Table of Contents

Advertisement

Quick Links

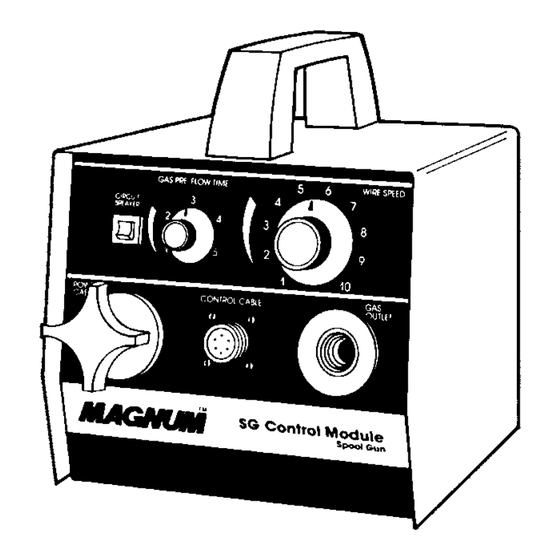

MAGNUM SG CONTROL MODULE

For use with machines having Code Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

™

THIS

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

IM398

February, 2000

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric MAGNUM SG CONTROL MODULE IM398

- Page 1 MAGNUM SG CONTROL MODULE For use with machines having Code Numbers: Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ... and thought- ful operation on your part.

-

Page 2: Electric And Magnetic Fields

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. - Page 4 WELDING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A L’Arc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment. for selecting a QUALITY product by Lincoln Electric. We want you to take pride in operating this Lincoln Electric Company product •••...

-

Page 7: Table Of Contents

TABLE OF CONTENTS SAFETY PRECAUTIONS ............2-5 PRODUCT DESCRIPTION. -

Page 8: Product Description

Product Description The Magnum SG Control Module is an interface between the welding power source and the Magnum Spool Gun. The Control Module and Spool Gun combination provide a system for welding primarily with aluminum electrode wire using a con- stant voltage welding power source. - Page 9 For Static (Transformer Type) Power Sources Power SP-150 SP-200 Source Spool K469-25 None None required required K469-25 K518 K518 Adapter with Adapter K517 Adapter K473 K516 Extension Adapter Cable K487-25 K516 Adapter K517 Adapter (No remote (No remote WFS control) WFS control) K487-25 K516 Adapter...

- Page 10 For Rotating (Engine-Driven Type) Power Sources: Machine* Classic II Classic II w/Wire Feeder Module Classic III Classic III w/Wire Feed Module Classic IIID Classic IIID w/Wire Feed Module Commander 300 Commander 400 (Stick) Commander 400 (Stick & Wire) Ranger 10 Ranger 10LX (Incl.

-

Page 11: Installation

Safety Precautions WARNING • Have an electrician install and service this equipment. • Turn the input power off at the fuse box before working on equipment. ELECTRIC • Do not touch electrically hot parts. SHOCK can kill Read “Arc Welding Safety Precautions” in the Operating Manual before proceeding. -

Page 12: Connection To Power Source

to Power Source Connect the control module to the power source using either a K492-10, K493-10 or K691-10 Input Cable Assembly (ordered separately), and follow the simple steps below. Installation of K492-10 Input Cable to Power Sources with a Terminal Strip 1. -

Page 13: Installation Of K691-10 Input Cable With14-Pin Connector To 115V Plug

2. Attach the control cable Amphenol, gas line con- nector, and electrode cable terminal to their respective connectors on the rear panel of the Control Module. 3. At the other end of the cable: Connect the gas line to the gas cylinder regulator 4. -

Page 14: Connection To Spool Gun

When connecting the Control Module to a non-Lincoln power source, determine which type of output contactor your power source has. If the switch is not in the correct position, remove the single screw securing the lockout bar and remove. Slide the switch to the correct position and reinstall lockout bar on other side using screw already in place there. -

Page 15: Operating Instructions

1. Inspect all cables and connectors for missing or incorrect connections. In particular, ensure that ground lead is correctly attached to chassis ground inside welder with terminal strip control connections. 2. Open gas cylinder valve and adjust regulator. 3. Set power source to minimum tap or output setting. -

Page 16: Setting Gas Flow Rate On Gas Cylinder Regulator

Setting Gas Flow Rate on Gas Cylinder Regulator Gas handling systems having adjustable flow valves should be set per the information in the spool gun operating manual. A typical value is 30 cubic feet per hour (cfh), or 14 liters per minute. -

Page 17: Wiring Diagram

DIAGRAMS Wiring Diagram -17-... - Page 18 NOTES...

- Page 19 Address: Telephone: _______________________________________________ |_|_| |_|_| Exp Date Month BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199 for fastest service, FAX this completed form to: 216-361-5901 Telephone: 216-383-2211 or, Titles: Price New Lessons in Arc Welding $5.00...

- Page 20 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● German ● WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic ● ● ● ● ● ● ● ● ● ●...

- Page 21 ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● Spanish ● PRECAUCION French ● ATTENTION German ● WARNUNG Portuguese ● ● Japanese Chinese Korean Arabic WARNING AVISO DE ATENÇÃO...

- Page 22 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the MAGNUM SG CONTROL MODULE IM398 and is the answer not in the manual?

Questions and answers