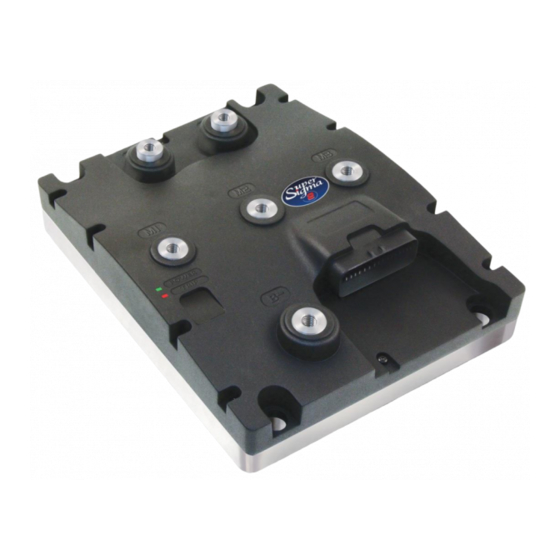

DMC SuperSigma2 Manuals

Manuals and User Guides for DMC SuperSigma2. We have 2 DMC SuperSigma2 manuals available for free PDF download: Advanced Manual, Quick Reference Manual

Advertisement

DMC SuperSigma2 Quick Reference Manual (58 pages)

Brand: DMC

|

Category: Industrial Equipment

|

Size: 2 MB

Table of Contents

Advertisement