ribbon Shield Ribbon Ribbon Lower Idler Lower Idler... -

Page 44: Quick Calibration

3.4 Quick Calibration Perform Quick Calibration during initial printer set-up or after changing the media, but not if using continuous media. Media with long gaps between labels may require a PAPER OUT DISTANCE change; see Section 4.2.1. Also, if UNCALIBRATED is displayed, see Section 5.2.1. With media loaded and the Media Sensor adjusted, press and hold the FEED Key until at •... -

Page 45: Using The Control Panel

The Control Panel, an event-driven user interface composed of a graphics display and keypad, provides the following printer functions and information: Current State Indicators Time & Date TUE 11:55 A 04 FEB 2003 COMM Printer Status PAUSED PAUSED DATAMAX Display Window MENU PAUSE FEED CANCEL TEST Display Item Function Current State COMM indicates data is being received and processed;... -

Page 46: Ready Mode

4.1.1 Ready Mode In Ready Mode, when the printer is idle waiting to accept data, the Keys have the following functions: TUE 11:55 A 04 FEB 2003 READY DATAMAX Key Labels MENU PAUSE FEED CANCEL TEST Keys Function The MENU Key takes the printer offline and into Menu Mode; see Section 4.2. -

Page 47: The System Menu

4.2 The System Menu After the MENU Key has been pressed (Menu Mode), the Selected Menu Branch appears on a reverse field in the Menu Window and the Keys have the following functions: TUE 11:55 A 04 FEB 2003 OFFLINE MENU WINDOW MEDIA SETTNGS Selected Menu Branch... - Page 48 controlling most printer functions The System Menu is multilayered, MEDIA SETTINGS • PRINT CONTROL • PRINTER OPTIONS • SYSTEM SETTINGS • COMMUNICATIONS • DIAGNOSTICS • MCL OPTIONS • Entering the menu takes the printer offline and halts the processing of new •...

-

Page 49: Media Settings

4.2.1 Media Settings The Media Settings menu contains label and ribbon settings, and printhead maintenance selections. Menu Item Details MEDIA TYPE Selects the printing method, where: DIRECT THERMAL Sets printing for heat reactive media. THERMAL TRANSFER Sets printing for media that requires ribbon to produce an image. - Page 50 Media Settings (continued) Menu Item Details RIBBON LOW OPTIONS Defines the response when THERMAL TRANSFER is selected and the ribbon supply diminishes, where: RIBBON LOW DIAMETER Sets the threshold that will trigger a Low Ribbon Warning prompt, where: 1.40in (1.00 – 2.00) Is the outer diameter size of the ribbon roll.

-

Page 51: Print Control

Media Settings (continued) Menu Item Details CLEAN HEAD NOW? Allows cleaning to begin, where: Initiates the cleaning process when using Cleaning Cards or Cleaning Film (see Section 5.5.1) and resets the Clean Head Counter. Exits the menu item without cleaning. 4.2.2 Print Control The Print Control menu contains print quality, throughput, formatting, and custom setup functions:... - Page 52 Print Control (continued) Menu Item Details ROW OFFSET Shifts the vertical SOP position on the label, where: 00.00in (0 – 99.99) Is the offset distance; see Section 7.1 for media details. COLUMN OFFSET Shifts the horizontal, left-justified SOP position to the right without shifting the Label Width termination point to the right, where: 00.00in (0 –...

-

Page 53: Printer Options

4.2.3 Printer Options The Printer Options menu contains module, file handling, and option functions: Menu Item Details MODULES Controls module functions (see Appendix A), where: PRINT DIRECTORY Prints files present and available memory in a module. (Selecting ALL will print the results from every module.) PRINT FILE Displays a list of stored files then prints the selected... - Page 54 Printer Options (continued) Menu Item Details RIBBON SAVER Controls the Ribbon Saver function (see Appendix G), where: AUTO The presence of the ribbon saver is automatically sensed. If detected, the ribbon saver is enabled; otherwise, it will be ignored. ENABLED Enables the ribbon saver.

- Page 55 Printer Options (continued) Menu Item Details BARCODE COUNT Specifies a number of bar codes per label then generates a fault if the number present is incorrect, where: (0 - 99) Sets the number of bar codes to count, where 00 (Auto Mode) allows a variable number.

- Page 56 Printer Options (continued) Menu Item Details GPIO PORT Controls the optional Applicator Interface GPIO function, where: GPIO DEVICE Sets the option to work with a specific device type, where: DISABLED Disables the option. APPLICATOR Enables parameters for related label applicator functions: Completion upon last SOP, de-asserts Data Ready •...

- Page 57 Printer Options (continued) Menu Item Details ACTIVE LOW Outputs a logic low upon completion. ACTIVE HIGH Outputs a logic high upon completion. RIBBON LOW Sets the low ribbon signal (as determined by RIBBON LOW OPTIONS; see Section 4.2.1), where: ACTIVE LOW Outputs a logic low when the roll reaches the setting.

- Page 58 Printer Options (continued) Menu Item Details TAG TYPE Selects the UHF tag type, where: EPC 0 EPC 0+ MATRICS EPC 0+ IMPINJ Is the selected type. EPC 1 EM 4022/1222 GEN 2 TAG DATA SIZE Selects the tag data size, where: 96-BIT Sets a 96-bit data size.

-

Page 59: System Settings

Printer Options (continued) Menu Item Details LEADING Adds nulls to the front (left) of the data if less than the size, or cuts the data if greater. TRAILING Adds nulls to the end (right) of the data if less than the size, or cuts the data if greater. - Page 60 System Settings (continued) Menu Item Details DELETE FILE Lists the files available and then after selection, removes that file from memory. An active file can not be deleted. FACTORY SETTING FILE Lists the files available, and then after selection that file will be restored whenever a Level One reset (see Section 5.6.2) is performed.

- Page 61 System Settings (continued) Menu Item Details TIME AND DATE Sets the time and date, where: SET HOUR Enters the time and date information. 06:30AM 01JAN2008 MEDIA COUNTERS ♦ Displays and controls various internal counters, where: ABSOLUTE COUNTER Are the total inches printed and the set date. (Non- resettable) RESETTABLE COUNTER Are the inches printed and the last reset date.

- Page 62 System Settings (continued) Menu Item Details APPLICATION VERSION Displays the firmware program number, version, and date. BOOT LOADER Displays the boot loader version and date. UPGRADE PRINTER CODE Upgrades the printer to the corresponding features level with the correct code entry (where authorization may be required).

- Page 63 System Settings (continued) Menu Item Details STANDARD Sets the dot zero origin for left justified printing. RIGHT HAND Sets the dot zero origin for right justified printing. LABEL ROTATION ♦ Allows label formats to be rotated for printing, where: ENABLED Prints after rotating the formats 180 degrees.

- Page 64 System Settings (continued) Menu Item Details MENU AND TEST Sets a password requirement for menu and test access. MODIFY PASSWORD Modifies the security password, where: Allows entry of a four-digit password (after confirmation). The default password is 0000. Exits the menu item without changing the current settings.

- Page 65 System Settings (continued) Menu Item Details XXX (XXX – XXX DOTS) Is the printed number of dots per inch (or mm) thereby reducing the width of the produced format; see Appendix B. No adjustment occurs at the default setting. ROW EMULATION Allows the row dot count to be adjusted, where: XXX (XXX –...

- Page 66 System Settings (continued) Menu Item Details STANDARD FONTS Prints using standard (internal) fonts. CG TIMES Prints using CG Times font. USER ID S50 Prints using a downloaded font. LABEL STORE Determines the data content when retrieving stored label formats, where: STATE &...

- Page 67 System Settings (continued) Menu Item Details VOID AND RETRY Actions depend upon the RETRY COUNT: If the count has not been exceeded, VOID is printed • on the failed label and reprinting automatically occurs; If the count has been exceeded, printing stops and •...

-

Page 68: Communications

System Settings (continued) Menu Item Details 0.50in (.10 to 2.00) Is the distance, measured from the trailing edge, which indirectly establishes the text size. VOID will not be printed if insufficient label space exists or if the fault occurred after printing completed. - Page 69 Communications (continued) Menu Item Details 9600 BPS 115000 BPS 57600 BPS 38400 BPS Is the serial speed in Bits Per Second. 28800 BPS 19200 BPS 4800 BPS 2400 BPS 1200 BPS PROTOCOL Sets the data flow control method (handshaking), where: BOTH Uses XON/XOFF and CTS/DTR.

- Page 70 Communications (continued) Menu Item Details SERIAL PORT C ♦ Controls the settings for the Applicator Interface COM C (J4) port, where the setting selections are the same as those given for the SERIAL PORT A. The maximum baud is 38.4K BPS. SERIAL PORT D ♦...

- Page 71 Communications (continued) Menu Item Details WLAN ADHOC Selects the DMXrfNETII default parameters, where: Exits the menu item without changing the current settings. Restores WiFi defaults and initiates infrastructure mode with an SSID of “Any.” All existing access point associations will be deleted then established with the closest available.

- Page 72 Communications (continued) Menu Item Details GATEWAY Specifies the network Gateway Address, where: 192.168.010.026 Is the address in standard octet format. SNMPTRAP DESTINATION Specifies the SNMP Trap Address, where: 000.000.000.000 Is the address in standard octet format where SNMP traps will be sent when SNMP service is installed on your receiver.

- Page 73 Communications (continued) Menu Item Details Sets the Maximum Transmission Unit packet size, where: Is the packet size, in bytes. 01500 (512 - 65515) Sets the Address Resolution Protocol notification rate, GRATUITOUS ARP where: 0000 (0 - 2048) Is the time, in minutes. PORT NUMBER Sets the network communications port, where: 09100 (1 - 65535)

- Page 74 Communications (continued) Menu Item Details SET FACTORY DEFAULTS Returns the factory-programmed values, where: Restores the default settings. The reset will be automatic; all settings will be restored except CUSTOM ADJUSTMENTS and calibrations. Exits the menu item without changing the current settings.

- Page 75 Communications (continued) Menu Item Details ESC SEQUENCES Sets handling for data containing invalid ESC sequences, where: ENABLED Processes commands normally. DISABLED Ignores ESC control codes during processing (as some systems send “banners” to the printer). Bitmapped font downloads will be disabled. HEAT COMMAND Determines how host Heat commands are handled, where:...

- Page 76 Communications (continued) Menu Item Details STX-V SW SETTINGS Determines how a host option enable command is handled, where: ENABLED Processes the command normally. DISABLED Controls the settings via the menu; see Section 4.2.3. MAX LENGTH COMMAND Determines how a host Maximum Label Length (<STX>M) command is handled, where: ENABLED Processes the command normally.

-

Page 77: Diagnostics

4.2.6 Diagnostics The Diagnostics menu contains testing functions: Menu Item Details HEX DUMP MODE Determines how the printer handles host data, where: DISABLED Processes data normally. ENABLED Prints received ASCII data without interpretation or processing; see Section 6.2. OPTIONS TESTING Performs option diagnostics, where: TEST CUTTER Tests the Cutter, where:... - Page 78 Diagnostics (continued) Menu Item Details TEST SCANNER Tests the Linear Scanner, where: ALIGNMENT TEST Reads a bar code then displays the decoded data, the code type and scan count, repeating. SCAN TEST Reads a bar code then displays the decoded data, the code type and scan count, non-repeating.

-

Page 79: Mcl Options

4.2.7 MCL Options The MCL Options menu contains alternate operating selections: Menu Item Details MCL OPTIONS Allows the printer to use the optional MCL (Macro Command Language) tool suite to accept peripheral device input data, where: Allows MCL operation to begin when the printer is MCL AT POWER-UP turned ON, where: DISABLED... -

Page 80: The Test Menu

Function The UP ARROW Key, program dependent, typically selects the previous menu item. The ENTER Key, program dependent, typically selects the current menu ENTER item or function. Consult your MCL provider for details regarding operation and support. 4.3 The Test Menu After the TEST Key has been pressed (Test Mode), the resident Selected Test Label appears on a reverse field in the Test Window and the Keys have the following functions: Received data processing is disabled when testing. - Page 81 LABEL WIDTH. Pressing the SYSTEM Key while in Test Mode provides a System Window with the following functions: TUE 11:55 A 04 FEB 2003 OFFLINE SYSTEM WINDOW DATAMAX PAUSE FEED CANCEL Key Labels Keys A-Class...

-

Page 82: Print Quality Label

Function The ESC (escape) Key returns Test Mode. The PAUSE Key suspends printing. Pressing the key again will return PAUSE operation. The FEED Key advances labels and clears any corrected faults. Also, pressing and holding this key causes the printer to perform a Quick FEED Calibration;... -

Page 83: Ribbon Test Label

4.3.3 Ribbon Test Label The Ribbon Test Label serves as a transfer function indicator for printers equipped with the thermal transfer option. Consisting of a fence-oriented bar code, this format can be used to ensure component functions and ribbon path alignment. - Page 84 A-Class...

-

Page 85: Operating, Adjusting And Maintaining The Printer

Operating, Adjusting and Maintaining the Printer 5.1 Displayed Messages During operation (when not in Menu or Test Mode) the printer displays several types of information: Prompts and Condition Messages (see below); and • Fault and Warning Messages (see Section 6.1.2). •... - Page 86 Prompts and Condition Messages (continued) Displayed Message Description Action The CANCEL or TEST Key was CANCEL REPRINT pressed during a fault. (See Press ENTER to cancel the FAULT HANDLING / VOID AND reprint. ENTER KEY = YES RETRY, Section 4.2.4.) The FEED Key was pressed following a fault and now the CLEARING FAULTS...

- Page 87 Prompts and Condition Messages (continued) Displayed Message Description Action The TEST Key was pressed and REMOVE RIBBON Remove ribbon and press held, or CLEAN HEAD NOW was any key to proceed. PRESS ANY KEY selected, but ribbon is installed. Press YES to accept the changes, or NO to discard them.

-

Page 88: Calibration

5.2 Calibration Calibration ensures correct media detection, and should be performed when Quick Calibration fails (see Section 3.4). 5.2.1 Standard Method Three calibration samples are required: Empty – with nothing over the sensor; • Gap (or Mark) – with media liner, a notch, or a mark over the sensor; and, •... - Page 89 Step Action Displayed Message Comment This sets the gap (or mark) value, where ‘yyy’ represents the current For die-cut media: sensor reading. Proceed according to the SCAN BACKING media type: (1) See Section 3.2 for PRESS ESC KEY <yyy> Die-Cut –Remove a label •...

-

Page 90: Advanced Entry

Step Action Displayed Message Comment Calibration was successful. If ‘Warning Low Observe the calibration CALIBRATION COMPLETE Backing’ is displayed, result. calibration was successful (for possible messages see Section 5.1). When calibrating gap or reflective media, press CALIBRATION COMPLETE and hold the FEED Key Press the ESC Key until at least one label is repeatedly to exit menu... - Page 91 Step Action Displayed Message Comment Press the MENU Key. Then, with MEDIA Press the ESC Key to MEDIA SETTINGS SETTINGS highlighted, abort this procedure. press the ENTER Key. Using the DOWN ARROW Key, scroll to SENSOR CALIBRATION then press Press the ESC Key to ADVANCED ENTRY the ENTER Key.

- Page 92 Step Action Displayed Message Comment Press the UP ARROW Key, GAIN TRAN incrementing the Gain (0 – 31) Number by one, and then <yyy> press the ENTER Key. Record the sensor reading Where ‘yyy’ represents - Or, for reflective media: as a Label Value in the the current sensor table.

- Page 93 Step Action Displayed Message Comment Lower and latch the Head GAIN TRAN Lift Lever. (0 - 31) Where ‘yyy’ represents <yyy> Using the UP or the DOWN the current sensor ARROW Key, set the Gain reading. - Or, for reflective media: Number to 00 and then press ENTER.

- Page 94 Step Action Displayed Message Comment In the table, where both In this example, Gain • the Label Value and TOF Number 18 is chosen GAIN TRAN Value are at least 20, because, where both (0 - 31) subtract the amounts and values are at least <yyy>...

- Page 95 Step Action Displayed Message Comment Complete a table (see example below) using three new measurements, as follows: (A) Raise the printhead assembly. Place the label (attached to liner) in the Media Sensor then lower and Where ‘yyy’ represents the latch the Head Lift current sensor reading.

- Page 96 Step Action Displayed Message Comment PAPER SENSOR LEVEL P* 198 G*000 E*000 GAP SENSOR LEVEL P* 198 G*084 E*000 Using the DOWN ARROW Key set the ‘Paper’ level to EMPTY SENSOR LEVEL the value determined in P* 198 G*084 E*014 the previous step and press the ENTER Key.

-

Page 97: Printhead Adjustments

Step Action Displayed Message Comment The printer is ready for use. If the calibration attempt fails, try desensitizing the sensor as follows: Go to MEDIA SETTINGS / SENSOR Press and hold the FEED CALIBRATION / Key until at least one label READY ADVANCED ENTRY / has been output. - Page 98 Head Lift Lever Leveling Cam 2. While observing the printed output, rotate the Leveling Cam counterclockwise until the image fades across the label, as shown in Example 1 (below). 3. While observing the printed output, rotate the Leveling Cam clockwise until the image is complete, with even contrast, as shown in Example 2 (below).

-

Page 99: Burn Line Adjustment

Line as follows: If you have questions regarding this procedure, contact a qualified technician or Datamax Technical Support before proceeding. 1. Load media (and ribbon, if required), as described in Section 3.1. 2. Loosen the two Locking Screws on the Printhead Assembly approximately ¼ turn counterclockwise. -

Page 100: Printhead Replacement

ESD prevention procedures. (2) If 24V OUT OF TOLERANCE is displayed (see Section 6.1.2), contact a • qualified technician or Datamax Technical Support before proceeding. Replace the printhead as follows: 1. Turn OFF the printer. Raise the Access Cover. - Page 101 Access Cover A-4xxx models: Printhead Assembly Ground Cable Screw Pivot Screw (and Washers) Captive Screw Access Cover A-6xxx models: Printhead Assembly Ground Cable Screw Pivot Screw (and Washers) Captive Screws A-Class...

- Page 102 4. Raise the Head Lift Lever then slide the Printhead Assembly forward. Remove the Ground Cable Screw then slide the Printhead Assembly off the Pivot Shaft and place the Printhead Assembly aside. Pivot Head Lift Shaft Lever Printhead Assembly 5. Carefully disconnect both Printhead Cables, and then remove the Printhead. 6.

- Page 103 8. Slide the Printhead Assembly completely onto the Pivot Shaft and, using the previously removed screw and washers, secure the Printhead Assembly. 9. Place the Printhead onto the locating pins (on the underside of the Printhead Assembly). (Use the Alignment Window in the Printhead Assembly to center the edge of the Printhead, as shown below, and then move the Printhead forward or backward to locate the pins.) The drawing illustrates the...

-

Page 104: Maintenance Schedule

5.5 Maintenance Schedule This section details the recommended maintenance supplies, schedules, and methods. Supplies The following items will help safely and effectively clean the printer: • Isopropyl alcohol • Cotton swabs • A clean, lint-free cloth • Soft-bristle brush • Soapy water and a mild detergent •... -

Page 105: Cleaning The Printhead

Visit our website at http://www.datamaxcorp.com/media/products/cleaning to learn more. Certified Datamax – The worry free choice for optimal printer performance. Cotton Swab Procedure (for users of direct thermal media, or thermal transfer media with wax ribbon): 1. - Page 106 Access Cover Head Lift Lever Printhead Cotton Swab Burn Line debris build-up example 3. Allow the printhead to dry. 4. Reinstall media (and ribbon, if needed). Close the cover. Plug in and turn ON the printer. Run a few sample labels and examine them. If symptoms persist, use the Cleaning Card Procedure;...

-

Page 107: Cleaning The Rollers

4. Close the cover. Press and hold the TEST Key until the Cleaning Card has been run through the printer. (As an alternate, ‘CLEAN HEAD NOW’ can be selected, see Section 4.2.1.) 5. Reinstall media (and ribbon, if needed). If necessary, adjust the Leveling Cam. Close the cover. -

Page 108: Cleaning The Peel Assembly

2. Raise the Head Lift Lever. Lower the Peel Assembly Release Lever. Remove media and ribbon. Rollers Head Lift Lever Peel Assembly Release Lever Peel Assembly 3. Using a cotton swab dampened with isopropyl alcohol, clean the Rollers, rotating each as necessary to clean its entire surface. - Page 109 Head Lift Lever Peel Assembly Release Lever Peel Assembly Latch Roller Knurled Roller 3. Using a cotton swab dampened with isopropyl alcohol, clean the Latch Roller and the Knurled Roller, rotating each as necessary to clean its entire surface. 4. After allowing the rollers to dry, replace ribbon and media. Close the Peel Assembly and lower the Head Lift Lever into the locked position.

-

Page 110: Cleaning The Media Sensor, Media Path, And Peel Bar

5.5.4 Cleaning the Media Sensor, Media Path, and Peel Bar Clean the Media Sensor, Media Path, and Peel Bar as follows: 1. Turn OFF and unplug the printer. Raise the access cover. 2. Raise the Head Lift Lever. Lower the Peel Assembly Release Lever. Remove media and ribbon. -

Page 111: Cleaning Exterior Surfaces

5.5.5 Cleaning Exterior Surfaces Clean the printer surfaces as follows: 1. Turn OFF and unplug the printer. 2. Using a soft cloth or sponge dampened with cleanser, wipe the exterior surfaces clean. 3. Allow the surfaces to dry. 4. Plug in and turn ON the printer. 5.6 Reset Methods There are three reset levels for the printer. -

Page 112: Updating The Firmware

5.7 Updating the Firmware Depending upon the firmware version, stored data on modules can be lost when performing an update. The printer’s application program (firmware) can be updated as versions become available. Identify then download onto your computer’s hard drive the updated version of firmware for your model printer from our web site at http://www.datamaxcorp.com Follow the steps below to install the firmware:... - Page 113 Firmware Update Error Messages Displayed Message Descriptions / Possible Causes / Solutions An error occurred during the decompression and transfer of file data from cache storage into the Flash memory. Confirm DECOMPRESSION ERROR the firmware version and try the download again; however, if the problem continues call for service.

-

Page 114: Updating The Boot Loader

5.8 Updating the Boot Loader Updates for the Boot Loader program can be found at ftp://ftp.datamaxcorp.com Before performing an update, identify the printer’s current Boot Loader version by printing a Configuration Label (see Section 4.3.2) and comparing the installed version to those available from the FTP site. -

Page 115: Downloading Fonts

5.9 Downloading Fonts Fonts (KANJI, HANGUL and CHINESE) can be downloaded and stored in a printer module. Font files are identified by part number and are protected by lock bits, which unlocked by entering the correct 6-digit code via the Control Panel. The printer can be easily and quickly updated: A. - Page 116 Font Download Messages (continued) Displayed Message Descriptions / Possible Causes / Solutions The download content was corrupted or a transmission error occurred. Check for corruption by printing a configuration label or by looking at the system window; a double question mark INVALID IMAGE before the plug-in part number indicates corruption.

-

Page 117: Troubleshooting

See HOST SETTINGS (Section 4.2.5) for more information and consult your software vendor for program information. If you have questions or if problems persist, contact a qualified technician or Datamax Technical Support. 6.1.1 General Resolutions... - Page 118 General Resolutions (continued) If experiencing this Try this solution… problem… Check the following possibilities: The Leveling Cam may be incorrectly adjusted (adjust it; • see Section 5.3.1); or, Light or no print on the side of the label: The Platen may be dirty or worn (clean and inspect; see •...

- Page 119 General Resolutions (continued) If experiencing this Try this solution… problem… Test the heat reactivity of the labels then proceed accordingly: No print using direct If the labels react, increase the HEAT setting via the • thermal media (labels software program or through the menu (see Section 4.2.2); advance normally): If the labels do not react, install different media.

-

Page 120: Warning And Fault Messages

General Resolutions (continued) If experiencing this Try this solution… problem… Check the following possibilities: Check the Leveling Cam for correct adjustment (readjust if • necessary; see Section 5.3.1); Review the print quality controls (adjust if necessary; see • Section 3.5); Poor print quality: If using thermal transfer, check the media and ribbon •... - Page 121 Warning Messages Displayed Message Description Possible Solution(s) The printer has detected a No action is required. If the 24V OUT OF TOLERANCE drop in the 24-volt power problem continues, cycle the supply. power OFF and ON. Defective printhead Replace the printhead if print DOT FAILURE elements have been quality becomes unacceptable.

- Page 122 Warning Messages Fault Messages (continued) Displayed Message Description Possible Solution(s) The selection you are attempting to make is not Enter a different setting or INVALID ENTRY valid or is not within the parameter that falls within the acceptable parameter acceptable range. range.

- Page 123 Fault Messages Displayed Message Description Possible Solution(s) The printer has detected Cycle printer power OFF and ADC FAULT an analog to digital circuit ON. If the fault does not clear, converter failure. call for service. The printhead is in the ‘up’ Lower and lock the Head Lift CLOSE HEAD / COVER position or the Cover...

- Page 124 Fault Messages (continued) Displayed Message Description Possible Solution(s) Scheduled cleaning has Clean the printhead (see Section HEAD CLEANING FAULT exceeded three times the 5.5.1). selected distance. Examine the printer for media then proceed accordingly: If the printer is out of •...

- Page 125 Fault Messages (continued) Displayed Message Description Possible Solution(s) Press any key to continue. Ensure that the reflective mark REFLECTIVE MODE was inserted face down. Also, Consistently low sensor ensure that the sensor is clean readings were detected. CANNOT CALIBRATE and that the reflective mark is made from carbon-based ink.

-

Page 126: Hex Dump Mode

Fault Messages (continued) Displayed Message Description Possible Solution(s) Check the following possibilities: Calibration may be necessary • (see Section 3.4); The Media Sensor may need • The printer could not find a adjustment (see Section 3.2); TOF mark within the maximum length setting, The Media Guide may need •... - Page 127 To decode the data the Class Series 2 Programmer’s Manual is an essential reference (see the Accessories CD-ROM). Also, some software programs use bit mapping, which can make analysis difficult – contact Datamax Technical Support with any questions. To return normal operating mode, enter DIAGNOSTICS and disable HEX DUMP MODE.

- Page 128 A-Class...

-

Page 129: Specifications

Specifications 7.1 Printer Specifications This section identifies parameters and features of the printer models. Embedded Bar Codes & Fonts See the Class Series 2 Programmer’s Manual for details. Interfaces Types: Main Logic CCA - (1) Parallel, IEEE 1284 Compliant (1) Serial, DB9 RS-232/422/485 (configurable) (1) USB, Version 1.1 Compliant Applicator Interface CCA - (1) Serial, EIA RS-232 DB9 (configurable) - Page 130 Electrical Power Supply: Auto-ranging switching type. AC Input Voltage Range: 90 – 132 / 180 – 264 VAC @ 47 – 63 Hz, auto-ranging Grounding: Unit must be connected to a properly grounded circuit. Power Consumption: A-4xxx models: 90 watts, typical operating; 10 watts, standby A-6xxx models: 120 watts, typical operating;...

- Page 131 Printing Type: Direct Thermal or optional Thermal Transfer Speed Range: A-4212 & A-6212: 2 – 12 IPS (50 – 304 MMPS) A-4310 & A-6310: 2 – 10 IPS (50 – 254 MMPS) A-4408: 2 – 8 IPS (50 – 203 MMPS) A-4606: 2 –...

- Page 132 Media & Ribbon Media Types: Wound-out labels only and tag stock; roll-fed, die-cut, notched, reflective, continuous, and fan-fold. Flat printable side, with no more than .0007 in. (.018 mm) protrusions on the opposite side (see below). Ribbon Types: ‘Coated Side In’ or ‘Coated Side Out’. Ribbon Width Range*: A-4xxx models: 1 - 4.65 inches (25 –...

- Page 133 Media Dimensional Requirements A-4xxx models A-6xxx models Designator Description Minimum Maximum Minimum Maximum inches inches inches inches Label width 1.00 4.65 2.00 Liner width 1.00 4.65 2.00 Gap (or notch) between labels – – – – Label length – – –...

-

Page 134: Approved Media And Ribbon

These supplies are specially formulated for use in our printers; use of non-Datamax supplies may affect the print quality, performance, and life of the printer or its components. For a current list of approved media, please contact a Media Representative at (407) 523-5650. - Page 135 Media and Ribbon Overview (continued) Ribbon Print Print Image Thermal Transfer Media Type Speed* Energy Durability Great Label TTL™ GPR Plus™ 10 – 12** Medium Medium Coated and uncoated paper, tag 2 – 10 stock, some films and synthetics GPRPlus™ Coated and glossy paper, tag Wax/Resin 2 –...

- Page 136 A-Class...

-

Page 137: Module Assignments

Appendix A Module Assignments Module Assignments Designator Size Type / Use DRAM . Default, as assigned (see SYSTEM SETTINGS / 1024 KB DEFAULT MODULE, Section 4.2.4). Storage for graphics, (default size) fonts, and label formats. 512 KB FLASH. Storage for graphics, fonts, and label formats. See [3], FLASH (Optional Expanded Flash Main Logic CCA). - Page 138 File Handling Messages Displayed Description Possible Solution(s) Message Insufficient space exists to store the file or The copy or format the module is protected - try storing to a FAILED request has failed. different location. (If the problem persists, this could indicate a hardware problem.) An existing file of the FILE EXISTS, same name and type...

-

Page 139: Cut Behind Setup

Cut Behind Setup The printer can queue then cut a specified number (0 – 2) of small labels, resulting in a throughput increase. To improve throughput when cutting batches of small labels, follow the procedure below: 1) Measure the length (L) of your media, label edge to label edge including gap, if any. 2) Determine the distance** (D) from the burn line to cutter blade. - Page 140 A-Class...

-

Page 141: Print Resolutions And Widths

Appendix B Print Resolutions and Widths Print Resolutions and Widths Maximum Print Width Default Model Resolution Setting Inches Millimeters 203 dots/inch A-4212 4.10 4.10 (8 dots/mm) 300 dots/inch A-4310 4.16 105.7 4.16 (11.8 dots/mm) 406 dots/inch A-4408 4.10 4.10 (16 dots/mm) 600 dots/inch A-4606 4.16... -

Page 142: Column & Row Emulation Ranges

Speed Ranges and Defaults (continued) Range Default Setting Model & Function MMPS MMPS A-4408: Print 51 – 203 Feed 2-10 51 – 254 Reverse 51 – 127 Slew 2-16 51 – 406 A-4606: Print 51 – 152 Feed 51 – 203 Reverse 51 –... -

Page 143: Pe Peel Bar Location

Appendix C PE Peel Bar Location Provided as a reference, the drawing below defines the previous peel point of PE models. PE Printer Peel Point Peel Bar PE to A-Class GPIO Adapter Cable A GPIO Adapter Cable (P/N 32-2562-01) for integration of the A-Class into an existing PE installation. - Page 144 A-Class...

-

Page 145: Applicator Interface Overview

Appendix D Applicator Interface Overview The Applicator Interface CCA contains the printer to an applicator interface circuitry; functions and suggested connections are given below, and in these related sections: • Operational settings; Section 4.2.3. • J3 (COM D) and J4 (COM C) setup; Section 4.2.5. •... - Page 146 GPI/O A (J1) Four dedicated inputs are available for control of printer functions. These inputs require no external pull-ups, are designed to interface to open-collector outputs and accept totem pole outputs from +4.5 to + 26 VDC. Optical isolators are available to provide isolation.

- Page 147 Failure to properly configure the GPIO Port can result in damage to the printer and / or connected devices. GPI/O Port A Overview Signal Signal Name Jumper Position Function / Description Number Direction Installed Printer chassis is used. Ground JMP 8 Removed Ground must be supplied.

- Page 148 GPI/O B (J2) Six unassigned inputs are designed to interface to open-collector outputs. These inputs require no external pull-ups and blocking diodes allow the use of totem pole outputs from +4.5 to + 26 VDC. Optical isolators are available to provide isolation. Two print control interface circuit examples are given below.

- Page 149 Failure to properly configure the GPIO Port can result in damage to the printer and / or connected devices. GPI/O Port B Overview Signal Name / Pin Number Jumper Position Function / Description Direction Printer +5VDC is used (.5 amp maximum). Installed Drawing more than .5 amps can result in unreliable printer operation.

- Page 150 COM C (J4) Serial Port C (see Section 2.2.2.2) functions as an RS-232 interface or as a dedicated device interface, according to the jumper settings indicated below: COM C Jumper Setting Functions Position Function JMP 12 JMP 13 JMP 14 JMP 15 RS-232 Communications RFID...

- Page 151 Indicators and Monitors Real-time verification of settings and activity of the GPIO ports is available via displayed and printed information: Unused, non-connected inputs and outputs will have an indeterminate state and assume a value of 1 or 0. Indicators: Sampled every millisecond, incoming (IN) and outgoing (OUT) signal activity can be observed on the card, where LED color changes correspond to signal state changes.

- Page 152 PRINT SIGNAL INFO: A hardcopy of the current GPI/O settings and signal states can be output (see Section 4.2.6, TEST GPIO / PRINT SIGNAL INFO) in the following format: GPIO SIGNAL INFO WED 11:04AM 4JUL2005 CARD ID#3 OUTPUT SIGNALS INPUT SIGNALS END OF PRINT START OF PRINT PIN# 3 GPIO A...

-

Page 153: Multi-Language Menu

Appendix E Multi-Language Menu Different languages can be downloaded to replace the English menu by constructing a spreadsheet that defines the printer dictionary. To change the language you will add a new language column (or modify the existing column) in the spreadsheet, click on the ‘Generate DPL file(s)’... - Page 154 B. Click the “Enable Macro” box. The following screen appears: C. Click on Column J and enter your new language, or modify an existing one. Some tips on this process: Message Size – When entering new messages, reference the ‘MAX’ column: this is •...

- Page 155 An error has occurred if the menu displays the new language selection, but all the messages remain in English. In this case, re-check your process or contact Datamax Technical Support (be prepared to provide the Common.xls and DPL download files created).

- Page 156 To restore the factory generated EFIGS image, download the file *832296.01A to the • printer. This file is located on the Datamax FTP site. The letter at the end of the file name (e.g., A) specifies the revision. The latest revision will be available on the FTP site.

-

Page 157: Saving A Configuration File

Appendix F Saving a Configuration File Configuration Files can be used to retain special printer settings, eliminating the need for repeated setups. Unique filenames can be assigned then the setups restored, as needed, via the host or printer menu. The following example saves a calibration setting in a configuration file: If file sharing among printers, DO NOT include unique parameters (such as calibrations and adjustments) when saving. - Page 158 A-Class...

-

Page 159: Ribbon Saver Overview

Appendix G Ribbon Saver Overview With the Ribbon Saver option, the printer can conserve ribbon use in blank label areas. Depending upon the label format, when more than .25 inches (6.4 mm) of ribbon can be saved in no-print areas, the printhead lifts off the platen and a brake stops ribbon motion, while the assist rollers continue to advance media. - Page 160 A-Class...

-

Page 161: Warranty Information

A-Class™ thermal printhead, rollers, and belts. This one year (365 days) warranty is valid only if a Datamax - approved thermal label media is used, as defined in the then current Datamax list of approved thermal/thermal transfer media, a copy of which is available from Datamax. -

Page 162: General Warranty Provisions

General Warranty Provisions Datamax makes no warranty as to the design, capability, capacity or suitability of any of its hardware, supplies, or software. Software is licensed on an “as is” basis without warranty. Except and to the extent... -

Page 163: Glossary

Glossary alphanumeric Consisting of alphabetic, numeric, punctuation and other symbols. backing material The silicon-coated paper carrier material to which labels with adhesive backing are affixed. Also referred to as “liner”. bar code A representation of alphanumeric information in a pattern of machine-readable marks. - Page 164 DPL (Datamax Programming Language) Programming commands used specifically for control of and label production in Datamax printers. A complete listing of commands can be found in the Class Series 2 Programmer’s Manual DPMM (dots per millimeter) A measurement of resolution, rated in the number of thermal elements contained in one millimeter of the printhead.

- Page 165 media sensor An electronic device equipped with photo sensors to detect media and the top-of-form on die-cut, notched or reflective media. MMPS (millimeters per second) Metric measurement of speeds. notched stock Media, typically tag stock, with holes or notches in the material that is used to signal the top-of-form.

- Page 166 A-Class...