LEMKEN SIRIUS 12 Manuals

Manuals and User Guides for LEMKEN SIRIUS 12. We have 2 LEMKEN SIRIUS 12 manuals available for free PDF download: Operating Instructions Manual

LEMKEN SIRIUS 12 Operating Instructions Manual (254 pages)

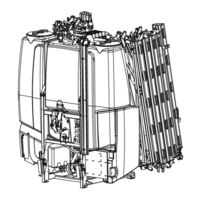

Mounted Field Sprayers

Brand: LEMKEN

|

Category: Paint Sprayer

|

Size: 10 MB

Table of Contents

-

-

Liability15

-

Guarantee15

-

Copyright16

-

Type Plate17

-

-

-

Target Group21

-

Intended Use21

-

Danger Areas28

-

-

-

Overview43

-

Seh/Ra45

-

-

Stands46

-

Main Tank58

-

Filter60

-

Pump60

-

Deflector60

-

Cardan Shaft61

-

-

Lighting62

-

Filler Valve70

-

Filler Hose74

-

Flowmeter77

-

-

HE Boom85

-

SEH/RA Boom86

-

-

-

HE Boom87

-

-

-

HE Boom93

-

SEH/RA Boom94

-

-

Boom95

-

HE Boom95

-

SEH/RA Boom96

-

-

-

HE Boom96

-

-

Nozzles98

-

-

-

Overview100

-

-

-

Overview114

-

-

Preparations121

-

Attachment123

-

-

-

11 Operation

126-

Boom Lighting147

-

All-Round Light147

-

-

Operation150

-

-

12 Cleaning

154-

General154

-

-

-

General161

-

-

-

General167

-

Suction Filter168

-

Pressure Filter168

-

Nozzle Filter171

-

-

-

-

Greasing182

-

Drive Shaft185

-

Protective Tube186

-

Safety Chain186

-

Sliding Tube186

-

Joints186

-

-

Safety Straps192

-

Sensors196

-

Pump196

-

Filter203

-

Test Connections203

-

General203

-

Pump Output203

-

Flow Meter204

-

-

Deflector205

-

-

Emergency Switch206

-

-

-

Tank Volume211

-

Drive Shaft212

-

Boom212

-

HE Boom213

-

SEH/RA Boom214

-

-

Pumps218

-

Flowmeter220

-

Oil Hydraulics220

-

Filter221

-

18 Appendix

222-

Nozzle Tables223

-

-

20 Notes

240 -

Index

253

Advertisement

LEMKEN SIRIUS 12 Operating Instructions Manual (213 pages)

MOUNTED FIELD SPRAYER

Brand: LEMKEN

|

Category: Farm Equipment

|

Size: 31 MB

Table of Contents

-

-

Safety14

-

Intended Use14

-

Type Plate32

-

Fluid Flow34

-

Headstock37

-

Overview37

-

Connections47

-

Filter48

-

Pump49

-

RA Boom50

-

Boom50

-

Sections52

-

Spacers52

-

Nozzles53

-

Drop Hoses54

-

Attachment58

-

Road Travel71

-

Operation72

-

Conversion80

-

Test Run99

-

Empty the Tanks108

-

Clean the Filter128

-

Detaching134

-

Preparations140

-

-

Maintenance141

-

Check Marking143

-

Oil Hydraulics143

-

Safety Equipment143

-

Electrics145

-

Boom146

-

Lubricating152

-

Disposal159

-

Shutdown159

-

Dimensions160

-

Technical Data160

-

Performance Data165

-

Connection Data166

-

Tank Volume169

-

Cardan Shaft171

-

12.10 Filter172

-

12.11 Pumps172

-

12.13 Boom174

-

Index176

-

Appendix183

-

H Nozzle Tables196

-

Advertisement