Subscribe to Our Youtube Channel

Summary of Contents for GreenWorks 41522

- Page 1 PANCAKE AIR COMPRESSOR 41522 Owner’s Manual TOLL-FREE HELPLINE: 1-888-90WORKS (888.909.6757) www.GreenWorksTools.com Read all safety rules and instructions carefully before operating this tool.

-

Page 2: Table Of Contents

CONTENTS Contents ..........................2 Product specifications......................2 General safety rules ......................3-8 Know your air compressor ...................... 9 Assembly instruction......................10-11 Operation ..........................12 Maintenance..........................13 Troubleshooting........................14-15 Warranty..........................16 Exploded View ........................17-18 Parts List..........................19-20 Notes ............................. 21 PRODUCT SPECIFICATIONS 6 GALLON PANCAKE COMPRESSOR Motor..........................Universal Running horsepower........................2HP Tank size........................6 U.S.GALLONS... -

Page 3: General Safety Rules

GENERAL SAFETY RULES IMPORTANT SAFETY INSTRUCTIONS W A R N I N G Do not operate this unit until you read and understand this instruction manual for safety, operation and maintenance instructions. HAZARD RISK OF EXPLOSION OR FIRE WHAT CAN HAPPEN HOW TO PREVENT IT well ventilated area free of within the motor and pressure... - Page 4 GENERAL SAFETY RULES WHAT CAN HAPPEN HOW TO PREVENT IT The compressed air directly from Air obtained directly from the your compressor is not safe for compressor should never be used to breathing. The air stream may supply air for human consumption. contain carbon monoxide, toxic In order to use air produced by this vapors, or solid particles from the...

- Page 5 GENERAL SAFETY RULES The following conditions could lead to a weakening of the air tank, and result in a violent air tank explosion: WHAT CAN HAPPEN HOW TO PREVENT IT Failure to properly drain condensed Drain air tank daily or after each water from air tank, causing rust use.

- Page 6 GENERAL SAFETY RULES RISK FROM FLYING OBJECTS WHAT CAN HAPPEN HOW TO PREVENT IT The compressed air stream can Always wear certified safety cause soft tissue damage to equipment: ANSI Z87 .1 eye exposed skin and can propel dirt, protection (CAN/CSA Z94.3) chips, loose particles, and small with side shields when using the objects at high speed, resulting in...

- Page 7 GENERAL SAFETY RULES RISK FROM MOVING PARTS WHAT CAN HAPPEN HOW TO PREVENT IT Moving parts such as the pulley, Never operate the compressor with guards or covers which are damaged flywheel, and belt can cause serious or removed. injury if they come into contact with Keep your hair, clothing,and gloves you or your clothing.

- Page 8 GENERAL SAFETY RULES RISK OF FALLING WHAT CAN HAPPEN HOW TO PREVENT IT A portable compressor can fall Always operate commpressor in a stable secure position to prevent from a table, workbench, or roof accidental movement of the unit. causing damage to the compressor Never operate compressor on a and could result in serious roof or other elevated position.

-

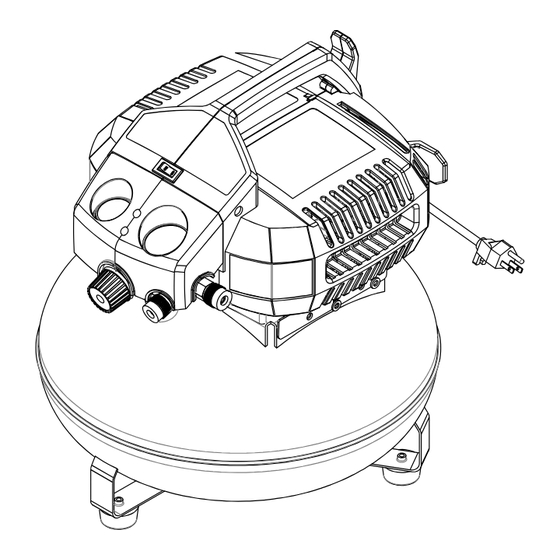

Page 9: Know Your Air Compressor

KNOW YOUR AIR COMPRESSOR The safe use of this product requires an understanding of the information on the tool and in this operator’s manual as well as a knowledge of the project you are attempting. Before use of this product, familiarize yourself with all operating features and safety rules. (See Fig. 1) Fig. -

Page 10: Assembly Instruction

ASSEMBLY INSTRUCTION ATTACHING AIR HOSE TO COMPRESSOR 1, Using your left hand push quick connect towards the body of the compressor. 2, Firmly press fit the male quick connect portion on the air hose into the female quick connect and release female quick connect locking hose in place. Fig. - Page 11 ASSEMBLY INSTRUCTION UNPACKING • This product requires assembly. W A R N I N G Do not use this product if any parts on the Packing List are already assembled to your product when you unpack it. Parts on this list are not assembled to the product by the manufacturer and require customer installation.

-

Page 12: Operation

OPERATION STARTUP 1. Before each startup,make sure the power switch is in the OFF position 2. Place air compressor on a flat,level surface. 3. Release pressure from the system. Drain moisture from the air tank by slowly opening the air tank drain valve by turning clockwise.Once all the moisture has drained out, close the fitting securely. -

Page 13: Maintenance

MAINTENANCE W A R N I N G Disconnect air compressor from power source and bleed off all air pressure before attempting any maintenance or repair. SHUTDOWN AND STORAGE: 1. Turn the switch to the OFF position 2. Turn the pressure regulator knob fully counterclockwise to close airflow from air outlet port. Check the outlet pressure gauge to ensure that it reads 0 PSI. -

Page 14: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSES SOLUTIONS The power cord is not plugged in. Plug the power cord into a grounded outlet. The power switch is in the 0 (off) Set the power switch to the I (on) position. position. Check Technical Specifications chapter(page 2) The extension cord is the wrong for the proper wire gauge and cord length. - Page 15 TROUBLESHOOTING PROBLEM POSSIBLE CAUSES SOLUTIONS regulator does The regulator or its internal parts Replace the regulator. not regulate are dirty or damaged. the pressure. There is a leak at one of the threads). Do not overtighten. The tank drain valve is open. Close the drain valve.

-

Page 16: Warranty

(1) year against defects in materials, parts or workmanship. GREENWORKS™, at its own discretion will repair or replace any and all parts found to be defective, through normal use, free of charge to the customer. This warranty is valid only for... -

Page 17: Exploded View

EXPLODED VIEW... - Page 18 EXPLODED VIEW...

-

Page 19: Parts List

PARTS LIST ITEM NO. PART NO. DESCRIPTION 3220150-2 bolt 33302531-5 housing pinch plate 34202531 pinch plate pad 3220203 screw ST3x12-C 34102753 left housing 3220515 bolt M4x8 3290651 internal-tooth washer 5 33302754 palte 32202497 bolt 31101116 6 gallon air compressor motor&pump assy . 3220323 bolt ST4×10-F 3750175... - Page 20 PARTS LIST ITEM NO. PART NO.D ESCRIPTIONQ clamp 8 10.1 329065 34101116 motor fan 10.2 6G air compressor moto r 10.3 36103116 32905302A shaft clamp 12 10.4 bearing 6201-2RS 10.5 3210275-1 bracket 10.6 33101116 bearing 6203-2RS 10.7 3210175-1 timing belt 10.8 3420675-4 10.9...

-

Page 21: Notes

NOTES... - Page 22 TOLL-FREE HELPLINE: 1-888-90WORKS (888.909.6757) Rev: 00 (10-02-13) Printed in China on 100% Recycled Paper...

Need help?

Do you have a question about the 41522 and is the answer not in the manual?

Questions and answers