Airoptic GasEye Manuals

Manuals and User Guides for Airoptic GasEye. We have 1 Airoptic GasEye manual available for free PDF download: User Manual

Airoptic GasEye User Manual (254 pages)

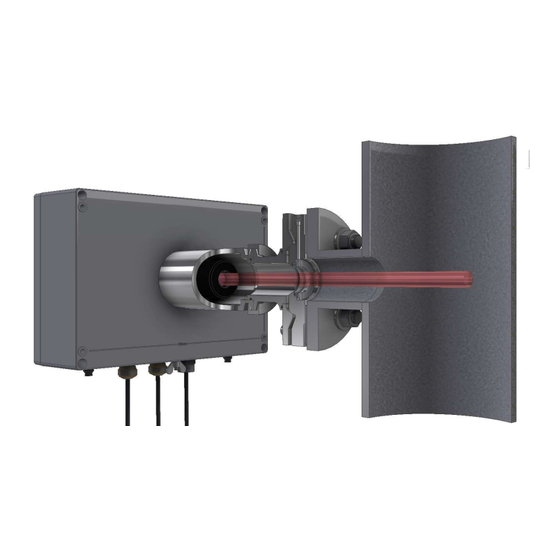

Cross Duct SG and MG

Brand: Airoptic

|

Category: Industrial Equipment

|

Size: 37 MB

Table of Contents

Advertisement

Advertisement