Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Homelite WF10MSP

-

Page 2: Table Of Contents

TABLE OF CONTENTS Introduction ..................................2 General Safety Rules ..............................3-4 Specific Safety Rules ..............................4-5 Symbols ..................................6-7 Electrical ....................................8 Glossary of Terms ................................9 Features ..................................10-12 Tools Needed ................................. 12 Loose Parts ..................................13 ... -

Page 3: General Safety Rules

GENERAL SAFETY RULES SECURE WORK. Use clamps or a vise to hold work WARNING: when practical, it is safer than using your hand and frees both hands to operate the tool. Read and understand all instructions. Failure to follow ... -

Page 4: Specific Safety Rules

GENERAL SAFETY RULES NEVER USE IN AN EXPLOSIVE ATMOSPHERE. DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON AND OFF. Have defective switches replaced by an Normal sparking of the motor could ignite fumes. authorized service center. ... - Page 5 SPECIFIC SAFETY RULES NEVER hand hold a workpiece that is too small to be IF THE POWER SUPPLY CORD IS DAMAGED, it must clamped. Keep hands clear of the cutting area. be replaced only by the manufacturer or by an authorized service center to avoid risk.

-

Page 6: Symbols

SYMBOLS Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer. SYMBOL NAME DESIGNATION/EXPLANATION Volts Voltage Amperes Current Hertz Frequency (cycles per second) -

Page 7: Symbols

SYMBOLS The following signal words and meanings are intended to explain the levels of risk associated with this product. SYMBOL SIGNAL MEANING Indicates an imminently hazardous situation, which, if not avoided, will result DANGER: in death or serious injury. Indicates a potentially hazardous situation, which, if not avoided, could result WARNING: in death or serious injury. -

Page 8: Electrical

ELECTRICAL SPEED AND WIRING EXTENSION CORDS Use only 3-wire extension cords that have 3-prong ground- The no-load speed of this tool is approximately 4,500 ing plugs and 3-pole receptacles that accept the tool’s plug. rpm. This speed is not constant and decreases under a load or with lower voltage. -

Page 9: Glossary Of Terms

GLOSSARY OF TERMS Non-Through Cuts Anti-Kickback Pawls (radial arm and table saws) Any cutting operation where the blade does not extend A device which, when properly installed and maintained, completely through the thickness of the workpiece. is designed to stop the workpiece from being kicked back toward the front of the saw during a ripping operation. -

Page 10: Features

FEATURES PRODUCT SPECIFICATIONS Cutting Capacity with Miter at 0°/Bevel 0°: Maximum nominal lumber sizes: ......2 x 6 Blade Diameter......10 in. Cutting Capacity with Miter at 45°/Bevel 0°: Blade Arbor . -

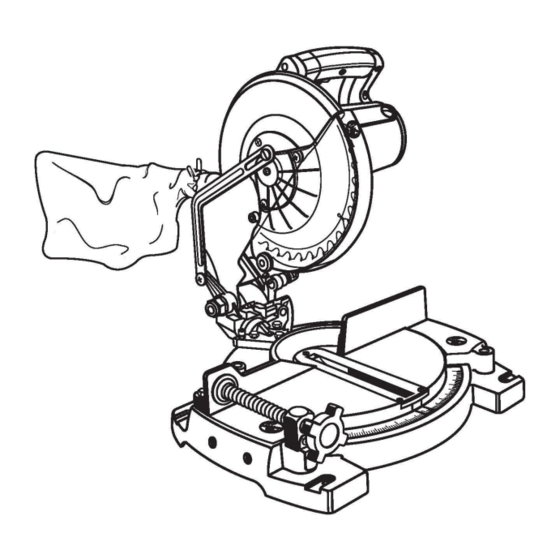

Page 11: Know Your Compound Miter Saw

FEATURES KNOW YOUR COMPOUND MITER SAW See Figure 1. The safe use of this product requires an understanding of MITER LOCK LOCK UNLOCK the information on the tool and in this operator’s manual as LEVERS well as a knowledge of the project you are attempting. Before use of this product, familiarize yourself with all operating features and safety rules. -

Page 12: Tools Needed

FEATURES ELECTRIC BRAKE WARNING: An electric brake has been provided to quickly stop blade rotation after the switch is released. The operation of any saw can result in foreign objects being thrown into your eyes, which can result in severe FENCE eye damage. -

Page 13: Loose Parts

LOOSE PARTS LIST The following items are included with your Compound Miter Saw: Hex Key (6 mm) Dust Bag Work Clamp Operator's Manual HEX KEY DUST BAG WORK CLAMP Fig. 6 WARNING: The use of attachments or accessories not listed might be hazardous and could cause serious personal injury. ASSEMBLY UNPACKING ... -

Page 14: Mounting Holes

ASSEMBLY MOUNTING HOLES WARNING: See Figure 8. Do not attempt to modify this tool or create accesso- WARNING: ries not recommended for use with this tool. Any such Always make sure your compound miter saw is securely alteration or modification is misuse and could result in a mounted to a workbench or an approved workstand. -

Page 15: Work Clamp

ASSEMBLY WORK CLAMP See Figure 9. WARNING: In some operations, the work clamp assembly may interfere with the operation of the blade guard assembly. Always make sure there is no interference with the blade guard prior to beginning any cutting operation to reduce the risk of serious personal injury. - Page 16 ASSEMBLY Depress the spindle lock button and rotate the blade until the spindle locks. Using the hex key provided, loosen and remove the blade SPINDLE bolt. LOCK NOTE: The blade bolt has left-hand threads. Turn blade BUTTON bolt clockwise to loosen. ...

- Page 17 ASSEMBLY NOTE: Many of the illustrations in this manual show only por- FRAMING tions of your compound miter saw. This is intentional so that FENCE MITER TABLE SQUARE we can clearly show points being made in the illustrations. Never operate your saw without all guards securely in place and in good operating condition.

- Page 18 ASSEMBLY SQUARING THE SAW BLADE TO THE FENCE FENCE See Figures 16 - 19. Unplug your saw. BLADE Pull the saw arm all the way down and engage the lock pin to hold the saw arm in transport position. ...

- Page 19 ASSEMBLY SQUARING THE BLADE TO THE MITER TABLE FENCE BLADE See Figures 20 - 23. Unplug your saw. Pull the saw arm all the way down and engage the lock pin to hold the saw arm in transport position. ...

-

Page 20: Operation

ASSEMBLY Your saw has two scale indicators, one on the bevel scale and one on the miter scale. After squaring adjustments have FENCE been made, it may be necessary to loosen the indicators screws and reset them to zero. BLADE COMBINATION MITER SQUARE... - Page 21 OPERATION CUTTING WITH YOUR COMPOUND MITER SAW WARNING: STRAIGHT CROSSCUT When using a work clamp or C-clamp to secure your workpiece, clamp the workpiece on one side of the blade only. The workpiece must remain free on one side of the blade to prevent the blade from binding in workpiece.

- Page 22 OPERATION TO BEVEL CUT MOUNTING See Figures 25 - 26. BRACKET A bevel cut is made by cutting across the grain of the workpiece with the blade angled to the workpiece. A straight bevel cut is made with the miter table set at the zero degree position and the blade set at an angle between 0°...

- Page 23 OPERATION TO COMPOUND MITER CUT A compound miter cut is a cut made using a miter angle and a bevel angle at the same time. This type of cut is used to make picture frames, cut molding, make boxes with sloping sides, and for certain roof framing cuts.

-

Page 24: Support Long Workpieces

OPERATION SUPPORT LONG WORKPIECES Grasp the saw handle firmly then squeeze the switch trigger. Allow several seconds for the blade to reach See Figure 29. maximum speed. Long workpieces need extra supports. Supports should be Slowly lower the blade into and through the workpiece. placed along the workpiece so it does not sag. -

Page 25: Cutting Compound Miters

OPERATION CUTTING COMPOUND MITERS To aid in making the correct settings, the compound angle setting chart below has been provided. Since compound cuts are the most difficult to accurately obtain, trial cuts should be made in scrap material, and much thought and planning made, prior to making the required cut. -

Page 26: Cutting Crown Molding

OPERATION CUTTING CROWN MOLDING When setting the bevel and miter angles for compound miters, remember that the settings are interdependent; changing This compound miter saw does an excellent job of cutting one angle changes the other angle as well. crown molding. In general, compound miter saws do a better Keep in mind that the angles for crown moldings are very job of cutting crown molding than any other tool made. - Page 27 OPERATION Bevel Angle Type of Cut Setting Left side, inside corner 1. Top edge of molding against fence 33.85˚ 2. Miter table set right 31.62˚ 3. Save left end of cut Right side, inside corner 1. Bottom edge of molding against fence 33.85˚...

-

Page 28: Adjustments

ADJUSTMENTS PIVOT ADJUSTMENTS WARNING: NOTE: These adjustments were made at the factory and Before performing any adjustment, make sure the tool is normally do not require readjustment. unplugged from the power supply. Failure to heed this TRAVEL PIVOT ADJUSTMENT warning could result in serious personal injury. ... -

Page 29: Adjustments

ADJUSTMENTS DEPTH STOP ADJUSTMENTS DEPTH STOP See Figure 35. ADJUSTMENT Unplug your saw. SCREW AND HEX NUT WARNING: MITER Failure to unplug your saw could result in accidental start- TABLE ing causing possible serious personal injury. To adjust the depth stop use a 10 mm wrench or adjustable wrench and loosen the hex nut at the rear of the miter THROAT saw arm. -

Page 30: Maintenance

MAINTENANCE WARNING: BRUSH When servicing, use only identical replacement parts. Use of any other parts may create a hazard or cause product damage. BRUSH ASSEMBLY WARNING: Always wear safety goggles or safety glasses with side BRUSH shields during power tool operation or when blowing ASSEMBLY dust. - Page 31 NOTES...

Need help?

Do you have a question about the WF10MSP and is the answer not in the manual?

Questions and answers