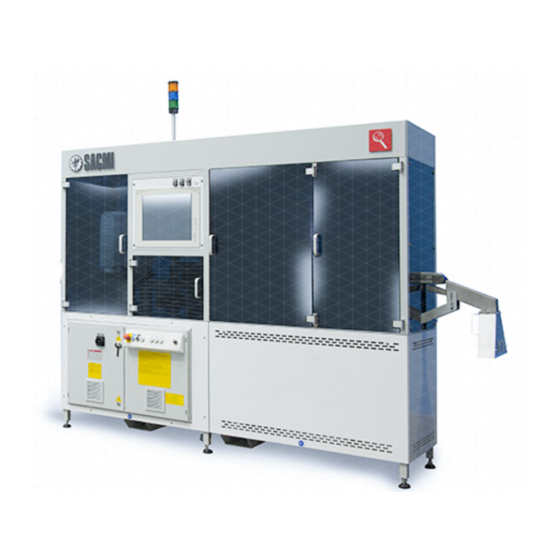

User Manuals: Sacmi Imola CHS Series Cap Inspection

Manuals and User Guides for Sacmi Imola CHS Series Cap Inspection. We have 1 Sacmi Imola CHS Series Cap Inspection manual available for free PDF download: Instruction Manual

Sacmi Imola CHS Series Instruction Manual (116 pages)

INSPECTION SYSTEM FOR PLASTIC/ALUMINUM CAPS

Brand: Sacmi

|

Category: Industrial Equipment

|

Size: 17 MB

Table of Contents

Advertisement

Advertisement