Table of Contents

Advertisement

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the vehicle, radio control equipment, etc.,

are accessible for checking at the same time.

ENGINE CONSTRUCTION, NOTES WHEN

ACCESSORIES, CARBURETOR

CONTROLS 11H, 11H(B)

GLOWPLUG, INSTALLATION

CONTENTS

2-5

6-7

8

9-11

ENGINES, CARBURETORS EXPLODED

VIEWS &PARTS LIST

12-13

14-15

1

16-19

20-23

24-25

26-29

30-37

38-39

40

Advertisement

Table of Contents

Summary of Contents for O.S. engine max-12TZ series

-

Page 1: Table Of Contents

CONTENTS SAFETY INSTRUCTIONS AND STARTING THE ENGINE & RUNNING-IN WARNINGS ABOUT YOUR O.S. ENGINE ('Breaking-in) 16-19 ENGINE CONSTRUCTION, NOTES WHEN APPLYING AN ELECTRIC STARTER FINAL ADJUSTMENT... -

Page 2: Safety Instructions And Warnings About Your O.s. Engine

As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some future date, your O.S. engine is acquired by another person, we would respectfully request that these instructions are also passed on to its new owner. - Page 3 NOTES This engine is intended for model cars. • • The wearing of safety glasses is also Do not attempt to use it for any other strongly recommended. purpose. Take care that the glowplug clip or • Mount the engine in your model •...

-

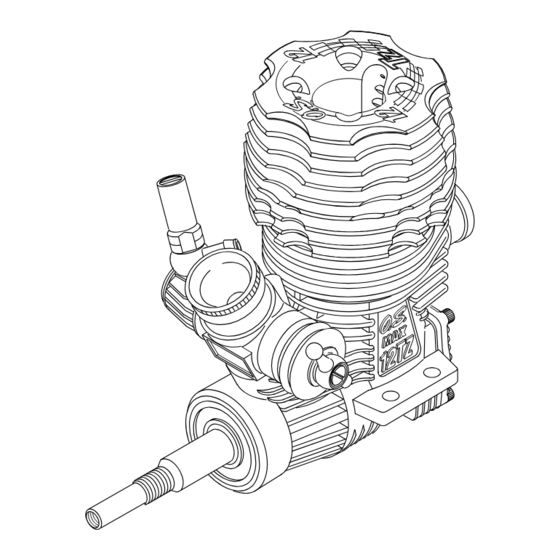

Page 4: Applying An Electric Starter

Near TDC ENGINE CONSTRUCTION With this engine, the piston will feel tight at the top of its stroke Piston (TDC) when the engine is cold. Cylinder Liner This is normal. The cylinder bore has a slight taper. The piston and cylinder are designed to Crankshaft achieve perfect... -

Page 5: About The Engine

12TZ SERIES INSTRUCTIONS MAX- Standard accessories This manual handles the following two versions. Glow Plug P6 T-type head MAX-12TZ(P)-T3 (3 port version) (Turbo head) 1piece (Hot Type) with 11H carburetor MAX-12TZ(P)-T5 (5 port version) Exhaust Seal Ring 1piece with 11H(B) carburetor ABOUT THE ENGINE 12TZ(P)-T5 only MAX-... -

Page 6: Basic Engine Parts

TOOLS 7.2V BATTERIES FOR STARTER BOX HEX SCREWDRIVER Batteries for starter box. Necessary for engine installation. Select according to the 1.5mm, 2mm, 2.5mm, 3mm starter box used. Be sure to full charge before using. SCREWDRIVER FUEL PUMP Necessary for carburetor adjustments. For filling the fuel tank, a simple, No.1, No.2, etc polyethylene "squeeze"... -

Page 7: Installation Of The Standard

Installing the carburetor reducer INSTALLATION OF THE 5.5mm (Black) bore reducer is installed on STANDARD ACCESSORIES both the 12TZ(P)-T3 and 12TZ(P)-T5 carburetor. Installing the glow plug. Insert P6 plug supplied Extra 6.5mm bore reducer is supplied with into heatsink-head care- the 12TZ(P)-T5 only. -

Page 8: Engine Installation

GLOWPLUG Glowplug life Since the compatibility of the glowplug and fuel Particularly in the case of very high performance may have a marked effect on performance and engines, glowplugs must be regarded as expendable reliability, it is suggested to use the O.S. P6 items. -

Page 9: Starting The Engine & Running-In ('Breaking-In)

STARTING THE ENGINE & RUNNING-IN ('Breaking-in) Lay the chassis on a stand and start the Excessively rich running and prolonged engine so that the tiers may not be in low speed running mean nothing. Prolon- contact with the ground. ged low speed running and low tempera- ture running may result in the oil in the fuel PRESSURIZED FUEL SYSTEM being gelled and piston/liner being agglu-... - Page 10 Swith on the transmitter and make sure that each linkage moves correctly. Turn the engine with starter box to draw he fuel into the engine. Attention: Deliver fuel into the carburetor. It is vitally important to set the throttle at the correct position before starting the Fuel engine.

-

Page 11: Final Adjustment

FINAL ADJUSTMENT Final adjustment should be carried out only after Run the vehicle (with throttle fully open) over the running-in has been completed. the longest available straight course, in order to observe the model's speed. Next return Needle Valve the car to the starting point, close the Needle- Valve 15˚... - Page 12 With the optimum mixture control position, light smoke is visible during high speed running,and the engine rpm increases smoothly during acceleration. Remember that, if the engine is operated with the fuel/air mixture slightly too lean, it will overheat and run unevenly. As with all engines, it is advisable to set both the needle-valve and metering needle slightly on the rich side of the best rpm setting, as a safety measure.

-

Page 13: Care And Maintenance

CARE AND MAINTENANCE The minute particles of foreign matter, that are 4. Then, inject some after-run oil into the engine, and present in any fuel may, by accumulating and rotate the engine with an electric starter for 4 to 5 partially obstructing fuel flow, cause engine seconds to distribute the oil to all the working performance to become erratic and unreliable. -

Page 14: Trouble Shooting

TROUBLE SHOOTING Symptom Engine fails to fire. Corrective action Cause Fuel tank is empty. Fill the tank with fuel and repeat Fuel not reaching the engine. Priming procedure. Glowplug element is burnt out. Replace glowplug. Glowplug battery discharged Recharge or replace the battery. Clean or replace fuel filter. - Page 15 Symptom Unstable idle Corrective action Cause Unsuitable glowplug Use suggested glowplug in the instructions. Do not use extremely high nitro Unsuitable fuel or low oil content fuel. Extremely light flywheel Add suitable load. Silencer is disconnected or has play Install silencer securely. Symptom Not reaching expected peak r.p.m.

- Page 16 MAX-12TZ (P)-T3 ENGINE EXPLODED VIEW MAX-12TZ (P)-T3 ENGINE PARTS LIST C.M3x16 Code No. Description 21534000 Outer Head (Blue) 21534100 Inner Head 21533000 Cylinder & Piston Assembly 21536000 Piston Pin 21817000 Piston Pin Retainer (2pcs.) 21535000 Connecting Rod 21538000 Carburetor Complete (Type 11H) 25381701 Carburetor Retainer Assembly 22631020...

- Page 17 11H CARBURETOR EXPLODED VIEW Type of screw C...Cap Screw M...Oval Fillister-Head Screw S.M3x3 F...Flat Head Screw N...Round Head Screw S...Set Screw 11H CARBURETOR PARTS LIST Code No. Description 21982600 Mixture Control Valve Assembly 27881820 "O" Ring(L) (2pcs.) 22781800 "O" Ring(S) (2pcs.) 21982970 Needle Valve Assembly 27881820...

- Page 18 MAX-12TZ (P)-T5 ENGINE EXPLODED VIEW MAX-12TZ (P)-T5 ENGINE PARTS LIST C.M3x16 Code No. Description 21534010 Outer Head (Silver) 21534100 Inner Head 21533010 Cylinder & Piston Assembly 21536000 Piston Pin 21817000 Piston Pin Retainer (2pcs.) 21535000 Connecting Rod Carburetor Complete ( Type 11H ( B )) 21538010 25381701 Carburetor Retainer Assembly...

- Page 19 11H ( B ) CARBURETOR EXPLODED VIEW Type of screw C...Cap Screw M...Oval Fillister-Head Screw S.M3x3 F...Flat Head Screw N...Round Head Screw S...Set Screw 11H ( B ) CARBURETOR PARTS LIST Code No. Description 21982600 Mixture Control Valve Assembly 27881820 "O"...

-

Page 20: O.s. Genuine Parts & Accessories

O.S. GENUINE PARTS & ACCESSORIES RACING ENGINE PARTS O.S. Glow Plug Exhaust Manifold Assembly Super Joint Tube 15 M1001 M1001SC (72106400) (72106420) Left side exhaust, Left side exhaust, (72103310) Spring connect type Joint tube type (71641600) Manifold Spring Manifold Spring (72106172) (72106172) (71641700) -

Page 21: Three View Drawing

THREE VIEW DRAWING Dimensions (mm) 12TZ ( P ) -T3 MAX- SPECIFICATIONS 2.11 cc ( 0.128 cu.in. ) Displacement 13.8 mm (0 .543 in. ) Bore 14.0 mm ( 0.551 in. ) Stroke 5,000-40,000 r.p.m. Practical R.P.M. 1.5 ps / 33,500 r.p.m. Power output 4- 3.3 224.5g (7.92 oz.)

Need help?

Do you have a question about the max-12TZ series and is the answer not in the manual?

Questions and answers