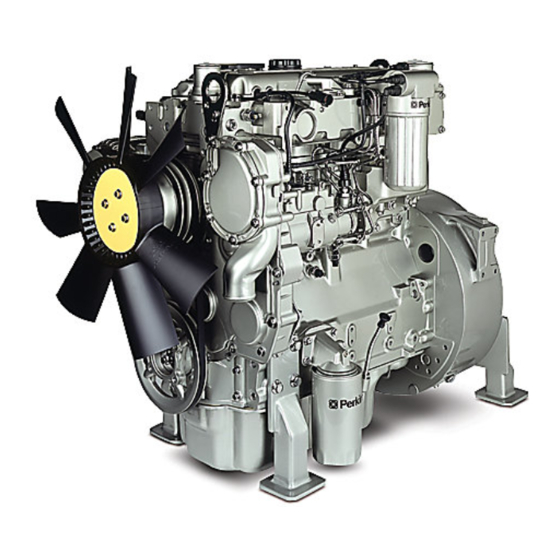

Perkins 1103 Disassembly And Assembly

Hide thumbs

Also See for 1103:

- Operation and maintenance manual (92 pages) ,

- Workshop manual (54 pages) ,

- Operation and maintenance manual (84 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Perkins 1103

- Page 1 SENR9779-02 December 2004 Disassembly and Assembly 1103 and 1104E Engines DC11-Up (Machine) DD11-Up (Machine) DJ11-Up (Machine) DK11-Up (Machine) RE11-Up (Machine) RG11-Up (Machine) RJ11-Up (Machine) RR11-Up (Machine) RS11-Up (Machine) DF11-Up (Engine) DG11-Up (Engine)

-

Page 2: Important Safety Information

Obtain the complete and most current information before you s t ar t any jo b . Perkins dea le rs hav e t he m os t c ur r en t i nfo rm ati on a va il abl e. -

Page 3: Table Of Contents

SENR9779-02 Table of Contents Table of Contents Crankshaft Front Seal - Remove ......71 Crankshaft Front Seal - Install ......72 Crankshaft Wear Sleeve (Front) - Remove ..73 Crankshaft Wear Sleeve (Front) - Install ....73 Disassembly and Assembly Section Front Cover - Remove and Install ...... -

Page 4: Disassembly And Assembly Section

SENR9779-02 Disassembly and Assembly Section Disassembly and Assembly NOTICE Section Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to i02219291 collect the fluid with suitable containers before open- Fuel Priming Pump - Remove ing any compartment or disassembling any compo- nent containing fluids. - Page 5 SENR9779-02 Disassembly and Assembly Section NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids.

-

Page 6: Fuel Filter Base - Remove And Install

SENR9779-02 Disassembly and Assembly Section 1. Clean the external surfaces of the fuel priming Note: The removal procedure is identical for the pump (2). Position the fuel priming pump (2) and four cylinder and the three cylinder engines. The install the two setscrews (3). illustrations show the four cylinder engine. - Page 7 SENR9779-02 Disassembly and Assembly Section 3. Push down against the spring pressure that is applied to the filter element (4). Rotate the filter element (4) counterclockwise in order to release the filter element from the filter case (2). 4. Discard the filter element (4) and the O-ring (3). Removal Procedure for the Spin-on Filter NOTICE...

- Page 8 SENR9779-02 Disassembly and Assembly Section 4. Install the new filter element (4) into the filter case (2). Push the filter element against the spring pressure and rotate the filter element in a clockwise direction in order to secure the filter element within the filter case (2).

-

Page 9: Fuel Injection Lines - Remove

SENR9779-02 Disassembly and Assembly Section 4. Install the spin-on filter (3) onto the filter head (5). 5. Tighten the spin-on filter by hand until the sealing ring contacts the filter head. Rotate the spin-on filter through 90 degrees. 6. Close the drain (1). 7. -

Page 10: Fuel Injector Cover - Remove And Install (If Equipped)

SENR9779-02 Disassembly and Assembly Section i02221380 Fuel Injector Cover - Remove and Install (If Equipped) g00955826 Illustration 13 Typical example 1. Inspect the fuel injection lines (1) for wear and for damage. Replace any fuel injection line (1) that is worn or any fuel injection line that is damaged. -

Page 11: Fuel Injection Pump - Remove (Delphi Dp210)

SENR9779-02 Disassembly and Assembly Section Installation Procedure i02216956 Fuel Injection Pump - Remove NOTICE (Delphi DP210) Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: The installation procedure is identical for the four cylinder and the three cylinder engines. The illustration shows the four cylinder engine. - Page 12 SENR9779-02 Disassembly and Assembly Section g00956204 g01011369 Illustration 16 Illustration 17 Typical example Typical example 2. Loosen the locking screw (5). Rotate the spacer 6. Remove the nut (8) and the washer from the shaft (6) in order to allow the locking screw (5) to tighten of the fuel injection pump.

-

Page 13: Fuel Injection Pump - Remove (Delphi Stp)

SENR9779-02 Disassembly and Assembly Section 11. Remove the fuel injection pump from the front 2. Loosen the locking screw (1). Rotate the spacer housing. Remove the O-ring (10) and discard the (2) in order to allow the locking screw (1) to tighten O-ring from the fuel injection pump. -

Page 14: Fuel Injection Pump - Remove (Delphi Dpg)

SENR9779-02 Disassembly and Assembly Section i02224700 Fuel Injection Pump - Remove (Delphi DPG) Removal Procedure g01062397 Illustration 21 Typical example Start By: 6. Remove the nut (7) and the washer from the shaft a. Remove the fuel injection lines. Refer to this of the fuel injection pump. - Page 15 SENR9779-02 Disassembly and Assembly Section g01122133 Illustration 24 6. Remove the nut (6) and the washer from the shaft of the fuel injection pump. 7. Use a suitable puller in order to remove the fuel injection pump gear (7). g01122132 Illustration 23 Note: Do not pry the fuel injection pump gear (7) 2.

-

Page 16: Fuel Injection Pump - Remove (Bosch Epve For The 1104 Engines Only)

SENR9779-02 Disassembly and Assembly Section i01941022 Fuel Injection Pump - Remove (Bosch EPVE for the 1104 engines only) Removal Procedure Start By: a. Remove the fuel injection lines. Refer to this Disassembly and Assembly Manual, “Fuel Injection Lines - Remove and Install”. g00996409 Illustration 26 b. -

Page 17: Fuel Injection Pump - Remove (Delphi Dpa)

SENR9779-02 Disassembly and Assembly Section 4. Loosen the locking screw (6). Move the spacer (5) 8. If necessary, remove the setscrew and the bracket in order to allow the locking screw (6) to tighten (10) from the cylinder block. against the shaft of the fuel injection pump. Rotate the fuel injection pump gear in a counterclockwise 9. - Page 18 SENR9779-02 Disassembly and Assembly Section g01120567 Illustration 31 Typical example 6. Remove the nut (6) and the washer from the shaft of the fuel injection pump. 7. Use a suitable puller in order to remove the fuel g01120559 Illustration 30 injection pump gear (7).

-

Page 19: Fuel Injection Pump - Install (Delphi Dp210)

The fuel injection pump must be returned to 3. Install the setscrew (15) and the bracket (11) onto your Perkins Dealer if the shaft of the fuel injection the cylinder block if the bracket was previously pump was rotated accidentally. -

Page 20: Fuel Injection Pump - Install (Delphi Stp)

12 N·m (106 lb in). screw. The fuel injection pump must be returned to your Perkins Dealer if the shaft of the fuel injection Note: The spacer (6) must be correctly positioned pump was rotated accidentally. - Page 21 SENR9779-02 Disassembly and Assembly Section 1. Ensure that the No. 1 cylinder is at top dead Note: Ensure that the mating surfaces of the fuel center on the compression stroke. Refer to the injection pump gear and the shaft of the fuel injection Testing and Adjusting Manual, “Fuel Injection pump are clean.

-

Page 22: Fuel Injection Pump - Install (Delphi Dpg)

The fuel injection pump must be returned to your Perkins Dealer if the shaft of the fuel injection pump was rotated accidentally. NOTICE Keep all parts clean from contaminants. - Page 23 SENR9779-02 Disassembly and Assembly Section g01122134 Illustration 42 Typical example Note: Do not lubricate the new O-ring (9). The O-ring should be installed dry. 2. Install the new O-ring (9) onto the fuel injection g01122132 Illustration 44 pump. Position the fuel injection pump onto the front housing.

-

Page 24: Fuel Injection Pump - Install (Bosch Epve For The 1104 Engines Only)

(Bosch EPVE for the 1104 engines only) g00996474 Illustration 46 2. Lightly lubricate a new O-ring (9) with Perkins 1766-501 Silicone Fluid MS200/1000. Install the new O-ring (9) onto the fuel injection pump. Position the fuel injection pump on the front housing. - Page 25 SENR9779-02 Disassembly and Assembly Section 5. Position the fuel injection pump gear (8) onto the 10. Loosen the locking screw (6). Move spacer (5) shaft of the fuel injection pump. Install the washer in order to prevent the locking screw (6) from and the nut (7).

-

Page 26: Fuel Injection Pump - Install (Delphi Dpa)

The locking screw (3) must remain locked until you are instructed to loosen the locking screw. The fuel injection pump must be returned to your Perkins Dealer if the shaft of the fuel injection pump was rotated accidentally. NOTICE Keep all parts clean from contaminants. -

Page 27: Fuel Injector - Remove

SENR9779-02 Disassembly and Assembly Section End By: a. Install the front cover. Refer to this Disassembly and Assembly Manual, “Front Cover - Remove and Install”. b. Install the crankshaft pulley. Refer to this Disassembly and Assembly Manual, “Crankshaft Pulley - Remove and Install”. c. -

Page 28: Fuel Injector - Install

SENR9779-02 Disassembly and Assembly Section g00975056 g01129982 Illustration 55 Illustration 56 2. Remove the fuel hose (2) from the fuel injector (1). 1. Lubricate the seat washer (6) with clean engine oil. Install a new seat washer (6) in the cylinder head. 3. -

Page 29: Turbocharger - Remove

SENR9779-02 Disassembly and Assembly Section i01944022 Turbocharger - Remove Removal Procedure g01038600 Illustration 57 NOTICE Typical example Keep all parts clean from contaminants. 4. If an exhaust elbow is installed, remove the Contaminants may cause rapid wear and shortened exhaust elbow. Refer to this Disassembly and component life. -

Page 30: Turbocharger - Install

SENR9779-02 Disassembly and Assembly Section 7. Remove the banjo bolts (5). Remove the oil 1. Remove all of the plastic plugs from all of the ports supply tube assembly (6) and the washers (7) of the turbocharger (1). Clean the mating surfaces from the turbocharger (1). -

Page 31: Exhaust Manifold - Remove And Install

SENR9779-02 Disassembly and Assembly Section Note: The top flange of the oil drain tube assembly (9) is secured to the turbocharger (1) with 6 mm setscrews (8). The bottom flange of the oil drain tube assembly (9) is secured to the cylinder block with 8 mm setscrews (11). - Page 32 SENR9779-02 Disassembly and Assembly Section 2. Position the new exhaust manifold gasket onto the studs in the cylinder head. Position the exhaust manifold (2) onto the studs. Install the setscrews (1) finger tight in order to secure the exhaust manifold to the cylinder head. 3.

-

Page 33: Exhaust Elbow - Remove And Install (If Equipped)

SENR9779-02 Disassembly and Assembly Section i02216959 Exhaust Elbow - Remove and Install (If Equipped) g00951398 Illustration 65 1. Loosely install two suitable studs into the holes (5 and 8) as guides. Removal Procedure Note: Do not use any sealant on the exhaust manifold gasket. -

Page 34: Inlet And Exhaust Valve Springs - Remove And Install

SENR9779-02 Disassembly and Assembly Section Installation Procedure i01947651 Inlet and Exhaust Valve Springs - Remove and Install Removal Procedure Table 1 Required Tools Part Number Part Description 21825666 Valve Spring Compressor 27610235 Setscrew Adapter Start By: a. Remove the rocker shaft assembly. Refer to this Disassembly and Assembly Manual, “Rocker Shaft and Pushrod - Remove”. - Page 35 SENR9779-02 Disassembly and Assembly Section Note: If you are replacing all of the valve springs, the procedure can be done on two cylinders at the same time. The procedure can be done on cylinder 1 and cylinder 4, and on cylinder 2 and cylinder 3. Remember that the crankshaft must not be turned while the valve springs are removed.

-

Page 36: Inlet And Exhaust Valves - Remove And Install

SENR9779-02 Disassembly and Assembly Section 3. Install the valve spring compressor (1) in position Note: Ensure that the machined face of the cylinder on the cylinder head in order to compress the head is kept on a clean, soft surface in order to appropriate valve spring (5). - Page 37 SENR9779-02 Disassembly and Assembly Section 4. Compress the valve spring (5). 5. Remove the valve keepers (3). 6. Carefully release the pressure on the valve spring compressor (1). Remove the valve spring compressor (1) and the setscrew adapter (2) from the cylinder head.

- Page 38 SENR9779-02 Disassembly and Assembly Section 6. Carefully turn over the cylinder head and ensure that all of the valves remain in place. Place the machined surface of the cylinder head onto a clean, soft surface. Note: The valve guides must be clean and dry before installing the valve stem seals (6).

-

Page 39: Inlet And Exhaust Valve Guides - Remove And Install

SENR9779-02 Disassembly and Assembly Section 13. Carefully release the pressure on the valve spring compressor (1). Remove the valve spring compressor (1) and the setscrew adapter (2) from the cylinder head. Gently strike the top of the appropriate valves with a soft hammer in order to ensure that the valve keepers (3) are properly installed. - Page 40 SENR9779-02 Disassembly and Assembly Section 2. Install the 27610234 Valve Guide Adaptor (8) into 8. Remove the valve seat inserts. Refer to this the 21825478 Valve Guide Remover/Replacer Disassembly and Assembly Manual, “Inlet and Exhaust Valve Seat Inserts - Remove and Install”. (2).

-

Page 41: Inlet And Exhaust Valve Seat Inserts - Remove And Install

SENR9779-02 Disassembly and Assembly Section Note: If the cylinder head has been previously i01947654 ground then the bottom face of valve seat must be Inlet and Exhaust Valve Seat ground in order to ensure that the valve seat will be Inserts - Remove and Install installed correctly into the cylinder head. - Page 42 SENR9779-02 Disassembly and Assembly Section 5. After installing the valve guides and valve seat Table 8 inserts, the valve guides must be reamed and Tool for the Inlet Valve Seat Inserts the valve seat inserts must be cut to the finished Callout Dimension diameter.

-

Page 43: Engine Oil Filter Base - Remove And Install

SENR9779-02 Disassembly and Assembly Section 6. Set the diameter of the cutter (3) to the correct size for the valve seat to be cut. Refer to the NOTICE Specifications Manual, “Cylinder Head Valves” for Care must be taken to ensure that fluids are contained the correct diameter. - Page 44 SENR9779-02 Disassembly and Assembly Section Installation Procedure for an Oil Filter with a Separate Filter Element NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Step 1 to Step 5 is the procedure for installing the oil filter base if the oil filter base was previously removed.

-

Page 45: Oil Filter

SENR9779-02 Disassembly and Assembly Section 5. Evenly tighten the setscrews (5) to a torque of 9. Tighten the drain plug (1) to a torque of 12 N·m 22 ± 5 N·m (16 ± 4 lb ft). (9 lb ft). 10. Inspect the O-ring for the drain plug for the engine oil pan. - Page 46 SENR9779-02 Disassembly and Assembly Section g01018706 g01018706 Illustration 85 Illustration 86 Typical example Typical example 4. Place a suitable container beneath the oil filter 1. Clean the oil passages within the oil filter base element (11). (12). Clean the mating surfaces of the cylinder block and the engine oil filter base (12).

-

Page 47: Engine Oil Cooler - Remove

SENR9779-02 Disassembly and Assembly Section NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. -

Page 48: Engine Oil Cooler - Install

SENR9779-02 Disassembly and Assembly Section 1. Drain the coolant from the engine into a suitable container. Drain the engine oil from the engine into a suitable container. Refer to the Operation and Maintenance Manual for the procedure on draining the engine coolant and the engine oil. 2. - Page 49 SENR9779-02 Disassembly and Assembly Section 2. If the oil cooler base (9) was removed from the cylinder block, install setscrews into setscrew holes (1) and (6) in the oil cooler base. Install a new joint onto the two setscrews and secure the oil cooler base (9) to the cylinder block.

-

Page 50: Engine Oil Relief Valve - Remove And Install (Engine Oil Pump)

SENR9779-02 Disassembly and Assembly Section Installation Procedure for the Four i01958106 Cylinder Engine Engine Oil Relief Valve - Remove and Install NOTICE (Engine Oil Pump) Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Removal Procedure Start By: a. -

Page 51: Engine Oil Relief Valve - Remove And Install (Balancer Unit For The 1104 Engines Only)

SENR9779-02 Disassembly and Assembly Section Installation Procedure i01958108 Engine Oil Relief Valve - NOTICE Remove and Install Keep all parts clean from contaminants. (Balancer Unit for the 1104 Contaminants may cause rapid wear and shortened engines only) component life. 1. Clean the spring (3) and the plunger (4) of the engine oil relief valve. -

Page 52: Engine Oil Pump - Remove (Engines Without A Balancer)

SENR9779-02 Disassembly and Assembly Section 1. Remove the plug (2). Remove the spring (3) and i01958101 the plunger (4) from the balancer unit (1). Engine Oil Pump - Remove (Engines Without a Balancer) Installation Procedure NOTICE Keep all parts clean from contaminants. Removal Procedure Contaminants may cause rapid wear and shortened component life. -

Page 53: Engine Oil Pump - Install (Engines Without A Balancer)

SENR9779-02 Disassembly and Assembly Section 2. Remove the setscrews (3). Remove the assembly 1. Clean all of the internal components of the oil of the engine oil pump (4) from the cylinder block. pump if the front cover of the oil pump was previously removed in order to inspect the internal 3. -

Page 54: Water Pump - Remove

SENR9779-02 Disassembly and Assembly Section NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. - Page 55 SENR9779-02 Disassembly and Assembly Section NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. g01019550 Illustration 104 1. Remove the setscrews (1) from the cover (2) of the water pump (3). Remove the joint between the cover (2) and the water pump (3).

-

Page 56: Water Pump - Assemble

SENR9779-02 Disassembly and Assembly Section 5. Support the machined face (10) of the housing of the water pump (3) on a suitable support. Press on the shaft (7) until the gear (11) and the bearing (12) are free from the shaft. Discard the shaft (7) and the bearing (12). -

Page 57: Water Pump - Install

SENR9779-02 Disassembly and Assembly Section 5. Use a suitable adapter in order to press the 10. Install the new coolant seal (6) onto the shaft bearing (12) against the shoulder of the recess (7) with the largest diameter of the coolant seal for the bearing. -

Page 58: Water Temperature Regulator - Remove And Install

SENR9779-02 Disassembly and Assembly Section 8. Tighten the setscrews (3) in the sequence that is shown in the illustration 111 to a torque of 22 N·m (16 lb ft). 9. Install the hose to the water pump inlet. Tighten the hose clamps. 10. - Page 59 SENR9779-02 Disassembly and Assembly Section 4. Install the 27610226 Thermostat Tool (5) into the water temperature regulator housing (1). Press on the tool (5) in order to squeeze the retainers (4). Rotate the tool (5) in order to release the water temperature regulator (3) from the tabs (6) of the water temperature regulator housing (1).

- Page 60 SENR9779-02 Disassembly and Assembly Section g01019377 g01019344 Illustration 116 Illustration 118 1. Clean the water temperature regulator housing (1). Ensure that the tabs (6) for the retainers (4) are clean. Ensure that the seat for the O-ring (7) is clean. g01019356 Illustration 119 4.

-

Page 61: Flywheel - Remove

SENR9779-02 Disassembly and Assembly Section 8. Fill the cooling system to the proper level. Refer Note: The flywheel (3) is heavy. Use suitable lifting to the Operation and Maintenance Manual, “Refill equipment to support the flywheel (3) before the Capacities” for further information. remainder of the setscrews (1) are removed. -

Page 62: Crankshaft Rear Seal - Remove

SENR9779-02 Disassembly and Assembly Section 1. Thoroughly clean the flywheel housing. Inspect Note: The flywheel (3) is heavy. Use suitable lifting the crankshaft rear seal for leaks. If there are any equipment to support the flywheel until the setscrews oil leaks refer to this Disassembly and Assembly (1) have been installed. -

Page 63: Crankshaft Rear Seal - Install

SENR9779-02 Disassembly and Assembly Section Note: The following procedure assumes that the crankshaft rear seal is a replacement assembly. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- NOTICE ing, adjusting and repair of the product. Be prepared to Keep all parts clean from contaminants. - Page 64 SENR9779-02 Disassembly and Assembly Section g01004958 Illustration 129 Typical example 4. Ensure that the plastic sleeve (2) is engaged onto the crankshaft flange (1). Push the assembly of the crankshaft rear seal (3) evenly and push the assembly smoothly onto the crankshaft flange (1) until the assembly is against the cylinder block.

-

Page 65: Crankshaft Wear Sleeve (Rear) - Remove

Illustration 131 Note: The alignment tool (4) is not currently available End By: from Perkins. Refer to the illustration 131 for the required dimensions in order to manufacture an a. Install the flywheel housing. Refer to this alignment tool (4) locally. -

Page 66: Crankshaft Wear Sleeve (Rear) - Install

SENR9779-02 Disassembly and Assembly Section 2. Insert a suitable tool between the crankshaft 1. Ensure that the crankshaft flange (4) is thoroughly flange and the wear sleeve next to the score mark. clean, dry, and free from old sealant prior to the The wear sleeve should break along the score installation of a new crankshaft wear sleeve (2). - Page 67 SENR9779-02 Disassembly and Assembly Section NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids.

-

Page 68: Crankshaft Pulley - Remove And Install

SENR9779-02 Disassembly and Assembly Section i02217476 Crankshaft Pulley - Remove and Install Standard and Non-standard Pulleys Start By: a. Remove the V-Belts. Refer to this Disassembly and Assembly Manual, “V-Belts - Remove and Install”. g01126955 Illustration 138 NOTICE Non-standard Pulley Keep all parts clean from contaminants. - Page 69 SENR9779-02 Disassembly and Assembly Section Install the Standard Pulley Remove the Non-standard Pulley when the Crankshaft is Not Replaced g00952102 Illustration 140 g01127338 Illustration 141 1. Clean the pulley (3) and clean the thrust block (2). Inspect the pulley (3) and the thrust block (2) for wear and for damage.

- Page 70 SENR9779-02 Disassembly and Assembly Section 1. Clean the pulley (3) and clean the thrust block 1. Remove the setscrews (1) and then remove the (2). Inspect the pulley (3) and the thrust block (2) thrust block (2). for wear and for damage. If necessary, replace any damaged component.

-

Page 71: Crankshaft Front Seal - Remove

SENR9779-02 Disassembly and Assembly Section 4. Align the pulley with the “T” mark (8) at the top and in line with the center line of the engine and NOTICE then install the pulley on the crankshaft. Use a Care must be taken to ensure that fluids are contained suitable straight edge (7) against the guide pins during performance of inspection, maintenance, test- (9) to aid alignment of the pulley. -

Page 72: Crankshaft Front Seal - Install

SENR9779-02 Disassembly and Assembly Section i01964540 Crankshaft Front Seal - Install Installation Procedure Table 14 Required Tools Part Part Description Number 21825577 Crankshaft Front Seal Replacer g01020716 21825580 Illustration 149 Fastener Plate 21825578 Pressure Plate Note: A sleeve (5) is attached to the new crankshaft front seal (6). -

Page 73: Crankshaft Wear Sleeve (Front) - Remove

SENR9779-02 Disassembly and Assembly Section 11. Immediately install the crankshaft pulley. Refer 4. Use a suitable solvent in order to remove any old to this Disassembly and Assembly Manual, sealant from the crankshaft pulley (1). “Crankshaft Pulley - Remove and Install”. i01964526 i01964525 Crankshaft Wear Sleeve (Front) -

Page 74: Front Cover - Remove And Install

SENR9779-02 Disassembly and Assembly Section Installation Procedure i02254888 Front Cover - Remove and Install Removal Procedure Start By: a. Remove the water pump. Refer to this Disassembly and Assembly Manual, “Water Pump - Remove and Install”. g00955548 Note: In order to remove the front cover, it is not Illustration 153 necessary to remove the cooling fan, the fan drive, the crankshaft pulley, or the alternator. -

Page 75: Gear Group (Front) - Remove

SENR9779-02 Disassembly and Assembly Section End By: a. If necessary, install the fan drive. Refer to this Disassembly and Assembly, “Fan Drive - Remove and Install”. b. If necessary, install the fan. Refer to this Disassembly and Assembly Manual, “Fan - Remove and Install”. - Page 76 SENR9779-02 Disassembly and Assembly Section 2. Insert the 27610211 Crankshaft timing pin (3) through the housing (front) and into the web of the crankshaft. Insert the 27610212 Camshaft timing pin (4) through the camshaft gear (5) and into the housing (front). 3.

-

Page 77: Gear Group (Front) - Install

SENR9779-02 Disassembly and Assembly Section 6. Install the idler gear (2). Refer to this Disassembly i02217478 and Assembly Manual, “Idler Gear - Remove and Gear Group (Front) - Install Install”. 7. Ensure that the mesh of the idler gear (2) is correct with the camshaft gear (1). -

Page 78: Idler Gear - Remove And Install

SENR9779-02 Disassembly and Assembly Section 16. Check the end play of the idler gear (2). Refer to this Disassembly and Assembly Manual, “Idler Gear - Remove and Install” and refer to the Specifications Manual, “Gear Group (Front)” for further information. 17. - Page 79 SENR9779-02 Disassembly and Assembly Section NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids.

- Page 80 SENR9779-02 Disassembly and Assembly Section g01023845 g01038900 Illustration 169 Illustration 166 Standard idler gear assembly 5. Remove the three setscrews (6) from the idler gear (8). Remove the plate (7) from the idler gear 6. Remove the assembly (9) of the idler gear (8) and (8).

- Page 81 SENR9779-02 Disassembly and Assembly Section Installation Procedure Table 18 Required Tools 27610212 Timing Pin (Camshaft) 27610211 Timing Pin (Crankshaft) NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. g01024165 Illustration 172 1. Clean all of the components and inspect all of the components that were removed in the previous Note: Ensure that the marks (19) on the idler gear procedure.

- Page 82 SENR9779-02 Disassembly and Assembly Section g01023942 g01038902 Illustration 174 Illustration 176 Heavy-duty idler gear assembly Note: The new bearing assembly (16) is supplied with a protective sleeve. Do not remove this protective sleeve. The protective sleeve prevents the rollers from falling out of the roller bearings. 4.

-

Page 83: Housing (Front) - Remove

SENR9779-02 Disassembly and Assembly Section 13. Lightly lubricate all of the gears with clean engine lubricating oil. End By: a. Install the rocker shaft. Refer to this Disassembly and Assembly Manual, “Rocker Shaft and Pushrod - Install”. b. Install the glow plugs if the glow plugs were previously removed. -

Page 84: Housing (Front) - Install

SENR9779-02 Disassembly and Assembly Section NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. - Page 85 SENR9779-02 Disassembly and Assembly Section Note: If it is necessary to replace the front housing (6), it may also be necessary to install blanking plugs which should be sealed with a suitable sealant into the front housing. 3. Install a new joint (7) to the front housing (6). g01024529 Illustration 183 Typical example...

-

Page 86: Accessory Drive - Remove And Install

SENR9779-02 Disassembly and Assembly Section 8. Install new O-rings onto the bypass tube (12). Apply POWERPART 21820221 Red Rubber Grease to the O-rings. Install the bypass tube (12) into the cylinder head. Install the setscrews (13). End By: a. Install the gear group (front). Refer to this Disassembly and Assembly Manual, “Gear Group (Front) - Install”. - Page 87 SENR9779-02 Disassembly and Assembly Section 4. Apply a small continuous bead (14) of 21820603 POWERPART Retainer (oil tolerant) to the outer surface of the bearing (8). Apply a small continuous bead (13) of 21820603 POWERPART Retainer (oil tolerant) to the inner surface of the bearing (8).

-

Page 88: Crankcase Breather - Remove And Install

A closed breather system is optional for turbocharged three cylinder and four cylinder engines in the 1100 Series. Note: 1103 engines, models DJ and DK that are equipped with a open crankcase breather do not have a diaphragm valve in the valve mechanism cover. - Page 89 (5) and especially clean the recess (11). Installation Procedure for the Diaphragm Valve Note: 1103 engines, models DJ and DK that are equipped with a closed breather system do not have a diaphragm valve in the valve mechanism cover.

-

Page 90: Valve Mechanism Cover - Remove And Install

SENR9779-02 Disassembly and Assembly Section 5. If equipped, ensure that the two domes on the plate (3) are uppermost and ensure that the offset hole is toward the connector (9) of the valve mechanism cover (5). Install the plate (3). Install the screws (2). - Page 91 SENR9779-02 Disassembly and Assembly Section NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids.

-

Page 92: Rocker Shaft And Pushrod - Remove

SENR9779-02 Disassembly and Assembly Section 5. If you are working on a four cylinder engine, i01947657 go to Step 6. If you are working on a three Rocker Shaft and Pushrod - cylinder engine, tighten the fasteners for the valve Remove mechanism cover in the sequence that is shown in Illustration 200. -

Page 93: Rocker Shaft - Disassemble

SENR9779-02 Disassembly and Assembly Section i01947658 Rocker Shaft - Disassemble Disassembly Procedure Table 21 Required Tools Part Description Suitable Pliers for External Circlips g01013998 Illustration 203 Start By: a. Remove the rocker shaft assembly. Refer to this Disassembly and Assembly Manual, “Rocker Shaft and Pushrod - Remove”. -

Page 94: Rocker Shaft - Assemble

SENR9779-02 Disassembly and Assembly Section 2. Place an identification mark on each of the 2. Check the clearance between the rocker shaft (6) components for installation. Ensure that you note and the bushing of every rocker arm (3 and 4). the component’s relationship to the machined flat Refer to the Specifications Manual, “Rocker Shaft”... -

Page 95: Rocker Shaft And Pushrod - Install

SENR9779-02 Disassembly and Assembly Section 1. Apply clean engine lubricating oil to both ends of i01947661 the pushrods (4). Install the pushrods (4). Rocker Shaft and Pushrod - Install Note: Ensure that the pushrods (4) are installed in the original location and that the pushrods are seated in the valve lifters correctly. -

Page 96: Cylinder Head - Remove

SENR9779-02 Disassembly and Assembly Section Note: The longest torx screw (5) must be installed at g. Remove the rocker shaft assembly and the the front of the cylinder head in hole (11). pushrods. Refer to this Disassembly and Assembly Manual, “Rocker Shaft and Pushrod - 6. -

Page 97: Cylinder Head - Install

SENR9779-02 Disassembly and Assembly Section 3. Refer to the illustration 213 for three cylinder engines or illustration 214 for four cylinder engines. Gradually loosen the setscrews (5) in the reverse numerical order. This will help prevent distortion of the cylinder head (4). 4. - Page 98 SENR9779-02 Disassembly and Assembly Section Note: Thoroughly clean the hole in the cylinder head Note: Ensure that the cylinder head (2) is positioned for the gas that is ventilated from the crankcase. onto the dowels (5). Ensure that the hole is not restricted by debris and/or oil deposits.

- Page 99 SENR9779-02 Disassembly and Assembly Section Note: For the three cylinder engine, the short a. Turn the short setscrews (2, 5, 6, 7, and 8) for setscrews (6) are installed into the holes that are the three cylinder or turn the short setscrews marked 2, 5, 6, 7, and 8.

-

Page 100: Lifter Group - Remove And Install

SENR9779-02 Disassembly and Assembly Section 15. Tighten the setscrews (6) for the cylinder head (2) g. Install the hose from the integral air inlet to the in numerical order. Refer to the illustration 218 for air filter. Refer to the OEM information for further the three cylinder and illustration 219 for the four details. -

Page 101: Camshaft - Remove And Install

SENR9779-02 Disassembly and Assembly Section Note: Place an identification mark on each cam i01977579 follower for installation purposes. Camshaft - Remove and Install Installation Procedure NOTICE Removal Procedure Keep all parts clean from contaminants. Start By: Contaminants may cause rapid wear and shortened component life. -

Page 102: Camshaft Gear - Remove And Install

SENR9779-02 Disassembly and Assembly Section i01977601 Camshaft Gear - Remove and Install Removal Procedure Start By: a. Remove the front cover if the front cover has not previously been removed. Refer to this Disassembly and Assembly Manual, “Front Cover g00951934 - Remove and Install”. -

Page 103: Camshaft Bearings - Remove And Install

SENR9779-02 Disassembly and Assembly Section 1. Inspect the camshaft gear (2) and the key in the camshaft for wear or damage. g01130526 Illustration 229 Typical example g00954352 Illustration 228 1. If the camshaft bearing (1) is worn or damaged 2. Ensure that the marked teeth on the camshaft use a suitable adapter in order to press the gear (2) are facing toward the front and that bearing out of the cylinder block. -

Page 104: Engine Oil Pan - Remove And Install

SENR9779-02 Disassembly and Assembly Section End By: 1. Remove all dirt, oil, and grease from the exterior surfaces of the oil pan (5). a. Install the camshaft. Refer to this Disassembly and Assembly Manual, “Camshaft - Remove and 2. Operate the engine until the engine is warm. Stop Install”. - Page 105 SENR9779-02 Disassembly and Assembly Section g01042312 g01042276 Illustration 232 Illustration 234 2. Install four temporary studs (7) as guides. Refer 4. Also, apply a sufficient amount of new silicon to illustration 232for the correct location of the rubber sealant if the silicon rubber sealant (9) temporary studs (7).

-

Page 106: Balancer - Remove (Some 1104 Engines Only)

SENR9779-02 Disassembly and Assembly Section 6. Install the setscrews (4) in order to secure the i02242016 engine oil pan (5) to the cylinder block. Tighten the Balancer - Remove setscrews (4) finger tight. (Some 1104 Engines Only) Removal Procedure Table 25 Required Tools Part Number Part Name... -

Page 107: Balancer - Install (Some 1104 Engines Only)

SENR9779-02 Disassembly and Assembly Section 5. Remove the nut (9). Use a suitable puller in order to remove the gear (10) from the shaft. 6. Remove the setscrews (11). Remove the cover (12). 7. Remove the rotor assembly (13). 8. If necessary, remove the dowel (14) and the hollow dowel (15). - Page 108 SENR9779-02 Disassembly and Assembly Section 11. Ensure that the dowel (14) and the hollow dowel (15) are installed in the balancer. 12. Ensure that the No. 1 piston is at top dead center on the compression stroke. Refer to the Testing and Adjusting Manual, “Fuel Injection Timing - Check”.

-

Page 109: Piston Cooling Jets - Remove And Install

SENR9779-02 Disassembly and Assembly Section Installation Procedure End By: a. Install the engine oil relief valve. Refer to this NOTICE Disassembly and Assembly Manual, “Engine Oil Keep all parts clean from contaminants. Relief Valve - Remove and Install (Balancer Unit for the Engine)”. -

Page 110: Pistons And Connecting Rods - Disassemble

Also spe- connecting rod assembly as this may cause damage. cial machinery is required. For more information refer to your authorized Perkins dealer or your Perkins dis- 4. Remove the torx screws (1) from the connecting tributor. -

Page 111: Pistons And Connecting Rods - Assemble

2. Use suitable pliers in order to remove the circlips wedge. For further information on installation of the (8). piston pin bushing, refer to your authorized Perkins dealer or your Perkins distributor for assistance. 3. Remove the piston pin (6) from the piston. - Page 112 SENR9779-02 Disassembly and Assembly Section 3. Align the mark (1) on the connecting rod to the boss cutout (2) of the piston. Also check that the arrow (3) that is marked on top of the piston is aligned. Install the piston pin into the piston and through the connecting rod.

-

Page 113: Pistons And Connecting Rods - Install

SENR9779-02 Disassembly and Assembly Section Note: The arrow or the “FRONT” mark that is on i01954465 the top of the piston must be toward the front of the Pistons and Connecting Rods engine. Ensure that the piston rings are 120 degrees - Install away from each other. -

Page 114: Connecting Rod Bearings - Remove

SENR9779-02 Disassembly and Assembly Section i01954554 i01953533 Connecting Rod Bearings - Connecting Rod Bearings - Remove Install Removal Procedure Installation Procedure Start By: NOTICE Keep all parts clean from contaminants. a. Remove the engine oil pump. Refer to Disassembly and Assembly, “Engine Oil Pump - Contaminants may cause rapid wear and shortened Remove”. -

Page 115: Crankshaft Main Bearings - Remove

SENR9779-02 Disassembly and Assembly Section b. Only if the engine is not equipped with a balancer, remove the engine oil pump. Refer to this Disassembly and Assembly Manual, “Engine Oil Pump - Remove”. c. If the engine is equipped with a balancer, remove the balancer. - Page 116 SENR9779-02 Disassembly and Assembly Section g00934803 g00934744 Illustration 257 Illustration 259 Typical example 3. Remove the lower bearing shell (3) from the main bearing cap (2). Keep the respective bearing shell 6. Remove the lower half of the thrust washer (5) (3) and the main bearing cap (2) together for from each side of the appropriate main bearing proper installation.

-

Page 117: Crankshaft Main Bearings - Install (Crankshaft In Position)

SENR9779-02 Disassembly and Assembly Section 2. Gently wipe the lower bearing shells (3) and the i01980478 upper bearing shells (4) in order to ensure that the Crankshaft Main Bearings - bearing shells are clean and dry. Inspect the lower Install bearing shells (3) and the upper bearing shells (4). - Page 118 SENR9779-02 Disassembly and Assembly Section Note: Thrust washers (5) and (6) are installed onto 11. Lightly lubricate the lower thrust washers (5) with one main bearing in order to limit crankshaft end play. clean engine oil. Install the lower thrust washers These thrust washers are installed onto No.

-

Page 119: Crankshaft - Remove

SENR9779-02 Disassembly and Assembly Section b. Install the crankshaft rear seal. Refer to this Disassembly and Assembly Manual, “Crankshaft NOTICE Rear Seal - Install”. Keep all parts clean from contaminants. c. Install the flywheel housing. Refer to this Contaminants may cause rapid wear and shortened Disassembly and Assembly Manual, “Flywheel component life. - Page 120 SENR9779-02 Disassembly and Assembly Section 9. Remove the upper main bearing shells (7). Keep the upper main bearing shells with the respective NOTICE main bearing caps (4). Do not allow the connecting rods to strike the piston cooling jets. Damage or misalignment may occur. Note: Thrust washers (9) and (10) are installed onto one main bearing in order to limit crankshaft end 5.

-

Page 121: Crankshaft - Install

SENR9779-02 Disassembly and Assembly Section 2. Gently wipe the lower bearing shells (3) and the i01981309 upper bearing shells (1) in order to ensure that the Crankshaft - Install bearing shells are clean and dry. Inspect the lower bearing shells (3) and the upper bearing shells (1). - Page 122 SENR9779-02 Disassembly and Assembly Section 6. Take care to ensure that you do not scratch any of the finished surfaces on the crankshaft and that you do not damage the upper main bearing shells (1) or dislodge the upper main bearing shells. The crankshaft is heavy.

- Page 123 SENR9779-02 Disassembly and Assembly Section 13. If the piston assemblies were removed previously, install the piston assemblies. Refer to this Disassembly and Assembly Manual, “Pistons and Connecting Rods - Install”. Go to Step 18. 14. If the piston assemblies are still inside the cylinder bores, ensure that the upper bearing shells for the connecting rods are centered in the connecting rods.

-

Page 124: Crankshaft Gear - Remove And Install

SENR9779-02 Disassembly and Assembly Section i01981176 Crankshaft Gear - Remove and Install Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. g01027386 Illustration 281 20. Check the crankshaft end play. Use a prybar to move the crankshaft toward the front of the engine. -

Page 125: Bearing Clearance - Check

(3). If the crankshaft gear (1) is a slip fit on the crankshaft (3), proceed to Step 5. Note: Perkins does not recommend the checking of the actual clearances of the bearing shells particularly Note: Ensure that heat is applied to the crankshaft on small engines. -

Page 126: Glow Plugs - Remove And Install (If Equipped)

SENR9779-02 Disassembly and Assembly Section 3. Carefully remove the bearing cap, but do not remove the Plastic Gauge (1). Measure the width NOTICE of the Plastic Gauge (1) while the Plastic Gauge Lead wire, shim stock or a dial bore gauge can dam- is in the bearing cap or on the crankshaft journal. - Page 127 SENR9779-02 Disassembly and Assembly Section 2. Remove the setscrews (1). Remove the cover (2) from the cylinder head. g01119840 Illustration 287 Typical example g01119840 Illustration 286 1. Clean the threads of the glow plugs. 3. Disconnect the harness assembly from the Deutch 2.

-

Page 128: V-Belts - Remove And Install

SENR9779-02 Disassembly and Assembly Section Installation Procedure i02011941 V-Belts - Remove and Install Removal Procedure g01015311 Illustration 290 1. Install the V-belts behind the fan and onto the correct pulleys. 2. Adjust the tension on the V-belts by moving the alternator away from the engine. -

Page 129: Fan Drive - Remove And Install

SENR9779-02 Disassembly and Assembly Section 6. Install the setscrews (1). Tighten the setscrews (1) to a torque of 12 N·m (9 lb ft). End By: a. Install the V-Belts. Refer to this Disassembly and Assembly Manual, “V-Belts - Remove and Install”. i02011983 Fan Drive - Remove and Install Removal Procedure... -

Page 130: Alternator - Remove

SENR9779-02 Disassembly and Assembly Section 2. Install the setscrews (1). Tighten the setscrews to i02245824 a torque of 44 N·m (32 lb ft). Alternator - Install End By: a. Install the fan. Refer to this Disassembly and Installation Procedure Assembly Manual, “Fan - Remove and Install”. Note: If the alternator pulley was removed, install the i02012014 alternator pulley and the nut (3). -

Page 131: Electric Starting Motor - Remove And Install

SENR9779-02 Disassembly and Assembly Section 6. Remove the electric starting motor (4) from the i01987613 flywheel housing. Electric Starting Motor - Remove and Install Installation Procedure Note: The installation procedure is identical for the three cylinder and the four cylinder engines. The Removal Procedure illustrations show the four cylinder engine. -

Page 132: Vacuum Pump - Remove And Install (Some 1104 Engines Only)

SENR9779-02 Disassembly and Assembly Section i01981804 i01981808 Vacuum Pump - Remove and Hydraulic Pump (Steering) - Install Remove (Some 1104 engines only) Removal Procedure 1. Disconnect all of the hydraulic fluid lines from the hydraulic steering pump. Insert plastic caps into all of the open ports in the hydraulic steering pump and insert plastic caps onto the open ends of the hydraulic fluid lines. -

Page 133: Index

SENR9779-02 Index Section Index Crankshaft Pulley - Remove and Install ....68 Removal and Installation of the Non-standard Accessory Drive - Remove and Install....86 Pulley (if equipped) .......... 69 Installation Procedure ........86 Removal and Installation of the Standard Pulley (if Removal Procedure ........... - Page 134 SENR9779-02 Index Section Engine Oil Relief Valve - Remove and Install Fuel Injection Pump - Install (Delphi STP)..... 20 (Balancer Unit for the 1104 engines only).... 51 Installation Procedure ........20 Installation Procedure ........52 Fuel Injection Pump - Remove (Bosch EPVE for the Removal Procedure ...........

- Page 135 SENR9779-02 Index Section Inlet and Exhaust Valve Guides - Remove and Install ..............39 Installation Procedure ........40 V-Belts - Remove and Install ....... 128 Removal Procedure ........... 39 Installation Procedure ........128 Inlet and Exhaust Valve Seat Inserts - Remove and Removal Procedure .........

- Page 136 ©2004 Perkins Engines Company Limited A ll R i ght s R es er ve d Printed in U.K.