Advertisement

Quick Links

SERVICE MANUAL

01

2003

49787

1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2

Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

4

Description of major ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

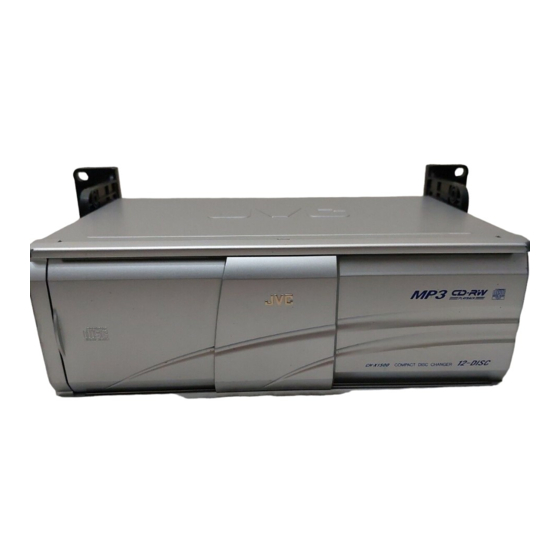

CD CHANGER

CH-X550

TABLE OF CONTENTS

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

CH-X550

Area Suffix

E ------- Continental Europe

No.49787

2003/01

Advertisement

Summary of Contents for JVC CH-X550

- Page 1 CH-X550 SERVICE MANUAL CD CHANGER 49787 2003 CH-X550 Area Suffix E ------- Continental Europe TABLE OF CONTENTS Important Safety Precautions ............1-2 Disassembly method .

-

Page 2: Important Safety Precautions

CH-X550 SECTION 1 Important Safety Precautions 1.1 Safety Precautions Burrs formed during molding may be left over on some parts of the chassis. Therefore, pay attention to such burrs in the case of preforming repair of this system. Please use enough caution not to see the beam directly or touch it in case of an adjustment or operation check. - Page 3 CH-X550 1.2 Preventing static electricity Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

-

Page 4: Disassembly Method

CH-X550 SECTION 2 Disassembly method 2.1 Replacement of the pickup (1) After removing the exterior (top and bottom). (2) Proceed to the pickup replacement section. (3) When applying grease, refer to the exploded view. Bottom cover Use new grease. 2.2 Mechanism section (1) Remove the exterior (required section only). - Page 5 CH-X550 2.3.2 Removing the top cover Turn to the top position (at a right angle), (See Fig.5 to 9) then push down to lift off. (1) Remove the four damper bracket fixing screws C to re- move the damper brackets.

- Page 6 CH-X550 2.3.3 Removing the fittings Catches a (See Fig.10) (1) Remove the fixing screw F. (2) Unhook the two catches a on the top edge of the fitting, then unhook the two catches b at the left/right bottom edg- Catches b Fitting Fig.10...

- Page 7 CH-X550 2.4 CD mechanism assembly Sensor assembly 2.4.1 Sensor assembly unit (See Fig.1) (1) Remove the two screws I securing the sensor assembly unit. (2) Unhook the spring on the back of the sensor assembly unit from the holes on the chassis.

- Page 8 CH-X550 2.4.4 Rear slider Can be removed at the stud position Rear slider (See Fig.4) (at the widest hole) (1) Position the unit with the front section facing down. Rotate Remove Shift the third gear located on the back of the main unit in the di- rection of the arrow (clockwise).

- Page 9 CH-X550 2.4.7 Lifter unit 2.4.8 Lifter bracket (See Fig.8 and 9) (See Fig.10) (1) Unhook the elevator spring located on the front side of the (1) Remove the two lifter bracket fixing screws L located on the unit. (Be sure to first unhook the spring from the lifter side back of the lifter unit.

- Page 10 CH-X550 2.4.10 Removing the mechanism board / pickup assembly Pickup assembly (See Fig.12 to 15) (1) Remove the three screws N fixing the mechanism board on Grounding point the back of the traverse mechanism. (2) Disconnect the two feed motor wires (blue and white), two...

- Page 11 CH-X550 2.4.11 Tray motor (See Fig.16 and 17 ) (1) Remove the two screws S securing the tray motor. (2) Remove the two screws T to remove the tray motor as- sembly from the tray motor holder. Tray motor assembly Fig.16...

- Page 12 CH-X550 2.4.13 Precautions on reassembling CAUTION: When reassembling, also refer to the disassembling proce- Rack arm dures. 2.4.13.1 Mounting the traverse mechanism (See Fig.19 to 23) (1) When mounting the pickup assembly, attach the feed slide shaft assembly to the traverse chassis.Apply E-JC-525 grease to the shaft.

- Page 13 CH-X550 2.4.13.2 Mounting the lifter unit (See Fig.24 to 26) (1) Insert the shafts f of the traverse mechanism assembly into the slide grooves g on the lifter unit. (2) Shift the hook of the lifter unit to the edge, and shift the slid- ing lever inside the side bracket unit to the edge as well.

- Page 14 CH-X550 2.4.13.3 Connection of the chassis (L) assembly and chassis (R) assembly (See Fig.27 to 29) (1) Attach the lower rod to the chassis (R) assembly. While Lifter unit shifting the rod toward the front side, mount the rod on the lifter unit.

- Page 15 CH-X550 2.4.13.4 Mounting the top plate (See Fig.30 to 33) (1) Mount the upper rod on the lifter side l and set it on the rear of the top plate, then mount the other end of the upper rod to m.

- Page 16 CH-X550 2.4.13.5 Mounting the front slider and rear slider Stud (See Fig.45 and 46) E-Washer Position so (1) Position the unit with the rear side facing down, then rotate that the stud Front slider the third gear in the direction of the arrow (clockwise) until...

- Page 17 CH-X550 2.4.13.6 Mounting the sensor board assembly (See Fig.36) (1) Attach the longer spring to the white resin, and attach the Sensor assembly fixing screws shorter spring temporarily to the sensor assembly bracket. (2) Mount the sensor assembly so that the shaft of the lift arm is inserted into the longer hole on the white resin located on the back of the sensor board assembly.

- Page 18 CH-X550 2.4.13.8 Pickup replacement procedure Main PCB assembly Third gear (See Fig.38 to 44) (1) Remove the bottom cover, front panel and top cover from the exterior section. (2) Unplug the flexible ribbon wire from connector CN502 on the traverse mechanism PC board assembly.

- Page 19 CH-X550 Pickup Feed slide shaft Rack arm Fig.42 Pickup Shaft Holder Middle gear Middle gear Chassis Fig.43 Enlarged diagram Lifter unit lever Fig.44 (No.49787)1-19...

-

Page 20: Adjustment

CH-X550 SECTION 3 Adjustment 3.1 Forced eject procedures Magazine eject does not function. RESET (Press EJECT for 3 sec.) Completed Check that the trays remain no more than 10 mm inside the magazine. Are trays stored in the magazine? Check visually. - Page 21 CH-X550 3.2 Troubleshooting 3.2.1 Servicing procedures for CH-X550 error displays Error display Servicing procedure E1: Eject error The magazine cannot be ejected until S601 (magazine switch) turns off. Can the magazine be ejected? YES → 1, NO → 2 1. The magazine switch (S601) does not turn off even though the magazine is completely ejected.

- Page 22 CH-X550 3.2.2 Error code The following error codes can be displayed and stored in up to 3 memories when the KD-MX3000 is used with the controller. Refer to the KD-MX3000 service manual regarding error code indication. The error code indication when using the earlier controller is the same as the CH-X99, KD-MK88 and other 12CD changer models.

- Page 23 CH-X550 3.3 Flow of functional operation until TOC read Power ON • When the laser diode correctly Set Function to CD • When the pickup correctly moves emits to the inner area of the disc Microprocessor $ 84 Disc inserted...

-

Page 24: General Section

CH-X550 3.3.1 General section Turn the power on with no magazine loaded. Reset Move the lifter until it The lifter moves up or Check the linear position comes to the STOP sensor (VR601). down and stops. position (shipping position). The position motor does... - Page 25 CH-X550 3.3.2 Feed section Is the voltage output at Is the wiring for IC521 Is 5V present at IC581 Check CD 9V IC521 pin u 5V or 0V? (90) ~ (100) correct? pin 6? and 5V. Check the vicinity of IC521.

- Page 26 CH-X550 3.3.6 Signal processing section No sound from either Compare the L-ch and R-ch Is the sound output from channel. to locate the defective point. both channels (L, R)? Check the vicinity of the Normal Is 9V present at IC101 pin Q981 audio power supply.

-

Page 27: Description Of Major Ics

CH-X550 SECTION 4 Description of major ICs 4.1 BA15218F-XE (IC101) : Dual operation amplifier • Pin layout OUT1 1 8 Vcc -IN1 2 7 OUT2 +IN1 3 6 -IN2 VEE 4 5 +IN2 • Block diagram OTHER Q114 OUTPUT (No.49787)1-27... - Page 28 CH-X550 4.2 BR24C01AF-W-X (IC604) : EEPROM • Pin layout • Pin function Symbol Description WP SCL SDA Power supply A0, A1, A2 Slave address setting terminal Serial clock input terminal I/O Slave/word address serial data input/output A2 GND Write protect terminal •...

- Page 29 CH-X550 4.3 FAN8037 (IC581) : CD driver • Pin layout & Block diagram 48 47 46 45 44 43 42 41 40 39 38 37 STAND BY T.S.D ALL MUTE POWER SAVE 13 14 15 16 17 18 19 20 21 22 23 24 •...

- Page 30 CH-X550 4.4 HD74HC126FP-X (IC651) : Buffer • Pin layout • Pin function Input Output Note: H:High level L:Low level X:Irrelevant Z:Off(High-impedance) State a 3-state input • Block diagram Output Input Output Sample as Load Circuit 1 Output Sample as Load Circuit 1...

- Page 31 CH-X550 4.5 IC-PST9333U-X (IC602) : Regulator • Pin layout • Block diagram Vcc 4 3 VOUT VOUT 2 GND NC 1 • Pin function Pin No. Symbol Function Non connect GND terminal VOUT Reset signal output terminal Vcc terminal/Voltage detect terminal...

- Page 32 CH-X550 4.6 TA2147F-X (IC501) : RF amp. • Terminal layout • Block diagram PEAK GVSW 12 RFDC 20 A TEBC 50 A RFRP BOTTOM RFRPIN PEAK RFGO 1.75k 240k 15pF x0.5 RFGC 240k 15pF x0.5 AGCIN 180k 40pF 1-32 (No.49787)

- Page 33 CH-X550 • Pin function Symbol Function 3.3V Power supply pin Main-beam amp input pin Main-beam amp input pin Sub-beam amp input pin Sub-beam input pin Monitor photo diode amp input pin Laser diode amp output pin "APC circuit ON/OFF control signal laser diode (LDO) control signal, input or bottom/peak detection frequency change pin."...

- Page 34 CH-X550 4.7 TC9490FA (IC521) : DSP & DAC • Pin layout & Block daiagram TEZI Clock generator SBAD 1-bit Servo control RFRP RFZI ZDET RFCT Digital equalizer Address automatic circuit adjustment circuit BUS0 Data CLV servo slicer BUS1 SLCO BUS2...

- Page 35 CH-X550 • Pin function Symbol Function Bit clock outputpin 32fs, 48fs, or 64fs selectable by command. LRCK L/R channel clock output pin."L" for L channe and "H" for R channel. Output polarity can be inverted by command. AOUT Audio data output pin. MSB-first or LSB-first selectable by command.

- Page 36 CH-X550 Symbol Function Tracking equalizer output pin. VREF Analog reference power supply voltage pin. RFGC RF amplitude adjustment control signal output pin. TEBC Tracking balance control signal output pin. APC circuit ON/OFF signal output pin. At laser on, high impedance with UHS="L", H output with UHS="H".

- Page 37 Memory power detect input Unused output port PWR SW CRTL+B detect input CD ON CD power control Hi:on BUS INT JVC bus com start interrupt input 27 PWR CONT Power supply control output Hi:on EJECT Eject key input POSMO+ Position motor control output...

- Page 38 CH-X550 VICTOR COMPANY OF JAPAN, LIMITED AV & MULTIMEDIA COMPANY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan (No.49787) Printed in Japan 200301WPC...

Need help?

Do you have a question about the CH-X550 and is the answer not in the manual?

Questions and answers