Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Duplo DP-21S II

- Page 1 DP-21S /21L /23S Instruction Manual Ver.2 Correct operation and periodic maintenance are essential for ensuring safe use of this machine. Thoroughly read this manual before using this machine. DUPLO CORPORATION Store this manual so that it can be retrieved whenever needed.

-

Page 3: Introduction

After using this manual, be sure to keep it in a place to handy reference. INFORMATION ON PRODUCT CERTIFICATION STENCIL COPIERS MODELS DP-24Sll, DP-22Sll, DP-23Sll, DP-21Sll DUPLO certified by Certification Body GOST-ASIA, (Registration number in State Register - ROSS SG.0001.11.BZ02) Certificate of Conformity: No.ROSS JP.BZ02.B04173... -

Page 4: Function Quick Reference

Function Quick Reference The following is a quick reference to the functions of the DP-21SII/21LII/23SII printer. Enlargement/Reduction ..(a P.36) This function copies a document on one standard paper size to another larger or smaller standard paper size. B4 Printout A4 Document B5 Printout 94% Reduction... - Page 5 Function Quick Reference Batch Printing ..(a P.55) You can print the specified number of sets of copies in each set. 1st set 2nd set 3rd set 5 copies x 2 sets 3 copies x 4 sets 2 copies x 5 sets Document Changing Print Quantity per Document ..

-

Page 6: Table Of Contents

Contents Introduction ......................... 1 Function Quick Reference ....................2 Notes on Safety (Please Read and Observe) ..............7 Safety Precautions ....................7 Warning Sticker ......................10 Positioning the Machine ................... 11 Maintenance ......................12 Printing and Duplicating Cautions ................13 Conventions Used in This Manual ................ - Page 7 Contents Chapter 3 Printing With Various Function Saving Settings ......................... 48 Saving Settings ......................48 Retrieving Settings ....................50 Clearing Settings ...................... 51 Printing Two Different Document Pages on One Page ..........52 Adjusting Plate Darkness ....................54 Batch Printing ........................55 Batch Printing ......................

- Page 8 Contents Chapter 7 Specifications and Maintenance Specifications ......................... 104 Appendix Index ..........................108 Quick Operation Guide ....................110...

-

Page 9: Notes On Safety (Please Read And Observe)

Notes on Safety (Please Read and Observe) Safety Precautions Various symbols and pictures are used in this manual and on the stickers affixed to the machine. These symbols and pictures provide warnings and instructions to prevent danger to you or other personnel, and to prevent damage to office property. - Page 10 Notes on Safety (Please Read and Observe) WARNING Do not modify the machine. • Doing so may result in fire or electric shock. Do not remove the rear lid, cabinet, or covers from the machine. • The inside of the machine contains high-voltage parts, which may cause electric shock. Do not remove or insert the power plug with wet hands.

- Page 11 Notes on Safety (Please Read and Observe) CAUTION Before moving the machine, remove the power plug from the outlet. • If the cord is damaged, this may result in fire or electric shock. Remove the power plug itself, not the cord. •...

-

Page 12: Warning Sticker

Notes on Safety (Please Read and Observe) Warning Sticker Keep the WARNING stickers clean at all times. If stickers become damaged or come off, replace them with new ones. ● Do not remove this cover. The inside of the printer contains movable cutting instruments, WARNING contact with which could result in injury. -

Page 13: Positioning The Machine

Notes on Safety (Please Read and Observe) Positioning the Machine Installing the machine on a flat, stable surface. Avoid installing the machine in a dusty area. Avoid installing the machine in the direct sunlight or heat, such as near a stove. Ink may deteriorate and may cause bad prints, while the machine may indicate errors due to overheating caused by sunlight. -

Page 14: Maintenance

Notes on Safety (Please Read and Observe) Maintenance Clean the exterior of the machine as described below. Tightly wring a soft cloth that has been moistened with water or neutral detergent, and wipe dirt from the ma- chine’s surface. Never use alcohol or organic solvents. Doing so may discolor or damage the machine exterior. -

Page 15: Printing And Duplicating Cautions

Notes on Safety (Please Read and Observe) Printing and Duplicating Cautions There are restrictions on what you may print on this printer. Please be aware that there are some printed materials that are illegal even to possess. 1. Printed Matter Banned by Law •... -

Page 16: Conventions Used In This Manual

Notes on Safety (Please Read and Observe) Conventions Used in This Manual Each page of descriptions in this manual of how to operate the DP-21SII/21LII/23SII is set up as follows. Title (Function) Enlargement and Reduction Enlarging/Reducing from Standard-Size Document to Standard-Size Paper You can enlarge or reduce a standard-size document onto standard-size printing paper. - Page 17 Chapter Before Using This Machine This chapter contains essential information such as the names of the machine parts, the names and functions of keys, etc., on the control panel, and the sizes of documents and printing papers that you can use. Please be sure to read this chapter carefully before attempting to use the printer.

-

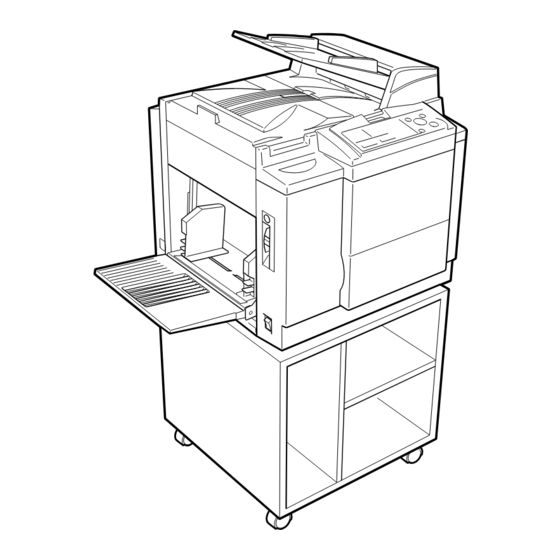

Page 18: System Setup

System Setup The machine and its optional equipment are set up as follows: Duplo Direct Print System Key card counter Tape cluster Personal computer Documents prepared on a personal computer can be Cabinet printed on this machine. PC interface kit is required to connect this machine to a personal computer. -

Page 19: Part Names And Their Functions

Part Names and Their Functions Printer Appearance Reference Name Function page Document guide Slide to match the width of the document. 30, 35, Documents of sheet type can be printed consecutively. Upper cover Open to replace the master roll, etc. Feed tray descend switch Press to lower the feed tray. -

Page 20: Master Roll

Part Names and Their Functions Master set lever When the master set lever is pushed, the master is pulled in and set. Master roll Upper cover Scanner unit Master cover release lever Master cover Lever This lever releases the ink Front cover pack holder. - Page 21 Part Names and Their Functions Master ejection core Reference Name Function page — Plate ejection box release lever Press to open the master ejection box. JOG switch Press and hold to rotate the drum for a set time. Use to remove —...

-

Page 22: Control Panel

Part Names and Their Functions Control Panel 1 : 1 Reference Name Function page “OK” monitor Flashes to display the content of the trouble and lights to indicated the part that caused the trouble in the machine. “ENLARGEMENT” key Press to set the enlargement ratio. “100%”... - Page 23 Part Names and Their Functions Reference Name Function page “STOP” key Press to stop printing on the way. If this key is pressed while the machine is stopped, the total number of prints and plates will be displayed on the LCD panel. “PRINT”...

-

Page 24: Lcd Panel

Part Names and Their Functions LCD Panel 1 0 0% sht 1set Reference Name Function page Print count Displays the number of prints to be made. Sets Displays the number of sets to be printed. Zoom ratio Displays the selected (enlargement/reduction)ratio. -

Page 25: Turning Power On/Off

Turning Power ON/OFF This section describes the operating sequence from turning ON the power switch until the printer is ready to make prints, and how to turn OFF the printer power. Turning ON Printer Power Connect the power cable to the printer and a wall outlet. -

Page 26: Turning Off Printer Power

Turning Power ON/OFF Turning OFF Printer Power Switch the power switch to the “ ” position. The power turns OFF and the display lamps on the control panel turn OFF. Standard Mode When the printer power is first turned ON or (ALL CLEAR) key is pressed, the functions are reset to standard mode. -

Page 27: Key Card Counter [Available Only With Key Card Counter Installed]

Turning Power ON/OFF Key Card Counter Available only with Key Card Counter installed With the key card counter installed, you can control the platemaking and print quantities per person or per department, etc. See the Instruction Manual for the Key Card Counter for details. ■... -

Page 28: Document/Printing Paper Specification

Document/Printing Paper Specification Acceptable Documents • Document thickness : 64g/m to 128g/m • Document size : A3 to A5 size ST to 11x17-in. (ST size in landscape mode: STR cannot be used.) • Stacking capacity in document tray : 100 sheets (64g/m IMPORTANT •... -

Page 29: How Platemaking And Printing Is Performed

How Platemaking and Printing is Performed The machine performs two processes: platemaking and printing. Platemaking In the “platemaking” process, the old master on the drum is removed while the thermal head creates the scanned image on the new master and transfers it onto the drum. Master roll Master ejection box Drum... - Page 31 Chapter Printing Using Basic Functions This chapter describes how to make prints using the basic functions, including how to load the document, set zoom ratio, etc. Basic Printmaking ....................30 Loading and Replacing Paper ................32 Loading Paper ..................... 32 Adjusting Paper Feed Pressure ..............

-

Page 32: Basic Printmaking

Basic Printmaking This section describes how to make prints using the basic functions. Turn ON the power. (a a a a a See page 23, “Turning Power ON/OFF”) • If the power is already ON, press (ALL CLEAR) key. Load paper. (a a a a a See page 32, “Loading and Replacing Paper.”) Load the document. - Page 33 Basic Printmaking Use the keypad to specify the number of prints to make. Tips • You can specify up to 9999 prints. • If you make a mistake entering the number of Key pad prints, press (CLEAR) key then enter the correct number.

-

Page 34: Loading And Replacing Paper

Loading and Replacing Paper Loading Paper This section describes how to load the printer with paper. You can load approximately 1,300 sheets in this printer. Open the support tray. Hold the lever and adjust the side guides to the paper size. Load a stack of aligned sheets between the paper guides and press the stack lightly toward the machine. -

Page 35: Adjusting Paper Feed Pressure

Loading and Replacing Paper Adjusting Paper Feed Pressure Adjust the paper feed pressure if an feeding error occurs when using thick or thin paper. ■ When no thick paper is fed Adjust the paper feed pressure adjuster lever to “HIGH”. ■... -

Page 36: Loading Documents

Loading Documents Positioning the Document The document can be loaded in the “portrait” or “landscape” position. IMPORTANT • A4 and B5-size documents can be loaded in the “portrait” or “landscape” position. • Use the landscape position when enlarging or reducing from standard-size documents to standard-size paper, such as A5 to A4. -

Page 37: Loading Document

Loading Documents Loading Document When one or more documents are loaded, platemaking and printing are automatically repeated until the document tray is empty. Align the document guide with the marks for Document Guide the size of document to be loaded. Place the document face-up in the document tray. -

Page 38: Enlargement And Reduction

Enlargement and Reduction Enlarging/Reducing from Standard-Size Document to Standard-Size Paper You can enlarge or reduce a standard-size document onto standard-size printing paper. The following zoom ratios are available when enlarging or reducing a standard-size document onto standard-size printing paper. ■ Enlargements You can enlarge a standard-size document onto standard-size paper using the following zoom ratios: ●... -

Page 39: 94% Reduction

Enlargement and Reduction Press (ENLARGEMENT) key or (REDUCTION) key several times to display the desired zoom ratio. In about 3 seconds, the screen changes to the number display screen and the zoom ratio is selected. Press (ENLARGEMENT) key or (REDUCTION) key to move the arrow on the LCD panel. ◆... - Page 40 Enlargement and Reduction Press (SELECT) key to display “ON”. 3.x 94% Press (FUNCTION SWITCH) key. 94% reduction is set, and the standard screen appears.. 100% sht 1set You can cancel 94% reduction using one of the following two methods. • Set to “OFF” in the same procedure. •...

-

Page 41: Selecting Printing Paper Size

Selecting Printing Paper Size Select a paper size. Press (FUNCTION SWITCH) key. The screen at right appears on the LCD panel. 1.PLATE SIZE Press (SELECT) key and display the paper size to be used. Each time (SELECT) key is pressed, the display of the LCD panel changes as follows. ◆... - Page 42 MEMO...

-

Page 43: Text/Photograph/Text And Photograph Mode

Selecting Printing Paper Size Text/Photograph/Text and Photograph Mode This function includes three modes for enhancing text and photographic documents. ■ Text/Photograph/Text and Photograph Mode In this mode, the print quality is adjusted to match the document. Text Text/Photograph Photograph ABCDEFGH ABCDEFGH ABCDEFGHIJKLNO ABCDEFGHIJKLNO... - Page 44 Text/Photograph/Txt and Photograph Mode Proceed with steps 1 to 4 of the sequence described in “Basic Printmaking” (a a a a a page 30). Press (DOCUMENT MODE SWITCH) key to select the desired mode. Each time (DOCUMENT MODE SWITCH) key is pressed, the lit document mode indicator lamp changes as follows.

-

Page 45: Print Output

Print Output Installing Print Tray Remove the print tray. Install the print tray. • When you use the printer on a table, install the print tray into the upper fitting. (Stacking capacity; 900 sheets, 55 kg, high-grade paper) • When you use a cabinet (option), install the print tray into the lower fitting. - Page 46 Print Output Open out the paper stopper. Adjust the paper stacker guides and paper stopper to the size of the printing paper.

-

Page 47: Truing Up Printed Pages

Print Output Truing up Printed Pages Available only when sorter is installed Adjust when the edges of the printed pages are not trued up. ■ Adjusting jump plate Adjust the plate according to the paper size. Ex: Expand the guides fully when using paper with B4 or larger size. - Page 49 Chapter Printing With Various Function This chapter describes how to make prints using the various printer functions. Saving Settings ....................48 Saving Settings .................... 48 Retrieving Settings ..................50 Clearing Settings ..................51 Printing Two Different Document Pages on One Page ........52 Adjusting Plate Darkness ..................

-

Page 50: Saving Settings

Saving Settings You can save and retrieve nine sets of settings for platemaking and printing. The settings are stored in memory even when the power is turned OFF. Tips The following settings are saved: • Number of prints (including sets) •... - Page 51 Saving Settings The screen changes to the paper size select screen. The settings are saved, and the standard screen appears. 100% sht 1set IMPORTANT • Any previous settings stored in the memory channel will be deleted when you save new settings.

-

Page 52: Retrieving Settings

Retrieving Settings Retrieving Settings Press (FUNCTION SWITCH) key. Press (SELECT) key several times to show the screen 5.MEMORYMODE at right. Press (FUNCTION SWITCH) key. Press (SELECT) key several times to display “RE- 5.MEMORYMODE RETRIEVE TRIEVE”. Each time (SELECT) key is pressed, the arrow on the LCD panel moves as follows. -

Page 53: Clearing Settings

Clearing Settings Clearing Settings Press (FUNCTION SWITCH) key. Press (SELECT) key several times to show the screen 5.MEMORYMODE at right. Press (FUNCTION SWITCH) key. Press (SELECT) key several times to return to the 5.MEMORYMODE CLEAR standard screen. The memory setting that you selected is cleared, and the standard screen appears. -

Page 54: Printing Two Different Document Pages On One Page

Printing Two Different Document Pages on One Page ■ 2 IN 1 Function This mode prints two different document pages on one page. Documents Printout Two-in-one (2-IN-1) Function allows you to print two small documents on one page and also easily print for creating booklets that will be saddle stitched. - Page 55 Printing Two Different Document Pages on One Page Press (FUNCTION SWITCH) key. Press (SELECT) key several times to show the screen 4. 2IN1 at right. Press (FUNCTION SWITCH) key. The 2 IN 1 screen appears. Press (SELECT) key several times to select “ON”.

-

Page 56: Adjusting Plate Darkness

Adjusting Plate Darkness The plate darkness (the level at which black and white are differentiated) can be adjusted in 3 steps. Make the plate more “dark” if the document is light, or “light” if the document is dark. IMPORTANT • Set the “Plate Darkness” before making the plate. •... -

Page 57: Batch Printing

Batch Printing You can print the specified number of sets of prints in each set. ■ Batch Printing (a a a a a page 55) The machine stops after each set of prints. 1st set 2nd set 3rd set 5 copies x 2 sets 3 copies x 4 sets 2 copies x 5 sets Document... - Page 58 Batch Printing Proceed with steps 1 to 5 of the sequence described in “Basic Printmaking” (a a a a a page 30). Press (CLEAR) key to clear the number display. 100% sht 1set Using the keypad, enter the number of prints. Example: 25 •...

- Page 59 Batch Printing Press key. The number of prints is set. 100% sht 0set Use the keypad to enter the number of sets. Example: 3 sets 100% sht 3set • If you make a mistake, start over again by press (CLEAR) key and start from the beginning. When you press (CLEAR) key, both the number of prints and the number of sets are...

- Page 60 Batch Printing Press (PRINT) key. The print runs starts from the last-entered set, and stops after the first set of printouts. Collate by inserting a piece of paper that acts as a marker or by removing the whole set from the machine. Press (PRINT) key.

-

Page 61: Batch Printing (Changing Print Quantity Per Document)

Batch Printing Batch Printing (changing print quantity per document) You can change the number of prints made from each document. You can separate the number of prints for up to 15 documents. IMPORTANT • Select “Batch Printing” before starting platemaking. Press (CLEAR) key to clear the number display. - Page 62 Batch Printing Use the keypad to enter the number of prints. Example: 25 • If you make a mistake, start over again by press (CLEAR) key and start from the beginning. Key pad When you press (CLEAR) key, both the number of prints and the number of sets are cancelled.

- Page 63 Batch Printing Press key. Repeat steps 2 to 6. Proceed with steps 2 and 4 of the sequence described in “Basic Printmaking” (a a a a a page 30). IMPORTANT • When loading document, load the document for the first-entered number of prints and sets uppermost and the document for the last-entered number of prints and sets at the bottom.

-

Page 64: Dividing Sections With Tape [Available Only With Tape Cluster Device]

Batch Printing Dividing Sections with Tape-04 Available only with Tape Cluster Device Only the specified number of sets is printed with the specified number of prints taken as one set. Paper tape is inserted when printing of each set is completed. You can enter up to 15 groups of number of prints x number of sets. - Page 65 Batch Printing Leave end of tape approximately 1 cm out. Close the cover. • The paper tapes are inserted so that the length of the paper tape separating sets is longer than the paper tape separating groups.

- Page 67 Chapter Miscellaneous Functions This chapter describes miscellaneous functions such as the confidential safeguard function, and the print speed and print position adjustments. Confidential Safeguard Function ..............66 Total Counter Display Function ................ 67 Print Speed Adjustment Function ..............68 Printing Position Adjustment Function ............69 On-Line Print Function [Available Only With Interface Kit Installed] ....

-

Page 68: Confidential Safeguard Function

Confidential Safeguard Function The confidential safeguard function, which prevents printing unless platemaking has been completed, is a simple means of prohibiting others from printing sensitive documents. IMPORTANT • When the Confidential Safeguard function is ON, printing cannot be performed with (PRINT) or (TEST PRINT) keys. -

Page 69: Total Counter Display Function

Total Counter Display Function This function displays the total numbers of prints and plates on the LCD panel. Check that the machine is not printing. IMPORTANT • If the machine is printing, press (STOP) key to stop the print run. Press (STOP) key. -

Page 70: Print Speed Adjustment Function

Print Speed Adjustment Function The printing speed can be selected from among 60 pages per minute, 80 pages per minute and 120 pages per minute. The default setting when the power is turned ON is about 80 pages per minute. Tips •... -

Page 71: Printing Position Adjustment Function

Printing Position Adjustment Function After platemaking has finished, you can fine-tune the position of the image (in the horizontal direction) within ±10mm. • You can adjust the printing position while the machine is printing. Press “PRINTING POSITION AD- 1 : 1 JUSTMENT”... -

Page 72: On-Line Print Function [Available Only With Interface Kit Installed]

On-Line Print Function Available Only With Interface Kit Installed This function allows you to make prints of documents directly from on-line data from personal computers. IMPORTANT • PC interface kit is required to connect this machine to a personal computer. •... - Page 73 Chapter Replacing Consumables This chapter describes how to supply paper, ink pack, and other consumables. Replacing the Ink Pack ..................72 Replacing the Master Roll ................. 75 Replacing the Master Ejection Core ..............78 Replacing the Drum Unit ................... 80 Removing the Drum Unit ................

-

Page 74: Replacing The Ink Pack

Replacing the Ink Pack The message “EXCHANGE INK” is displayed on the LCD panel when the remaining ink is low. Replace the ink pack using the following procedure. EXCHANGE INK IMPORTANT • Only use ink packs designed for this machine. Open the front cover. - Page 75 Replacing the Ink Pack Remove the cap from a new ink pack. Ink pack IMPORTANT • Do not leave an ink pack uncapped for longer than necessary. Insert the ink pack so that the groove on the lip fits onto the “U” groove of the holder. Ink pack Ink pack “U”...

- Page 76 Replacing the Ink Pack Close the front cover. Front cover...

-

Page 77: Replacing The Master Roll

Replacing the Master Roll The message “ROLL-MASTER END” is displayed on the LCD panel when the master roll is used up. Replace the master roll using the following procedure. ROLL-MASTER END IMPORTANT • Only use a master roll designed for use in this machine. Upper cover Open the upper cover. - Page 78 Replacing the Master Roll Take out a new master roll from the bag. Set the master roll in the direction as shown in the illustration at right. Pull out the master , and insert the master aligned with the loading line under the guide panel until it contacts the roller.

- Page 79 Replacing the Master Roll Make sure that the leading edge of the master is protruding from the inner side of the master cover. IMPORTANT • If the master cannot be set correctly, its leading edge will not be visible. Open the master cover, and set again.

-

Page 80: Replacing The Master Ejection Core

Replacing the Master Ejection Core The message “EXCHANGE EJECT ROLL” is displayed on the LCD panel when the master ejection core is full. Remove the master ejection core using the following procedure: EXCHANGE EJECT ROLL IMPORTANT • Use only a master ejection core designed for use in this machine. Press the plate ejection box release lever to open Plate ejection box release lever the master ejection box. - Page 81 Replacing the Master Ejection Core Holding the edges of the master ejection core, pull out the core and discard it. IMPORTANT • Ink adheres to the master ejection core. Take care to prevent ink from getting onto your clothing. Insert a new master ejection core. Gently close the master ejection box cover, pressing it until it locks.

-

Page 82: Replacing The Drum Unit

Replacing the Drum Unit Removing the Drum Unit Press and hold the JOG switch until the drum JOG switch comes to a stop with a beep. WARNING • Do not touch the drum or rollers when you operate the JOG switch. •... -

Page 83: Installing The Drum Unit

Replacing the Drum Unit Installing the Drum Unit Hold the drum level and place the drum guide roller onto the rail in the machine. Roller Rail Release the handle at the far end of the drum and press the drum in about 10cm while lifting up the front end slightly. - Page 84 Replacing the Drum Unit Lever Lower the lever. Close the front cover. Front cover...

- Page 85 Chapter Troubleshooting This chapter describes how to remove paper jams and what to do when error messages are displayed. Countermeasures to Troubles ................84 Power Does Not Turn ON ................84 Platemaking/Printing is Not Possible ............84 Error Messages ....................85 Supplying or Changing Paper While Printing ..........

-

Page 86: Countermeasures To Troubles

Countermeasures to Troubles Power Does Not Turn ON If the power does not turn ON, check the following. THE MACHINE DOESN'T TURN ON. IS POWER PLUG INSERTED? Insert the power plug securely. IS POWER SWITCH ON? Turn the power switch ON. Please contact your service person. -

Page 87: Error Messages

Error Messages Message Countermeasure There is no paper in the feed tray. Load the feed tray with printing paper. SET PRINT PAPER There is no ink. Replace the old ink pack with a new one. (a For details, see page 72, “Replacing the Ink Pack”.) EXCHANGE INK There is no master. - Page 88 Error Messages Message Countermeasure A paper jam has occurred in the feed tray. Remove the jammed paper. (a For details, see page 92, “When ‘PAPER LEFT JAM’ is displayed (Feed Tray)”.) PAPER LEFT JAM. A paper jam has occurred on the print tray side. Inspect the print tray side and remove the jammed paper.

-

Page 89: Service Call

Error Messages Message Countermeasure Cannot print. This message is displayed just after the master setting error or PLEASE plate ejection error occurs. It is also displayed if you (PRINT) key or (TEST PLATE MAKING PRINT) key without making a plate while the confidential safeguard function is activated. -

Page 90: Supplying Or Changing Paper While Printing

Supplying or Changing Paper While Printing If Paper Runs Out During Printing If paper runs out during printing, printing stops and the feed tray is lowered automatically. SET PRINT PAPER Load paper (a a a a a See page 32, “Loading and Replacing Paper”.) Press (PRINT) key. - Page 91 Supplying or Changing Paper While Printing IMPORTANT • If the sheet is still in the feed roller ring, pull it out and align it with the stack. Align the stack to be added and place it on top of the existing stack. Press the stack lightly toward the machine.

-

Page 92: Changing Paper Selection While Printing

Supplying or Changing Paper While Printing Changing Paper Selection While Printing Press (STOP) key. Printing stops. Press the feed tray descend switch continuously. Feed tray descend switch Release the switch when the paper tray is at the proper height. The feed tray will stop. IMPORTANT •... - Page 93 Supplying or Changing Paper While Printing When the feed tray comes to a stop, reset the paper size. Press (PRINT) key. The feed tray will rise automatically and printing will resume.

-

Page 94: Paper Jams

Paper Jams When “PAPER LEFT JAM” is Displayed (Feed Tray) When a paper jam occurs in the feed tray, the message “PAPER LEFT JAM” is displayed on the LCD. Follow the procedure below to remove the jammed paper. PAPER LEFT JAM. Switch to lower the feed tray slightly. -

Page 95: When "Paper Right Jam" Is Displayed (Print Tray)

Paper Jams When “PAPER RIGHT JAM” is Displayed (Print Tray) When a paper jams in the print tray, “PAPER RIGHT JAM” is displayed on the LCD panel. Follow the procedure below to remove the jammed paper. PAPER RIGHT JAM. Press the plate ejection box release lever to open Plate ejection box release lever the master ejection box. -

Page 96: Paper Adhering To Drum

Paper Jams Close the master ejection box, pressing it until it locks. ■ Paper Adhering to Drum If paper has adhered to the drum, follow the procedure below to remove it. Press the plate ejection box release lever to open Plate ejection box release lever the master ejection box. - Page 97 Paper Jams Peel off the edge of the paper from the drum. Pull the paper toward the ejection side while pressing the JOG switch to peel the paper off. IMPORTANT • Make sure that the peeled paper does not stick to your clothing. JOG switch Hold the JOG switch down until the drum comes to a stop with a beep.

-

Page 98: When "Master Eject Miss" Is Displayed

When “MASTER EJECT MISS” is Displayed When and old master remains on the drum, “MASTER EJECT MISS” is displayed on the LCD panel. Remove it by following the procedure below. MASTER EJECT MISS Press the plate ejection box release lever to open Plate ejection box release lever the master ejection box. - Page 99 When “MASTER EJECT MISS” is Displayed Master clamp Lift the lever toward you. Lever The master clamp opens and the edge of the master will be released from the clamp. If the master is stuck, release it Master manually. Return the lever. Pull the front end of the master toward you and press the JOG switch intermittently.

- Page 100 When “MASTER EJECT MISS” is Displayed Press (STOP) key. The message is deleted. Make another plate.

-

Page 101: When "Master Set Miss" Is Displayed

When “PLATE EJECTION ERROR” is Displayed When “MASTER SET MISS” is Displayed The message “MASTER SET MISS” is displayed on the LCD panel. Remove the master and remake the plate by following the procedure below. MASTER SET MISS Upper cover Open the upper cover. - Page 102 When “MASTER SET MISS” is Displayed Check that the error message is deleted. Make a new plate and start printing. IMPORTANT • The message “PLS PLATE MAKING” is displayed on the LCD panel when (PRINT) key is pressed without platemaking being carried out.

-

Page 103: Cleaning Sheet : How To Use

Cleaning Sheet : How to use The scanning section inside ADF can be cleaned by using Cleaning sheet. Press (FUNCTION SWITCH) key to show the screen at right. 6.CLEANING Press (FUNCTION SWITCH) key. The CLEANING MODE operation selection screen appears. 6.CLEANING Press (SELECT) key and select "ON."... - Page 104 Set the Cleaning sheet in the ADF. Press (PRINT) key. The LCD indicates "-CLEANING-" and the machine starts --CLEANING-- cleaning process.

-

Page 105: Chapter 7 Specifications And Maintenance

Chapter Specifications and Maintenance This chapter lists the machine specifications and describes maintenance, etc. Specifications ....................104... -

Page 106: Specifications

Specifications Product name/model No. Duprinter DP-21SII Duprinter DP-21LII Duprinter DP-23SII Model Table top Platemaking method Thermal digital platemaking Platemaking time 24 seconds (A4, same size) Resolution 300 dpi (Main scanning direction) x 600 dpi (Sub scanning direction) Scanning method Printing method Stencil printing Document type Sheet... - Page 107 Specifications Product name/model No. Duprinter DP-21SII Duprinter DP-21LII Duprinter DP-23SII Power source 120 VAC model 120VAC 60 Hz, 2.1 A 230 VAC model 230VAC 50 Hz, 1.1 A Size In use: 1270mm (W) x 615mm (D) x 710mm (H) In storage: 695mm (W) x 615mm (D) x 710mm (H) Weight Machine 68kg Operating temperature...

-

Page 109: Appendix

Appendix This section contains an index and quick reference diagrams for basic operations. Index ........................108 Quick Operation Guide ..................110... -

Page 110: Index

........... 31, 67 Document/Printing Paper Specification ..... 26 drum handle ..............18 drum unit ..........16, 18, 27, 80 Duplo Direct Print System .......... 16 On-Line Print Function ..........70 Enlargement and Reduction ........36 Paper Adhering to Drum ..........94 Enlargements .............. - Page 111 Index Print Speed Adjustment Function ....... 68 print tray ............... 19, 43 Printer Appearance ............. 17 Warning Sticker ............10 Printing ............... 27 When “MASTER SET MISS” is Displayed ..... 99 Printing and Duplicating Cautions ......13 When “MAST. EJECT ERROR” is Displayed ... 96 Printing Position Adjustment Function ......

-

Page 112: Quick Operation Guide

Quick Operation Guide ●Platemaking Install the print tray. Open the supplemental paper tray. Hold the lever and adjust the side guides to the paper size. Place a stack of aligned sheets in the feeder tray. - Page 113 Quick Operation Guide Raise the paper stacker guides and Make the required settings on the paper stopper, and adjust them to control panel. the size of the printing paper. Enlargement and Reduction, Plate Darkness, Document mode, 94% Reduction, 2 IN 1 Function Press (PLATE MAKING) key.

- Page 116 DUPLO CORPORATION Duplo building, 1-6, Oyama 4 chome, Sagamihara, Kanagawa 229-1180, Japan TEL: +81-42-775-3602 FAX: +81-42-775-3606 E-mail : Info@duplo.com M7-Y1501 2005.04...

Need help?

Do you have a question about the DP-21S II and is the answer not in the manual?

Questions and answers