Miller Millermatic 211 Auto-Set Owner's Manual

Millermatic 211 auto-set w/mvp and m-100 gun

Hide thumbs

Also See for Millermatic 211 Auto-Set:

- Installation and operation manual (38 pages) ,

- Owner's manual (52 pages)

Table of Contents

Troubleshooting

Summary of Contents for Miller Millermatic 211 Auto-Set

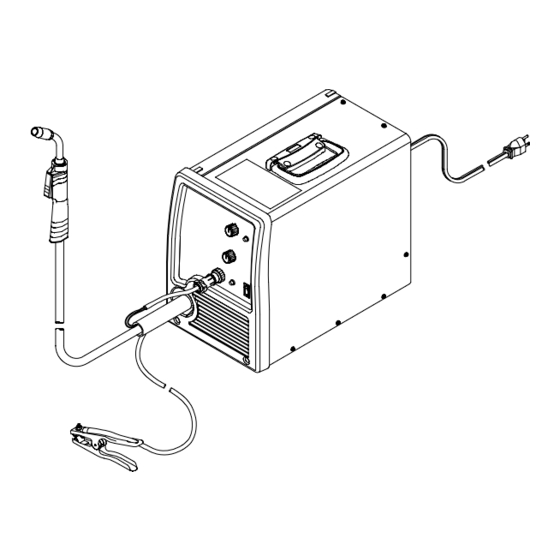

- Page 1 OM-239 988G 2010−06 Processes MIG (GMAW) Welding Flux Cored (FCAW) Welding Description Arc Welding Power Source And Wire Feeder Millermatic 211 ™ Auto-Set w/MVP And M-100 Gun Visit our website at File: MIG (GMAW) www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ........1-1. - Page 4 TABLE OF CONTENTS SECTION 8 − MIG WELDING (GMAW) GUIDELINES ..........8-1.

-

Page 5: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som _2010−03 Protect yourself and others from injury — read and follow these precautions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. not avoided, will result in death or serious injury. The possible hazards are shown in the adjoining symbols or explained in the text. - Page 6 D Remove stick electrode from holder or cut off welding wire at FUMES AND GASES can be hazardous. contact tip when not in use. D Wear oil-free protective garments such as leather gloves, heavy Welding produces fumes and gases. Breathing shirt, cuffless trousers, high shoes, and a cap.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. MOVING PARTS can injure. D Do not install or place unit on, over, or near D Keep away from moving parts such as fans. combustible surfaces. D Keep all doors, panels, covers, and guards D Do not install unit near flammables. -

Page 8: California Proposition 65 Warnings

1-4. California Proposition 65 Warnings For Gasoline Engines: Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to Engine exhaust contains chemicals known to the State of cause birth defects and, in some cases, cancer. (California California to cause cancer, birth defects, or other reproduc- Health &... -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION fre_som_2010−03 Se protéger et protéger les autres contre le risque de blessure — lire et respecter ces consignes. 2-1. Symboles utilisés DANGER! − Indique une situation dangereuse qui si on Indique des instructions spécifiques. - Page 10 Il reste une TENSION DC NON NÉGLIGEABLE dans LE SOUDAGE peut provoquer un les sources de soudage onduleur UNE FOIS incendie ou une explosion. l’alimentation coupée. Le soudage effectué sur des conteneurs fermés tels D Arrêter les convertisseurs, débrancher le courant électrique et que des réservoirs, tambours ou des conduites peut décharger les condensateurs d’alimentation selon les instructions provoquer leur éclatement.

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

ACCUMULATIONS LES BOUTEILLES peuvent exploser risquent de provoquer des blessures si elles sont endommagées. ou même la mort. Des bouteilles de gaz protecteur contiennent du gaz sous haute pression. Si une bouteille est endom- D Fermer l’alimentation du gaz protecteur en cas magée, elle peut exploser. -

Page 12: Proposition Californienne 65 Avertissements

Les PIÈCES MOBILES peuvent RAYONNEMENT HAUTE causer des blessures. FRÉQUENCE (H.F.) risque provoquer des interférences. D Ne pas s’approcher des organes mobiles. D Ne pas s’approcher des points de coincement D Le rayonnement haute fréquence (H.F.) peut tels que des rouleaux de commande. provoquer des interférences avec les équi- pements de radio−navigation et de com- munication, les services de sécurité... -

Page 13: Principales Normes De Sécurité

2-5. Principales normes de sécurité Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, 25 West 43rd Street, New York, NY 10036 (téléphone : 212-642-4900, de Global Engineering Documents (téléphone : 1-877-413-5184, site site Internet : www.ansi.org). Internet : www.global.ihs.com). Standard for Fire Prevention During Welding, Cutting, and Other Hot Safe Practices for the Preparation of Containers and Piping for Welding Work, NFPA Standard 51B, de National Fire Protection Association,... - Page 14 OM-239 988 Page 10...

-

Page 15: Section 3 − Specifications

A complete Parts List is available on-line at www.MillerWelds.com SECTION 3 − SPECIFICATIONS 3-1. Specifications A. 120 VAC w/Auto−SetE Amperes Input at Maximum Rated Welding Rated Load Out- Weight Overall Amperage Range Open-Circuit Output put 120 V, 60 Hz, W/ Gun Dimensions Voltage DC Single-Phase... -

Page 16: Duty Cycle And Overheating

A complete Parts List is available on-line at www.MillerWelds.com 3-2. Duty Cycle And Overheating Duty Cycle is percentage of 10 minutes that unit can weld at rated load without overheating. If unit overheats, thermostat(s) A. 120 VAC opens, output stops, and cooling Input fan runs. -

Page 17: Volt-Ampere Curves

A complete Parts List is available on-line at www.MillerWelds.com 3-3. Volt-Ampere Curves The volt-ampere curves show the A. 120 VAC Input minimum and maximum voltage and amperage output capabilities of the welding power source. Curves of other settings fall between the curves shown. -

Page 18: Section 4 − Installation

A complete Parts List is available on-line at www.MillerWelds.com SECTION 4 − INSTALLATION 4-1. Installing Welding Gun Drive Assembly Gun Securing Knob Gun End Loosen knob. Insert end of gun through opening in front panel until it bottoms against drive assembly. -

Page 19: Work Cable Routing Inside Unit

A complete Parts List is available on-line at www.MillerWelds.com 4-3. Work Cable Routing Inside Unit Work Cable Output Terminal Block Insert work cable through opening in front panel and route along back of front panel to output terminal block. Close door. Ref. -

Page 20: Installing Gas Supply

A complete Parts List is available on-line at www.MillerWelds.com 4-6. Installing Gas Supply Obtain gas cylinder and chain to running gear, wall, other stationary support so cylinder cannot fall and break off valve. DO NOT use Argon/Mixed gas regulator/flowmeter with CO shielding gas. -

Page 21: Connecting 1-Phase Input Power For 230 Vac Input

A complete Parts List is available on-line at www.MillerWelds.com 4-7. Connecting 1-Phase Input Power For 230 VAC Input Installation must meet all National and Local Codes − have only qualified persons make this installation. =GND/PE Earth Ground Disconnect and lockout/tagout input power before connecting input conductors from unit. -

Page 22: Electrical Service Guide For 230 Vac Input

A complete Parts List is available on-line at www.MillerWelds.com 4-8. Electrical Service Guide For 230 VAC Input Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda- tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source. 60 Hz Single Phase... -

Page 23: Serial Number And Rating Label Location

A complete Parts List is available on-line at www.MillerWelds.com 4-10. Serial Number And Rating Label Location The serial number and rating information for this product is located on back. Use rating label to determine input power requirements and/or rated output. For future reference, write serial number in space provided on back cover of this manual. -

Page 24: Installing Wire Spool And Adjusting Hub Tension

A complete Parts List is available on-line at www.MillerWelds.com 4-12. Installing Wire Spool And Adjusting Hub Tension Installing 4 in. (102 mm) Wire Spool When a slight force is needed to turn spool, tension is set. Installing 8 in. (203 mm) Wire Spool Adapter used with 8 in. -

Page 25: Threading Welding Wire

A complete Parts List is available on-line at www.MillerWelds.com 4-13. Threading Welding Wire Wire Spool Welding Wire Inlet Wire Guide Pressure Adjustment Knob Drive Roll Gun Conduit Cable Lay gun cable out straight. Tools Needed: Hold wire tightly to keep it from unraveling. -

Page 26: Removing Mig Gun From Welding Power Source

A complete Parts List is available on-line at www.MillerWelds.com 4-14. Removing MIG Gun From Welding Power Source Open Pressure Assembly Cut Off End Of Wire Knob Hold wire tightly to keep it from unraveling. Loosen Knob, Disconnect Gun Trigger Rewind Wire Onto Spool, Fasten Plug, And Pull Gun From Unit End Of Wire To Spool Ref. -

Page 27: Connecting Spool Gun To Millermatic 211

A complete Parts List is available on-line at www.MillerWelds.com 4-15. Connecting Spool Gun To Millermatic 211 Drive Assembly Spool Gun Gun Securing Knob Gun End Loosen thumbscrew. Insert end through opening until it bottoms against drive assembly. Tighten gun securing knob. Spool gun must be inserted completely to prevent leakage of shielding gas. -

Page 28: Cable Management Strap

A complete Parts List is available on-line at www.MillerWelds.com 4-16. Cable Management Strap Cable Management Strap Coil power cable and work cable, and secure to unit using the cable management strap. 805 392-B OM-239 988 Page 24... -

Page 29: Section 5 − Operation

A complete Parts List is available on-line at www.MillerWelds.com SECTION 5 − OPERATION 5-1. Controls Ref. 239 991-B Wire Speed Control MIG Gun/Spool Gun Switch Auto−Set™ light will turn on, and the unit will provide the appropriate wire feed speed for Switch allows selecting either a MIG gun or the material thickness selected using the Turn control clockwise inside white scale... -

Page 30: Power Switch

A complete Parts List is available on-line at www.MillerWelds.com 5-2. Power Switch Power Switch The power switch also functions as supplementary protector CB1 (see Section 6-2). 805 389-A OM-239 988 Page 26... - Page 31 A complete Parts List is available on-line at www.MillerWelds.com Notes OM-239 988 Page 27...

-

Page 32: Weld Parameter Chart

A complete Parts List is available on-line at www.MillerWelds.com 5-3. Weld Parameter Chart OM-239 988 Page 28... - Page 33 A complete Parts List is available on-line at www.MillerWelds.com #246372 239 992-B OM-239 988 Page 29...

-

Page 34: Section 6 − Maintenance & Troubleshooting

A complete Parts List is available on-line at www.MillerWelds.com SECTION 6 − MAINTENANCE & TROUBLESHOOTING 6-1. Routine Maintenance Maintain more often Disconnect power during severe conditions. before maintaining. n = Check Z = Change ~ = Clean l = Replace Reference * To be done by Factory Authorized Service Agent Every... -

Page 35: Changing Drive Roll Or Wire Inlet Guide

A complete Parts List is available on-line at www.MillerWelds.com 6-4. Changing Drive Roll Or Wire Inlet Guide Inlet Wire Guide Remove guide by pressing on barbed area or cutting off one end near housing and pulling it out of hole. Push new guide into hole from rear until it snaps in place. -

Page 36: Troubleshooting Table

A complete Parts List is available on-line at www.MillerWelds.com 6-5. Troubleshooting Table Trouble Remedy Secure power cord plug in receptacle (see Section 4-11). No weld output; wire does not feed; fan does not run. Replace building line fuse or reset circuit breaker if open. Place Power switch in On position (see Section 5-2). - Page 37 Notes OM-239 988 Page 33...

-

Page 38: Section 7 − Electrical Diagram

SECTION 7 − ELECTRICAL DIAGRAM Figure 7-1. Circuit Diagram OM-239 988 Page 34... - Page 39 244 399-B OM-239 988 Page 35...

-

Page 40: Section 8 − Mig Welding (Gmaw) Guidelines

SECTION 8 − MIG WELDING (GMAW) GUIDELINES mig1 2009−12 8-1. Typical MIG Process Connections Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. Place work clamp as close to the weld as possible. Regulator/ Flowmeter Wire Feeder/... -

Page 41: Typical Mig Process Control Settings

8-2. Typical MIG Process Control Settings These settings are guidelines only. Material and wire type, joint design, fitup, position, shielding gas, etc. affect settings. Test welds to be sure they comply to specifications. Material thickness determines weld parameters. 1/8 or 0.125 in. Convert Material Thickness to Amperage (A) -

Page 42: Holding And Positioning Welding Gun

8-3. Holding And Positioning Welding Gun Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in. (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam. Hold Gun and Control Gun Trigger Workpiece... -

Page 43: Conditions That Affect Weld Bead Shape

8-4. Conditions That Affect Weld Bead Shape Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed (weld current), and voltage. ° Push ° Drag Perpendicular GUN ANGLES AND WELD BEAD PROFILES Short Normal Long... -

Page 44: Gun Movement During Welding

8-5. Gun Movement During Welding Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads works better. Stringer Bead − Steady Movement Along Seam Weave Bead −... -

Page 45: Troubleshooting − Excessive Spatter

8-8. Troubleshooting − Excessive Spatter Excessive Spatter − scattering of molten metal particles that cool to solid form near weld bead. S-0636 Possible Causes Corrective Actions Wire feed speed too high. Select lower wire feed speed. Voltage too high. Select lower voltage range. Electrode extension (stickout) too long. -

Page 46: Troubleshooting − Lack Of Penetration

8-11. Troubleshooting − Lack Of Penetration Lack Of Penetration − shallow fusion between weld metal and base metal. Lack of Penetration Good Penetration S-0638 Possible Causes Corrective Actions Improper joint preparation. Material too thick. Joint preparation and design must provide access to bottom of groove while maintaining proper welding wire extension and arc characteristics. -

Page 47: Troubleshooting − Waviness Of Bead

8-14. Troubleshooting − Waviness Of Bead Waviness Of Bead − weld metal that is not parallel and does not cover joint formed by base metal. S-0641 Possible Causes Corrective Actions Welding wire extends too far out of nozzle. Be sure welding wire extends not more than 1/2 in. (13 mm) beyond nozzle. Unsteady hand. -

Page 48: Common Mig Shielding Gases

8-16. Common MIG Shielding Gases This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been developed over the years. The most commonly used shielding gases are listed in the following table. - Page 49 Problem Probable Cause Remedy Wire slipping in drive rolls. Adjust pressure setting on wire feed rolls. Replace worn Welding arc not stable. drive rolls if necessary. Wrong size gun liner or contact tip. Match liner and contact tip to wire size and type. Incorrect voltage setting for selected wire feed speed on Readjust welding parameters.

-

Page 50: Recommended Spare Parts

SECTION 9 − PARTS LIST 9-1. Recommended Spare Parts Item Part Description Quantity ..... 246 372 NOZZLE, slip type .500 orf flush . - Page 51 Effective January 1, 2010 (Equipment with a serial number preface of MA or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other Warranty Questions? guarantees or warranties expressed or implied. LIMITED WARRANTY − Subject to the terms and conditions 90 Days —...

- Page 52 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2010 Miller Electric Mfg. Co. 2010−01...

Need help?

Do you have a question about the Millermatic 211 Auto-Set and is the answer not in the manual?

Questions and answers