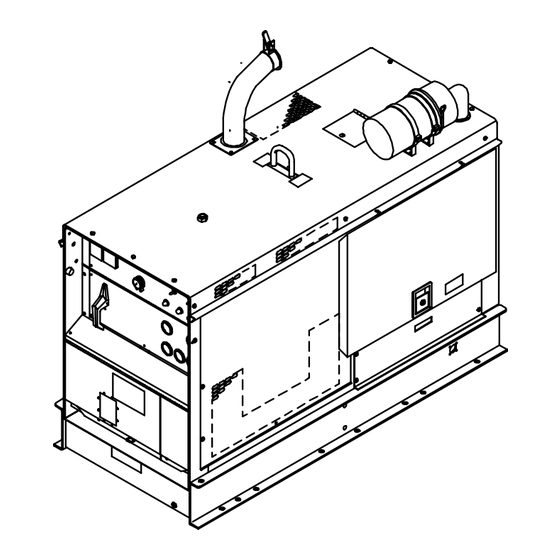

Miller Electric CBI 801D Manuals

Manuals and User Guides for Miller Electric CBI 801D. We have 1 Miller Electric CBI 801D manual available for free PDF download: Owner's Manual

Miller Electric CBI 801D Owner's Manual (56 pages)

Engine Driven Welding Generator

Brand: Miller Electric

|

Category: Inverter

|

Size: 1 MB

Table of Contents

Advertisement