SKF QLS 401 Manuals

Manuals and User Guides for SKF QLS 401. We have 2 SKF QLS 401 manuals available for free PDF download: Assembly Instructions Manual, Installation Instructions Manual

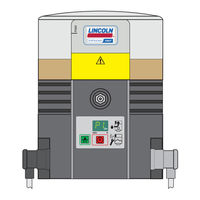

SKF QLS 401 Assembly Instructions Manual (62 pages)

Electrically operated pump for the feeding of lubricants in interval operation inside a centralized lubrication system

Brand: SKF

|

Category: Lubrication systems

|

Size: 2 MB

Table of Contents

Advertisement

SKF QLS 401 Installation Instructions Manual (58 pages)

Brand: SKF

|

Category: Lubrication systems

|

Size: 2 MB

Table of Contents

Advertisement