Wayne WIP150 Operating Instructions & Parts Manual

Hide thumbs

Also See for WIP150:

- Operating instructions and parts manual (4 pages) ,

- Operating instructions and parts manual (4 pages)

Table of Contents

Advertisement

Available languages

Available languages

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, serious injury or death.

Installer: Please leave this manual for the owner's use.

QUICK START INSTRUCTIONS

STEP 1 - VERIFY PACKAGE CONTENTS

DISCHARGE

SUCTION

INLET

STEP 2 - VERIFY EXISTING PUMP VOLTAGE

All electrical wiring or service should

115 V

be done by a qualified electrician. You

must match the voltage of our pump to

the existing power supply.

230 V

STEP 3 - HOW TO CHANGE VOLTAGE SELECTOR

This pump is factory wired for 230 volts. To change the voltage to

115 volts follow the steps below:

1. Disconnect the pump from power.

2. Remove cover from back of motor to find voltage selector.

3. Pull selector knob out.

4. Rotate selector knob to correct voltage setting.

5. Push selector knob back in place.

6. Reinstall cover to back of motor.

© 2012,

WAYNE/Scott Fetzer Company.

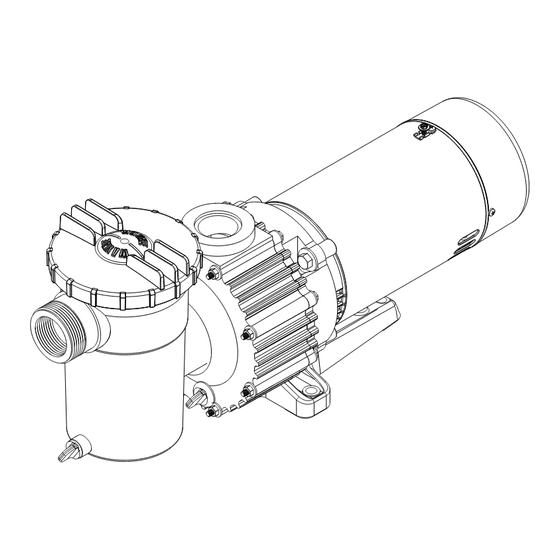

SWIMMING POOL PUMP

OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS - WIP150 / WIP100 / WIP90 (TITLE 20 COMPLIANT)

(1) PUMP

(1) LID

(1) GASKET

(1) STRAINER

VOLTAGE SELECTOR

For parts, product & service information

visit www.waynepumps.com

STEP 4 - ELECTRIC BONDING

Use solid copper bonding conductor

not smaller than 8 AWG (8.4 mm

STEP 5 - PUMP PLUMBING

Before attempting installation of any swimming pool pump, read and

understand ALL guidelines (ANSI/APSP/ICC-15 2011) regarding suction

and installation. Suction pipe should be as large or larger than discharge

pipe. Avoid using a suction pipe smaller than pump connection.

ANSI/APSP-16 (2011) Certified

No Valves Between

Component Anti-Entrapment

Tee and Main Drains

Cover/Grate or Suction Fitting

Suction Outlet

(Main Drain)

Valves OK Between

Pump and Tee

WARNING – DO NOT attempt installation

of swimming pool pump unless you have read

and understand the following standards, guidelines and regulations:

ANSI/APSP-16 (2011); ANSI/APSP-7 (2006); ANSI/ASME A112.19.17

(2010); ASTM F2387 (2004); Virginia Graeme Baker Pool and Spa Safety

Act (2007); CPSC's publication entitled Guidelines for Entrapment

Hazards; and any successor standards or state law requirements.

DO NOT enter the swimming pool if any drain cover is broken or

missing. Close the swimming pool or spa. Immediately call your

professional to make repairs. Prime pump before attempting to operate.

To prime pumps located above water level, remove strainer cover, fill

strainer body with water then replace cover. If pump and all piping is

located below water level, the pump will self prime.

After pump has been primed, energize motor and open all suction and

discharge line valves. If no flow is observed in five minutes, stop the

motor and re-prime. If the pump fails to operate, check for air leaks.

Refer to troubleshooting section.

After about 10 minutes of operation, check the return fittings for air

bubbles. A continuous flow of air indicates leaks in the suction line.

Locate and correct any leaks immediately.

FOR FURTHER INSTRUCTIONS, SAFETY REQUIREMENTS/

STANDARDS/ REGULATIONS FOR INSTALLATION REFER

TO THE INFORMATION PROVIDED IN THIS MANUAL.

WIP SERIES

SWIMMING POOL PUMP

).

2

At Least

3 Feet

ANSI/APSP-16 (2011) Certified

Component Anti-Entrapment

Cover/Grate or Suction Fitting

Suction Outlet

(Main Drain)

Pump

320405-001 10/12

Advertisement

Table of Contents

Summary of Contents for Wayne WIP150

- Page 1 SWIMMING POOL PUMP OPERATING INSTRUCTIONS & PARTS MANUAL MODELS - WIP150 / WIP100 / WIP90 (TITLE 20 COMPLIANT) READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD. Failure to follow these instructions could result in property damage, serious injury or death.

-

Page 2: Swimming Pool Pump

SWIMMING POOL PUMP OPERATING INSTRUCTIONS & PARTS MANUAL MODELS - WIP150 / WIP100 / WIP90 (TITLE 20 COMPLIANT) READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD. Failure to follow these instructions could result in property damage, serious injury or death. -

Page 3: Installation

WIP SERIES POOL PUMP backwards. NEVER attempt to start pump if shaft is rotating due to a suction fitting must be at least 3 feet apart (Figure A). The system must hydraulic turbine action, this COULD cause pump to operate in reverse be built so that it cannot operate with the swimming pool pump drawing and damage internal components. -

Page 4: Installation (Electrical)

Operating Instructions and Parts Manual GFCI is required in the circuit. For size of GFCI required and test INSTALLATION (ELECTRICAL) procedures for GFCI, see manufacturer’s instructions. Disconnect, tag, and lock out power source before NEVER ground to a gas supply attempting to install, service, relocate or perform any line, use dedicated grounding maintenance. -

Page 5: Maintenance

WIP SERIES POOL PUMP 5. Clean and then reposition the basket into the pump. Take care to seat the OPERATION (CON'T) basket properly. 6. Clean the o-ring and re-lubricate with petroleum jelly if necessary. The motor is equipped with an internal thermal protection circuit to guard against overheating. -

Page 6: Troubleshooting And Replacement Parts

Please provide following information: - Model number - Serial number (if any) - Part description and number as shown in parts list Address parts correspondence to: WAYNE Water Systems 101 Production Drive Harrison, OH 45030 U.S.A. Ref. No. Description Order No. -

Page 7: Limited Warranty

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall WAYNE Pumps or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated equip ment, cost of capital, cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s cus tom ers for such... -

Page 8: Sélecteur De Tension

POMPE DE PISCINE MODE D'EMPLOI ET LISTE DES PIÈCES DÉTACHÉES MODÈLES : WIP150 / WIP100 / WIP90 (CONFORMES À LA NORME 20 DE CALIFORNIE) LIRE, S’ASSURER DE COMPRENDRE ET SUIVRE TOUTES LES INSTRUCTIONS DE CE MANUEL - NE PAS JETER. -

Page 9: Directives De Sécurité

POMPE DE PISCINE MODE D'EMPLOI ET LISTE DES PIÈCES DÉTACHÉES MODÈLES : WIP150 / WIP100 / WIP90 (CONFORMES À LA NORME 20 DE CALIFORNIE) LIRE, S’ASSURER DE COMPRENDRE ET SUIVRE TOUTES LES INSTRUCTIONS DE CE MANUEL - NE PAS JETER. - Page 10 POMPE DE PISCINE DE LA SÉRIE WIP PROTECTION CONTRE LE PIÉGEAGE DIRECTIVES DE SÉCURITÉ POUR LES PISCINES Se reporter à la norme ANSI/APSP-7-2006 ou à la version la plus récente SURVEILLANCE PAR UN ADULTE RESPONSABLE pour éviter un piégeage par aspiration. L'aspiration de la pompe doit Une surveillance constante par un adulte responsable est obligatoire être conçue pour éliminer la possibilité...

-

Page 11: Installation Électrique

Mode d'emploi et liste des pièces détachées Une contrainte excessive sur la pompe exercée par un mauvais alignement des tuyaux peut provoquer une rupture du carter de pompe. FIL DE RACCORDEMENT CONNEXION TUYAUTERIE DE LA POMPE DE LA VIS DE CONNEXION Risque d'explosion/d’incendie : N'utiliser des adhésifs/colles que... -

Page 12: Entretien

POMPE DE PISCINE DE LA SÉRIE WIP Utiliser la borne de mise à la terre présente dans la boîte de la borne Maintenir un niveau correct d'acidité ou d'alcalinité de l'eau de piscine. Les valeurs de pH supérieures à pH 7,0 à... - Page 13 Tableau de dépannage AVERTISSEMENT Ceci représente le symbole d'alerte de sécurité. Il est utilisé pour vous prévenir des risques possibles de blessures corporelles. Respecter tous les messages de sécurité qui suivent ce symbole pour éviter tout risque de blessure ou la mort. Évitez les blessures.

-

Page 14: Pièces De Rechange

- Numéro de modèle - Numéro de série (le cas échéant) - Description et numéro de pièce indiqués dans la liste des pièces Adresser toute correspondance relative aux pièces à : WAYNE Water Systems 101 Production Drive Harrison, OH 45030 U.S.A. Nº de Nº... - Page 15 Garantie Limitée Pendant un an à compter de la date d’achat, WAYNE Water Systems Division (« WAYNE Pumps »), s’engage auprès de l’acheteur d’origine à réparer ou à remplacer, à sa discrétion, toute pièce de ses (« Produits ») pompes à eau dont la défectuosité...

- Page 16 BOMBA PARA PISCINA MANUAL DE INSTRUCCIONES DE FUNCIONAMIENTO Y PIEZAS DE REPUESTO MODELOS - WIP150 / WIP100 / WIP90 (CUMPLEN CON EL TÍTULO 20) LEA, ENTIENDA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL. NO LO DESECHE. No seguir estas instrucciones podría provocar daño a la propiedad, lesiones graves o la muerte.

- Page 17 BOMBA PARA PISCINA MANUAL DE INSTRUCCIONES DE FUNCIONAMIENTO Y PIEZAS DE REPUESTO MODELOS - WIP150 / WIP100 / WIP90 (CUMPLEN CON EL TÍTULO 20) LEA, ENTIENDA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL. NO LO DESECHE. No seguir estas instrucciones podría provocar daño a la propiedad, lesiones graves o la muerte.

-

Page 18: Instalación

BOMBA PARA PISCINA SERIE WIP PROTECCIÓN CONTRA EL ENTRAMPAMIENTO PAUTAS DE SEGURIDAD DE LA PISCINA Consulte ANSI/APSP-7-2006 o la versión más reciente para evitar quedar SUPERVISIÓN DE UN ADULTO RESPONSIBLE atrapado por succión. La succión de la bomba debe ser configurada para En el ambiente de piscinas o hidromasajes, la supervisión de un adulto eliminar la posibilidad de entrampamiento de succión o entrampamiento/ responsable y constante es obligatoria. -

Page 19: Instalación Eléctrica

Manual de instrucciones de funcionamiento y piezas de repuesto La tensión excesiva en una tubería causada por un alineamiento incorrecto podría hacer que la caja falle. CABLE DE CONEXIÓN CONEXIÓN PLOMERÍA DE BOMBA DEL PERNO DE RETORNO Peligro de explosión/incendio: Aplique adhesivo SOLO en un área bien ventilada. -

Page 20: Mantenimiento

BOMBA PARA PISCINA SERIE WIP terminales, en la parte de atrás del motor. Use el tamaño y tipo de alambre Mantenga el nivel correcto de acidez o de alcalinidad del agua de la piscina. Las lecturas del pH por encima requeridos por los códigos locales. - Page 21 Tabla de diagnóstico y resolución de problemas ADVERTENCIA Este es el símbolo de alerta de seguridad. Se utiliza para alertarle sobre los peligros potenciales de lesiones personales. Obedezca todos los mensajes de seguridad que siguen a este símbolo para evitar posibles lesiones o la muerte. Evite las lesiones.

-

Page 22: Piezas De Repuesto

- Número de serie (si corresponde) - Descripción y número de la pieza como se indica en la lista de piezas Dirija su correspondencia sobre piezas de repuesto a: WAYNE Water Systems 101 Production Drive Harrison, OH 45030 U.S.A. N.º de Ref. - Page 23 Bombas de agua (“Producto”) que después de un examen sean halladas por Wayne como defectuosas en su material o mano de obra. Sírvase llamar a WAYNE Pumps (1-800-237-0987) para recibir instrucciones.

- Page 24 Notes / Remarques / Notas www.waynepumps.com...

Need help?

Do you have a question about the WIP150 and is the answer not in the manual?

Questions and answers