Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Alpha Technologies AlphaGen DCX2000

-

Page 1: Operation Manual

AlphaGen DCX2000 36VDC Portable Generator Operation Manual Effective: June 2014... -

Page 2: Safety Notes

Safety Notes Review the drawings and illustrations contained in this manual before proceeding. If there are any questions regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha representative. Save this document for future reference. - Page 3 NOTICE: Review this manual before proceeding. If there are questions regarding the safe installation or operation of this product, please contact Alpha Technologies or your nearest Alpha representative. Contacting Alpha Technologies: www.alpha.com For general product information and customer service (7 AM to 5 PM, Pacific Time), call...

-

Page 4: Table Of Contents

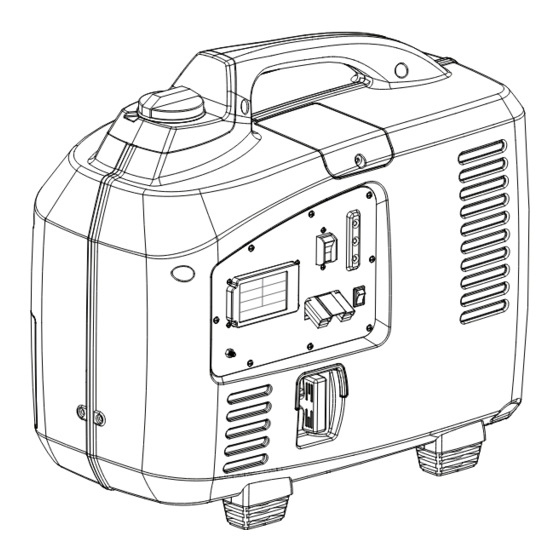

Table of Contents DCX2000 Portable Generator Safety Notes ......................6 Introduction ............................... 7 DCX2000 Generator Components ....................7 Operation ..............................9 Oil Level ............................9 Fuel Level ........................... 10 Air Cleaner ..........................11 Power System Connections ......................12 2.4.1 Y-Style Connection ......................12 2.4.2 Ring Lug Style Connection .................... - Page 5 Figures & Tables Fig. 1-1, DCX2000 Generator Components ......................7 Fig. 1-2, Engine Serial Number ..........................8 Fig. 2-1, Oil Level ..............................9 Fig. 2-2, Checking Fuel Level ..........................10 Fig. 2-3, Checking Air Cleaner..........................11 Fig. 2-4, Y-Style Connection ..........................12 Fig.

-

Page 6: Dcx2000 Portable Generator Safety Notes

DCX2000 Portable Generator Safety Notes The manufacturer cannot anticipate every circumstance that may involve a hazard, therefore, these warnings are not comprehensive. WARNING! FUMES HAZARD • Engine exhaust contains carbon monoxide gas, which can be deadly in closed or poorly ventilated areas. -

Page 7: Introduction

Introduction The Alphagen DCX2000 portable DC generator supplies DC voltage to a power supply battery bus when commercial AC power is not available. The generator is designed to be temporarily connected to the DC bus of a standard Alpha 36V uninterruptable power supply (UPS). Upon loss of commercial AC power, the existing batteries immediately supply the power supply inverters. -

Page 8: Fig. 1-2, Engine Serial Number

Introduction, continued DCX2000 Generator Components, continued The engine serial number is stamped on the engine block (remove maintenance panel). 11085603 Serial Number Fig. 1-2, Engine Serial Number 041-135-B0-001 Rev. A1 (06/2014) -

Page 9: Operation

Operation 2.1 Oil Level WARNING! ELECTRICAL HAZARD Power OFF the generator engine and place on a level surface before servicing. CAUTION! • Using non-detergent oil or 2-stroke engine oil will shorten service life and void the warranty. Use only high-detergent, premium quality, 4-stroke engine oil, certified to meet U.S. automobile manufacturer’s requirements for API Service Classification SG/SF/SJ/SL/SM/SN. -

Page 10: Fuel Level

Operation, continued 2.2 Fuel Level WARNING! FIRE & FUMES HAZARD Gasoline is extremely flammable and can be explosive. Refuel in a well-ventilated area with the engine OFF. Keep all smoking materials, sparks, and other sources of combustion away from the generator during refueling. The area must be free of spilled fuel before starting the engine. -

Page 11: Air Cleaner

Operation, continued 2.3 Air Cleaner CAUTION! Never run the engine without the air cleaner element in place. Rapid engine wear will result from contaminants entering through the carburetor into the engine. Tools Required: #2 Philips Head Screwdriver Procedure: 1. Remove the maintenance cover. 2. -

Page 12: Power System Connections

Operation, continued Power System Connections 2.4.1 Y-Style Connection ALM/ STRG A OUTPUT STRG B FLASH = MIN ALM STRG C ALARM SOLID = MAJ ALM STRG D TEST Rx/Tx PWR GRN = OK BLUE = WARN RED = OUT L R I BATTERY TEMP BATTERY... -

Page 13: Ring Lug Style Connection

Operation, continued Power System Connections, continued 2.4.2 Ring Lug Style Connection ALM/ STRG A OUTPUT STRG B FLASH = MIN ALM STRG C ALARM SOLID = MAJ ALM STRG D TEST Rx/Tx PWR GRN = OK BLUE = WARN RED = OUT L R I BATTERY TEMP... -

Page 14: Alligator Clamp Style Connection

Operation, continued Power System Connections, continued 2.4.3 Alligator Clamp Style Connection ALM/ STRG A OUTPUT STRG B FLASH = MIN ALM STRG C ALARM SOLID = MAJ ALM STRG D TEST Rx/Tx PWR GRN = OK BLUE = WARN RED = OUT L R I BATTERY TEMP... -

Page 15: Start-Up

Operation, continued 2.5 Start-Up Before starting the engine, verify the output circuit breaker is in the OFF position. Procedure: 1. Connect output cable to the generator’s DC output connection and the power supply. 2. Turn the fuel valve to the ON position. If the fuel tank was just filled, pump the fuel primer bulb 7 times to get fuel to the carburetor. -

Page 16: Operation At High Altitude

Operation, continued 2.6 Operation at High Altitude The standard carburetor air-fuel mixture will be excessively rich at high altitudes. This will decrease performance and increase fuel consumption. High altitude performance can be improved by installing a smaller diameter main fuel jet in the carburetor. If you always operate the generator at altitudes higher than 5000 feet (1500 m) above sea level, have an authorized Alpha Service Center install a high altitude main jet. -

Page 17: Output, Alarm And Oil Leds

Operation, continued 2.9 Output, Alarm and Oil LEDs CAUTION! Before connecting or reconnecting a power supply to the generator, check that it is in good condition and that its electrical rating does not exceed that of the generator. Use Fig. 2-10 and Table 2-1 to understand the different LED states of the generator. LCD Display ALARM OUTPUT... -

Page 18: Servicing

Servicing The maintenance schedule (Section 3.2, Maintenance Schedule) maintains the generator in peak operating condition. The oil should be changed between the first 4 to 6 hours of operation to remove any manufacturing debris or contamination. WARNING! FUMES HAZARD The exhaust contains poisonous carbon monoxide gas. Shut off the engine before performing any maintenance. -

Page 19: Fig. 3-1, Air Quality Index Label

Servicing, continued Emission Control System, continued Replacement Parts and Accessories The parts making up the emission control system have been specifically approved and certified by the regulatory agencies. Replacement parts supplied by Alpha have been manufactured to the same production standard as the original parts. The use of replacement parts or accessories which are not designed by Alpha may affect the engine emission performance. -

Page 20: Maintenance Schedule

Servicing, continued 3.2 Maintenance Schedule Regular Service period. Perform at every indicated month or operating hour interval, whichever occurs first. Maintenance Item 1st Month Every 3 Months Every 6 Months Once per Year Procedure Each Use 4 to 6 Hours 50 Hours 100 Hours 300 Hours... -

Page 21: Changing Oil

Servicing, continued 3.3 Changing Oil WARNING! BURN HAZARD Engine oil is HOT! Avoid contact with skin and clothing. CAUTION! Switch the engine OFF before draining the oil. Recommended oil is synthetic SAE 15W-40 when ambient temperature is above 32° F (0° C). Synthetic SAE 0W-40 is recommended if operating temperatures are below 32°... -

Page 22: Air Cleaner Service

Servicing, continued 3.4 Air Cleaner Service WARNING! FIRE HAZARD Do not use gasoline or low flash point solvents for cleaning. They are flammable and explosive under certain conditions. CAUTION! Never run the generator without the air cleaner, otherwise rapid engine wear may result. A dirty air cleaner will restrict air flow to the carburetor. -

Page 23: Spark Plug Maintenance

Servicing, continued 3.5 Spark Plug Maintenance To ensure proper engine operation, the spark plug must be in good repair and properly gapped. Replace and properly gap the spark plug per the following procedure. Tools Required: #2 Philips Head Screwdriver A7RTC Resistor-type Spark Plug Procedure: 1. -

Page 24: Spark Arrestor Maintenance

Servicing, continued 3.6 Spark Arrestor Maintenance CAUTION! If the generator has been running, the muffler will be very hot. Allow it to cool before proceeding. NOTICE: The spark arrestor must be serviced every 100 hours to maintain its efficiency. Tools Required: #2 Philips Head Screwdriver Procedure: 1. -

Page 25: Transport And Storage Instructions

Transport and Storage Instructions 4.1 Transporting the Generator When transporting the generator, it should always be secured upright in its normal operating position with the fuel valve and engine switch turned OFF. WARNING! FIRE & FUMES HAZARD When transporting the generator, do not overfill the tank, and do not operate the generator while it is on or in a vehicle. -

Page 26: Long Term Storage

Transport and Storage Instructions, continued 4.4 Long Term Storage WARNING! FIRE HAZARD Gasoline is extremely flammable and explosive under certain conditions. Do not smoke or allow flames or sparks in the area. 1. Be sure the storage area is free of excessive humidity and dust. 2. -

Page 27: Troubleshooting

Troubleshooting Description of Problem Corrective Action Engine will not start Low or empty fuel tank Refuel the fuel tank Engine and/or fuel switch off Turn the engine switch and fuel switch ON Low or empty oil tank Add recommended oil No spark from spark plug Replace spark plug Engine still does not start... -

Page 28: Specifications

Specifications DCX2000 Portable Generator Specifications Generator Model DCX2000-36 Rated Voltage (VDC) 39.5 Rated Current (A) 50.6 Max Current (A) 62.5A Rated Output (W) 2000 Max Output (W) 2200 Engine Model XG-152F Type 4 stroke, vertical shaft, air-cooled, OHC, gasoline engine Displacement 125 cc Compression Ratio... -

Page 29: Warranty Information

7.1 California Emissions Control Warranty Statement Warranty Rights and Obligations The California Air Resources Board (CARB) and Alpha Technologies, Inc. have established the following emissions control system warranty on 2008 and later small off-road engines (SORE). In California, new SOREs must be designed, built, and equipped to meet the State’s stringent anti-smog standards. Alpha must warrant the emissions control system on SOREs for the periods of time listed below provided there has been no abuse, neglect or improper maintenance of the SOREs. -

Page 30: Emission Control System Warranty

Warranty Information, continued 7.2 Emission Control System Warranty The generator engine complies with U.S. Environmental Protection Agency, Environment of Canada, and the state of California (if the model is certified by CARB). The following systems and/or parts are covered by this warranty. Failures or improper operation of the following systems and components will be diagnosed and repaired with no charge for labor or parts. - Page 32 Tel: +357 25 375 675 Fax: +357 25 359 595 Visit us at www.alpha.com Due to continuing product development, Alpha Technologies reserves the right to change specifications without notice. Copyright 2014 Alpha Technologies. All Rights Reserved. Alpha is a registered trademark of Alpha Technologies.

Need help?

Do you have a question about the AlphaGen DCX2000 and is the answer not in the manual?

Questions and answers