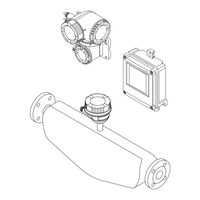

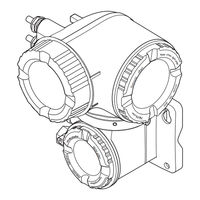

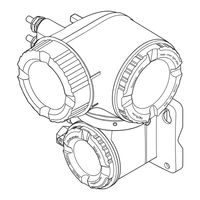

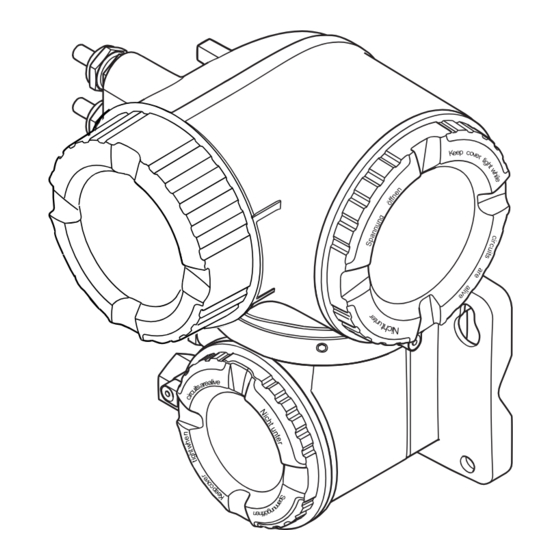

Endress+Hauser Hart Proline Promag P 500 Manuals

Manuals and User Guides for Endress+Hauser Hart Proline Promag P 500. We have 4 Endress+Hauser Hart Proline Promag P 500 manuals available for free PDF download: Operating Instructions Manual, Special Documentation

Endress+Hauser Hart Proline Promag P 500 Operating Instructions Manual (282 pages)

Coriolis flowmeter

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 8 MB

Table of Contents

-

Symbols6

-

Security10

-

Proline 50013

-

Installation21

-

Requirements52

-

Relay Output55

-

Status Input55

-

Display Area65

-

Editing View69

-

Text Editor69

-

Requirements77

-

Logging on80

-

Function Row81

-

Logging out82

-

Fieldcare86

-

Devicecare87

-

Profile GSD90

-

Block Model93

-

TOTAL Module95

-

Structure100

-

Commissioning103

-

PROFIBUS Network103

-

Endress+Hauser105

-

Interface109

-

Simulation149

-

Operation156

-

Totalizer159

-

Output Values161

-

Transmitter171

-

Diagnostics List233

-

Maintenance240

-

Maintenance Work240

-

Repair241

-

General Notes241

-

Spare Parts241

-

Return241

-

Disposal242

-

Accessories243

-

For the Sensor244

-

Technical Data246

-

Application246

-

Input247

-

Output249

-

Output Signal249

-

Power Supply254

-

Mounting260

-

Environment260

-

Process261

-

Window Material264

-

Measuring Tubes265

-

Index276

Advertisement

Endress+Hauser Hart Proline Promag P 500 Operating Instructions Manual (252 pages)

Electromagnetic flowmeter

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 12 MB

Table of Contents

-

-

Security11

-

-

-

-

-

Editing View79

-

Code85

-

-

10 Commissioning

110-

Function Check110

-

-

-

Interface114

-

-

-

Switch Output121

-

-

Simulation148

-

-

-

11 Operation

155-

-

Totalizer156

-

Output Values159

-

-

Conditions161

-

-

-

-

Diodes169

-

Transmitter169

-

-

Diagnostic List205

-

13 Maintenance

211 -

14 Repair

212 -

15 Accessories

214 -

-

Application218

-

Input218

-

Output222

-

Power Supply227

-

Installation229

-

Environment229

-

Process230

-

-

Index

246

Endress+Hauser Hart Proline Promag P 500 Operating Instructions Manual (210 pages)

Electromagnetic flowmeter

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 10 MB

Table of Contents

-

-

IT Security11

-

-

-

-

-

Editing View69

-

Code75

-

-

-

-

Switch Output103

-

-

Simulation129

-

-

11 Operation

136-

-

Conditions142

-

-

-

-

Diodes148

-

Transmitter148

-

-

-

Fieldcare156

-

-

Diagnostic List163

-

13 Maintenance

170 -

14 Repairs

171 -

15 Accessories

173 -

-

Application176

-

Input176

-

Output179

-

Power Supply184

-

Installation186

-

Environment186

-

Process187

-

-

Index

204

Advertisement

Endress+Hauser Hart Proline Promag P 500 Special Documentation (52 pages)

Brand: Endress+Hauser

|

Category: Industrial Equipment

|

Size: 4 MB

Table of Contents

Advertisement

Related Products

- Endress+Hauser Proline Prowirl 73

- Endress+Hauser Proline Promass 80F

- Endress+Hauser Prosonic Flow 500-digital

- Endress+Hauser Proline Promass 40

- Endress+Hauser PROFIBUS-PA

- Endress+Hauser promag 50 PROFIBUS-PA

- Endress+Hauser Proline Promass F 200 FOUNDATION Fieldbus

- Endress+Hauser Promag 100

- Endress+Hauser Proline Promass P 500 PROFIBUS DP

- Endress+Hauser Prosonic Flow P 500