Advertisement

Quick Links

For use with machines having Code Number:

This manual covers equipment which is no

longer in production by The Lincoln Electric Co.

Speci cations and availability of optional

features may have changed.

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

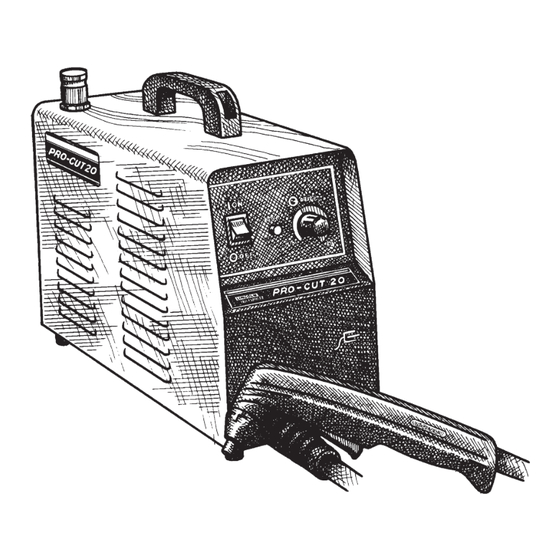

PRO-CUT

10464

THIS

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

20

TM

IM594

May, 2000

Advertisement

Summary of Contents for Lincoln Electric Pro-cut 20

- Page 1 May, 2000 10464 For use with machines having Code Number: This manual covers equipment which is no longer in production by The Lincoln Electric Co. Speci cations and availability of optional features may have changed. Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind.

-

Page 2: Electric Shock Can Kill

SAFETY WARNING PLASMA CUTTING or GOUGING can be hazardous. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING. Read and understand the following safety highlights. For additional safety information it is strongly recommended that you pur- chase a copy of “Safety in Welding &... - Page 3 SAFETY 4.g. Sparks and spatter are thrown from the plasma arc. Wear PLASMA ARC can injure. safety glasses, ear protection and oil free protective garments such as leather gloves, heavy shirt, cuffless trousers, high shoes and a cap over your hair. Wear ear plugs when cutting or gouging out of position or in confined places.

- Page 4 SAFETY zones où l’on pique le laitier. PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de Pour votre propre protection lire et observer toutes les instructions prévenir tout risque d’incendie dû aux étincelles. et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté...

- Page 5 QUALITY product by Lincoln Electric. We want you Thank You to take pride in operating this Lincoln Electric Company product ••• as much pride as we have in bringing this product to you! Please Examine Carton and Equipment For Damage Immediately When this equipment is shipped, title passes to the purchaser upon receipt by the carrier.

-

Page 6: Table Of Contents

General Options / Accessories ................C-1 Maintenance ....................Section D Safety Precautions ....................D-1 Routine Maintenance.....................D-1 Periodic Maintenance ....................D-1 Troubleshooting ....................Section E Safety Precautions....................E-1 How to Use Troubleshooting Guide...............E-1 Troubleshooting Guide ..................E-2 Wiring Diagrams ....................Section F Wiring Diagram ......................F-1 Parts Lists ......................Appendix PRO-CUT 20 ...................P310 Series Torch........................P210-L... -

Page 7: Installation

INSTALLATION TECHNICAL SPECIFICATIONS - PRO-CUT 20 (K1579-1) INPUT - SINGLE PHASE / 60 HERTZ ONLY Standard Voltage 1Ø Input Current at Rated Output 115/230/1/60Hz 115: 34A@20% 230: 18A@20% RATED OUTPUT Duty Cycle AMPS VOLTS 20% Duty Cycle OUTPUT Current Open Circuit... -

Page 8: Safety Precautions

A source of clean, dry air or nitrogen must be supplied INPUT ELECTRICAL to the Pro-Cut 20. Oil in the air is a severe problem CONNECTIONS and must be avoided. The supply pressure must be between 80 and 150 psi. The flow rate is approximate- The Pro-Cut 20 is rated for 115VAC or 230VAC inputs ly 4.0 cfm (113 l/min.). -

Page 9: Gas Input Connections

Torch • Supply pressure must be between 80 psi and 150 psi. The Pro-Cut 20 is sent from the factory with a PCT 20 cutting torch installed. Additional cutting torches can • Flow rate should be approximately 4.0 be ordered from the K1615 series. Hand-held torches cfm (113 I/min.). -

Page 10: Operation

FUMES AND GASES can be dangerous. The Pro-Cut 20 initiates the plasma arc with a simple, • Keep your head out of fumes. yet reliable, touch start mechanism. This system elimi- nates many of the failure problems associated with hi- •... -

Page 11: User Responsibility

CONTROLS - Latching Parts-in-Place mechanism. Requires the operator to turn the machine off and then on to The PRO-CUT 20 comes with an ON/OFF POWER reset. SWITCH, OUTPUT CURRENT CONTROL, and PURGE BUTTON. - Preflow/Postflow timing. Preflow is eliminated if arc DESIGN FEATURES AND is re-initiated in Postflow. -

Page 12: Cutting Capability

CUTTING CAPABILITY The PRO-CUT 20 is rated at 20 amps, at 20% duty cycle on a 10 minute basis. If the duty cycle is exceeded, a thermal protector will shut off the output of the machine until it cools to the normal operating temperature. -

Page 13: Limitations

Do not exceed output current and duty cycle rating of - Adjust the gas regulator for 65 PSI for 15’ or 25’ machine. Do not use the PRO-CUT 20 for pipe thaw- torches. ing. -

Page 14: Pilot Arc Discussion

The maximum wear depth of the elec- trode is approximately .062”. A green and erratic arc will indicate definite electrode failure and the electrode should be replaced immediately. • Replace the nozzle when the orifice exit is eroded away or oval shaped. PRO-CUT 20... -

Page 15: Procedure Recommendations

PRO-CUT System: age to the torch or reduce cut quality. WARNING ELECTRIC SHOCK CAN KILL. • Turn off machine at the disconnect switch on the front of the machine before tightening, cleaning or replacing consumables. ---------------------------------------------------------------------------- PRO-CUT 20... -

Page 16: Accessories

ACCESSORIES VORTECH™ NOZZLES The following options/accessories are available for your PRO-CUT 20 from your local Lincoln Distributor. • Only Genuine Lincoln Electric consumables yield the best cutting performance for the PRO-CUT 20. S22147-028 - VORTECH™ nozzle with an .028” (0.7 •... -

Page 17: Maintenance

- Printed circuit boards and heat sinks REPLACEMENT OF INTERNAL FUSES - Power switch The Pro-Cut 20 has additional protection provided to 3. Examine the sheet metal case for dents or break- some circuits through internal fuses. For replacement age. Repair the case as required. Keep the case in... -

Page 18: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 19 3. Possible faulty Control board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PRO-CUT 20...

-

Page 20: Torch

4. Possible faulty Control board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PRO-CUT 20... - Page 21 65 psi. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PRO-CUT 20...

- Page 22 5. Possible faulty Control board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. PRO-CUT 20...

- Page 23 Remove any foreign material that may block air flow. Blow the machine out with a clean, dry air stream. 3. The input voltage is not within ±10% of rated values. 4. Possible faulty Control board. PRO-CUT 20...

- Page 24 DIAGRAMS PRO-CUT 20...

- Page 25 Year AMERICAN EXPRESS USE THIS FORM TO ORDER: Order from: BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199 for fastest service, FAX this completed form to: 216-361-5901 BOOKS OR FREE INFORMATIVE CATALOGS Telephone: 216-383-2211 or,...

- Page 26 ● ● ● Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. ● Insulate yourself from work and ground. Spanish ● ● ● No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE...

- Page 27 ● ● ● Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or ● WARNING Use ventilation or exhaust to guards off. remove fumes from breathing zone. ● Spanish Los humos fuera de la zona de res- ●...

- Page 28 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the Pro-cut 20 and is the answer not in the manual?

Questions and answers