Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Instruction Manual

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Duplo DF-1000

- Page 1 SERVICE MANUAL Air Suction Paper Folder DF-1000 Feb. 2006 Revision 0 DUPLO DF-1000 12T-M12M0-0602-0...

- Page 2 Trademark The product name and company name used in this manual are the trademark or registered trademark of the respective companies. Note This manual must be handled with extreme caution, particularly ensure against leakage of technical details. DUPLO DF-1000 12T-M12M0-0602-0...

- Page 3 Since it is not possible to list all imaginable dangers which may occur during servicing, the SP must carry out servicing with extreme care to ensure safety at all times, in addition to observing the precautions labeled on the product and indicated in this manual. DUPLO DF-1000 12T-M12M0-0602-0...

- Page 4 Contains menu maps, electrical parts layout, board layout, overall schematic diagrams, and wiring diagrams. This manual does not describe disassembly/assembly procedures for all parts. For details on parts not listed in this manual, please refer to the separate “Parts Catalog”. DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 5: Power Supply

Make sure that the combined power consumption of the appliances to be connected does not exceed the capacity rating of the power outlets or plug receptacles. Exceeding the capacity rating could cause the power outlets, plug receptacles, or power extension cords to overheat and catch a fire. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 6: Operating Environment

fields. Otherwise incorrect operations and malfunctions may occur. Install this unit on a level, stable stand or floor, with sufficient space around it. Failure to do so could result in the unit overturning and causing injury. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 7: Maintenance, Etc

Accumulated dust could result in a fire. Always grip the plug when disconnecting the power plug from the power outlet. Forcibly pulling on the power cord could cause damage, resulting in a fire or an electrical shock. DUPLO DF-1000 12T-M12M0-0602-0... - Page 8 Static electricity may accumulate in the human body during contact with clothing. This static electricity may damage electrical devices or change the electrical characteristics of devices. DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 9: Warning And Caution Label Locations

The warning and caution labels are pasted or printed on the unit to ensure the safety of users. Do not remove nor change them. If these labels become dirty or damaged, replace with new ones. Caution Label for SP DUPLO DF-1000 12T-M12M0-0602-0... -

Page 10: Environmental Preservation

Please handle the following parts with particular care as they are subject to regulations of each country and are difficult to sort (complex materials) by material. Batteries Boards Power cords, I/F cables, cables such as bundled wire units Electrical parts such as sensors, switches, motors, clutches, solenoids, etc. viii DUPLO DF-1000 12T-M12M0-0602-0... -

Page 11: Table Of Contents

6.1 List of Maintenance Items ......1-19 4.2 Folding Plate Section .........2-26 6.2 Cleaning by User ........1-19 4.2.1 Outline ...........2-26 6.2.1 Cleaning the sensors ......1-19 4.2.2 Folding stopper sections of folding 6.2.2 Cleaning the suction belts ....1-21 plates 1 and 2 .........2-26 DUPLO DF-1000 12T-M12M0-0602-0... - Page 12 2.3.3 Removing the registration secondary roller ............3-7 2.3.4 Removing the registration roller ..3-7 3 Folding Section ........3-8 3.1 Folding Plate Section .........3-8 3.1.1 Removing the folding stoppers .....3-8 3.1.2 Removing the folding plate stopper motors (MOT2, MOT3) ......3-8 DUPLO DF-1000 12T-M12M0-0602-0...

- Page 13 4.1.5 Adjusting the gap of the screw shaft unit ............5-16 4.1.6 Adjusting the motor deceleration pulley section ............5-17 4.1.7 Adjusting the folding stopper section ...5-18 4.1.8 Adjusting the attaching position of the switching adjusting plate ....5-18 4.2 Folding Roller Section .......5-19 DUPLO DF-1000 12T-M12M0-0602-0...

- Page 14 3.4.1 When “NO PAPER” is displayed ..7-10 3.4.2 When “TOP COVER-L OPEN” is displayed ..........7-10 3.4.3 When “TOP COVER-R OPEN” is displayed ..........7-10 3.4.4 When “SIDE COVER OPEN” is displayed ..........7-10 4 Troubleshooting for Operation Failures ........... 7-11 DUPLO DF-1000 12T-M12M0-0602-0...

- Page 15 Chapter 1 INTRODUCTION DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 16: Features

Stable and high speed paper feed is realized by the adoption of the air suction paper feed method used in the collator system. 6. Skew correction Use of skew rollers (registration rollers) corrects skewing of paper. 7. Operability features and additional functions succeeded from DF-920 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 17: Specifications

(20 lb) fine quality paper is single folded [A] : 1.0 mm or less Folding misalignment [B] : 0.5 mm or less [C] : 1.5 mm or less Dog-ear [D] : 0.5 mm or less W dent DUPLO DF-1000 12T-M12M0-0602-0... - Page 18 11" × 17" 8.5" × 14" 8.5" × 11" 7" × 8.5" 5.5" × 8.5" (LGR) (LGL) (LTR) (STMT) (INV) Single fold Double fold Irregular accordion fold Letter fold Accordion fold Folded paper length within 250 mm Custom fold DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 19: Functions

1 registration 47 to 217 mm ∗ 0 mm for single folding. Folded size by (1.85 to 8.54 inch) folding plate 2 182 to 432 mm Non-standard paper length (7.2 to 17 inch) registration DUPLO DF-1000 12T-M12M0-0602-0... -

Page 20: Paper

The upper and lower curl amount should be above 130 mm Curl amount in radius (R), the curl height (H) should be less than 5 mm, without corrugation. NOTE When using paper curled more than the above, correct the curl. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 21: Others

2.4.2 Error detection functions Item Contents Mis-feed, continuous-feed, paper jam Paper feed error detection function Opening/closing of top cover L/R and side cover Other detection functions With/without folding plate Paper feed tray UP/DOWN error Safety lever ON/OFF DUPLO DF-1000 12T-M12M0-0602-0... -

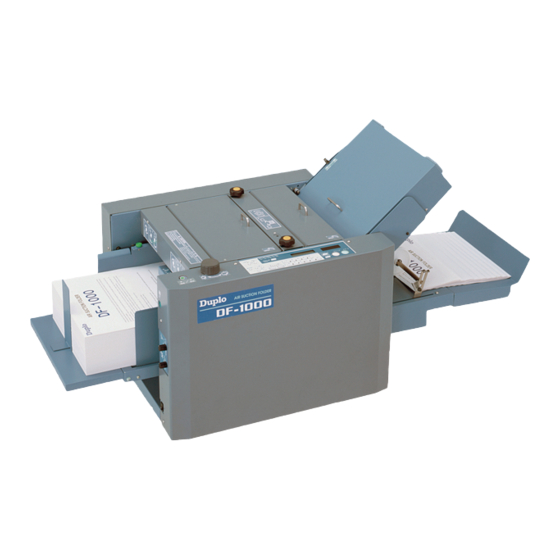

Page 22: Names Of Parts

[17] Separating-air duct [7] Paper feed tray [18] Separator [8] Auxiliary paper feed tray [19] Suction belt [9] Rear guide [20] Shutter [10] Power cord inlet [21] Level sensor [11] Power switch [22] Paper switch (USA model only) DUPLO DF-1000 12T-M12M0-0602-0... - Page 23 [26] Skew roller fixing knob [37] Paper receiving tray [27] Jam correction knob [38] Side cover [28] Folding plate connector [39] Thin paper feed button [29] Stacker unit connector [30] Stacker unit [31] Stacker roller [32] Stacker belt DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 24: Control Panel

Numerical display When using the add count mode, displays the number of sheets [14] (Counter) processed. When using the subtract count mode, displays the number of sheets left to be processed. 1-10 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 25: User Menu (Function Setting Mode)

5 SEC operations after several seconds. 10 SEC NOTE The setting is erased when the power is turned OFF. AIR POWER NORMAL* Function for adjusting the air amount for separating LIGHT paper. 1-11 DUPLO DF-1000 12T-M12M0-0602-0... - Page 26 NORMAL The stacker belt operates according to the paper ejection timing. CONTINUOUS The stacker belt operates continuously. The correction value of the folding stopper positions can THICK PAPER NOT CORRECTED* CORRECTED be changed for thick paper. 1-12 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 27: User Adjustments

B 3) Tighten the side guide adjusting knobs and secure the side guides. 4) Perform test folding and check that the folding misalignment has improved. Moving direction of side guide Example of adjusting knob needle position 1-13 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 28: Skew Correction By Skew Correction Knob

Top position [A] : Above 127.9 g/m Bottom position [B] : Less than 127.9 g/m NOTE Be sure to set the left and right knobs at the same position. 3) Close the top cover L. 1-14 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 29: Folding Position Adjustments

Folded plane 2 is long. Press the [–] key of the folding plate 2 folding stopper adjusting key. Folded plane 2 is short. Press the [+] key of the folding plate 2 folding stopper adjusting key. 1-15 DUPLO DF-1000 12T-M12M0-0602-0... - Page 30 190 to 208 The values which can be corrected vary in the –0.2 (7.5" to 8.2") to –4.7 mm (–0.008" to –0.19") range according to the paper length. 209 to 432 No restriction (8.3" to 17.0") 1-16 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 31: Paper Ejection Adjustments

111 to 140 4.34" to 5.51" Use the [1] key if paper jams at 141 to 170 5.52" to 6.69" the [2] position. 171 to 210 6.70" to 8.27" 211 to 250 8.28" to 9.84" 1-17 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 32: Changing The Stacker Roller Height

1) Lift up the stacker roller [1]. 2) Turn down the lever [2] of the stacker support in the arrow direction. NOTE After completing folding operations, be sure to return the stacker roller to the original position. 1-18 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 33: User Maintenance

6.2.1 Cleaning the sensors a. Lower paper sensor (PS8) 1) Clean the protection film [1] of the paper sensor (PS8) under the paper feed tray with a dry and soft cloth. 1-19 DUPLO DF-1000 12T-M12M0-0602-0... - Page 34 1) Loosen the two knob screws and remove the paper ejection guide (Center). 2) Insert the nozzle of the dust removal spray (canned air) into the cut-away on the sensor cover, and blow air. 3) Reinstall the paper ejection guide to its original position. 1-20 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 35: Cleaning The Suction Belts

NOTE If the folding plate is not secured at the correct position, the knob will not only feel heavy, but the folding rollers and folding plate may get damaged. 6) Close the top cover R. 1-21 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 36: Cleaning The Stacker Belts

3) Return the stacker roller to its original position. 6.3 Replacement by User In normal use (excluding malfunctions), there are no parts requiring replacement by the user to maintain product performance and work quality. 1-22 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 37: Operations

Chapter 2 OPERATIONS DUPLO DF-1000 12T-M12M0-0602-0... -

Page 38: Outline

1 OUTLINE 1 OUTLINE 1.1 Function Configuration The functions of this unit can broadly be divided into the paper feed section, folding section, and paper ejection section. Folding section Paper feed section Paper ejection section DUPLO DF-1000 12T-M12M0-0602-0... -

Page 39: Block Diagram Of Structure

Registration clutch Stacker belt clutch (CLH3) (CLH2) Suction solenoid Stacker roller moving (SOL1) motor (MOT5) PS P.W.B. unit Stacker roller home sensor (PS11) (PCB4) Paper ejection outlet Legal paper detection sensor (PS12) sensor (PS13) � USA model only DUPLO DF-1000 12T-M12M0-0602-0... - Page 40 If the protection circuit operates due to some reason, the DC output will go OFF. To recover from this state, turn OFF the power switch, wait for more than three minutes, and turn ON the power switch. DUPLO DF-1000 12T-M12M0-0602-0...

- Page 41 [7] Cover detection section Refer to “2 EXTERNAL COVER/CONTROL SECTION”. [8] Paper feed section Refer to “3 PAPER FEED SECTION”. [9] Folding section Refer to “4 FOLDING SECTION”. [10] Paper ejection section Refer to “5 PAPER EJECTION SECTION”. DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 42: Basic Operations

Folding operations 4) Paper feed 5) After paper is folded using the folding plate and folding roller, paper is ejected onto the stacker unit. Refer to “4.1.2 Folding operations”. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 43: Stopping Operations When Problems Occur

The paper ejection outlet sensor (PS12) does not turn OFF even after a certain period of time. When the top cover L, top cover R, or side cover is open When folding plate set errors, paper feed tray UP errors, paper feed tray DOWN errors, motor problems of each part are detected DUPLO DF-1000 12T-M12M0-0602-0... -

Page 44: External Cover/Control Section

When the top cover R is detected as open, this message appears on the control panel. [7] Side cover switch (SW2) <DC 24 V, microswitch> Detects the open/close of the side cover. “SIDE COVER OPEN”; When the side cover is detected as open, this message appears on the control panel. DUPLO DF-1000 12T-M12M0-0602-0... - Page 45 1) One of the following switches activate; SW1, SW2, SW3, SW5, or SW6. 2) The interlock relay (RL1) on the MC unit goes OFF. 3) The 24 VA supplied to the motor driver from RL1 goes OFF. 4) All motors (MOT1 to 4) stop. DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 46: Main Motor Control

The processing speed can be switched in five steps using the speed key on the control panel. Reference (Actual value measured) Condition: When 64 g/m fine quality paper is single folded Processing speed (sheets/minute) Speed key setting 8.5" × 11" (LTR) 11" × 17" (LGR) 5 (Fast) 1 (Slow) 2-10 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 47: Counter

The following is carried out for paper jams occurring after the paper feed inlet sensor (PS10) detects the trail edge of the paper. Internal jam; The total count becomes “–1” at the point of detection. Paper ejection section jam; The total count remains “+1” even if jam is detected. 2-11 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 48: Configuration

Detects whether paper is at the paper feedable position. [3] Paper feed tray sensor 2 (PS9) <DC 5 V, photosensor> Detects paper feed tray height. [4] Paper feed inlet sensor (PS10) <DC 5 V, photosensor (light-emitting and receiving separation type)> Detects paper feed state. 2-12 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 49: Paper Feed Operations

8) Paper is conveyed to the registration section by the conveyance roller, and hits the stationary registration roller (skew correction). 9) The registration roller rotates (registration brake OFF, registration clutch ON), and paper is conveyed to the folding roller. 2-13 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 50: Paper Feed Tray Section

Configuration Shield plate Side guide adjusting knobs Side guide dial Side guide Side guide Left side pulleys, Right side pulleys, timing belts timing belts [1] PS P.W.B. unit (PCB4) Detects paper width. Composed of photosensors. 2-14 DUPLO DF-1000 12T-M12M0-0602-0... - Page 51 Loosening the side guide adjusting knob enables fine adjustment of the fixing position of the side guide and skew correction of paper on the paper feed tray. Side guide L Side guide adjusting knob Fulcrum ±1 mm ±1 mm Side guide R Side guide adjusting knob Fulcrum 2-15 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 52: Tray Up/Down Section

Refer to “3.1.2 Paper feed operations”. The home position of the paper feed tray is detected when the pin (screw + spacer) attached on the rack at the frame B side turns OFF the paper feed tray home switch (SW4). 2-16 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 53: Suction Conveyance Section

When several sheets of paper are being fed by the suction belt, the separator drops the second sheet of paper onwards. Rotating the separator adjusting knob moves the separator up and down. NOTE Adjust the separator height according to the paper thickness and type. 2-17 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 54: Suction Section

Transmits the drive of the main motor to the suction belt via the conveyance roller. [5] Thin paper feed button (SW9) <DC 5 V, push switch with built-in LED> Turns ON/OFF the operations of the suction solenoid (SOL1). 2-18 DUPLO DF-1000 12T-M12M0-0602-0... - Page 55 When fine quality paper less than 81.9 g/m is used, press the thin paper feed button (SW9) to process as thin paper. When this button is pressed, paper will be fed with the suction solenoid (SOL1) in the OFF state (valve open state). 2-19 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 56: Conveyance Section

Paper feed interval control Paper feed Remarks Paper feed interval setting Processing speed start time FAST A (Quick) The paper feed start time A to D differs according to the size of standard paper. NORMAL SLOW D (Slow) 2-20 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 57: Registration Section

Secondary registration roller Registration roller BRK1 CLH3 MOT1 PS10 NOTE Adjust the tilt of the secondary registration roller using the skew correction knob as necessary. Refer to “Chapter 1 INTRODUCTION > 5.2.2 Skew correction by skew correction knob”. 2-21 DUPLO DF-1000 12T-M12M0-0602-0... - Page 58 8) When the paper feed inlet sensor (PS10) detects the paper lead edge, the registration brake (BRK1) goes OFF. 9) Hereafter, steps 2) to 7) are repeated. 10) After processing the set number of sheets, the main motor (MOT1) stops and at the same time, the registration brake (BRK1) goes OFF. 2-22 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 59: Folding Section

6) The slackened part of the paper is sandwiched between folding roller 2 and folding roller 3. (Second folding) Paper ejection 7) Paper is conveyed to the paper ejection section by folding rollers 2 and 3. 2-23 DUPLO DF-1000 12T-M12M0-0602-0... - Page 60 4 FOLDING SECTION b. Single fold c. Double fold d. Irregular accordion fold 2-24 DUPLO DF-1000 12T-M12M0-0602-0...

- Page 61 4 FOLDING SECTION e. Letter fold f. Accordion fold 2-25 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 62: Folding Plate Section

Detects the index plate attached to the folding plate stopper motor and the distance moved by the folding stopper. [4] Folding plate 1 home sensor (PS3) [8] Folding plate 2 home sensor (PS6) <DC 5 V, photosensor> Detects the home position of the folding stopper. 2-26 DUPLO DF-1000 12T-M12M0-0602-0... - Page 63 Code No.1 : Correction value of folding plate 1 home position Code No.2 : Correction value of folding plate 2 home position Code No.3 : Correction value of switching shaft home position Refer to “Chapter 6 MAINTENANCE MODE > 3 MENUS AND FUNCTIONS”. 2-27 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 64: Folding Roller Section

4.3.1 Configuration Reference The basic structure is the same as DF-920/915. < R > < L > Symbol Part name Symbol Part name Idler roller Folding roller 1 Center press roller Folding roller 2 Folding roller 3 2-28 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 65: Paper Ejection Section

Detects paper ejection. 5.1.2 Paper ejection operations 1) Folded paper is ejected by folding roller 3 and ejection roller. 2) Ejected paper is conveyed to the paper receiving tray by the stacker roller and stacker belt. 2-29 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 66: Stacker Belt Section

The drive of the stacker belt is transmitted from the main motor via the stacker belt clutch (CLH2) and shaft coupling. Stacker belts Timing belt Timing belt Main motor (MOT1) [1] Stacker belt clutch (CLH2) <DC 24 V, electromagnetic clutch> Transmits drive from the main motor to the stacker belt. 2-30 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 67: Stacker Roller Section

Detects the home position of the stacker roller. [2] Stacker roller moving motor (MOT5) <DC 24 V, DC motor> Motor for moving the stacker roller. Controls the distance moved by the stacker roller together with the stacker roller home sensor (PS11). 2-31 DUPLO DF-1000 12T-M12M0-0602-0... - Page 68 Memo 2-32 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 69: Disassembly/Assembly

Chapter 3 DISASSEMBLY/ASSEMBLY DUPLO DF-1000 12T-M12M0-0602-0... -

Page 70: External Cover/Control Section

[4] Top cover L [5] Top cover R [6] Stacker side cover [7] Main cover B [8] Side cover [9] Folding plate upper cover [10] Folding plate lower cover — Secure together with folding plate upper cover. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 71: Control Panel Section

EEPROM of the MC unit. Refer to “Chapter 6 MAINTENANCE MODE > 5 DATA INITIALIZATION”. 2) Setting data Reset various data in the maintenance mode as necessary, such as home position adjustment of folding plates and switching shaft, etc. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 72: Power Supply/Drive

R e f e r t o “ C h a p t e r 5 S T A N D A R D S / ADJUSTMENTS > 2.2.1 Adjusting the tention of the timing belt”. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 73: Removing The Paper Feed Tray Motor

R e f e r t o “ C h a p t e r 5 S T A N D A R D S / ADJUSTMENTS > 2.2.1 Adjusting the tention of the timing belt”. 5) Remove the paper feed tray motor. [1] Fixing screw (Remove) ......4 [3] Connector [4] Paper feed tray motor DUPLO DF-1000 12T-M12M0-0602-0... -

Page 74: Paper Feed Section

2.2.2 Removing the suction belts 1) Remove the secondary roller of the suction conveyance unit. 2) Remove the set collar and bearing on the paper feed shaft, and remove the paper feed shaft. 3) Remove the flat belts. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 75: Registration Section

2.3.4 Removing the registration roller 1) Remove the registration clutch (CLH3). 2) Remove the registration brake (BRK1). 3) Remove the E-ring at frame B. 4) Remove the bearing holder from inside the frame and pull out the registration roller. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 76: Folding Section

Do not remove the fixing screws of the connecting plate (at folding plate 2 unit) and remove the connecting plate. As the connecting plate is adjusted by tool at assembly, it cannot be adjusted on the market. 5) Remove the sensor bracket. 6) Remove the connector. 7) Remove the folding plate index sensor. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 77: Removing The Folding Plate Home Sensors (Ps3, Ps6)

12) Remove the timing pulley of the jam correction knob, and remove the timing belt. 13) Remove the timing pulley and helical gear at frame B. NOTE When installing the helical gear, install from the center press roller. Remember also to insert the key. DUPLO DF-1000 12T-M12M0-0602-0... - Page 78 23) Remove the portion fixing the paper ejection stay and main body together (frame B side). 24) Remove folding roller 1. Remove while widening the clearance between the frames slightly. 25) Remove the bearing holder and remove the center press roller. 3-10 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 79: Paper Ejection Section

2) Remove the stacker roller moving motor. 3) Remove the lever unit, roller, and joint, etc. 4) Remove the stacker belts. NOTE When installing the stacker belt, install according to the instructions on the rotating direction printed inside the belt. 3-11 DUPLO DF-1000 12T-M12M0-0602-0... - Page 80 Memo 3-12 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 81: Maintenance/Inspection

Chapter 4 MAINTENANCE/INSPECTION DUPLO DF-1000 12T-M12M0-0602-0... -

Page 82: List Of Maintenance Tools

Thickness gauge Gap adjustments Level For adjusting the paper feed tray position Refer to “Chapter 5 STANDARDS/ ADJUSTMENTS > 3.1.1 Adjusting the paper feed tray position”. 1.2 Special Tools There are no special tools for this unit. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 83: Product Lifespan/Parts Lifespan

11A-10200 Paper feed section Flat belt 11A-11393 Spring C 12H-30470 Folding section Pulley unit 12H-40390 Paper ejection section Valve head unit 12T-24480 Paper feed section Spring T 12T-24690 Spring T 12T-26280 Flat belt 12T-42190 Paper ejection section DUPLO DF-1000 12T-M12M0-0602-0... -

Page 84: Periodic Maintenance

Area where press reference p i l l a r a n d p r e s s b a r a r e connected Plate spring of folding roller Equivalent to Dow Corning MOLY KOTE 41 grease DUPLO DF-1000 12T-M12M0-0602-0... -

Page 85: Standards/Adjustments

Chapter 5 STANDARDS/ADJUSTMENTS DUPLO DF-1000 12T-M12M0-0602-0... -

Page 86: Basic Adjustment Procedures

7) Measure the center of the ejected paper (second sheet), and adjust so that the following reference values are satisfied. Reference value of USA model UK model folded plane length Folded plane length [C] 139.5 ± 0.5 mm 148.5 ± 0.5 mm Conveyance direction Conveyance direction DUPLO DF-1000 12T-M12M0-0602-0... -

Page 87: External Cover/Control Section

[2] Sensor bracket c. Safety lever switch (SW7) <Adjustment value> When the paper feed tray is at the lower limit position, the clearance [B] should be 0.7 ± 0.2 [1] Fixing screw (Loosen) ....... 2 [2] Sensor bracket DUPLO DF-1000 12T-M12M0-0602-0... -

Page 88: Drive Section

When a load of 3 N is applied vertically to the belt at measuring point [C], the slack should be 3 to 5 mm. [3] Paper feed tray motor Adjusting screw ........4 d. Other drive belts <Adjustment value> Do not tauten the drive belts [D], [E], and [F] excessively. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 89: Attaching Position Of Motor Pulley

figure. [1] Motor pulley [2] Frame B (37 mm) 62 ± 0.5 mm b. Paper feed tray motor (MOT4) Attach the motor pulley as shown in the figure. [1] Motor pulley (14 mm) 30 ± 0.5 mm DUPLO DF-1000 12T-M12M0-0602-0... -

Page 90: Paper Feed Section

At this time, check that the clearance between the stopper plate and arm is 1.5 to 3.5 <Adjustment value> 100 to 102 mm [3] Stopper plate 5) Adjust the attaching position so that the paper feed tray home switch (SW4) turns ON at step [4] Fixing screw (Loosen) ....... 2 [5] Sensor bracket DUPLO DF-1000 12T-M12M0-0602-0... - Page 91 3 PAPER FEED SECTION 90° 1.5 to 3.5 mm 100 to 102 mm DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 92: Adjusting The Side Guide

1 N (102 gf) is applied near the belt center [A] with a 5 N (510 gf) tension gauge, the belt slackens by 3 to 5 mm. 360 mm (73 mm) (210 mm) (73 mm) 90° 90° DUPLO DF-1000 12T-M12M0-0602-0... -

Page 93: Suction Conveyance Section

1) Loosen the set screw of the separator adjusting knob. [1] Separator adjusting knob (Set screw) 2) Slide the bracket in the arrow direction until it stops. [2] Bracket 3) Adjust the separator adjusting knob to “1”, and tighten the set screw. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 94: Adjusting The Suction Conveyance Unit Position

Refer to “Chapter 6 MAINTENANCE MODE > 3 MENUS AND FUNCTIONS”. 3) Adjust the attaching position of the plate [1] so that the level sensor adjusting lever [2] does not exceed the distance in step 2). 7 ± 0.5 mm 5-10 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 95: Adjusting The Suction Solenoid (Sol1) Position

<Adjustment value> Adjust so that when the lever protrusion amount [A] from the shutter is 1 ± 0.2 mm, it is detected by the sensor. [1] Shutter [2] Lever [3] Sensor bracket (Adjusting screw ........2) 5-11 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 96: Folding Section

7) Rotate the conveyance roller by hand to convey the paper. Convey until the paper lead edge touches the registration secondary roller. 8) Rotate the registration secondary roller by hand to convey the paper. Convey until the paper lead edge touches the idler roller. 5-12 DUPLO DF-1000 12T-M12M0-0602-0... - Page 97 The adjustment method is the same as the folding plate 1 folding stopper. 15) Install the folding plate 1 unit and install the folding plate to the main body. 16) Perform from step 3) and check that the parallel adjustment of each folding stopper has been completed appropriately. 5-13 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 98: Adjusting The Home Position Of The Switching Shaft

finger), folding roller 2 may get damaged. 6) Press the [clear] key while pressing the [stop] key. The folding stopper executes initial operations and the folding plate 2 folding stopper moves to the home position of the switching shaft. 5-14 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 99: Adjusting The Home Position Of The Folding Stopper

Pressing the key once increases the folded plane length by 0.125 mm. Speed key [–]: Pressing the key once decreases the folded plane length by 0.125 mm. 7) Repeat steps 3) to 6) until the respective folded plane length becomes the reference value. 5-15 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 100: Checking The Conveyance Path Gap Of Folding Plate

[A] between the chassis [2] (motor side) and bearing [3], and adjust the thrust play to the following value. <Adjustment value> More than 0.1 mm but less than 0.15 mm. (Thickness gauge of 0.1 can be inserted but not 0.15.) 5-16 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 101: Adjusting The Motor Deceleration Pulley Section

When a load of 3 N is applied to the timing belt at measuring points [B] and [C], the respective slack should be 2 to 3 mm. [3] Deceleration timing belt 1 [4] Deceleration timing belt 2 [5] Motor deceleration pulley 5-17 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 102: Adjusting The Folding Stopper Section

figure, paying attention to the parallelity of the left and right sides. [1] Switching adjusting plate (Screw ............2) NOTE Apply a very small amount of thread locking to the fixing screw of the switching adjusting plate. (Equivalent to Loctite 242: Medium strength) 5-18 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 103: Folding Roller Section

(Reference value: Gap between 0.1 to 0.2 [1] Adjusting screw [2] Folding roller 1 [3] Center press roller 36.1 mm 35.9 mm 35.9 mm 35.9 mm < Rear > 5-19 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 104: Checking The Folding Roller Nip

T of the concerned roller and adjust the nip amount uniform. Refer to “4.2.1 Adjusting the attaching position of the press spring T”. [ i ] [ i ] [ A ] [ c ] 5-20 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 105: Adjusting The Attaching Position Of The Conveyance Plate

2) In the state of step 1), attach the folding plate to the main body of the unit. 3) Tighten the fixing screw [B2]. Secure with the folding plate attached to the main body. 4) Remove the folding plate and tighten fixing screw [B1]. 5-21 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 106: Paper Ejection Section

Gap [A] between shafts is 39.7 ± 0.5 mm. [1] Adjusting screw ........2 [2] Motor bracket 5.2.2 Adjusting the stacker roller home sensor (PS11) position <Adjustment value> Secure at top of long hole. [3] Adjusting screw ........2 [4] Sensor angle 5-22 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 107: Maintenance Mode

Chapter 6 MAINTENANCE MODE DUPLO DF-1000 12T-M12M0-0602-0... -

Page 108: Outline

Version upgrade Menu for upgrading the program version. (Code No. 18) d. Test checks Menu for checking operations such as LEDs, 7-segment window, switches, sensors, motors, clutches, etc. (Code No. 21 to 27, 31 to 36) DUPLO DF-1000 12T-M12M0-0602-0... -

Page 109: Maintenance Mode Operations

Upon entering the maintenance mode, “MAINTENANCE MENU” will appear on the LCD. 2.2 Exiting the Maintenance Mode a. Method 1 1) Turn off the power switch. b. Method 2 1) Press the [clear] key two times continuously. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 110: Menus And Functions

Mode for setting the unit of the size displayed on the 5.SET MM/INCH MILLIMETER* INCH LCD. At shipment, this is set according to the destination of the unit. Japanese model : MILLIMETER USA model : INCH UK model : MILLIMETER DUPLO DF-1000 12T-M12M0-0602-0... - Page 111 Mode for upgrading the program version. 18.PROG VER UP R e f e r t o “ 4 U P G R A D I N G T H E P R O G R A M VERSION”. DUPLO DF-1000 12T-M12M0-0602-0...

- Page 112 Folding plate 2 folding stopper adjusting key [+] Stacker roller moves outside (away from paper ejection section). NOTE If the stacker roller is fed too outside, the motor locks. Folding plate 2 folding stopper adjusting key [–] Stacker roller moves inside (home position side). DUPLO DF-1000 12T-M12M0-0602-0...

- Page 113 Do not leave the unit with the clutch operating. Otherwise, the clutch will overheat, resulting in malfunction. Paper feed clutch (CLH1) Operates with the [start] key. Stacker belt clutch (CLH2) Operates with the [stop] key. Registration clutch (CLH3) Operates with the [test] key. DUPLO DF-1000 12T-M12M0-0602-0...

- Page 114 Mode for making the folding stoppers of folding plates 1 and 2 parallel. Refer to “Chapter 5 STANDARDS/ADJUSTMENTS > 4.1.1 Adjusting the parallelity of the folding stopper”. NOTE The folding stopper will not operate if any one interlock switch is not closed. DUPLO DF-1000 12T-M12M0-0602-0...

- Page 115 Sensor which is ON. [–] displayed; Sensor which is OFF. Available paper sizes for UK model (from left); B6, A5, B5, A4, B4, A3 Available paper sizes for USA model (from left); INV, STMT, LTR, LGR, LGL DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 116: Other Functions

For this reason, the up/down operations of the paper feed tray will become slower than normally, and the overall processing speed will drop. b. Operations 1) Turn ON the power switch while pressing the [stop] and [mode] keys. NOTE This setting is cleared when the power switch is turned OFF. 6-10 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 117: Upgrading The Program Version

A program with a different ID is written in the EPROM. 6) Enter the maintenance mode, select “15. MC ROM VER”, and check that the new version is displayed on the LCD. 7) Turn OFF the power, and remove the EPROM. 6-11 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 118: Data Initialization

Procedure for initializing total count at the same time 1) Turn OFF the power switch. 2) While pressing the [start] key, [stop] key, and [clear] key together, turn ON the power switch. All data in the EEPROM (U1) including the total count is initialized. 6-12 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 119: Troubleshooting

Chapter 7 TROUBLESHOOTING DUPLO DF-1000 12T-M12M0-0602-0... -

Page 120: Outline

3. Operational problems (No error message is displayed on the control panel) Example; Power does not turn ON Nothing is displayed on control panel Key operations are disabled If these phenomena occur, refer to the following and perform the appropriate measure. Refer to “4 TROUBLESHOOTING FOR OPERATION FAILURES”. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 121: Troubleshooting By Phenomenon

Yes: Use the original paper before change. If paper has been changed, the folding stopper position must be corrected. Adjust each part according to the basic adjustment procedure. Refer to “Chapter 5 STANDARDS/ADJUSTMENTS > 1 BASIC ADJUSTMENT PROCEDURES”. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 122: Folding Misalignment Along Sides Of Paper

4) Are the left and right skew roller spring pressure adjusting knobs set at the same position? Set at the same position. Yes: Adjust each part according to the basic adjustment procedure. Refer to “Chapter 5 STANDARDS/ADJUSTMENTS > 1 BASIC ADJUSTMENT PROCEDURES”. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 123: Troubleshooting By Message Displayed

Refer to “Chapter 6 MAINTENANCE MODE > 3.1 Menu List”. Check the optical axis, connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the sensor. Yes: Replace the MC unit. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 124: Error Messages

Refer to “Chapter 6 MAINTENANCE MODE > 3.1 Menu List”. Check the connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the solenoid. Yes: Replace the MC unit. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 125: Trouble Messages

4) Is the problem resolved by replacing the folding plate 2 index sensor A (PS4) or B (PS5)? Yes: End. Check the connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the MC unit. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 126: When "Motor Error 3" Is Displayed

Refer to “Chapter 6 MAINTENANCE MODE > 3.1 Menu List”. Check the connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the motor. Yes: Replace the MC unit. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 127: When "Tray Up Error" Is Displayed

Refer to “Chapter 6 MAINTENANCE MODE > 3.1 Menu List”. Check the connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the switch. Yes: Replace the MC unit. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 128: Other Messages

Refer to “Chapter 6 MAINTENANCE MODE > 3.1 Menu List”. Check the connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the switch. Yes: Replace the MC unit. 7-10 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 129: Troubleshooting For Operation Failures

Yes: Replace the bundled wires. Check for problems in the electric parts of the part connected to and replace if faulty. 4) Is the problem resolved by replacing the control panel? Yes: End. Replace the MC unit. 7-11 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 130: Key Operations Are Disabled On Control Panel

Take note that this unit does not detect PS P.W.B. unit (PCB4) problems. Check the connection of connectors and if bundled wires have disconnected or short-circuited, and if they are found to be normal, replace the PS P.W.B. unit. Yes: Replace the MC unit. 7-12 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 131: Appendix

Appendix DUPLO DF-1000 12T-M12M0-0602-0... -

Page 132: List Of Displayed Messages

“finished size + certain time” after the sensor detected the paper lead edge. ∗ 1 : Calculated from conveyance distance inside the unit. The conveyance distance inside the unit changes according to the positions of the folding stoppers. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 133: Trouble

While the paper feed tray is descending, the paper feed tray home switch (SW4) does not turn ON within the specified time. TRAY UP ERROR The paper feed tray upper limit switch (SW6) turns ON. TRAY DOWN ERROR The safety lever switch (SW7) turns ON. DUPLO DF-1000 12T-M12M0-0602-0... -

Page 134: Layout Of Electrical Parts

PCB2 PCB3 PCB1 Symbol Name Remarks BRK1 Registration brake PCB1 MC unit PCB2 Control panel PCB3 Switching power supply Power switch Safety lever switch Safety function parts Tray down button Thin paper feed button (Suction solenoid switch) DUPLO DF-1000 12T-M12M0-0602-0... -

Page 135: Back Of Unit

Top cover R switch Safety function parts Side cover switch Safety function parts Folding plate switch Safety function parts Paper feed tray home switch Top cover L switch Safety function parts Paper feed tray upper limit switch Safety function parts DUPLO DF-1000 12T-M12M0-0602-0... -

Page 136: Inside Unit

2.3 Inside Unit PS10a PS12b PS10b FAN2 FAN1 Symbol Name Remarks FAN1 Blower fan FAN2 Suction fan PS10a Paper feed inlet sensor Light-emitting side PS10b Paper feed inlet sensor Light-receiving side PS12b Paper ejection outlet sensor Light-receiving side DUPLO DF-1000 12T-M12M0-0602-0... -

Page 137: Paper Feed Section

P a r t s d i f f e r b e t w e e n U K model and USA model Paper feed tray sensor 1 PS8a Paper sensor Light-emitting side PS8b Paper sensor Light-receiving side Paper feed tray sensor 2 PS13 Legal paper detection sensor USA model only DUPLO DF-1000 12T-M12M0-0602-0... -

Page 138: Folding Plate Section

Folding plate 2 stopper motor Folding plate 1 index sensor A Folding plate 1 index sensor B Folding plate 1 home sensor Folding plate 2 index sensor A Folding plate 2 index sensor B Folding plate 2 home sensor DUPLO DF-1000 12T-M12M0-0602-0... -

Page 139: Paper Ejection Section

2 LAYOUT OF ELECTRICAL PARTS 2.6 Paper Ejection Section PS12a MOT5 PS11 Symbol Name Remarks MOT5 Stacker roller moving motor PS11 Stacker roller home sensor PS12a Paper ejection outlet sensor Light-emitting side DUPLO DF-1000 12T-M12M0-0602-0... -

Page 140: Layout Of Boards

3 LAYOUT OF BOARDS 3 LAYOUT OF BOARDS 3.1 MC Unit A-10 DUPLO DF-1000 12T-M12M0-0602-0... -

Page 141: Control Panel

3.3 Switching Power Supply CN52 VR51 3.4 PS P.W.B. Unit a. UK model PH6 (B6) PH5 (A5) PH4 (B5) PH3 (A4) PH2 (B4) PH1 (A3) b. USA model PH3 (HL) PH3 (Hr) PH2 (L) PH1 (LL) A-11 DUPLO DF-1000 12T-M12M0-0602-0... - Page 142 Memo A-12 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 143: Overall Schematic Diagram

4 OVERALL SCHEMATIC DIAGRAM PCB1 PCB2 PCB3 PS8b PS8a MOT1 UK model PCB4 USA model PCB4 PS10a PS10b PS13 PS11 4 OVERALL SCHEMATIC DIAGRAM PS12b PS12a 12T-85022 A-13 DUPLO DF-1000 12T-M12M0-0602-0... - Page 144 Memo A-14 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 145: Wiring Diagram

Fan bracket 12T-2437 Suction duct A 12T-8208 3303 3303 3304 3304 Bundled wire unit 8 Cable clamp 056-09001 3302 056-09002 3303 5 WIRING DIAGRAM 056-09003 3304 056-09004 3305 056-09006 3307 056-09007 3308 056-09009 3330 12T-85031 (1/2) A-15 DUPLO DF-1000 12T-M12M0-0602-0... - Page 146 Frame B 051-10172 DC fan motor View of 3 , 4 12T-2619 Yellow, Light blue, Pink Fan bracket 98R-8023 Photointerrupter Gray, Light blue, Pink 12T-8205 Light blue, Bundled wire unit 5 Purple Yellow, Gray 12T-85031 (2/2) A-16 DUPLO DF-1000 12T-M12M0-0602-0...

-

Page 147: Duplo Df-1000 12T-M12M0

DUPLO CORPORATION Duplo building, 1-6, Oyama 4 chome, Sagamihara, Kanagawa 229-1180, Japan Revision 0 (Feb. 2006) DUPLO DF-1000 12T-M12M0-0602-0... - Page 148 12T-M12M0 DUPLO DF-1000 12T-M12M0-0602-0...

Need help?

Do you have a question about the DF-1000 and is the answer not in the manual?

Questions and answers