Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for PSC Magellan 2300HS

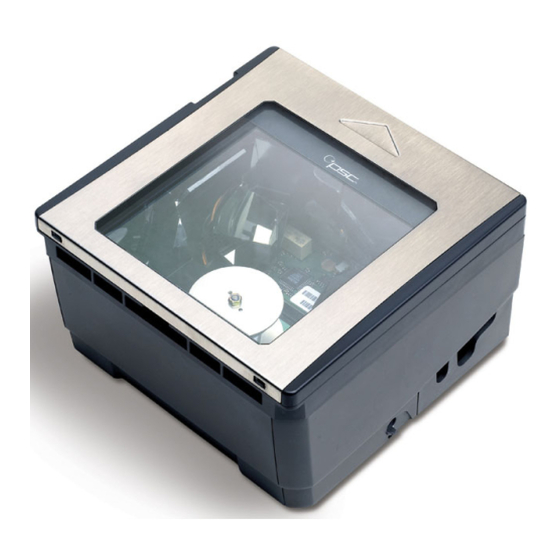

- Page 1 ® Magellan 2200VS and 2300HS Product Reference Guide...

- Page 2 An Unpublished Work - All rights reserved. No part of the contents of this documentation or the procedures described therein may be reproduced or transmitted in any form or by any means without prior written permission of PSC Inc. or its wholly owned subsidiaries ("PSC").

-

Page 3: Table Of Contents

Table of Contents Chapter 1. Introduction ..................1-1 Manual Overview ................... 1-1 How to Use This Manual ................1-2 Scanner Nomenclature ................... 1-3 Connectors ....................1-4 Physical Parameters ..................1-5 Scanning ....................1-5 AC Adapter ..................... 1-5 Electrical Specifications .................. 1-6 Power Supply .................. - Page 4 Chapter 5. Programming .................. 5-1 Introduction to Label Programming ..............5-1 Understanding the Basics ................5-1 Integrating the Scanner With Your Host System ..........5-1 Customizing Your Scanner’s Operation ............5-2 Programming Overview .................. 5-3 Programming via Handheld Device ............. 5-4 What Is Programming Mode? ..............

- Page 5 RS-232 Host Echo .................. 5-71 RS-232 Host Echo Quiet Interval .............. 5-72 RS-232 Ignore Host Commands ............... 5-73 RS-232 TTL ................... 5-74 RS-232 TTL Invert ................. 5-75 RS-232 Beep on ASCII BEL ..............5-76 RS-232 Beep on Not on File ..............5-77 RS-232 ACK NAK Enable .................

- Page 6 UPC-A 5-Digit Supplemental Label ID ............5-127 UPC-A 128 Supplemental Label ID ............5-128 UPC-E Enable .................... 5-129 UPC-E Number System Character Transmission ........5-130 UPC-E Check Character Transmission ............5-131 Expand UPC-E to UPC-A ................ 5-132 Expand UPC-E to EAN-13 ............... 5-133 UPC-E Label ID ..................

- Page 7 RSS Expanded EAN-128 Emulation ............5-181 RSS Expanded 2D Component Enable ............. 5-182 RSS Expanded AIM ID ................5-183 RSS Expanded Label ID ................ 5-184 RSS Expanded Length Control ............... 5-185 RSS Expanded Maximum Label Length ............ 5-186 RSS Expanded Minimum Label Length ............. 5-187 RSS Expanded Fixed Length 1 ...............

- Page 8 I 2 of 5 Minimum Label Length ............... 5-228 I 2 of 5 Fixed Length 1 ................5-229 I 2 of 5 Fixed Length 2 ................5-230 I 2 of 5 Stitching .................. 5-231 Codabar Enable ..................5-232 Codabar Start Stop Character Transmission ..........5-233 Codabar Start Stop Character Set ............

- Page 9 Appendix C. Keypad................C-1 Appendix D. Host Commands............... D-1 Appendix E. Factory Defaults............... E-1 Appendix F. Handheld Data Format Requirements....... F-1 Handheld Data Format Requirements General ..........F-1 PSC Handheld Data Format Requirements ........... F-2 AIM Formats ..................F-10 Product Reference Guide...

- Page 10 viii ® Magellan 2200VS and 2300HS...

-

Page 11: Chapter 1. Introduction

Chapter 1 Introduction This Product Reference Guide contains comprehensive instructions on how to install the scanner, how to program it using special programming feature bar code labels, and advanced user information as described in the following overview. Manual Overview , presents the manual’s contents, describes features Chapter 1, Introduction and specifications, provides regulatory and safety information, and lists the bar code symbologies the scanner will read. -

Page 12: How To Use This Manual

Introduction , outlines wire requirements, connector Appendix B, Cable Information specifications and pinout details for associated product cabling. , furnishes bar codes representing the digits and char- Appendix C, Keypad acters required to enter extended programming data needed during certain programming sessions. -

Page 13: Scanner Nomenclature

Scanner Nomenclature Manual Conventions ‘NOTE’ blocks contain information that is helpful and rec- ommended. They provide information that is critical to operations and/or procedures described in this manual. ‘CAUTION’ blocks inform you that proper handling (adherence to the procedures described) is required to avoid damage to equipment and/or property. -

Page 14: Connectors

Introduction Connectors The appearance of the connector panel will vary depending upon the fac- tory options purchased with your model. Reference Figure 1-2 Figure 1-2. Connector Panel EAS Opening Scanner Host Aux. Port Power EAS Connection POS TERMINAL AUXILIARY PORT POWER ·... -

Page 15: Physical Parameters

Physical Parameters Physical Parameters This section provides specifications for performance, environmental and electrical parameters. Reference the second section of this manual, Site , for physical measurements of all models and Preparation and Installation some accessories. Scanning The scanner has a scan zone immediately in front of (or above) the scan window where the scanner projects laser light in order to scan items. -

Page 16: Electrical Specifications

Introduction Figure 1-4. Environmental Specifications Operation +40 C +104 F 10 C 50 F Temperature 10 to +40 C 50 to +104 F Dust Resistant Optics Cavity, IP5X Illumination Artificial Light: Sunlight: 450 Foot-candles 0-8,000 Foot-candles Humidity 5 - 95% NC Storage +70 C +158 F... -

Page 17: Power Supply

Electrical Specifications Power Supply The scanner utilizes the following power supply models. VOLTAGE PART NUMBER 120V US 4004-0705 230V UK 4004-0706 240V SAA 4004-0707 100V MITI 4004-0708 230V EURO 4004-0709 120V Desktop US 4004-0710 Safe operation of your scanner or scanner requires properly grounded elec- trical outlets. -

Page 18: Laser And Product Safety

Introduction Laser and Product Safety Laser safety requirements are based on IEC Standard Publication 60825-1 (2001) and CDRH 21CFR, Chapter 1, Subchapter J and (CDRH) Laser Product Performance Standard, User information [1040.10(h)1]: • User Maintenance. No user maintenance of the system other than cleaning of the scan window(s) is required. - Page 19 Laser and Product Safety Safety precautions to be taken: No adjustments or alteration of the scanner housing are to be attempted by the user. The failure of the facet wheel motor while the unit is continuing to emit a laser beam causes the emission levels to exceed those for inherently safe operation.

-

Page 20: Labeling

PRODUCT SERVICE AVOID DIRECT EYE EXPOSURE. NRTL COVERED BY ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 4,709,195 Use ONLY PSC INC. AC/DC Power Supply 4,709,369 4,712,853 4,749,879 4,786,798 4,792,666 4,798,943 4,799,164 Input: 50 - 60 Hz (0.5 - 0.25A) Output:... - Page 21 NRTL COVERED BY ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 4,709,195 contact your nearest sales or service office. Use ONLY PSC INC. AC/DC Power Supply 4,709,369 4,712,853 4,749,879 4,786,798 4,792,666 4,798,943 4,799,164 Output: Input: 50 - 60 Hz (0.5 - 0.25A)

-

Page 22: Agency Compliances

CDRH SGM-1 specification Australia AS 2211 Class 1 Europe IEC 60825-1 Class 1 ® Contact PSC Marketing at (541) 683-5700, or your PSC representative for a complete listing of approvals for other countries. 1-12 ® Magellan 2200VS and 2300HS... -

Page 23: Bar Codes Supported

Bar Codes Supported Bar Codes Supported The scanner can read/decode the following bar code types (symbologies): • UPC Versions A & E • UPC Supplementals and Add-ons (2 & 5 digit supplementals and Code 128) • Reduced Space Symbology (RSS) RSS-14 and RSS expanded; both support stacked component. - Page 24 Introduction NOTES 1-14 ® Magellan 2200VS and 2300HS...

-

Page 25: Chapter 2. Site Preparation And Installation

Unpacking Chapter 2 Site Preparation and Installation This chapter outlines the procedures for unpacking the scanner, verifying function, preparing the countertop or wall, routing cables, and installing the scanner. Unpacking To unpack the unit: • Inspect the package for signs of damage that may have occurred dur- ing shipping. -

Page 26: Operational Verification

Site Preparation and Installation Operational Verification Follow these steps to ensure that your unit has arrived undamaged and is fully functional before installing it in the counter and connecting it to your POS system: 1. [2200VS scanners ONLY] Remove the mounting bracket. 2. -

Page 27: Installation: Model 2200Vs

Installation: Model 2200VS 4. The scanner should beep to indicate it has passed the power-up Self- test routine, and the green LED (lamp) will light continuously, indi- cating the scanner is ready to scan. Reference Chapter 4, Problem Isolation if the scanner does not perform as expected. - Page 28 Site Preparation and Installation 2. Determine if a cable-routing hole is necessary. If so, hold the scan- ner or mounting bracket in the desired, installed position to deter- mine the center of the hole. Mark the center and drill a 1-1/4” (3.2cm) hole.

- Page 29 Installation: Model 2200VS ® Figure 2-2. Magellan 2200VS Installation Route cables for countertop mount Connector Cover Route cables for wall mount Product Reference Guide...

-

Page 30: Installation: Model 2300Hs

Site Preparation and Installation Installation: Model 2300HS ® The Magellan 2300HS scanner is mounted flush with the countertop to promote comfortable and ergonomic slide-through scanning. Installation as described below. 1. Determine the best location for scanner. Some considerations are: • Proximity to the user. Verify that checkstand features allow the unit to be within easy reach of the user, without interfering with cash drawers or other equipment. - Page 31 Installation: Model 2300HS Figure 2-3. Countertop Modification Options a. Shelf installation b. Adapter w/flange above counter 6.07" (154.2mm) 6.26" (159mm) Rim of adapter 6.07" (154.2mm) Cut hole 6.26" Cut hole (159mm) Rim rests on top of counter 3.42" (86.9mm) 3.47" (88.1mm) Shelf Depth c.

- Page 32 Site Preparation and Installation ® Figure 2-4. Magellan 2300HS Cable Routing Options Connector Cover 9. Verify operation by scanning a few known-good bar code labels. The scanner should now be communicating the bar code data to the POS terminal. Reference Chapter 4, Problem Isolation if the scanner does not perform as expected.

-

Page 33: Chapter 3. Operation And Maintenance

Chapter 3 Operation and Maintenance The information contained in this section describes how to operate and maintain the scanner. Topics include scanning tips, and scan window cleaning and replacement. Product Reference Guide... -

Page 34: Scanning Items: Model 2200Vs

Operation and Maintenance Scanning Items: Model 2200VS Item bar codes are scanned by either... • sliding or pushing items through the scan volume in a right-to-left or left-to-right motion (see a). This is known as “Sweep” Figure 1 scanning, and is the best choice for high throughput super- and hypermarket installations where it is necessary to minimize the need to grip or lift items. -

Page 35: Scanning Items: Model 2300Hs

Scanning Items: Model 2300HS Scanning Items: Model 2300HS The scanner is mounted so its scan window is flush with the countertop. This allows for maximum working space, and also permits the user to slide items over its surface without having to grasp or pick them up. Bar codes are effortlessly scanned when swept through the zone projected from the substantial scan window as shown in Figure 1... -

Page 36: Operational Controls

Operation and Maintenance Operational Controls The function of scanner controls and indicators is listed in Appendix A, . Turn to that appendix for full LED/Beeper Indications & Controls details. Operational Modes The scanner features a number of modes that are important to both the user and the system support personnel. -

Page 37: Operating Mode

Operational Modes Error Reporting If a fatal error is detected during Selftest or operation, the scanner will not advance to Normal Operation Mode. Selftest diagnostics will cause the scanner to sound a long, low tone. When this occurs, error codes may be accessed by momentarily pressing the Volume/Tone Push Button. -

Page 38: Sleep Mode

Operation and Maintenance Once the scanner enters Normal Operation, it begins a countdown sequence. If there is no activity during a preset period of time (also called time-out ), the unit will shut off the laser and/or motor in order to pro- long the life of the electrical and mechanical components. -

Page 39: Additional Functions

Additional Functions Additional Functions Additional scanner functions include programming, running scanner diagnostics, or initiating a reset. Programming Scanners are typically programmed at the factory to settings specified by the customer. Generally, POS system interface and bar code symbologies are pre-configured to operate in the target environment. con- Chapter 5 tains the necessary instructions, bar codes, and descriptions to program/... -

Page 40: Scanner Reset

Operation and Maintenance Scanner Reset As with any electronic equipment, it is sometimes necessary to reset the electronics. The reset procedure allows you to initiate a reset command to the scanner. This may be necessary if the POS terminal has been switched off or the store system has been reset while the unit is on. -

Page 41: Chapter 4. Problem Isolation

Chapter 4 Problem Isolation In the event of a suspected functional problem, use the troubleshooting references provided in this section. This useful information will help you identify and resolve the cause of the problem. The scanner incorporates features that indicate when a problem occurs. The scanner may: •... -

Page 42: Diagnostic Procedures

Problem Isolation Diagnostic Tests for details about running diag- Chapter 3, Scanner Diagnostic Mode nostic tests for the scanner. If a problem is discovered during diagnostics, the scanner will provide feedback about the source of the problem. The remainder of this section describes these failure indications and includes troubleshooting flowcharts to help isolate the problem. -

Page 43: Error Codes

Error Codes Error Codes If an error is detected, the scanner will sound a long low tone (for three seconds) and flash its LED, indicating a failure. When this occurs, press the Volume/Tone Push button to hear the error code. If it is configured to do so, the scanner will sound a series of beeps corresponding to the error code and/or flash its LED simultaneous to the beeps. -

Page 44: Flowcharts

Problem Isolation Flowcharts The problem isolation flowcharts on the following pages allow you to identify and troubleshoot problems with your system. Figure 4-1. Problem Isolation: Start For units using an AC/DC adapter, verify that... 1. AC Adapter is connected to a functional AC outlet. 2. - Page 45 Flowcharts Figure 4-2. Problem Isolation: Selftest SELFTEST START Scan the Factory Is the Is the Is the Defaults bar code in error code error code Section 6 to enable the blinking in default configuration error file. Restart the unit. No interface selected (Null Interface).

-

Page 46: Problem Isolation

Problem Isolation Figure 4-3. Problem Isolation: Poor/No Reading Have you verified that the scan window(s) is/are clean and scratch-free? POOR/NO READING Before proceeding, verify that START bar code samples presented to scanner are of good quality and a symbology the scanner Enter Scanner Diagnostic Mode by can read. - Page 47 Flowcharts Figure 4-4. Problem Isolation: No Transmit to POS NO TRANSMIT TO POS START Check the interface (I/F) Verify programmable cable connections. If parameters using the possible, retest the information and programming Does the system using a known- bar codes provided in Section scanner read DONE good I/F cable.

- Page 48 Problem Isolation NOTES ® Magellan 2200VS and 2300HS...

-

Page 49: Chapter 5. Programming

Chapter 5 Programming Introduction to Label Programming The programming bar code labels contained in this manual will allow you to customize and configure features and settings for your scanner. To ensure full compatibility and proper function, use only the programming bar codes in this manual and other product-specific publications to pro- gram scanner features. -

Page 50: Customizing Your Scanner's Operation

Programming You may also want to contact the dealer or your system administrator if you have no record of how your scanner was pre-programmed at the fac- tory. Scanners are typically programmed with the default settings for spe- cific interface types (see for more Appendix E Factory Defaults... -

Page 51: Programming Overview

Programming Overview • Symbology Programming - gives the scanner the capability to auto- discriminate as few as one, and as many as all available symbologies. For optimal scanner performance enable only those symbologies required. Additionally the scanner may be programmed with the standard options available for the various symbologies, such as check digit, minimum label length, fixed and variable length bar codes, etc. -

Page 52: Programming Via Handheld Device

The scanner can also accept programming via its auxiliary port using a handheld scanning device. Eligible handheld devices must have the ability to transmit Code 128 function codes such as the programming bar codes ® presented in this manual. PSC models QuickScan 1000 and Quick- ® Scan 6000 support this functionality. -

Page 53: Programming Session

Programming Overview Programming Session A typical programming session is conducted as follows: 1. Scan the SWITCH bar code to place the scanner in Programming Mode. Depending upon its current programming, the scanner may emit a beep or beeps, indicating it has read the bar code and the green LED will flash on and off slowly while the scanner remains in Programming Mode. - Page 54 Programming It is recommended that programming sessions be limited to one feature at a time. Should you make a mistake in the programming sequence, it can be difficult to discover where an error has been made if several features are programmed at once. Additionally, it can be confusing to determine which features may or may not have NOTE been successfully set following such a session.

-

Page 55: Programming Sequence

Programming Overview Programming Sequence To modify a scanner feature (item), the programming bar codes contained in this manual must be scanned in a given sequence depending upon the feature being programmed (as shown in ). There are three possi- Table 5-1 ble programming sequences: If the scanner’s interface type must be changed, always be sure that interface configuration is the FIRST item scanned during a program-... - Page 56 Programming Table 5-1. Programming Sequence ITEM TAG ITEM VALUE END/RESET ENABLE NEW FEATURE SWITCH SWITCH 3 4 5 ENABLE NEW FEATURE USING THE FOLLOWING SETTINGS... SWITCH SWITCH ONE BAR CODE CONTAINS SWITCH + ITEM TAG + ITEM VALUE + SWITCH ®...

-

Page 57: Led And Beeper Indicators

LED and Beeper Indicators LED and Beeper Indicators The scanner provides a set of indicators that verify/announce the various scanner functions. If You Make a Mistake... If, during a programming session, you find that you are unsure of the scanner’s settings or wish to reset the scanner’s configuration, use the Return to Factory Settings label below to return the scanner’s configura- tion to the factory settings. -

Page 58: Test Mode

Programming RETURN TO FACTORY SETTINGS Test Mode Use this feature to place the scanner into a testing, or “demo” mode. This special mode disables the scanner interface, meaning that bar code data is not sent out to the host via the scanner interface. This allows the bar code to be scanned continuously without requiring a response from the POS terminal. -

Page 59: General Scanner Features

General Scanner Features General Scanner Features Double Read Timeout The Double Read Timeout feature sets a time limit that determines how much time must pass before reading the same label again (e.g. two identi- cal items in succession). To set the Double Read Timeout: 1. - Page 60 Programming Double Read Timeout — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. DOUBLE READ TIMEOUT = 800ms DOUBLE READ TIMEOUT = 1 SECOND 5-12 ®...

-

Page 61: Laser Timeout

General Scanner Features Laser Timeout The laser timeout feature sets the time for switching the visible laser diodes (VLDs) off if the scanner is idle. Using this feature can prolong the life of the VLDs. To set the Laser Timeout: 1. - Page 62 Programming Laser Timeout — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. LASER TIMEOUT = 10 MINUTES LASER TIMEOUT = 15 MINUTES 5-14 ®...

-

Page 63: Motor Timeout

General Scanner Features Motor Timeout The Motor Timeout feature sets the time for automatically switching the motor off when the scanner is not in use. Laser safety requires that the laser switch off before the motor. If you set the motor timeout shorter than the laser timeout, the motor and the laser will both shut off when the motor timeout expires. - Page 64 Programming Motor Timeout — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. MOTOR TIMEOUT = 10 MINUTES MOTOR TIMEOUT = 15 MINUTES 5-16 ®...

- Page 65 General Scanner Features Motor Timeout — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. MOTOR TIMEOUT = 30 MINUTES MOTOR TIMEOUT = 60 MINUTES 5-17 Product Reference Guide...

-

Page 66: Green Led Idle State

Programming Green LED Idle State This feature specifies the state of the green scanner LED when the scanner is idle and ready to read a label. Options are: • • On dim To set the LED Idle State: 1. Scan the SWITCH bar code. 2. -

Page 67: Scanner Button Options

General Scanner Features Scanner Button Options Configure the scanner volume button to one of the following modes of operation: • Enable all functions: Volume, tone, diagnostics and reset. • Enable only volume, tone and reset. • Enable reset only. • Disable all button functions To set the desired Scanner Button Option: 1. - Page 68 Programming Scanner Button Options — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. SCANNER BUTTON OPTION = ENABLE RESET ONLY SCANNER BUTTON OPTION = DISABLE ALL BUTTON FUNCTIONS 5-20 ®...

-

Page 69: Power-Up Beep Control

General Scanner Features Power-up Beep Control Specifies the type of audible indication that is made when entering scan- ner-active mode on power-up. Choices are: • No beep • One beep • Three beeps To set the Power-up Beep: 1. Scan the SWITCH bar code. 2. - Page 70 Programming Power-up Beep Control — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. POWER-UP BEEP = ONE BEEP POWER-UP BEEP = THREE BEEPS 5-22 ®...

-

Page 71: Good Read Beep Control

General Scanner Features Good Read Beep Control This feature enables/disables scanner beep upon successfully decoding of a label. To set this feature: 1. Scan the SWITCH bar code. 2. Scan your selection from the two bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 72: Good Read Beep Frequency

Programming Good Read Beep Frequency Adjusts the scanner’s good read beep to sound at low, medium, or high fre- quency (controls the beeper’s pitch/tone). • Low = 660 Hz • Medium = 866 Hz • High = 1600 Hz To set the Good Read Beep Frequency: 1. - Page 73 General Scanner Features Good Read Beep Frequency — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. GOOD READ BEEP FREQUENCY = MEDIUM GOOD READ BEEP FREQUENCY = HIGH 5-25 Product Reference Guide...

-

Page 74: Good Read Beep Length

Programming Good Read Beep Length Specifies the duration of a good read beep. To set the good read beep length: 1. Scan the SWITCH bar code. 2. Scan the bar code, . You’ll need SET GOOD READ BEEP LENGTH to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 75: Good Read Beep Volume

General Scanner Features Good Read Beep Volume Selects the beeper volume upon a good read beep. There are four select- able volumes, with each volume incrementing upward from the previous decibel level: • 0 = Lowest Volume • 1 = Medium-Low Volume •... - Page 76 Programming Good Read Beep Volume — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. GOOD READ BEEP VOLUME = MEDIUM LOW GOOD READ BEEP VOLUME = MEDIUM 5-28 ®...

- Page 77 General Scanner Features Good Read Beep Volume — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. GOOD READ BEEP VOLUME = HIGH 5-29 Product Reference Guide...

-

Page 78: Good Read When To Indicate

Programming Good Read When to Indicate This feature specifies when the scanner will provide indication (beep and/ or flash its green LED) upon successfully reading a bar code. • Good Read = Indicate after decode • Good Read = Indicate after transmit •... - Page 79 General Scanner Features Good Read When to Indicate — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. GOOD READ = INDICATE AFTER TRANSMIT GOOD READ = INDICATE AFTER CTS GOES INACTIVE, THEN ACTIVE (RS-232 ONLY) 5-31...

-

Page 80: Eas Active State

Programming EAS Active State Specifies the active state polarity of EAS (Electronic Article Surveillance); the inactive state is its opposite polarity. EAS output goes active during the good read of a bar code, allowing the EAS device to deactivate a tag on the product. -

Page 81: Eas Timeout

General Scanner Features EAS Timeout Specifies the amount of time that an EAS (Electronic Article Surveillance) signal is held in its active state for a good read. To set the EAS Timeout: 1. Scan the SWITCH bar code. 2. Scan the bar code, SET EAS TIMEOUT below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 82: Aux Port Mode

(only one option can be active at a time). • Disabled — Port is inactive ® • External Handheld Input — Supports PSC handheld scanners (QuickScan 1000, QuickScan 6000, PowerScan) as well as other ® models such as the Symbol HotShot. Call your dealer for more information about supported devices. - Page 83 General Scanner Features Aux Port Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. AUX PORT MODE = EXTERNAL HANDHELD INPUT AUX PORT MODE = PIR 5-35 Product Reference Guide...

-

Page 84: Productivity Index Reporting (Pir)

Programming Productivity Index Reporting (PIR) When PIR is enabled, label quality data is appended to decoded data before being presented to the POS. The PIR feature allows the scanner to provide information to an external computer indicating how easy the label was to read. -

Page 85: Interface Related Features

Interface Related Features Interface Related Features Interface Type Specifies the current scanner interface. Selections are: INTERFACE TYPE PAGE NUMBER RS-232 Standard 5-39 RS-232 Wincor-Nixdorf 5-40 RS-232 Single Cable 5-41 IBM USB 5-43 Port 17 5-42 USB Keyboard 5-44 PC Keyboard Wedge 5-45 NOT USER-SELECTABLE Common factory configuration for... - Page 86 Programming Interface Type — continued To select the desired interface: Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface. ALWAYS make interface selections with the host cable DISCONNECTED.

- Page 87 Interface Related Features RS-232 Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

- Page 88 Programming RS-232 Wincor-Nixdorf Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempt- ing to change to an incompatible interface.

- Page 89 Interface Related Features RS-232 Single Cable Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempt- ing to change to an incompatible interface.

-

Page 90: Ibm Port 17 Interface Selection

Programming IBM Port 17 Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface. -

Page 91: Ibm Usb Interface Selection

Interface Related Features IBM USB Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface. - Page 92 Programming USB Keyboard Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

-

Page 93: Pc Keyboard Wedge Interface Selection

Interface Related Features PC Keyboard Wedge Interface Selection This scanner supports a variety of PC Keyboard interfaces. The table below defines the different interface selections. Scan the corresponding bar code starting on page 5-46 to select the desired keyboard interface. I/F Type PCs Supported Page... - Page 94 Programming PC Keyboard Wedge Interface Types Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

- Page 95 Interface Related Features PC Keyboard Wedge Interface Types — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

- Page 96 Programming PC Keyboard Wedge Interface Types — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

- Page 97 Interface Related Features PC Keyboard Wedge Interface Types — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

- Page 98 Programming PC Keyboard Wedge Interface Types — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS terminal by attempting to change to an incompatible interface.

-

Page 99: Maximum Host-Transmitted Message Length

Interface Related Features Maximum Host-Transmitted Message Length Specifies the maximum number of data characters allowed in messages transmitted to the host. To set the Maximum Host-Transmitted Message Length: 1. Scan the SWITCH bar code. 2. Scan the bar code, SET MAXIMUM HOST-TRANSMITTED MES- below. -

Page 100: Number Of Host Transmission Buffers

Programming Number of Host Transmission Buffers Specifies the number of host transmission(s) that may be buffered. By buffering data from a bar code, the scanner can continue to read a new bar code while the old one is being transmitted to the host. Selecting BUFF- ERS = 1 means that the first bar code must be transmitted before a new one can be read. -

Page 101: Global Prefix

Interface Related Features Global Prefix This feature applies to RS-232 interfaces (Standard, Wincor-Nixdorf, and Single Cable). It specifies the prefix that is added to beginning of label transmission. To specify the Global Prefix Character(s): 1. Scan the SWITCH bar code. 2. - Page 102 Programming Global Prefix — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. SET GLOBAL PREFIX TERMINATE SEQUENCE 5-54 ® Magellan 2200VS and 2300HS...

-

Page 103: Global Suffix

Interface Related Features Global Suffix This feature applies to RS-232 interfaces (Standard, Wincor-Nixdorf, and Single Cable). It specifies the suffix that is added to end of a label trans- mission. Three standard options are available below. Contact your dealer for other alternate settings for this feature. •... - Page 104 Programming Global Suffix — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. GLOBAL SUFFIX = CR GLOBAL SUFFIX = CR LF 5-56 ®...

-

Page 105: Ibm Features

IBM Features IBM Features IBM Transmit Labels in Code 39 Format This feature enables/disables scanner's ability to set a symbology identifier for a specified label to Code 39 before transmitting that label data to an IBM host. This applies to: Code 128, Code 93 and Codabar for IBM Port 5B;... -

Page 106: Ibm Usb Scanner Device Type

Programming IBM USB Scanner Device Type The IBM-USB protocol allows for the scanner to be identified as one of two different types of barcode scanners. Depending on what other scan- ners you may already have connected to a USB POS, you may need to change this setting to enable all scanners to communicate. -

Page 107: Features

RS-232 Features RS-232 Features RS-232 Baud Rate This feature selects the baud rate required for sending and receiving data. Single cable interfaces are limited to Baud Rate selections up to 19200. They cannot communicate at Baud Rates of 38400 and up. NOTE To specify the RS-232 Baud Rate: 1. - Page 108 Programming RS-232 Baud Rate — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 BAUD RATE = 4800 RS-232 BAUD RATE = 9600 5-60 ®...

- Page 109 RS-232 Features RS-232 Baud Rate — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 BAUD RATE = 19200 RS-232 BAUD RATE = 38400 5-61 Product Reference Guide...

- Page 110 Programming RS-232 Baud Rate — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 BAUD RATE = 57600 RS-232 BAUD RATE = 115200 5-62 ®...

-

Page 111: Number Of Data Bits

RS-232 Features RS-232 Number of Data Bits Specifies number of data bits required for sending and receiving data. To set this feature: 1. Scan the SWITCH bar code. 2. Scan the bar code below representing the desired Data Bit setting. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 112: Number Of Stop Bits

Programming RS-232 Number of Stop Bits Specifies number of stop bits required for sending and receiving data. To set this feature: 1. Scan the SWITCH bar code. 2. Scan the bar code below representing the desired Stop Bit setting. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 113: Parity

RS-232 Features RS-232 Parity Specifies parity required for sending and receiving data. Options for this setting are: • RS-232 PARITY = NONE • RS-232 PARITY = EVEN • RS-232 PARITY = ODD To set this feature: 1. Scan the SWITCH bar code. 2. - Page 114 Programming RS-232 Parity — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 PARITY = EVEN RS-232 PARITY = ODD 5-66 ®...

-

Page 115: Hardware Control

RS-232 Features RS-232 Hardware Control Enables/disables use of the RS-232 CTS signal for flow control and/or scan control. Options are: • Disable — The scanner transmits to the host regardless of any activ- ity on the CTS line. • Enable CTS Flow Control — The CTS signal controls transmission of data to the host. - Page 116 Programming RS-232 Hardware Control — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 HARDWARE CONTROL = ENABLE CTS FLOW CONTROL RS-232 HARDWARE CONTROL = ENABLE CTS SCAN CONTROL 5-68 ®...

-

Page 117: Intercharacter Delay

RS-232 Features RS-232 Intercharacter Delay Specifies delay between the end of one character and the beginning of the next in 10-millisecond increments. To set the RS-232 Intercharacter Delay: 1. Scan the SWITCH bar code. 2. Scan the bar code below, SET RS-232 INTERCHARACTER DELAY You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend... -

Page 118: Software Flow Control

Programming RS-232 Software Flow Control Enables/disables RS-232 Flow Control using XON/ XOFF characters. This item will be ignored when the feature, RS-232 NAK Character, is enabled NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 119: Host Echo

RS-232 Features RS-232 Host Echo When enabled, this feature passes all data through the scanner to the host as it comes in. This feature is used for applications where “daisy chaining” of RS-232 devices onto the same cable is necessary. If, for example, one of the devices in the chain is a terminal where someone is entering data while another person is simultaneously scanning a bar code requiring transmis- sion to the host, the scanner will wait for the RS-232 channel to be quiet... -

Page 120: Host Echo Quiet Interval

Programming RS-232 Host Echo Quiet Interval This setting specifies the time interval of RS-232 channel inactivity which must transpire before the scanner will break the host echo loop to transmit the bar code data that has just been scanned to the host. •... -

Page 121: Ignore Host Commands

RS-232 Features RS-232 Ignore Host Commands When set to ignore host commands, the scanner will ignore all host com- mands except for the minimum set necessary to keep the interface active and transmit labels. For normal operation of the interface, disable this fea- ture. -

Page 122: Ttl

Programming RS-232 TTL Specifies whether RS-232 interface provides TTL levels on the output pins TxD and RTS. Choices are: • Normal RS-232 levels • TTL levels To set this feature: 1. Scan the SWITCH bar code. 2. Scan the bar code below which represents the desired setting for this feature. -

Page 123: Ttl Invert

RS-232 Features RS-232 TTL Invert Enables/disables inversion of TTL. To set this feature: 1. Scan the SWITCH bar code. 2. Scan the bar code below which represents the desired setting for this feature. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 124: Beep On Ascii Bel

Programming RS-232 Beep on ASCII BEL Enables/disables ability of scanner to beep (sound a good read tone) on receiving an ASCII BEL (07 hex). • Disable • Enable To enable/disable this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 125: Beep On Not On File

RS-232 Features RS-232 Beep on Not on File Select for the host to beep (or not) when a not-on-file condition is detected by the host. This feature is also applicable to single cable RS-232. RS-232 BEEP ON NOT ON FILE = DISABLE ENABLE 5-77 Product Reference Guide... -

Page 126: Ack Nak Enable

Programming RS-232 ACK NAK Enable This enables/disables the ability of the scanner to support the RS-232 ACK/NAK protocol. When configured, the scanner and/or host sends an “ACK” when it receives data properly, and sends “NAK” when the data is in error. Selections for this option are: •... - Page 127 RS-232 Features RS-232 ACK NAK Enable — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 ACK/NAK = HOST ACKNOWLEDGEMENT RS-232 ACK/NAK = LABEL &...

-

Page 128: Ack Character

Programming RS-232 ACK Character This feature specifies which ASCII character will be used as an ACK char- acter. DO NOT set this feature to use previously defined characters such as XON, XOFF or host commands as this will conflict with normal opera- tion of these characters. -

Page 129: Nak Character

RS-232 Features RS-232 NAK Character This feature specifies which ASCII character will be used as a NAK char- acter. DO NOT set this feature to use previously defined characters such as XON, XOFF or host commands as this will conflict with normal operation of these characters. -

Page 130: Retry On Ack Nak Timeout

Programming RS-232 Retry on ACK NAK Timeout This option specifies the action scanner performs on expiration of the 232 ACK NAK Timeout Value To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 131: Ack Nak Timeout Value

RS-232 Features RS-232 ACK NAK Timeout Value This item specifies the time the scanner will wait for an ACK character from the host following a label transmission. • 0 = Infinite timeout • 1 - 75 = Timeout in 200-millisecond increments To set the ACK NAK Timeout Value: 1. -

Page 132: Ack Nak Retry Count

Programming RS-232 ACK NAK Retry Count This feature sets the number of times for the scanner to retry a label trans- mission under a retry condition. To set the RS-232 ACK NAK Retry Count: 1. Scan the SWITCH bar code. 2. -

Page 133: Ack Nak Error Handling

RS-232 Features RS-232 ACK NAK Error Handling This item specifies the method the scanner will use to handle errors detected while waiting to receive the ACK character from the host. Errors include unrecognized host commands and communication errors such as parity or framing errors. - Page 134 Programming RS-232 ACK NAK Error Handling — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 ACK NAK ERROR HANDLING = ASSUME ACK RS-232 ACK NAK ERROR HANDLING = ASSUME NAK 5-86 ®...

-

Page 135: Label Id Control

RS-232 Features RS-232 Label ID Control This feature specifies whether or not Label IDs are transmitted to the host and if so, whether to attach them as a prefix or suffix. RS-232 LABEL ID CONTROL = DISABLE RS-232 LABEL ID CONTROL = ENABLE AS PREFIX 5-87 Product Reference Guide... - Page 136 Programming RS-232 Label ID Control — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RS-232 LABEL ID CONTROL = ENABLE AS SUFFIX 5-88 ®...

-

Page 137: Single Cable Rs-232 Options

Single Cable RS-232 Options Single Cable RS-232 Options The RS-232 Single Cable interface shares some configuration options with other RS-232 interfaces. Rather than repeat them in this section as Single Cable options, please find them referenced as follows: • RS-232 Baud Rate on page 5-59 •... -

Page 138: Single Cable Rs-232 Rts Cts Selection

Programming Single Cable RS-232 RTS CTS Selection Specifies how RTS and CTS are used to control the data flow. RTS is con- trolled by the Scanner and can be continuously held high/low, or can be asserted during label transmission. The scanner looks at CTS, as the con- figuration values state, to determine when to send label data. - Page 139 Single Cable RS-232 Options Single Cable RS-232 RTS CTS Selection — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RTS CTS SELECTION = OPTION 2 RTS CTS SELECTION = OPTION 3 5-91 Product Reference Guide...

- Page 140 Programming Single Cable RS-232 RTS CTS Selection — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. RTS CTS SELECTION = OPTION 4 RTS CTS SELECTION = OPTION 5 5-92 ®...

-

Page 141: Single Cable Rs-232 Use Bcc

Single Cable RS-232 Options Single Cable RS-232 Use BCC Enables/disables the ability of the scanner to use BCC. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 142: Single Cable Rs-232 Use Ack/Nak

Programming Single Cable RS-232 Use ACK/NAK Enables/disables the ability of the scanner to use ACK/NAK. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 143: Single Cable Rs-232 Use Stx

Single Cable RS-232 Options Single Cable RS-232 Use STX Enables/disables the ability of the scanner to use STX. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 144: Set Single Cable Rs-232 Stx Character

Programming Set Single Cable RS-232 STX Character This feature selects the STX character. To specify the STX Character: 1. Scan the SWITCH bar code. 2. Scan the bar code, SET SINGLE CABLE RS-232 STX CHARACTER below. You’ll need to cover any unused bar codes on this and the fac- ing page to ensure the scanner reads only the bar code you intend to scan. -

Page 145: Single Cable Rs-232 Use Etx

Single Cable RS-232 Options Single Cable RS-232 Use ETX Enables/disables the ability of the scanner to use ETX. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 146: Set Single Cable Rs-232 Etx Character

Programming Set Single Cable RS-232 ETX Character Allows selection of the ETX character. To specify the ETX Character: 1. Scan the SWITCH bar code. 2. Scan the bar code, SET SINGLE CABLE RS-232 ETX CHARACTER below. You’ll need to cover any unused bar codes on this and the fac- ing page to ensure the scanner reads only the bar code you intend to scan. -

Page 147: Pc Keyboard Wedge And Usb Keyboard Interfaces

PC Keyboard Wedge and USB Keyboard Interfaces PC Keyboard Wedge and USB Keyboard Interfaces This section contains the following PC Keyboard Wedge and USB Key- board Interface parameters in the order listed: • Connect to a Laptop/No Keyboard Attached (PC Keyboard Wedge ONLY) •... -

Page 148: Connect To A Laptop/No Keyboard Attached

Programming Connect to a Laptop/No Keyboard Attached This feature applies to PC Keyboard Wedge ONLY. NOTE If no keyboard is attached, the scanner must provide the acknowledge sig- nal to the PC. In this case, enable the "Laptop/No External Keyboard" mode. - Page 149 PC Keyboard Wedge and USB Keyboard Interfaces Send Control/Function Characters Options for this feature are: Send Control Characters — transmits all ASCII characters except NUL (00h) . Disable Control Characters — disabling this feature limits transmis- sion of ASCII characters to the following: •...

-

Page 150: Send Control/Function Characters - Continued

Programming Send Control/Function Characters — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. DISABLE CONTROL CHARACTERS SEND FUNCTION CHARACTER 5-102 ®... - Page 151 PC Keyboard Wedge and USB Keyboard Interfaces Caps Lock Three caps lock settings are available. These are: Caps Lock Off — •sends character data to the host in normal format. Caps Lock On — •sends character data to the host in reverse case (a.z) = (A.Z) (A.Z) = (a.z) Use this feature if your keyboard's caps lock key is on.

-

Page 152: Caps Lock - Continued

Programming Caps Lock — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. CAPS LOCK: CAPS LOCK = SHIFT LOCK 5-104 ®... - Page 153 PC Keyboard Wedge and USB Keyboard Interfaces Country Mode The following country/languages can be selected when configured for wedge I/F Type E or USB Keyboard: • USA • France • Portugal • Japanese 106-Key • Belgium • Germany • Spain •...

-

Page 154: Country Mode - Continued

Programming Country Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. COUNTRY MODE: BRITAIN COUNTRY MODE: DENMARK 5-106 ® Magellan 2200VS and 2300HS... -

Page 155: Country Mode — Continued

PC Keyboard Wedge and USB Keyboard Interfaces Country Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. COUNTRY MODE: FRANCE COUNTRY MODE: GERMANY 5-107 Product Reference Guide... -

Page 156: Country Mode - Continued

Programming Country Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. COUNTRY MODE: ITALY COUNTRY MODE: NORWAY 5-108 ® Magellan 2200VS and 2300HS... -

Page 157: Country Mode - Continued

PC Keyboard Wedge and USB Keyboard Interfaces Country Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. COUNTRY MODE: PORTUGAL COUNTRY MODE: SPAIN 5-109 Product Reference Guide... -

Page 158: Country Mode - Continued

Programming Country Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. COUNTRY MODE: SWEDEN COUNTRY MODE: SWITZERLAND 5-110 ® Magellan 2200VS and 2300HS... -

Page 159: Country Mode - Continued

PC Keyboard Wedge and USB Keyboard Interfaces Country Mode — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. COUNTRY MODE: JAPANESE 106-KEY 5-111 Product Reference Guide... - Page 160 Programming Keyboard Wedge Intercharacter Delay This feature applies to PC Keyboard Wedge ONLY. NOTE Intercharacter Delay refers to the pause, if any, between each character before it is sent to the host. This time delay is used to control the flow of data from the scanner.

-

Page 161: Keyboard Wedge Intercharacter Delay - Continued

PC Keyboard Wedge and USB Keyboard Interfaces Keyboard Wedge Intercharacter Delay — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. KEYBOARD WEDGE INTERCHARACTER DELAY = 20 MILLISECONDS KEYBOARD WEDGE INTERCHARACTER DELAY = 30 MILLISECONDS 5-113... -

Page 162: Keyboard Wedge Intercharacter Delay — Continued

Programming Keyboard Wedge Intercharacter Delay — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. KEYBOARD WEDGE INTERCHARACTER DELAY = 40 MILLISECONDS KEYBOARD WEDGE INTERCHARACTER DELAY = 60 MILLISECONDS 5-114 ®... -

Page 163: Keyboard Wedge Intercharacter Delay - Continued

PC Keyboard Wedge and USB Keyboard Interfaces Keyboard Wedge Intercharacter Delay — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. KEYBOARD WEDGE INTERCHARACTER DELAY = 80 MILLISECONDS KEYBOARD WEDGE INTERCHARACTER DELAY = 100 MILLISECONDS 5-115... - Page 164 Programming Quiet Interval This feature applies to PC Keyboard Wedge ONLY. NOTE Quiet Interval is the amount of time to look for keyboard activity before the scanner breaks the keyboard connection in order to transmit data to the host. QUIET INTERVAL = 10 MILLISECONDS QUIET INTERVAL = 20 MILLISECONDS 5-116 ®...

-

Page 165: Quiet Interval - Continued

PC Keyboard Wedge and USB Keyboard Interfaces Quiet Interval — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. QUIET INTERVAL = 50 MILLISECONDS QUIET INTERVAL = 100 MILLISECONDS 5-117 Product Reference Guide... -

Page 166: Quiet Interval — Continued

Programming Quiet Interval — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. QUIET INTERVAL = 200 MILLISECONDS QUIET INTERVAL = 500 MILLISECONDS 5-118 ®... -

Page 167: Quiet Interval - Continued

PC Keyboard Wedge and USB Keyboard Interfaces Quiet Interval — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. QUIET INTERVAL = ONE SECOND 5-119 Product Reference Guide... -

Page 168: Symbology Programming

Programming Symbology Programming If the scanner’s interface type must be changed, always be sure that interface configuration is the FIRST item scanned during a program- ming session. (Changing an interface type resets ALL other configura- tion items — including symbology programming — to the factory default NOTE for that interface type.) UPC-A Enable... -

Page 169: Upc-A Number System Character Transmission

UPC-A Enable UPC-A Number System Character Transmission Enables/disables transmission of a UPC-A number system character. This feature MUST be enabled for IBM interfaces for proper function. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. -

Page 170: Upc-A Check Character Transmission

Programming UPC-A Check Character Transmission Enables/disables transmission of a UPC-A check character. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 171: Expand Upc-A To Ean-13

UPC-A Enable Expand UPC-A to EAN-13 Enables/disables expansion of UPC-A labels to EAN/JAN-13. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 172: Upc/Ean Aim Id

Programming UPC/EAN AIM ID This feature enables/disables transmission of the UPC/EAN AIM symbol- ogy identifier. To set this feature: 1. Scan the SWITCH bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 173: Upc-A Label Id

UPC-A Enable UPC-A Label ID This feature specifies a UPC-A label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 174: Upc-A 2-Digit Supplemental Label Id

Programming UPC-A 2-Digit Supplemental Label ID This feature specifies a UPC-A 2-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 175: Upc-A 5-Digit Supplemental Label Id

UPC-A Enable UPC-A 5-Digit Supplemental Label ID This feature specifies a UPC-A 5-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 176: Upc-A 128 Supplemental Label Id

Programming UPC-A 128 Supplemental Label ID This feature specifies a UPC-A 128 Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 177: Upc-E Enable

UPC-E Enable UPC-E Enable Enables/disables the ability of the scanner to decode UPC-E labels. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 178: Upc-E Number System Character Transmission

Programming UPC-E Number System Character Transmission Enables/disables transmission of a UPC-E number system character. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 179: Upc-E Check Character Transmission

UPC-E Enable UPC-E Check Character Transmission Enables/disables transmission of a UPC-E check character. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 180: Expand Upc-E To Upc-A

Programming Expand UPC-E to UPC-A Enables/disables expansion of UPC-E labels to UPC-A. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 181: Expand Upc-E To Ean-13

UPC-E Enable Expand UPC-E to EAN-13 Enables/disables expansion of UPC-E labels to EAN/JAN-13. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 182: Upc-E Label Id

Programming UPC-E Label ID This feature specifies a UPC-E label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 183: Upc-E 2-Digit Supplemental Label Id

UPC-E Enable UPC-E 2-Digit Supplemental Label ID This feature specifies a UPC-E 2-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 184: Upc-E 5-Digit Supplemental Label Id

Programming UPC-E 5-Digit Supplemental Label ID This feature specifies a UPC-E 5-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 185: Upc-E 128 Supplemental Label Id

UPC-E Enable UPC-E 128 Supplemental Label ID This feature specifies a UPC-E 128 Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 186: Enable

Programming EAN-13 Enable Enables/disables the ability of the scanner to decode EAN/JAN-13 labels. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 187: First Character Transmission

EAN-13 Enable EAN-13 First Character Transmission Enables/disables transmission of EAN/JAN-13 first character. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 188: Check Character Transmission

Programming EAN-13 Check Character Transmission Enables/disables transmission of an EAN/JAN-13 check character. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 189: Isbn Conversion Enable

EAN-13 Enable EAN-13 ISBN Conversion Enable Enables/disables conversion of EAN/JAN-13 labels starting with 978 to Bookland ISBN labels. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 190: Ean 13 Label Id

Programming EAN 13 Label ID This feature specifies an EAN 13 label ID to be added to bar code data. To set this feature: The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 191: 2-Digit Supplemental Label Id

EAN-13 Enable EAN-13 2-Digit Supplemental Label ID This feature specifies an EAN-13 2-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 192: 5-Digit Supplemental Label Id

Programming EAN-13 5-Digit Supplemental Label ID This feature specifies an EAN-13 5-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 193: 128 Supplemental Label Id

EAN-13 Enable EAN-13 128 Supplemental Label ID This feature specifies an EAN-13 128 Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 194: Bookland Aim Id

Programming Bookland AIM ID This feature enables/disables transmission of the Bookland AIM symbol- ogy identifier. To set this feature: 1. Scan the SWITCH bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 195: Bookland Label Id

EAN-13 Enable Bookland Label ID This feature specifies a Bookland label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 196: Enable

Programming EAN-8 Enable Enables/disables the ability of the scanner to decode EAN/JAN-8 labels. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 197: Check Character Transmission

EAN-8 Enable EAN-8 Check Character Transmission Enables/disables transmission of an EAN/JAN-8 check character. This item is ignored when the advanced feature, Full Label Edit, is enabled. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 198: Expand Ean-8 To Ean-13

Programming Expand EAN-8 to EAN-13 Enables/disables expansion of EAN/JAN-8 labels to EAN/JAN-13. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 199: Ean 8 Label Id

EAN-8 Enable EAN 8 Label ID This feature specifies an EAN 8 label ID to be added to bar code data. To set this feature: The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 200: 2-Digit Supplemental Label Id

Programming EAN-8 2-Digit Supplemental Label ID This feature specifies an EAN-8 2-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 201: 5-Digit Supplemental Label Id

EAN-8 Enable EAN-8 5-Digit Supplemental Label ID This feature specifies an EAN-8 5-Digit Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 202: 128 Supplemental Label Id

Programming EAN-8 128 Supplemental Label ID This feature specifies an EAN-8 128 Supplemental label ID to be added to bar code data. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 203: Decoding Levels

EAN-8 Enable EAN-8 Decoding Levels Decoding levels allow the decoder to be set to perform at one of four selectable levels: • Very Conservative — Slower scan time, virtually eleminates mis- reads. The most secure setting. • Slightly More Aggressive — Faster scanning, more aggressive, yet minimizes misreads. - Page 204 Programming EAN-8 Decoding Levels — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. EAN-8 DECODING LEVELS = VERY CONSERVATIVE EAN-8 DECODING LEVELS = SLIGHTLY MORE AGGRESSIVE 5-156 ®...

- Page 205 EAN-8 Enable EAN-8 Decoding Levels — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. EAN-8 DECODING LEVELS = MODERATELY AGGRESSIVE EAN-8 DECODING LEVELS = VERY AGGRESSIVE 5-157 Product Reference Guide...

-

Page 206: Other Upc/Ean Options

Programming Other UPC/EAN Options The following pages contain other selectable features for UPC/EAN sym- bologies: • UPC/EAN Reconstruction • Price Weight Check • Enable EAN Two Label • Addons • UPC-A and EAN-13 Decoding Levels 5-158 ® Magellan 2200VS and 2300HS... -

Page 207: Upc/Ean Reconstruction

Other UPC/EAN Options UPC/EAN Reconstruction Enables/disables the ability of the scanner to decode a class of UPC/EAN labels with voids. The label voids may be caused by printing defects or physical damage. This feature may be helpful in environments with in- store printed labels. -

Page 208: Price Weight Check

Programming Price Weight Check Enables/disables calculation and verification of price/weight check digits. Applies to all UPC-A and EAN/JAN-13 labels with eligible Number Sys- tem/First Character digits. Options are: • Disable • 4-digit price/weight • 5-digit price/weight • 4-digit European price/weight •... - Page 209 Other UPC/EAN Options Price Weight Check — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. PRICE WEIGHT CHECK = 4-DIGIT PRICE/WEIGHT PRICE WEIGHT CHECK = 5-DIGIT PRICE/WEIGHT 5-161 Product Reference Guide...

- Page 210 Programming Price Weight Check — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. PRICE WEIGHT CHECK = 4-DIGIT EUROPEAN PRICE/WEIGHT PRICE WEIGHT CHECK = 5-DIGIT EUROPEAN PRICE/WEIGHT 5-162 ®...

-

Page 211: Enable Ean Two Label

Other UPC/EAN Options Enable EAN Two Label Enables/disables the ability of the scanner to decode EAN two-label pairs. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 212: Addons

Programming Addons The scanner is capable of processing different types of addon codes, including: • 2-Digit Supplemental • 5-Digit Supplemental Options are provided on the following pages for your convenience: • Disable all addons — The scanner will not look for or read addons. •... - Page 213 Other UPC/EAN Options Addons — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. ADDONS = OPTIONAL 2-DIGIT AND 5-DIGIT SUPPLEMENTAL 5-165 Product Reference Guide...

-

Page 214: Upc-A And Ean-13 Decoding Levels

Programming UPC-A and EAN-13 Decoding Levels Decoding levels allow the decoder to be set to perform at one of four selectable levels: • Very Conservative — Slower scan time, virtually eleminates mis- reads. The most secure setting. • Slightly More Aggressive — Faster scanning, more aggressive, yet minimizes misreads. - Page 215 Other UPC/EAN Options UPC-A and EAN-13 Decoding Levels — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. UPC-A/EAN-13 DECODING LEVELS = VERY CONSERVATIVE UPC-A/EAN-13 DECODING LEVELS = SLIGHTLY MORE AGGRESSIVE 5-167 Product Reference Guide...

- Page 216 Programming UPC-A and EAN-13 Decoding Levels — continued Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. UPC-A/EAN-13 DECODING LEVELS = MODERATELY AGGRESSIVE UPC-A/EAN-13 DECODING LEVELS = VERY AGGRESSIVE 5-168 ®...

-

Page 217: Gtin Enable

GTIN Enable GTIN Enable Enables/Disables the ability to convert UPCE, UPCA, EAN8, and EAN13 labels into the GTIN 14-character format. If add-on information is present on the base label prior to the conversion taking place, the add-on information will be appended to the converted GTIN bar code. -

Page 218: Gtin Label Id

Programming GTIN Label ID This feature specifies a GTIN label ID to be added to bar code data when GTIN conversion is enabled. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. NOTE To set this feature: 1. -

Page 219: Gtin 2-Digit Supplemental Label Id

GTIN Enable GTIN 2-Digit Supplemental Label ID This feature specifies a GTIN label ID to be added to bar code data when GTIN conversion is enabled and 2-digit supplemental addon bar code labels are converted. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 220: Gtin 5-Digit Supplemental Label Id

Programming GTIN 5-Digit Supplemental Label ID This feature specifies a GTIN label ID to be added to bar code data when GTIN conversion is enabled and 5-digit supplemental addon bar code labels are converted. The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 221: Gtin Code 128 Supplemental Label Id

GTIN Enable GTIN Code 128 Supplemental Label ID This feature specifies a GTIN label ID to be added to bar code data when GTIN conversion is enabled and Code 128 supplemental addon bar code labels are converted The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 222: Enable

Programming RSS-14 Enable Enables/disables the ability of the scanner to decode RSS-14 labels. This value-added feature is a factory-programmed option. Contact your dealer for information about upgrading your system to include this advanced capability. NOTE To set this feature: 1. Scan the SWITCH bar code. 2. -

Page 223: Check Character Transmission

RSS-14 Enable RSS-14 Check Character Transmission Enables/disables transmission of the RSS-14 check character. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 224: Rss-14/Ean-128 Emulation

Programming RSS-14/EAN-128 Emulation Enables/disables the ability of RSS-14 to be transmitted as EAN-128. To set this feature: 1. Scan the SWITCH bar code. 2. Scan either the enable or disable bar code below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 225: Component Enable

RSS-14 Enable RSS-14 2D Component Enable When this feature is enabled, the software will not decode an RSS-14 bar code with a 2D component associated with it, and the 2D component will be discarded. To set this feature: 1. Scan the SWITCH bar code. 2. -

Page 226: Aim Id

Programming RSS-14 AIM ID This feature enables/disables transmission of the RSS-14 AIM symbology identifier. To set this feature: 1. Scan the SWITCH bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 227: Label Id

RSS-14 Enable RSS-14 Label ID This feature specifies an RSS-14 label ID to be added to bar code data. To set this feature: The programming feature, RS-232 Label ID Control, designates whether the Label ID is transmitted as a prefix or suffix or if Label ID is disabled. -

Page 228: Rss Expanded Enable

Programming RSS Expanded Enable Enables/disables the ability of the scanner to decode RSS-Expanded labels. This value-added feature is a factory-programmed option. Contact your dealer for information about upgrading your system to include this advanced capability. NOTE To set this feature: 1. -