Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for WAGNER ProSpray 22

- Page 1 ® Operating manual Airless high-pressure spraying unit ProSpray 22...

- Page 2 The operating instructions state that the following points must always be observed before starting up: 1. Faulty units must not be used. 2. Secure WAGNER spray gun using the safety catch on the trigger. 3. Ensure that the unit is properly earthed. The connection must take place through a correctly earthed two-pole and earth socket outlet.

-

Page 3: Table Of Contents

Airless process ..........11.2 Inlet and outlet valve........38/39 Functioning of the unit ........11.3 Packings ............39/40 Legend for explanatory diagram 11.4 ProSpray 22 connection diagram ....ProSpray 22 ..........Explanatory diagram ProSpray 22 ....Accessories and spare parts ...... Technical data.......... -

Page 4: Safety Regulations For Airless Spraying

1 MΩ. Danger For reasons of function, safety and durability Caution! Danger of injury through injection! use only original WAGNER high-pressure hoses. Never point the spray gun at yourself, other persons or animals. Never use the spray gun without spray jet safety guard. - Page 5 Cleaning units with solvents When cleaning the unit with solvents, the solvent should never be sprayed or pumped back into a container with a small opening (bunghole). An explosive gas/air Danger mixture can be produced. The container must be earthed. ProSpray 22...

-

Page 6: General View Of Application

No other materials should be used for spraying without WAGNER’s approval. WAGNER ProSpray units are electrically driven high- pressure spraying units. Filtering A gear unit transfers the driving force to a crankshaft. -

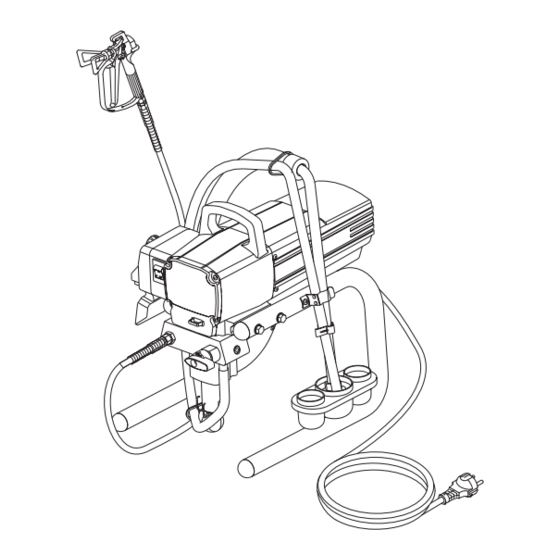

Page 7: Legend For Explanatory Diagram Prospray 22

Description of unit 3.3 Legend for explanatory diagram ProSpray 22 Spray gun ON/OFF switch High-pressure hose Control system cover Return hose Digital Electronic Spray Control (ESC) system Suction hose Control panel indicators Frame Pressure control knob Drip cup Oil cup for EasyGlide (EasyGlide prevents... -

Page 8: Technical Data

Description of unit Starting operation 3.5 Technical data ProSpray 22 4. Starting operation Voltage: 230 V AC, 50/60 Hz or 4.1 High-pressure hose, spray gun and 120 V AC, 50/60 Hz separating oil Max. current consumption: 230 V AC 1. Screw the high-pressure hose (2) to the coating mate-... -

Page 9: Control Panel Indicators

SER V IC E pressure and the relief valve is in the SPRAY posi- tion, either the spray tip is worn or the sprayer is in need of service/repair. ProSpray 22... -

Page 10: Connection To The Mains Network

6. Close the relief valve, valve position SPRAY setting with good atomization. (p spray). 9. The unit is ready to spray. 7. Pull the trigger of the spray gun. 8. Spray the cleaning agent from the unit into an open collecting container. ProSpray 22... -

Page 11: Digital Electronic Spray Control (Esc) System

Once the desired setting has been reached, press the #4 key to set and the Main Screen will appear. To select or change the remaining three pre-sets, scroll to the User Pre-Sets screen and repeat the above procedure. ProSpray 22... -

Page 12: Spraying Technique

ENTER NEW CODE Enter the new security code. NUMBER Once the new code is entered, Only use WAGNER original-high-pressure the display will automatically hoses in order to ensure functionality, safety ask that the new code be re-entered for verification. If the same and durability. -

Page 13: Cleaning Unit From Outside

Danger of short circult through pane- trating water ! Never spray down the unit with high-pressure or high-pressure steam Danger cleaners. Wipe down unit externally with a cloth which has been immersed in a suitable cleaning agent. ProSpray 22... -

Page 14: Remedy In Case Of Faults

Remove and replace valve balls. Valve seats worn. Remove and replace valve seats. Remove and replace packing. Coating material exits Upper packing is worn. at the top of the fluid Remove and replace piston. section Piston is worn. ProSpray 22... - Page 15 Additionally, follow all other temperature of the Digital ESC warnings to reduce the risk of an injection System has risen too high. Take the sprayer to a Wagner injury, injury from moving parts or electric authorized service center for repair.

-

Page 16: Servicing

Servicing of the unit should be carried out once annually 2. Switch the unit ON and then OFF so that the con- by the WAGNER service. necting rod is positioned in the lower stroke position. 1. Check high-pressure hoses, device connecting line and plug for damage. -

Page 17: Packings

7. Push piston (3) downward out of the pump manifold (2). 8. Unscrew retainer nut (6) from the pump manifold (2) and remove piston guide (7). 9. Remove upper packing (8) and lower packing (9) from the pump manifold (2). ProSpray 22... -

Page 18: Packings

Screw inlet valve housing to the pump mani- fold. 25. Push connection bend of suction hose into the inlet valve housing (Fig. 10, Item 1) and secure with retain- ing clip. Screw on return hose and clamp to suction hose. 26. Install front cover. ProSpray 22... -

Page 19: Prospray 22 Connection Diagram

Repairs at the unit 11.4 ProSpray 22 connection diagram 120 V AC Pressure Sensor Potentiometer Pressure Sensor Jumper GREEN Ground Switch Motor AC-Motor AC-Motor AC-Line AC-Neut Surge Suppressor Control Panel Electronic Pressure Board Control (EPC) WHITE WHITE 240 V AC... -

Page 20: Accessories And Spare Parts

Accessories and spare parts 12. Accessories and spare parts 12.1 Accessories for ProSpray 22 (accessories illustration, see Page 96) Item Order No. Description Item Order No. Description 0149 040 Spray gun G 08 9984 573 High-pressure hose DN 4 mm, 7.5 m... -

Page 21: Spare Parts List For Fluid Section

0551 509 Lower seal insertion tool 0508 619 118 ml EasyGlide (prevents increased wear and tear to the packings) 0508 620 118 ml EasyClean (for the fluid section interior) 9984 507 High-pressure hose DN 6 mm, 15 m ProSpray 22... -

Page 22: Spare Parts List For Drive Assembly

(spare parts diagram, see Page 100) Item Order No. Description 0508 608 Suction hose 0508 605 Return hose 0508 738 Filter 9871 105 O-ring (2) 0507 937 Clamp 9822 526 Retaining clip 0551 106 Suction hose assembly (includes items 1–6) ProSpray 22... -

Page 23: Appendix

Order no. 0999 321 Length 100 cm Order no. 0096 015 Length 45 cm Order no. 0999 322 Length 200 cm Order no. 0096 016 Length 60 cm Order no. 0999 323 Length 300 cm Order no. 0096 017 ProSpray 22... -

Page 24: Airless Tip Table

13.4 Airless tip table Trade Tip 2 F thread (11/16 - 16 UN) G thread (7/8 - 14 UN) up to 270 bar for Wagner spray guns for Graco/Titan spray guns (27 MPa) Order no. 1006 001 Order no. 1006 002... -

Page 25: Sales And Service Companies

254 66 Helsingborg Denmark Hong Kong Sweden Phone 43632811 Phone 852 / 865 1802 Phone 042/150020 Fax 43430528 Fax 852 / 529 1753 Fax 042/150035 A list of international WAGNER distributors is available on request 03 / 05 ProSpray 22... - Page 26 Zubeh rbild g Accessories illustration f Illustration des accessoires i Figura degli accessori ProSpray 22 ProSpray 22...

- Page 27 Ersatzteilbild Spare parts diagram Illustration des pi ces de rechange Figura dei ricambi ProSpray 22 d Hauptbaugruppe g Main Assembly f Ensemble principal i Gruppo principale ProSpray 22...

-

Page 28: Fluid Section

Ersatzteilbild Spare parts diagram Illustration des pi ces de rechange Figura dei ricambi ProSpray 22 d Farbstufe g Fluid section f Pompe peinture i Stadio della vernice ProSpray 22... -

Page 29: Drive Assembly

Ersatzteilbild Spare parts diagram Illustration des pi ces de rechange Figura dei ricambi ProSpray 22 d Baugruppe Antrieb g Drive Assembly f Ensemble moteur i Gruppo azionamento ProSpray 22... - Page 30 Ersatzteilbild Spare parts diagram Illustration des pi ces de rechange Figura dei ricambi ProSpray 22 d Gestell g Frame f Support i Telaio ProSpray 22 d Ansaugsystem g Suction system f Syst me d aspiration i Sistema di aspirazione ProSpray 22...

-

Page 31: Important Notes On Product Liability

Der Betreiber ist verpflichtet, das Gerät zur Prüfung anzumelden. manufacturer´s liability can fully or partially be inapplicable; Wenden Sie sich bitte an die Kundendienststellen der Firma WAGNER. in extreme cases usage of the entire device (Diese Vorschrift gilt nur für Deutschland). -

Page 32: Declaration Of Conformity

Konformit tserkl rung D claration de conformit Hiermit erklären wir, dass die Bauart von Par la présente, nous déclarons, que le type de WAGNER ProSpray 22 WAGNER ProSpray 22. folgenden einschlägigen Bestimmungen entspricht: Correspond aux dispositions pertinentes suivantes: 73/23 EWG, 89/336 EWG, 92/31 EWG, 93/68 EWG, 73/23 CEE, 89/336 CEE, 92/31 CEE, 93/68 CEE, 98/37 EWG.

Need help?

Do you have a question about the ProSpray 22 and is the answer not in the manual?

Questions and answers