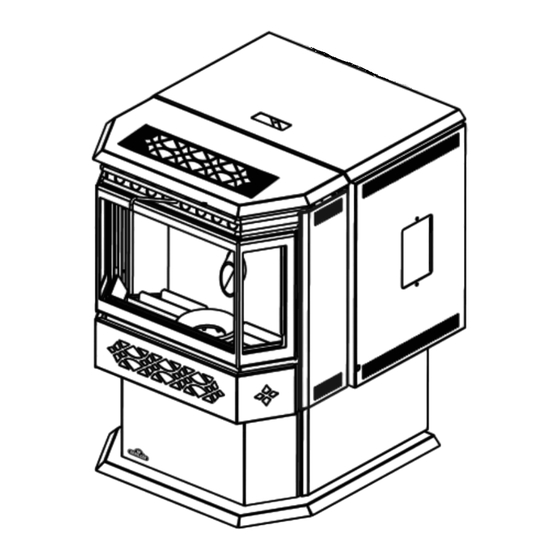

Napoleon NPS40 Installation And Operating Insctructions

Hide thumbs

Also See for NPS40:

- Installation and operating instructions manual (44 pages) ,

- Installation and operating instruction (36 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Napoleon NPS40

- Page 1 W415-0616 / E / 10.08.08 $10.00 W415-0616 / E / 10.08.08...

-

Page 2: Table Of Contents

TABLE OF CONTENTS IntroductIon WARNINGS & SAFETY PRECAUTIONS WARRANTY dImENSIONS 1.3.1 NPS40 1.3.2 NPI40 COmPlETE WITh NI800 FlAShING 1.3.3 NPI40 COmPlETE WITh Ak9 AdAPTER ANd CISk FlAShING 1.3.4 NPI40 COmPlETE WITh Ak8 AdAPTER ANd GICSk FlAShING INSTAllATION OvERvIEW General InformatIon... - Page 3 IN ThE EvENT OF A jAmmEd AUGER 10.0 normal operatInG sounds 11.0 WIrInG dIaGram 12.0 replacements 12.1 COmmON REPlACEmENT PARTS 12.2 NPS40 REPlACEmENT PARTS 12.3 NPI40 REPlACEmENT PARTS 12.4 COmmON ACCESSORY PARTS 12.5 NPI40 ACCESSORY PARTS 13.0 troubleshootInG 14.0 servIce and maIntenance loG 15.0...

-

Page 4: Introduction

1.0 INTROdUCTION WARNINGS & SAFETY PRECAUTIONS Do Not operate the heater if you smell Before installing this heater, contact smoke coming from the heater. Turn the local building or fire authority and the Pellet Feed dial to “OFF”, monitor follow their guidelines. Notify your your heater, and call a trained insurance company of this heater as technician... - Page 5 This heater must be connected to a During a power outage this heater will standard 115 V., 60Hz grounded not operate. If a power outage does electrical outlet. Do not use an occur, check the heater for smoke adapter plug or sever the grounding spillage and open a window if any prong.

-

Page 6: Warranty

NAPOLEON® reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty claim. All specifications and designs are subject to change without prior notice due to on-going product improvements. NAPOLEON® is a registered trademark of wolf steel ltd. Patents U.S. 5.303.693.801 - can. -

Page 7: Dimensions

1.3.1 NPS40 fIGure 1.3.1b fIGure 1.3.1a 1.3.2 NPI40 COmPLETE WITh NI800 FLAShING fIGure 1.3.2a fIGure 1.3.2b 38 3/8” 12 1/2” 15” Stand-off’s 29 5/16” 21 1/2” 20 5/8” 7 5/8” 2 3/4” Center 26 1/2” line of exhaust Center line 20 3/8”... -

Page 8: Npi40 Complete With Ak9 Adapter And Cisk Flashing

1.3.3 NPI40 COmPLETE WITh Ak9 AdAPTER ANd CISk FLAShING fIGure 1.3.3b fIGure 1.3.3a 16 1/2” 10 5/8” 31” 28 1/8” Stand-offs 20 5/8” 7 5/8” 2 3/4” Center 26 1/2” line of 46 7/16” exhaust Center line of air intake 20 3/8”... -

Page 9: Npi40 Complete With Ak8 Adapter And Gicsk Flashing

1.3.4 NPI40 COmPLETE WITh Ak8 AdAPTER ANd GICSk FLAShING fIGure 1.3.4a fIGure 1.3.4b 46 7/16” 10 5/16” 15 5/8” Stand-offs 29 3/16” 20 3/8” 7 5/8” 2 3/4” Center 26 1/2” line of exhaust Center line of air intake 20 3/8” 8”... -

Page 10: Installation Overview

INSTALLATION OvERvIEW See the section “INSTALLATION - MINIMUM MANTEL CLEARANCES” fIGure 1.4 See the section Drywall “MINIMUM FRAMING (or other DIMENSIONS” combustible material) See the section See the sections “MINIMUM “GENERAL VENTING” CLEARANCES TO and “INSTALLATION” COMBUSTIBLES” Side Wall See the section “INSTALLATION INTO A BUILT-IN ENCLOSURE”... -

Page 11: General Information

Rate (Pounds per hour)** 1.0 to 5.0 maximum burn Time on low burn** 55 hours (NPS40), 45 hours (NPI40) hopper Capacity 55 Pounds (NPS40), 45 Pounds (NPI40) * Heating capacity will vary depending on the home's floor plan, degree of insulation, and the outside temperature. It is also affected by the fuel size, quality, and moisture level. -

Page 12: Specifications

30 1/2" NPS40 depth 26 5/8" Weight 210 Pounds Exhaust Collar 3" Intake Collar 2" NPS40 hopper Cap. 55 Pounds NPI40 hopper Cap. 45 Pounds Exempt burn Rate** 1.0 to 5.0 (Pounds Per hour) bTU/h** 8500 to 42500 minimum Fireplace Opening Size... -

Page 13: Installation Planning

If the heater is placed in a location where the ceiling height is less than 7' above the base of the heater, the installation must follow the requirements in the section "Alcove Installations Requirements". INSTALLATION OPTIONS nps40: To install in a Residential or mobile home see the section "Mobile Home Requirements". For alcove installations see the section "Alcove Installation Requirements". -

Page 14: Outside Air

OUTSIdE AIR Available from your Authorized Dealer (114KT) Outside air must not be drawn from an enclosed space (garage, unventilated crawl space). NOTE: Wolf Steel Ltd. strongly suggests using outside air for all residential installations, especially for those that are energy efficient, air-tight homes. Outside air supply must not be over 15' long. -

Page 15: General Venting

4.0 GENERAL vENTING WARNING Pellet vent must maintain a minimum 3" clearance to any combustible (install vent at clearances specified by the vent manufacturer). Do not connect the pellet vent to a vent or chimney serving any other appliance or heater. Do not install a flue damper in the exhaust venting system of this unit. -

Page 16: Minimum Air Terminal Location Clearances

mINImUm AIR TERmINAL LOCATION CLEARANCES fIGure 4.5 Illustration dimensions are to the center and the exhaust exit point of the vent. CLEARANCE Clearance above grade, veranda porch, deck or balcony. 24 INCHES (Including Vegetation and Mulch) Clearance beside or below any windows or doors that open. 48 INCHES 12 INCHES* Clearance above any window or door that opens. -

Page 17: Alcove Installation

ALCOvE INSTALLATION fIGure 4.6 minimum alcove dimensions STOvE vENTING INSTALLATION ExAmPLES 4.7.1 hORIzONTAL ExhAUST ThROUGh WALL INSTALLATION 3” Minimum fIGure 4.7.1 12” Minimum Wall Thimble 6” 5’ Maximum Minimum 11-3/4” Floor 17-3/8” Protection Outside Air (Recommended) Wall Thimble W415-0616 / E / 10.08.08 Outside Air... -

Page 18: Through Wall With Vertical Rise And Horizontal Termination

4.7.2 ThROUGh WALL WITh vERTICAL RISE ANd hORIzONTAL TERmINATION Wall Thimble fIGure 4.7.2 Outside Air (Recommended) 3” 2” 6” Minimum Floor Protection 4.7.3 mINImUm INSIdE vERTICAL CLEARANCES Vertical Cap Storm Collar Roof Flashing fIGure 4.6.3 Vent must maintain 3” Ceiling Support clearance to combus- tibles. -

Page 19: Class A Chimney Retrofit

4.7.4 CLASS A ChImNEY RETROFIT Vertical Cap Storm Collar Roof Flashing fIGure 4.7.4 Vent must maintain Class A Chimney 3” clearance to Ceiling Support combustibles. 3” 2” Floor Protection Outside air (Recommended) (Installation show- ing inlet of outside air in ventilated crawl space) 4.7.5 hEARTh mOUNT INSTALLATION Vertical Cap... -

Page 20: Installation Into A Masonry Fireplace

4.7.6 INSTALLATION INTO A mASONRY FIREPLACE WARNING Do not remove bricks or mortar from the fireplace. Prior to installation: When installing into a masonry fireplace, do not remove any bricks or masonry. Do not weaken the structure, or reduce the protection for combustible materials to less then that required by the National Building Code. -

Page 21: Stove Installation

5.0 STOvE INSTALLATION mINImUm CLEARANCE TO COmBUSTIBLES 5.1.1 STRAIGhT INSTALLATION fIGure 5.1.1b Through the Wall Installations Interior vertical vents fIGure 5.1.1a 5.1.2 CORNER INSTALLATION Through the Wall vents Interior vertical vents fIGure 5.1.2b fIGure 5.1.2a note: If interior vertical pellet vent is used, the clearance to the back wall is determined by the upward-turning elbow or "tee". -

Page 22: Insert Installation

6.0 INSERT INSTALLATION mASONRY FIREPLACE INSTALLATION WARNING Do not remove bricks or mortar from the fireplace. Prior to installation: Vertical Stand-offs may be removed to fit the insert into the fireplace. Storm Collar fIGure 6.1 When installing the insert into a masonry fireplace, do not remove any bricks Cover Plate or masonry. -

Page 23: Factory Built (Metal) Fireplace

FACTORY BUILT (mETAL) FIREPLACE fIGure 6.2 Prior to installation: Vertical Stand-offs may be removed to fit the insert into the fireplace. Do not weaken the structure, or reduce the protection for combustible materials to less then that required by the National Building Code. Bolted or screwed together pieces Storm Collar (smoke shelf / deflectors) may be removed, but must be able to be re-installed if the... -

Page 24: Installation Into A Combustible Enclosure

INSTALLATION INTO A COmBUSTIBLE ENCLOSURE WARNING the stand-offs located on the back of the insert must not be removed when installing the insert into a built-in combustible enclosure. WARNING When installing the insert as a "built-in" heater, it is important to maintain the clearances to combustibles, see "mINImUm ClEARANCE TO COmbUSTIblES"... -

Page 25: Minimum Enclosure Clearances

6.3.2 mINImUm ENCLOSURE CLEARANCES fIGure 6.3.2 6 3/8” Minimum 2 1/4” 40” 3” all around (Refer to vent manufacturer’s instructions) 27” Stand-offs 7 5/8” 6” 2 3/4” Non-combustible Stand-offs - Warning do not remove floor protection 6.3.3 mINImUm CLEARANCE TO COmBUSTIBLES Side wall to heater 8"... -

Page 26: Horizontal Vent Installation

hORIzONTAL vENT INSTALLATION ● 6.4.1 If you plan on connecting outside air it is recommended to do so at this time. ● 6.4.2 A hole must be made in the back of the fireplace to accommodate the pellet vent. Connect the pellet vent to the back of the stove and position in place. -

Page 27: Insert Finishing

7.0 INSERT FINIShING FLAShING INSTALLATION fIGure 7.1.1 7.1.1 Secure the Right Flashing to the right side of the heater using two of the #8 x 1/2" screws. note: feed the air control rod into the air control slot on the right flashing SHIPPING CONTROL before securing. -

Page 28: Installing Viewing Door

INSTALLING vIEWING dOOR The main viewing door has been boxed separate from the heater, but must be installed before burning the heater. fIGure 7.3 7.3.1 Open both side panels, exposing the bushing on the left and the latches on the right. (Insert 7.3.2 Align the pins on the door to the bushing on the left side of the heater. -

Page 29: Lighting Instructions

LIGhTING INSTRUCTIONS WARNING Never use gasoline, lantern fuel, lighter fluid to start or "freshen-up" a fire in this heater. Keep all such fluids away from heater when in use. Due to different installation set ups, length and size of venting and fuel quality, the low feed setting from the factory will not always be correct. -

Page 30: General Maintenance

9.0 GENERAL mAINTENANCE dAILY (WhENEvER USING ThE hEATER) 9.1.1 OPEN mAIN vIEWING dOOR WARNING The front of the heater becomes very hot during operation. Let the heater cool completely before conducting service. A. Open the side doors on either side of fIGure 9.1.1a fIGure 9.1.1b the heater. -

Page 31: Cleaning The Heat Exchanger Tubes

9.1.5 CLEANING ThE hEAT ExChANGER TUBES WARNING The front edge of the hopper lid becomes very hot, do not touch the area below the handle. This rod becomes very hot during operation. Wait till heater has cooled completely or you must wear heat resistant gloves when cleaning or handling this heater. -

Page 32: Bi-Weekly (Or Every 10 Bags Of Pellets)

NOTE: More frequent cleaning may be required depending on pellet quality. 9.3.1 vACUUm hOPPER NPS40: Run the heater until the pellets run out, then open the hopper and vacuum out the entire hopper. The dust and any other debris near the bottom should be removed to prevent excessive build-up. -

Page 33: Soot And Fly Ash Formation

9.3.2 SOOT ANd FLY ASh FORmATION The products of combustion will contain small particles of fly ash. The fly ash will collect in the exhaust venting system and restrict the flow of the flue gases. Incomplete combustion occurs during startup, shutdown, or incorrect operation of the room heater will lead to some soot formation which will collect in the exhaust venting system. -

Page 34: Check All Seals

9.3.6 ChECk ALL SEALS Check for air leaks around the door, glass, and ash pan and replace gaskets as required. Air leaks into the firebox will decrease the heater's performance greatly, leading to excessive soot, inefficient burning, and may even cause a malfunction. Test the door seal by shutting the door on a piece of paper in various locations. -

Page 35: Normal Operating Sounds

10.0 NORmAL OPERATING SOUNdS fIGure 10.0 TP - OPERATING SOUNdS_PEllET W415-0616 / E / 10.08.08... -

Page 36: Wiring Diagram

11.0 WIRING dIAGRAm fIGure 11.0 Slip-on (.250) FI (1 wire) Slip-on (.250) FI (2 wires) Slip-on (.250) FI (2 wires) Blower Purple over-ride Purple Switch Grey High Limit Switch Grey Black Brown Brown Purple Brown Low Limit Ignitor Convection Purple Switch Brown Blower... -

Page 37: Replacements

W660-0062 vARIAblE SPEEd W/O PAl NUT SWITCh W555-0061 SCRAPER ROd W105-0012 NYlON bUShING W570-0110 SCREW SET W750-0215 hARNESS WIRE W385-0334 NAPOlEON® lOGO W010-1528 CONTROl dOOR W475-0555 bOTTOm OI PANEl W720-0089 IGNITOR hOUSING W390-0012 CONTROl PANEl lATCh W010-1490 ExhAUST TUbE W357-0004... - Page 38 ExhAUST COllAR W010-0219 ExhAUST COvER W290-0122 ExhAUST GASkET W010-1673 RIGhT lOUvRE ASSEmblY W010-1685 lEFT lOUvRE ASSEmblY W010-1567 AIR CONTROl NPS40 COmPONENTS part no. descrIptIon W010-1508 WEldEd TOP ASSEmblY W010-1527 SIdE dOOR ASSEmblY W010-1529 hOPPER dOOR ASSEmblY W010-1667 ASh PAN ASSEmblY...

- Page 39 PORCElAIN REFlECTIvE RAdIANT PANElS 114kT OUTSIdE AIR kIT - 5 FT (2" dIA.) NP841kT bRICk, REFRACTORY NPl41 dECORATIvE lOG SET NPS40 ACCESSORIES part no. descrIptIon NPhE-40 hOPPER ExTENSION (INCREASES hOPPER CAPACITY FROm 55 lbS TO 100 lbS PEllETS) NPI40 ACCESSORIES part no.

-

Page 40: Common Replacement Parts

12.1 COmmON REPLACEmENT PARTS W415-0616 / E / 10.08.08... -

Page 41: Nps40 Replacement Parts

12.2 NPS40 REPLACEmENT PARTS W415-0616 / E / 10.08.08... -

Page 42: Npi40 Replacement Parts

12.3 NPI40 REPLACEmENT PARTS W415-0616 / E / 10.08.08... -

Page 43: Common Accessory Parts

12.4 COmmON ACCESSORY PARTS PRPP40 NPL41 12.5 NPI40 ACCESSORY PARTS NI800 W415-0616 / E / 10.08.08... -

Page 44: Troubleshooting

13.0 TROUBLEShOOTING ALL TROUBLE SHOOTING PROCEDURES SHOULD BE CARRIED OUT BY QUALIFIED TECHNICIANS OR INSTALLERS. WARNING When checking connections, installing jumper wires (for test purposes only) or replacing components, unplug heater from the receptacle to prevent electrical shock or dampage to the component. NOTE: Many of the following tests will require that the side panels are removed from the stove or the insert be removed from its cavity to access the components. - Page 45 SYMPTOM TEST SOLUTION - Hopper lid must be closed. The auger motor is - Make certain the exhaust blower is operating. not functioning - Check the condition of the vacuum hose (located on the left side of the heater). Should not be cracked normally or torn.

- Page 46 SYMPTOM TEST SOLUTION The 200°F (93°) - Reset the sensor and determine whether it was the convection blower or 160°F (71°C) temperature sensor failure. Bypass the 160°F (71°C) sensor. Does the convection blower not come on high? If no high limit tempera- than replace the blower.

-

Page 47: Service And Maintenance Log

14.0 SERvICE ANd mAINTENANCE LOG TP - SERvICE hISTORY W415-0616 / E / 10.08.08... -

Page 48: Notes

15.0 NOTES NOTES TP - NOTES W415-0616 / E / 10.08.08...

Need help?

Do you have a question about the NPS40 and is the answer not in the manual?

Questions and answers