Table of Contents

Advertisement

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

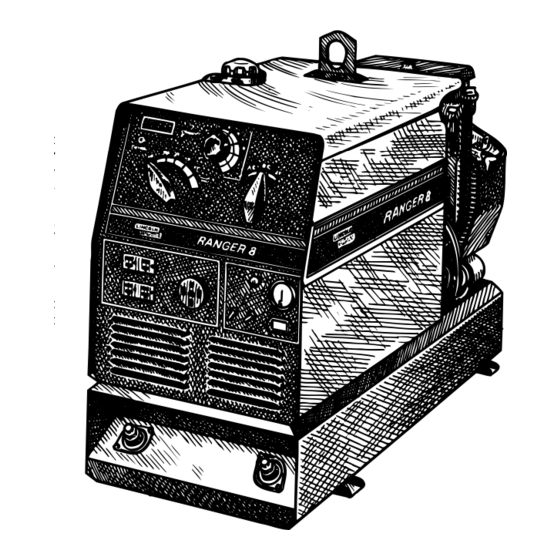

RANGER

For Machines with Code Numbers 10373, 10374, 10375, 10376,

THIS

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

8

™

10535, 10536, 10537,10538, or

10541,10886

R

Copyright © 2002 Lincoln Global Inc.

IM510-E

January, 2002

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric RANGER 8

- Page 1 For Machines with Code Numbers 10373, 10374, 10375, 10376, Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ... and thought- ful operation on your part.

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. - Page 4 WELDING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A L’Arc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment. for selecting a QUALITY product by Lincoln Electric. We want you to take pride in operating this Lincoln Electric Company product •••...

-

Page 7: Table Of Contents

Connection of Wire Feeders ...A-5 Connection of Tig Module ...A-6 Additional Safety Precautions ...A-6 Auxiliary Power Receptacles, and Plugs ...A-6,A-7 Motor Starting ...A-7 Electrical Device Used with the Ranger 8 ...A-8 Auxiliary Power While Welding...A-9 Premises Wiring ...A-10 Operation...Section B General Description...B-1 Design Features ...B-1... -

Page 8: Installation

TECHNICAL SPECIFICATIONS - Ranger 8 (K1418-1) (K1418-2 CSA MEETS CANADIAN STD.) Make/Model Description Onan P216 (K1418-1) (K1418-2) 2 cylinder 4 Cycle Air-Cooled Kohler CH20 Gasoline (K1419-1) Engine. (K1419-2) Aluminum Alloy with Cast Iron Liners, Electrical Ignition Honda GX620 (K2160-1) HEIGHT WIDTH 30.3 in. -

Page 9: Specifications

AC STICK / TIG (CC) OUTPUT A 225 OUTPUT RANGE B 50 OUTPUT RANGE OUTPUT AMPS DC STICK / TIG (CC) OUTPUT A 210 OUTPUT RANGE B 50 OUTPUT RANGE OUTPUT AMPS DC WIRE FEED (CV) OUTPUT CV OUTPUT RANGE OUTPUT AMPS RANGER 8... -

Page 10: Installation Instructions

To prevent dangerous electric shock, other equipment to which this engine driven welder supplies power must: • be grounded to the frame of the welder using a grounded type plug, or • be double insulated. INSTALLATION When this welder is mounted on a truck or trailer, it’s frame must be securely connected to the metal frame of the vehicle. -

Page 11: Pre-Operation Engine Service

• Wipe up spilled fuel and allow fumes to clear before starting engine. ------------------------------------------------------------------------ The Ranger 8 is shipped with the engine crankcase filled with SAE 10W-30 oil. Check the oil level before starting the engine. If it is not up to the full mark on the dip stick, add oil as required. -

Page 12: Angle Of Operation

3.5% per 1000 feet for altitudes above 377 feet. CAUTION Do not operate a Ranger 8 with a high altitude jet installed at altitudes below 5000 ft. This will result in the engine running too lean and result in higher engine operating temperatures which can shorten engine life. -

Page 13: Additional Safety Precautions

TIG Module for installation instructions. Note: The TIG Module does not require the use of a high frequency bypass capacitor. However, if the Ranger 8 is used with any other high frequency equip- ment, the bypass capacitor must be installed - order kit T12246. -

Page 14: Motor Starting

Total From Each Half of Both 115V Each 115V Duplexes Duplex K1418-2, K1419-2 and K2160-1 Total From Both 115V Duplexes RANGER 8 CSA Machines Total From Both 115V Duplexes CSA Machines Each Half of Total From Each 115V Both 115V... -

Page 15: Electrical Device Used With The Ranger 8

ELECTRICAL DEVICE USE WITH THE RANGER 8. Type Resistive Capacitive Inductive Capacitive/Inductive The Lincoln Electric Company is not responsible for any damage to electrical components improperly connect- ed to the RANGER 8. INSTALLATION TABLE lll Common Electrical Devices Heaters, toasters, incandescent light bulbs, electric range, hot pan, skillet, coffee maker. -

Page 16: Auxiliary Power While Welding

INSTALLATION 2. Take necessary steps to assure load is limited to the capacity of the Ranger 8 by installing a 35 amp 230V double pole circuit breaker. Maximum rated load for the 230V auxiliary is 35 amperes. Loading above 35 amperes will reduce output... -

Page 17: Premises Wiring

VOLT PLUG NEMA TYPE 14-50 50 AMP, 115/230 VOLT RECEPTACLE Connection of Ranger 8 to premises wiring must be done by a licensed electrician and must com- ply with the National Electrical Code and all other applicable electrical codes. INSTALLATION... -

Page 18: Operation

• Quiet muffler with reversible exhaust feature; either right or left side of machine. ENGINE OPTIONS Three Engines are available for the Ranger 8 Welders; the Onan P216 Performer®*, the Kohler 20 HP Command®* and the Honda GX620. All three engines have the following features: •... -

Page 19: Fuel Consumption

Ranger 8 Approximate Fuel Consumption 16 H.P. PERFORMER Low Idle - No Load .4 Gallons/Hour 2200 RPM (1.5 Liters/Hour) High Idle - No Load .9 Gallons/Hour 3700 RPM (3.5 Liters/Hour) AC CC Weld Output 1.5 Gallons/Hour 225 Amps @ 25 Volts (5.8 Liters/Hour) -

Page 20: Starting The Engine

Stop the engine by placing the “Engine” switch in the “OFF” position. A fuel shut off valve is not required on the Ranger 8 because the fuel tank is mounted below the engine. Break-in Period It is normal for any engine to use a greater amount of oil until the break-in is accomplished. -

Page 21: Welding Process

For best arc stability, use settings 5 through 10. The Ranger 8 can be used with a broad range of AC and DC stick electrodes. See “Welding Tips 1” included with the Ranger 8 for electrodes within the rating of this unit and recommended welding currents of each. -

Page 22: Summary Of Welding Processes

WHEN NOT MODE WELDING AUTO HIGH Cold AUTO Cold HIGH Cold RANGER 8 TO START WELDING Touch electrode to work. Welding starts immediately and engine goes to high idle. Press Amptrol, contactor closes, welding starts immediately. Press gun trigger, LN-25 contactor closes. -

Page 23: Optional Equipment

K936-3 Remote Control Cable - Control cable for connect- ing the K930-2 TIG Module to a Ranger 8 equipped with a K892-1 Remote Kit. 9-Socket to a grounded 115 V plug and a 6 pin MS-connector. (Contains circuits 2, 4, 31, 32, 75, 76,... -

Page 24: Recommended Equipment/ Accessories

K892-1 Remote control Receptacle Kit and K444-1 Remote voltage Control Kit are required for voltage control at the feeder. LN7-K240 Contactor Kit is required. Magnum Gun is required for gas-shielded welding. Innershield Gun is required for gasless welding. ACCESSORIES RANGER 8... -

Page 25: Safety Precautions

Switch contacts should not be greased. To keep contacts clean, rotate the switch through its entire range frequently. Good practice is to turn the han- dle from maximum to minimum setting twice each morning before starting to weld. RANGER 8 CAUTION Onan Honda P216... -

Page 26: Engine Adjustments

• CONNECTING A BATTERY CHARGER - Remove bat- tery from welder by disconnecting negative cable first, then positive cable and battery clamp. When rein- stalling, connect negative cable last. Keep well venti- lated. -

Page 27: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 28 No voltage signal from the current sensor. No open circuit voltage on output studs. Faulty P.C. Board. CAUTION RANGER 8 RECOMMENDED COURSE OF ACTION If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized...

- Page 29 Fuel filter clogged. Air filter clogged. Spark plugs do not have specified gap. Spark plugs are fouled. CAUTION RANGER 8 RECOMMENDED COURSE OF ACTION If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized...

- Page 30 201A 200B DIAGRAMS RANGER 8...

- Page 31 201A 200B DIAGRAMS RANGER 8...

- Page 32 201A 200B DIAGRAMS RANGER 8...

- Page 33 201A 200B DIAGRAMS RANGER 8...

- Page 34 201A 200B DIAGRAMS RANGER 8...

- Page 35 IN "OUTPUT CONTROL REMOTE" POSITION. CONNECTION OF RANGER 8 TO LN-7 & K240 CONTACTOR KIT C O N N E C T I O N O F L N - 7 & K 2 4 0 C O N T A C T O R K I T W I T H 1 1 5 V O L T A C A U X I L I A R Y P O W E R A N D C V O U T P U T C O N T R O L C A B L E N .

- Page 36 DIAGRAMS RANGER 8...

- Page 37 DIAGRAMS RANGER 8...

- Page 38 NOTES RANGER 8...

- Page 39 Address: Telephone: _______________________________________________ |_|_| |_|_| Exp Date Month BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199 for fastest service, FAX this completed form to: 216-361-5901 Telephone: 216-383-2211 or, Titles: Price New Lessons in Arc Welding $5.00...

- Page 40 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic READ AND UNDERSTAND THE MANUFACTURER’S INSTRUCTION FOR THIS EQUIPMENT AND THE CONSUMABLES TO BE USED AND FOLLOW YOUR EMPLOYER’S SAFETY PRACTICES. SE RECOMIENDA LEER Y ENTENDER LAS INSTRUCCIONES DEL FABRICANTE PARA EL USO DE ESTE EQUIPO Y LOS CONSUMIBLES QUE VA A UTILIZAR, SIGA LAS MEDIDAS DE SEGURIDAD DE SU SUPERVISOR.

- Page 41 ● ● Keep your head out of fumes. Turn power off before servicing. ● Use ventilation or exhaust to remove fumes from breathing zone. ● Los humos fuera de la zona de res- ● Desconectar el cable de ali- piración. mentación de poder de la máquina ●...

- Page 42 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the RANGER 8 and is the answer not in the manual?

Questions and answers