Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for DMC SuperSigma2

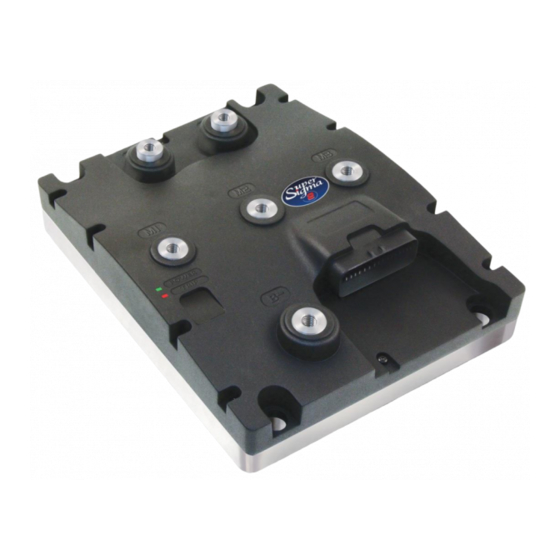

- Page 1 SuperSigma2 ADM for Permanent Magnets Synchronous motors ADVANCED MANUAL V 1.5.6 This user manual details the features of the standard controller range: PMS range 24-96V 250-600Arms Preliminary information, we reserve the right to update and/or modify this manual at any time without prior notice.

- Page 2 Adjustment, AT and Limits menus. Updated reference to QRM manual, added walkie-related parameters, added 1.5.6 17-01-2020 warnings for FW and RV inputs both active, modified F10 description SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 2 (97) ©2019 DMC GmbH Herten Germany...

-

Page 3: Table Of Contents

OWER IRING MENU 1 “ADJUSTMENT” ............................23 1 “T ” ........................... 23 RACTION DJUSTMENTS M1-1T Acceleration delay “Accel” ........................... 24 M1-2T Deceleration delay “Decel” .......................... 25 SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 3 (97) ©2019 DMC GmbH Herten Germany... - Page 4 Dual motor angle 2 ”DMang2” ........................ 40 M1-64T Dual motor angle 3 ”DMang3” ........................ 40 M1-65T Dual motor speed 1 ”DMspd1” ........................ 40 M1-66T Dual motor speed 2 ”DMspd2” ........................ 40 SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 4 (97) ©2019 DMC GmbH Herten Germany...

- Page 5 Motor Temperature threshold (for output driver) “MotTmpTh” ............. 55 M3-22T Controller Temperature threshold (for output driver) “CtrTmpTh” ............55 M3-23T Line Contactor pull-in level ”LCPlInLv” ..................... 56 SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 5 (97) ©2019 DMC GmbH Herten Germany...

- Page 6 Sin/Cos Sensor Delay Angle at 100 Hz “SensDel” ..................66 M4-17 Auto Tuning Type “ATuneType” ........................66 ............................67 NITIATING AUTO TUNING ............................... 68 UTO TUNING ERRORS ............................... 69 ECALCULATION SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 6 (97) ©2019 DMC GmbH Herten Germany...

- Page 7 Low voltage error threshold “LVerror” ......................80 M7-18 High Voltage Cut Back start threshold HVCBstrt ..................81 M7-19 High voltage cut back end threshold “HVCBend” ..................81 SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 7 (97) ©2019 DMC GmbH Herten Germany...

- Page 8 OTOR SUB ERROR CODES USE OF CALIBRATOR AND PC INTERFACE ......................95 AVAILABLE APPLICATION NOTES AND MANUALS .....................96 MECHANICAL DRAWINGS ..........................97 15.1 ............................. 97 UPER IGMA ONTROLLERS CONTACT INFORMATION ..........................97 SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 8 (97) ©2019 DMC GmbH Herten Germany...

-

Page 9: About This Manual

2) In case a Sigmagauge or a DMC Display is used, or the chopping on outputs 1, 2 or 3 is used, enter the “Menu 8 “BDI” Battery Discharge Indicator” menu and setup the parameters for BDI calculation. -

Page 10: Control Connections

It is typically used for the lateral shifting of the forks on a forklift truck. When this input is activated the pump speed is set to the value of the programmable parameter “M1-7P Speed 3 demand ”Pspeed3” SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 10 (97) ©2019 DMC GmbH Herten Germany... -

Page 11: Pin 5

When pin 6 is activated, the pump will operate at a speed value settable with the parameter “M1-10P Speed 6 demand (power steer) ”Pspeed6””. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 11 (97) -

Page 12: Pin 7 Speed Limit 3 / Handbrake -- Pump Inhibit

1 “Pin 1 Forward i/p -- Pump Potentiometer Switch 1” if it is enabled. Pin 10 Analogue supply 0V This input is the analog input ground for potentiometers. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 12 (97) ©2019 DMC GmbH Herten Germany... -

Page 13: Pin 11 Analogue Ad2 -- Footbrake Pot

This has to be connected to the negative side of the Line Contactor coil. The controller is driving this output. The maximum rating for this connection is 3A and it is fully protected for use with inductive loads. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 13 (97) ©2019 DMC GmbH Herten Germany... -

Page 14: Pin 16 Contactor 2 O/P (Magnet Brake - Fan Control)

This pin is connected to a 120 Ohm resistor. If the controller is the CAN network wiring ending node, this pin could be connected to the pin 25 or pin 21. See [2] for further details. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 14 (97) ©2019 DMC GmbH Herten Germany... -

Page 15: Pin 25 Can H2

This pin has to be connected to the cathode (black lined side) of KTY84-130 thermistor or Pt 1000 ohm 0°C thermal sensor. The motor thermal sensor type can be selected by parameter “M7-1 Motor Temp Sensor Type “MtempTyp”” SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 15 (97) -

Page 16: Light Wiring Of Pms Controller

Connector B - Communications - 8 8 Way pin 35 Way pin layout: Way: layout: Most inputs are Normally Open (NO) except for the speed inputs, these are Normally Closed (NC) SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 16 (97) ©2019 DMC GmbH Herten Germany... -

Page 17: Light Wiring Example For Traction

2.1.2 Light wiring example for traction The reported wiring example is referred to active low inputs SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 17 (97) ©2019 DMC GmbH Herten Germany... -

Page 18: Connectors' Pin Assignment For Pump

35 Way pin layout: For pump controllers “Pump switch 6” and “Pump inhibit” are active low. In “Menu 3 “Controller Setup for Pump”” it is possible to change them to active high. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 18 (97) -

Page 19: Light Wiring Example For Pump

2.1.4 Light wiring example for pump The reported wiring example is referred to active low inputs SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 19 (97) ©2019 DMC GmbH Herten Germany... -

Page 20: Selecting Active Low Or High Digital Inputs

2.2 Selecting active Low or High digital inputs The DMC Sigma2 controllers have the ability to set all digital inputs at runtime as active low or as active high. This setting is made in the controller setup menu. It is not possible to mix active low and active high inputs. -

Page 21: Active High Digital Inputs

2.2.2 Active High digital inputs For using Active High digital input The DMC Sigma2 controller must be setup for active high digital inputs by setting the parameter “M3-16TActive low or high digital inputs ”ActvL/H”” to 1. 2.2.2.1 Using a mechanical switch An active high digital input can be activated using a simple mechanical switch. -

Page 22: Power Wiring

2.4 Power Wiring When an emergency battery disconnect switch is fitted, the key switch must be fed through an auxiliary switch to prevent over voltage damage due to disconnect during regen. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 22 (97) -

Page 23: Menu 1 "Adjustment

It is therefore important to properly set up and configure Controller’s settings in “Menu 3 “Controller Setup””, recycle the key and then move to Adjustment menu, where only active parameters will be visible. DMC PC programmer interface is displaying always all parameters. 3.1 Menu 1 “Traction Adjustments”... -

Page 24: M1-1T Acceleration Delay "Accel

Important for speed control: When speed control selected (“M3-2T Control Mode “Spd/Torq””=0) using a very low value of time will bring bumpy response to accelerator deflection. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 24 (97) ©2019 DMC GmbH Herten Germany... -

Page 25: M1-2T Deceleration Delay "Decel

0 (Speed Mode) or 2 (Torque mode with speed mode for the end of braking) or 3. It is usually used in conjunction with the parameter “M1-51T Electric brake delay “EBrkDly”” to operate the electromechanical brake. This set is active if Hill Hold is disabled (“M3-4T Hill hold ”Off/HH/S”” set to 0 ). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 25 (97) - Page 26 Despite this, recall that when the vehicle is powered on the accelerator status should be pressed more than 50%, otherwise F13 S001 happens. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 26 (97)

- Page 27 Important for speed control: When speed control selected (“M3-2T Control Mode “Spd/Torq””=0) using a very low value of time will bring a very harsh foot braking. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 27 (97) ©2019 DMC GmbH Herten Germany...

- Page 28 M1-21T Restraint hill hold torque threshold ”HHTrqTH” This setting is only active when “M3-4T Hill hold ”Off/HH/S”” is set to 1 or 2. It defines the torque threshold to detect the “level ground” condition. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 28 (97)

- Page 29 During the end of braking operation, If pedal brake is removed and a direction selected with accelerator pedal demand (add foot switch in case of ride vehicle) the vehicle will start to move in the selected direction. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 29 (97) ©2019 DMC GmbH Herten Germany...

- Page 30 During the end of braking operation, If pedal brake is removed and a direction selected with accelerator pedal demand (add foot switch in case of ride vehicle) the vehicle will start to move in the selected direction. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 30 (97) ©2019 DMC GmbH Herten Germany...

- Page 31 During the end of braking operation, If pedal brake is removed and a direction selected with accelerator pedal demand (add foot switch in case of ride vehicle) the vehicle will start to move in the selected direction. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 31 (97) ©2019 DMC GmbH Herten Germany...

- Page 32 During the end of braking operation, If pedal brake is removed and a direction selected with accelerator pedal demand (add foot switch in case of ride vehicle) the vehicle will start to move in the selected direction. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 32 (97) ©2019 DMC GmbH Herten Germany...

- Page 33 “M1-9T Neutral brake-End delay “NBrkEnd”” time is used. After that time the vehicle will roll on the slope at the restraint hill hold speed. • VERY IMPORTANT: Take care of consideration at step 5). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 33 (97) ©2019 DMC GmbH Herten Germany...

- Page 34 “M1-9T Neutral brake-End delay “NBrkEnd”” time is used. After that time the vehicle will roll on the slope at the restraint hill hold speed. • VERY IMPORTANT: Take care of consideration at step 6). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 34 (97) ©2019 DMC GmbH Herten Germany...

- Page 35 7. The controller keep pulsing until handbrake input (digital input 7) becomes active. Otherwise the controller never stops pulsing until it is switched off! If digital input 7 is select as speed input 3 it never stops pulsing even if this is activated. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 35 (97)

- Page 36 5 and 6 are configured to select Drive Style 1 (refer to Control set up “M3-5TI/O Pin 5 and 6 ”Sp/In/Ad”” for configuration details). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 36 (97)

- Page 37 This sets the time taken to ramp down from full driving torque to zero torque when a brake operation is required (direction, footbrake, neutral). Increasing the value gives a smoother but longer transition from drive to braking. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 37 (97) ©2019 DMC GmbH Herten Germany...

- Page 38 The ramp time for braking is changed proportionally to “Brake Pot Value” (see brake pot value in test menu M11-11 "BrakePot" [%], M11-12 "BrakePot" [V]) from “M1-8T Neutral brake ramp time “NBrkRamp””(when “Brake Pot” =0%) to “M1-14T Foot brake ramp time “FbrkRamp”” (when “Brake Pot” =100%). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 38 (97)

- Page 39 This value sets the voltage on “Pin 9 Analogue AD1 i/p Accelerator -- Potentiometer” on 35-way connector from which reverse drive commences. Together with “M1-59T Wig/Wag fwd threshold ”FwdTH””, this parameter forms a ‘dead band’ in which the wig-wag assumes a neutral position. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 39 (97)

-

Page 40: M1-67T Dual Motor Speed 3 "Dmspd3

The torque of the inner motor is halved to prevent a sudden increase in speed when steering rapidly beyond the “M1- 63T Dual motor angle 2 ”DMang2”“ setting. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 40 (97) - Page 41 100% (left or right) will be 84 Hz. ! IMPORTANT If any speed limit is active the percentage of speed will refer to that speed limit and not to the “M4-13 Maximum Motor Frequency “Fmotmax””. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 41 (97)

-

Page 42: M1-68T Speed Ratio (Display Kph) "Spdratio

For example if the actual motor speed is 3000 RPM and ”SpdRatio” is set to 100, the Vehicle Speed value that can be seen in the status menu or in the DMC display is 30.0 Kph. M1-69T Vehicle max. Speed ”VmaxSpd”... -

Page 43: Menu 1 "Pump Adjustments

Speed 3 and Speed 6. The pump motor will accelerate or decelerate to the new speed demand using the programmed Acceleration and Deceleration rates. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 43 (97) -

Page 44: M1-8P Speed 4 Demand "Pspeed4

See setting “M1-16T Speed threshold Ramp time to zero speed ”SpdRmpTm”” for traction control. M1-18P Zero Speed threshold to end braking “ZSpdTh” See setting “M1-18T Zero Speed Threshold to enter hill hold or neutral brake end ”ZSpdTh”” for traction control. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 44 (97) -

Page 45: Menu 2 "Status

Vehicle 1 Kph – To reset the max and min temperatures logged data, press the button at the same time when the controller is in neutral. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 45 (97) ©2019 DMC GmbH Herten Germany... -

Page 46: Status Tables

Not able to hold speed Not able to hold flux Not able to hold flux current Not able to hold circle limitation Not able to hold hexagon limit Circle limitation SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 46 (97) ©2019 DMC GmbH Herten Germany... -

Page 47: Menu 3 "Controller Setup

0 – 2 Active low or high digital 0 = Active low digital inputs Actv L/H 0 – 1 inputs 1 = Active high digital inputs SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 47 (97) ©2019 DMC GmbH Herten Germany... - Page 48 0 = Don't load defaults Loading Default LoadDefs 0 – 1 1 = Load defaults (*) Recycle the key switch to make changes active. (Also indicated on calibrator ‘key’) SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 48 (97) ©2019 DMC GmbH Herten Germany...

-

Page 49: M3-1T Accel. Characteristic "Lin/Curv

If speed mode (0) is selected vehicle must have at least electromagnet brake! • If a torque mode (3) is selected the vehicle must have at least electromagnet brake! SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 49 (97) ©2019 DMC GmbH Herten Germany... -

Page 50: M3-3T Proportional Direction Brake "Off /Bpro

If the motor begins to move again, without Accelerator demand being applied, then the controller let the motor coast until accelerator is applied again. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 50 (97) -

Page 51: M3-5T I/O Pin 5 And 6 "Sp/In/Ad

M1-37T Maximum Drive Torque 2 (Torque Mode Only) “MxDrTrq2” M1-38T Neutral Brake Torque 2 (Torque Mode Only) “NBrkTrq2” M1-39T Neutral brake ramp time 2 “NBrkRmp2” M1-40T Direction Brake torque 2 (Torque Mode Only) “DBrkTrq2” SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 51 (97) ©2019 DMC GmbH Herten Germany... -

Page 52: M3-6T I/O Pin 7 "Spd3/Hbk

7 of 35-Way Connector is closed. When the switch is closed, the Sigmagauge and DMC Display will show a ‘parked’ icon. Handbrake input is used in conjunction with Hill Hold function (refer to parameter “M3-4T Hill hold ”Off/HH/S””). -

Page 53: M3-9T Tiller Function "Tillfunc

“M1-69T Vehicle max. Speed ”VmaxSpd””. Mind that is MPH is chosen in the DMC Color Display menu, one must take care of including in the calculation of the parameter “M1-68T Speed ratio (display Kph) ”SpdRatio”” the scaling from KPH to MPH. -

Page 54: M3-13T Accelerator Damping Factor "Acceldam

For the Digital Inputs connection and wiring details refer to section “2.2 Selecting active Low or High digital inputs”. The change of this parameters is actuated after a key power off-on cycle. This parameter requires a key cycle off-on to be effective. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 54 (97) -

Page 55: M3-17T Accelerator Supply Wire Off Detection "Splywrof

M3-22T Controller Temperature threshold (for output driver) “CtrTmpTh” These two settings represent the temperature thresholds to drive output 2 and/or 3 according to setting “M3-19T Driver output 2 configuration “Drv2Cfg”” and “M3-20T Driver output 3 configuration “Drv3Cfg””. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 55 (97) -

Page 56: M3-23T Line Contactor Pull-In Level "Lcplinlv

“M8-2 Nominal battery voltage “NomBatV”” in the BDI menu. If it set to 100% the full battery voltage will be applied. M3-32T n/a This settings is not used with PMS motor technology SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 56 (97) ©2019 DMC GmbH Herten Germany... -

Page 57: M3-33T Calibration Data Option "Calvalue

If this parameter is set to 1 (load defaults) all the setting in all menus will be restored to the default factory values. This parameter requires a key cycle off-on to be effective. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 57 (97) -

Page 58: Menu 3 "Controller Setup For Pump

3 = both motor and controller temperature cooling enabled Drive Output Motor Temp 10 – 127 MotTmpTh Adjustable from 10 to 127 °C. Default is 70 °C °C SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 58 (97) ©2019 DMC GmbH Herten Germany... -

Page 59: M3-1P Accel. Characteristic "Lin/Curv

If set to 0 (NoSw), a potentiometer without an integrated switch connected to pin 1 can be used. • If set to 1 (Sw), then a potentiometer with a switch can be connected to pin 1. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 59 (97) -

Page 60: M3-6P Display Status Field - "Of/D/V/K

M3-6P Display Status Field – “Of/D/V/K” This sets the type of information that will appear in the General Indication Field of the Sigmagauge or the DMC Display. • If set to 0 (None), then the General Indication Field will be blank. -

Page 61: M3-13P Line Contactor Coil Holding Voltage "Lcholdvl

“M3-21T Motor Temperature threshold (for output driver) “MotTmpTh””- 8 °C of hysteresis AND controller temperature gets lower than threshold “M3-22T Controller Temperature threshold (for output driver) “CtrTmpTh””- 8 °C of hysteresis. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 61 (97) -

Page 62: M3-19P Driver Output 3 Configuration "Drv3Cfg

If this parameter is set to 1 (load defaults) all the setting in all menus will be restored to the default factory values. This parameter requires a key cycle off-on to be effective. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 62 (97) -

Page 63: Pms Motor Auto Tuning

6 PMS Motor Auto Tuning The SuperSigma2 is capable of performing auto tuning of the motor parameters and, on PMS models, it also does auto- setup of several motor feedback sensors (Sin/Cos, Hall sensors and Resolvers). The auto tuning only needs a basic set of parameters to be entered. After initiating the auto tuning, the motor will spin: it is therefore important for the motor to have the possibility to spin freely. -

Page 64: Menu 4 "Pms Motor Auto Tuning

If set to 1 (Hall sensor), a three channel position hall sensor must be connected. Selection to 1 is available on request. Refer to DMC for details. • If set to 2 (Sensorless), no sensor is required. This Selection is available on request. Refer to DMC for details. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 64 (97) ©2019 DMC GmbH Herten Germany... -

Page 65: M4-3 Sensor Supply Voltage "Sensuppv

This parameter sets the maximum current that will be injected into the motor when it is working in the field weakening region. If field weakening is not required this value must be set to 1, otherwise a proper value should be entered. Refer to motor manufacturer for proper value. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 65 (97) -

Page 66: M4-13 Maximum Motor Frequency "Fmotmax

It set to 1 (Full autotuning), the procedure will tune the position sensor and perform the measurements of inductance and Back-EMF. VERY IMPORTANT In both cases the motor must spin totally free of load. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 66 (97) ©2019 DMC GmbH Herten Germany... -

Page 67: Initiating Auto Tuning

In case of errors the following screen will be shown: *** AUTO TUNING *** failed with code 4 (select to return) ********************* In case of an error, verify the error code in the next section. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 67 (97) ©2019 DMC GmbH Herten Germany... -

Page 68: Auto Tuning Errors

Unable to calculate the PI gains: Perform auto tuning again starting from default values (if Autotune type 1 has been chosen), Check Ke and Lph-ph values. Motor calculated maximum speed exceeds 500Hz: Refer to DMC Unable to calculate limit curves. Check motor parameters (Fmotmax, I demag) in the auto tuning menu Unable to Measure Ke (e.m.f. -

Page 69: Recalculation

2) Reduce PI Speed gains (settings “M5-1 Proportional gain speed controller “Kp Spd””, “M5-2 Integral gain speed controller “Ki Spd””, “M5-5 Proportional gain speed controller below threshold “KpSpdLow”” and “M5-6 Integral gain speed controller below threshold “KiSpdLow””) in Menu 5 “PMS Motor Setup”. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 69 (97) -

Page 70: Menu 5 "Pms Motor Setup

Parameters from 10 to 16 are calculated by the auto tuning algorithm or recalculation process. If it is necessary to tune these parameters, please consult DMC first. Mistakes in the motor setup tables can cause serious accidents and/or defective controllers and/or defective motors. -

Page 71: M5-3 Enable Double Pi Settings For Speed Controller "Spdpix2

In speed mode this function allows to avoid continuous adjustment of current while driving on flat ground with vehicle unloaded, thus reducing the heating up of motor and controller. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 71 (97) -

Page 72: M5-9 Speed Limit Action Ramp Time "Splimtim

This parameter is calculated by autotuning and should not be modified. M5-18 Voltage Limiter Filter Frequency FVlimFlt This parameter is calculated by autotuning and should not be modified. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 72 (97) ©2019 DMC GmbH Herten Germany... -

Page 73: Menu 6 "Pms Motor Advanced

8 Menu 6 “PMS Motor Advanced” These parameters are reported for indication only and it is not possible to modify them without the assistance of DMC engineers. Cal. Calibrator Step Parameter Min. Max. Default Ref. text size Decouple Iq and Id controllers... -

Page 74: Menu 7 "Limits Setup

2 a Pt1000 sensor that has 1000 Ohm @25°C has to be connected. Refer to “Pin 34 Thermistor AD4 i/p” and “Pin 35 Thermistor 0V” for details of connection. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 74 (97) -

Page 75: M7-2 Motor Temp. Cutback Start "Tempstrt

+ �� + �� = 50 °�� + �� ������ �������������� �������� ℎ������������ �������� When completing this for several insulation classes, it leads to the following table. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 75 (97) ©2019 DMC GmbH Herten Germany... - Page 76 This rise time must be measured or calculated. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 76 (97)

- Page 77 According to the sheet, 400 Arms is allowed to flow through the motor for a maximum time of 20 s. After that the I t will cut back the current to the first step (63 %, 250 Arms). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 77 (97)

-

Page 78: M7-9 Performance Table Speed 1 "Ptspd1

“FmotMax” in the Autotune menu. Current Ma x. dri ve currrent Ma x Currrent 1 Ma x. Current 2 Ma x Current 3 Speed Speed 3 Speed 2 Speed 1 SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 78 (97) ©2019 DMC GmbH Herten Germany... - Page 79 The motor module current reduction map in field weakening is reducing current as a function of the speed too. See settings 5.14 to 5.18. It means that the lower value for current limiting between the Performance table and motor module current reduction map is applied. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 79 (97)

-

Page 80: M7-15 Low Voltage Cut Back Start Threshold "Lvcbstrt

Low voltage cut back end threshold • Low voltage error threshold The location, unit, range and step size of these adjustments can be found in the “Menu 7 “Limits Setup””. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 80 (97) ©2019 DMC GmbH Herten Germany... -

Page 81: M7-18 High Voltage Cut Back Start Threshold Hvcbstrt

• High voltage error threshold The location, unit, range and step size of these adjustments can be found in reference in the “Menu 7 “Limits Setup””. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 81 (97) ©2019 DMC GmbH Herten Germany... -

Page 82: M7-21 Absolute Maximum Motor Speed "Absmaxsp

Setting to 100% the “M7-22 Torque Threshold for Stall Protection “TrqTHLim”” the function is disabled. As default stall protection is disabled. M7-24 n/a M7-25 n/a These two settings are not active in PMS software SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 82 (97) ©2019 DMC GmbH Herten Germany... -

Page 83: M7-26 Timed Current Limit Timer "Ithtime

If the motor current is above 420Arms for 10 seconds, then the controller will reduce the maximum current available to 400Arms for a period of 30 seconds (3 x 10 secs). SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 83 (97) -

Page 84: Menu 8 "Bdi" Battery Discharge Indicator

If set to 1 Battery with BCL via can enabled. BDI value is calculated inside controller as standard (if standalone controller set as master or received via DMC can protocol from the master controller if multimotor and set as slave). -

Page 85: M8-2 Nominal Battery Voltage "Nombatv

M8-3 BDI reset level “BDIreset” This sets the voltage at which the BDI will reset to show a 100% charged battery on the Sigmagauge or the DMC Display. This setting only has an effect at power-up. The adjustable range is from 18V to controller absolute maximum voltage, that corresponds to 125% of the nominal operating voltage of the controller. -

Page 86: Menu 9 "Can Bus Setup

The SuperSigma2 controller uses our own CAN bus protocol for sending and receiving information to and from other CAN nodes. The protocol is designed for the SuperSigma2 to act as a slave in an existing CAN environment. Detailed information about the protocol will be provided on request. See [2] for further details. -

Page 87: M9-1 Can Node Number "Can Node

All slaves send out their device, fault code and sub code and pulsing information to the Sigmagauge or DMC Display. In a non-CANbus system, the controller(s) should have this parameter set to 0. This is particularly important if the BDI is used, as the BDI calculation will not work when a controller is set up as a slave. -

Page 88: M9-5 Last Node Sharing Line Contactor "Lstnode

Inputs have to be considered normally open (if switch connected open DIx=0, if switch connected closed Dix=1). The node number is assigned only once at power up. SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 88 (97) ©2019 DMC GmbH Herten Germany... -

Page 89: Diagnostics

Shared Line Contactor HMI option is activated (“ShareLC”>=2) on but not control via CAN HMI active (CANMsgs>=4). Solution set CANMsgs < 4. Errors continue at next page… SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 89 (97) ©2019 DMC GmbH Herten Germany... - Page 90 Foot Brake switch active when inching Hand Brake active when inching Both inching buttons active when inching Inching buttons active when normal drive Belly switch active Errors continue at next page… SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 90 (97) ©2019 DMC GmbH Herten Germany...

- Page 91 Battery voltage above High Voltage error adjustment Capacitor voltage above High Voltage error adjustment M1 mosfets Low sided mosfets short circuit in M2 mosfets neutral M3 mosfets Errors continue at next page… SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 91 (97) ©2019 DMC GmbH Herten Germany...

- Page 92 Motor Module initialization error > 0 See table "Motor sub error codes" Motor Module configuration > 0 See table "Motor sub error codes" inconsistency Errors continue at next page… SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 92 (97) ©2019 DMC GmbH Herten Germany...

- Page 93 Time out on configuration upload Generic time out Time out on getting stable inputs Time out on motor ready System Fault > 0 Internal system error Contact DMC SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 93 (97) ©2019 DMC GmbH Herten Germany...

-

Page 94: Pms Motor Sub Error Codes

Unable to perform recalculation: limit curves; check motor parameters (Ls, Ke, Fmax, Idemag) in auto tune menu. Unable to calculate controller gains: check motor parameters (Ls, Ke, Fmax, Idemag) and perform recalculation or do autotuning again. Internal error refer to DMC SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 94 (97) ©2019 DMC GmbH Herten Germany... -

Page 95: Use Of Calibrator And Pc Interface

13 Use of Calibrator and PC interface Starting from V02.07.01 the V01.02.08 DMC PC interface or later for SuperSigma2 has to be used. V01.02.08 DMC PC interface can open setting list generated with previous releases. V01.02.08 DMC PC interface is dedicated to SuperSigma2 generation but it is still compatible with Sigma Drive controllers. -

Page 96: Available Application Notes And Manuals

Sigma2 - AN 130102 - I2t Setup 160105 AN 160105 SuperSigma2 - CAN Messages_V2_8 V2.8 160105 Sigma2 AN 160105 - SuperSigma2 Can HMI Protocol V1.7 V1.7 SuperSigma2 PMS Quick Reference Manual V01.02.02 SW 02.09.0 V01.02.00 SuperSigma2 AM PMS – V1.5.6... -

Page 97: Mechanical Drawings

16 Contact information DMC GmbH Auf dem Hochstück 11 45701 Herten Germany Tel: +49 (0) 2366 10070 Fax: +49 (0) 2366 100750 Email: info@dmcde.de Web: www.dmcde.de SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 97 (97) ©2019 DMC GmbH Herten Germany...

Need help?

Do you have a question about the SuperSigma2 and is the answer not in the manual?

Questions and answers