Summary of Contents for Murex Transarc 250

- Page 1 Transarc 250 Instruction manual and spare parts list 0460 810 074 080825 Valid for serial no. 819- -xxx- -xxxx...

-

Page 2: Table Of Contents

1 DIRECTIVE ............2 SAFETY . -

Page 3: Directive

Murex Welding Products Ltd, EN8 7TF England, gives its unreserved guarantee that welding power source Transarc 250 from serial number 819 (2008 w.19) are constructed and tested in compliance with the standard EN 60974--1 and EN 60974--10 (Class A) in accordance with the requirements of directive (2006/95/EC) and (2004/108/EEC). - Page 4 WARNING Arc welding and cutting can be injurious to yourself and others. Take precausions when welding. Ask for your employer’s safety practices which should be based on manufacturers’ hazard data. ELECTRIC SHOCK - Can kill Install and earth the welding unit in accordance with applicable standards. Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

-

Page 5: Introduction

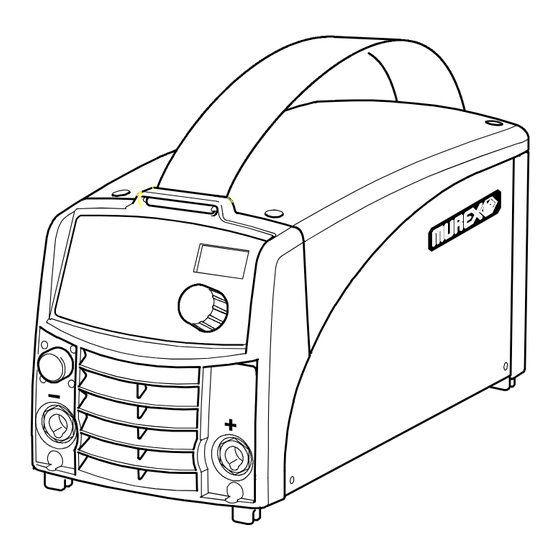

We can provide you with all necessary welding protection and accessories. INTRODUCTION The Transarc 250 is a welding current power source intended for use with coated electrodes (MMA welding) and TIG welding. Accessories for the product can be found on page 26. -

Page 6: Installation

Transarc 250 Power factor at maximum current 0.94 0.93 Efficiency at maximum current 83 % 79 % Open- -circuit voltage without VRD 65 V with VRD < 35 V Operating temperature --10 to +40˚C Transportation temperature --20 to +55˚C Continual sound pressure at no- -load <70 db (A) -

Page 7: Mains Power Supply

A protective earth connection must be made in accordance with regulations. Rating plate with supply connection data 5.3.1 Recommended fuse sizes and minimum cable area Transarc 250 Mains voltage 400V Mains cable area mm 4 G 1.5... -

Page 8: Operation

OPERATION General safety regulations for the handling of the equipment can be found on page 3. Read through before you start using the equipment! Connections and control devices Mains voltage switch Connection for remote control unit Connection (+) Control panel, see title 7. TIG: return cable MMA: welding cable or return cable Connection (--) -

Page 9: Control Panel

CONTROL PANEL When mains power is supplied the unit runs a self diagnosis of the LEDs and the display, the program version is displayed and in this example the program version is 0.18. Display Indication of which parameter is shown in the display (current, voltage or percent) Choice of current indication (A) or voltage indication (V) during... -

Page 10: Mma Welding

MMA WELDING Symbol and function explantions MMA welding MMA welding may also be referred to as welding with coated electrodes. Striking the arc melts the electrode, and its coating forms protective slag. Setting current A higher current produces a wider weld pool, with better penetration into the workpiece. -

Page 11: Tig Welding

8.1.1 Hidden functions There is one hidden function in the control panel. To access the functions hold button depressed for 5 seconds. The display shows a letter and a value. The correct function is selected by pressing the buttons. The knob is used to change the value of the selected function. Function letter Function Drop welding... -

Page 12: Maintenance

Active panel Settings are made from the control panel. Remote control unit Settings are made from the remote control unit. The remote control unit must be connected to the remote control unit socket on the machine before activation. When the remote control unit is activated the panel is inactive. -

Page 13: Welding Torch

It is normally sufficient to blow the power source clean with dry compressed air (reduced pressure) once a year. Clogged or blocked air inlets and outlets otherwise result in overheating. 10.2 Welding torch The wear parts should be cleaned and replaced at regular intervals in order to achieve trouble--free welding. -

Page 14: Fault- -Tracing

Repair and electrical work should be performed by an authorized serviceman. Use only original spare and wear parts. Transarc 250 is designed and tested in accordance with the international and Europe- an standards EN 60974- -1 and EN 60974- -10. It is the obligation of the service unit which has carried out the service or repair work to make sure that the product still conforms to the said standard. - Page 15 - - 15 - -...

-

Page 16: Diagram

Diagram - - 16 - - Edition 080825 bh34e... - Page 17 - - 17 - - Edition 080825 bh34e...

- Page 18 - - 18 - -...

-

Page 19: Spare Parts List

Ordering number 0460 300 891 Transarc 250 Spare parts are to be ordered through the nearest MUREX agency. Kindly indicate type of unit, serial number, denominations and ordering numbers according to the spare parts list. Maintenance and repair work should be performed by an experienced person, and electrical work only by a trained electrician. - Page 20 Transarc 250 C = component designation in the circuit diagram Item Ordering no. Denomination Notes 0460 479 003 Side cover Left 0458 950 001 Sign 0366 588 001 4- -K Front panel Included in item AA50 0460 690 005 Label...

- Page 21 Transarc 250 R0460 810 074/E080825/PNO TAG - - 21 - - bh36saa1...

- Page 22 Transarc 250 C = component designation in the circuit diagram Item Ordering no. Denomination Notes 0192 790 102 Circuit card holder 0487 584 880 Printed circuit board EMC board 2AP1 0194 034 002 Ferrite core 0459 197 887 Control module (VRD) digital...

- Page 23 Transarc 250 R0460 810 074/E080825/PNO TAG - - 23 - - bh34sab1...

- Page 24 Transarc 250 C = component designation in the circuit diagram Item Ordering no. Denomination Notes 0460 329 880 Transformer 15TM1 0460 414 001 15EV1 0460 312 001 Heat sink rectifier Inverter Primary module Included in AC50 Printed circuit board Power board, Included in AC50...

- Page 25 Transarc 250 R0460 810 074/E080825/PNO TAG - - 25 - - bh34sac1...

-

Page 26: Accessories

Transarc 250 Accessories Remote control unit AT1 ....0459 491 896 MMA and TIG: setting of current Remote control unit AT1 CF .... - Page 27 Transarc 250 Tig torch TXH 150 4 m ....0460 011 843 Tig torch TXH 150 8 m ....

- Page 28 Murex Welding Products Ltd Hanover House Queensgate Britannia Road Waltham Cross Hertfordshire EN8 7TF England...

Need help?

Do you have a question about the Transarc 250 and is the answer not in the manual?

Questions and answers