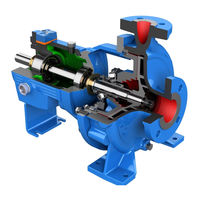

ITT Goulds Pumps XHD Manuals

Manuals and User Guides for ITT Goulds Pumps XHD. We have 3 ITT Goulds Pumps XHD manuals available for free PDF download: Installation, Operation And Maintenance Manual

ITT Goulds Pumps XHD Installation, Operation And Maintenance Manual (160 pages)

Brand: ITT

|

Category: Water Pump

|

Size: 12 MB

Table of Contents

Advertisement

ITT Goulds Pumps XHD Installation, Operation And Maintenance Manual (155 pages)

Brand: ITT

|

Category: Water Pump

|

Size: 15 MB

Table of Contents

ITT Goulds Pumps XHD Installation, Operation And Maintenance Manual (128 pages)

Brand: ITT

|

Category: Water Pump

|

Size: 20 MB

Table of Contents

Advertisement

Advertisement