Table of Contents

Advertisement

Quick Links

OWNER'S OPERATION AND INSTALLATION MANUAL

PFS

Patent Pending

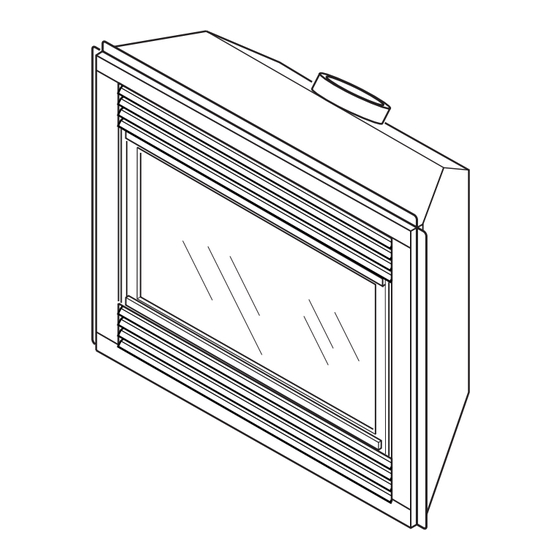

NATURAL GAS MODELS (V)KC42N AND (V)KCC42N SERIES

PROPANE/LP GAS MODELS (V)KC42P AND (V)KCC42P SERIES

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

For more information, visit www.fmiproducts.com

DIRECT-VENT FIREPLACE

®

US

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for FMI KC42N series

- Page 1 DIRECT-VENT FIREPLACE OWNER’S OPERATION AND INSTALLATION MANUAL ® Patent Pending NATURAL GAS MODELS (V)KC42N AND (V)KCC42N SERIES PROPANE/LP GAS MODELS (V)KC42P AND (V)KCC42P SERIES WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

-

Page 2: Table Of Contents

TAbLE OF CONTENTS Safety ..............2 Cleaning and Maintenance ........ 30 Product Identification ........... 4 Troubleshooting ..........32 Local Codes............5 Specifications ............ 36 Product Features ..........5 Replacement Parts ..........36 Pre-Installation Preparation ......... 5 Service Hints ............. 36 Location of Termination Cap ........ - Page 3 SAFETy Continued Carbon Monoxide Poisoning: Early signs WARNING: Do not allow fans of carbon monoxide poisoning resemble the to blow directly into the fireplace. flu, with headaches, dizziness or nausea. If you have these signs, the fireplace may not Avoid any drafts that alter burner be working properly.

-

Page 4: Product Identification

SAFETy Continued 2. If you smell gas from carpeting, bedding material, etc. • shut off gas supply Turn off the gas valve and pilot light before • do not try to light any appliance cleaning fireplace. • do not touch any electrical switch; do 6. -

Page 5: Local Codes

PRE-INSTALLATION PREPARATION LOCATION AND SPACE REqUIREMENTS Determine the safest and most efficient loca- tion for your FMI PRODUCTS, LLC direct-vent Flush with a wall fireplace. Make sure that rafters and wall studs are not in the way of the venting system. - Page 6 PRE-INSTALLATION PREPARATION Continued • If your fireplace is to be installed directly on CLEARANCES carpeting, vinyl tile or any combustible ma- Minimum clearances to combustibles for the terial other than wood, it must be installed fireplace are as follows: on a metal or wood panel extending the full *Back and sides 0"...

- Page 7 PRE-INSTALLATION PREPARATION Continued Wall " Top of Louver Opening " 23" Horizontal Vent " Vertical Vent Figure 4 - Framing Clearances for Installation Against an Exterior Wall Mantel from Mantel Top of Louver Ref. Depth Ref. Opening " " " 14"...

-

Page 8: Location Of Termination Cap

LOCATION OF TERMINATION CAP Fixed Openable Fixed Closed Closed Openable TERMINATION CAP AIR SUPPLY INLET GAS METER RESTRICTED AREA (TERMINATION PROHIBITED) I = clearance to service regulator vent outlet [*72" (182.9 cm) A = clearance above grade, veranda, porch, deck, or balcony [*12"... -

Page 9: Venting Installation

NOTICE: Do not seal termination These models are tested and approved for cap to vent pipe. Cap must be use with FMI PRODUCTS, LLC (direct-vent) removable for vent inspection pipe components and terminations. and maintenance. The venting system must terminate on the out-... -

Page 10: Opening

VENTING INSTALLATION Continued INSTALLATION PLANNING 5. Carefully determine location where vent pipe assembly will penetrate outside There are two basic types of direct-vent wall. Center of hole should line up with installation: center line of horizontal vent pipe. Mark • Horizontal Termination wall for a 11 "... - Page 11 VENTING INSTALLATION Continued WARNING: Do not recess Apply Mastic to All vent termination into any wall. Four Sides This will cause a fire hazard. Vent Cap 6. Noncombustible Exterior Wall: Position horizontal vent cap in center of 8 " round hole and attach to exterior wall with four wood screws provided.

-

Page 12: Venting Installation

VENTING INSTALLATION Continued Minimum Pipe GROUND FLOOR INSTALLATION Siding Standoff Overlap 1 " Recommended Applications: • Installation using cabinet surrounds Direct-Vent • Through the wall using round or square Pipe Screws termination (up to 12" adjustable pipe) • NOT FOR CORNER INSTALLATION Wall Firestop Adjustable... - Page 13 VENTING INSTALLATION Continued CORNER INSTALLATION Required Recommended Applications: Vertical (V) Vertical Pipe Horizontal (H) " min. None 30" max. • Corner ground floor installation " min. 1 ft. 48" max. • Ground floor installation where pipe vents " min. 2 ft. 60"...

- Page 14 VENTING INSTALLATION Continued HORIZONTAL SYSTEM INSTALLATION USING TWO 90° ELBOWS The following configurations show the minimum vertical rise requirements for a horizontal system using two 90° elbows. 45° Elbow Venting with Two 90° Elbows Horizontal (H Vertical (V) Horizontal (H Horizontal (H 5' min.

-

Page 15: Opening

VENTING INSTALLATION Continued INSTALLATION FOR VERTICAL should be framed to 11 " x 11 " inside dimensions, as shown in Figure 9 on page TERMINATION 10 using framing lumber the same size as Note: Vertical restrictor must be installed in ceiling joists. - Page 16 VENTING INSTALLATION Continued 5. Place flashing over pipe section(s) ex- similar factors may cause poor draft or tending through roof. Secure base of down-drafting in high winds. Increasing flashing to roof and framing with roofing vent height may solve this problem. nails.

- Page 17 (see Figure 25, page 18) and a round Shown) horizontal termination be used. HIGH ALTITUDE INSTALLATION Your FMI PRODUCTS, LLC direct-vent fireplace has been tested and approved for elevations from 0-2000 feet. Fireplaces for High Altitude (models ending in -HA) are for installation above 4000 feet only.

- Page 18 Termination Kit (Includes Round PARTS LIST FOR VENTING KITS Termination, Wall Firestop, 45° Elbow) AND COMPONENTS HHT-58 High Wind Round Horizontal FMI PRODUCTS, LLC (5"/8") Pipe & Vent Kits Termination Kit, Galvanized Number Description HTS-58 Horizontal Square Termination, P58-6 6" Section Double Wall Pipe,...

-

Page 19: Fireplace Installation

FIREPLACE 5. Mount speed control box to switch bracket by placing plastic control shaft forward INSTALLATION through round opening in switch bracket (see Figure 27). CHECK GAS TYPE 6. While supporting speed control, secure Use proper gas type for the fireplace unit you control shaft with lock nut by pushing are installing. -

Page 20: Fireplace Installation

FIREPLACE INSTALLATION Continued 3. Place blower against lower rear wall of CAUTION: Never touch the firebox outer wrapper with exhaust port di- rected upward and thermodisc positioned blower wheel while in operation. up near fireplace bottom. Thermodisc must be oriented near fireplace bottom 9. - Page 21 FIREPLACE INSTALLATION Continued 7. Check to make sure that power cord is INSTALLING GAS PIPING TO completely clear of blower wheel and FIREPLACE LOCATION that there are no foreign objects in blower wheel. Also double check all wire leads WARNING: A qualified and make sure wire routing is not pinched service person must connect or in a precarious position.

-

Page 22: Fireplace Installation

FIREPLACE We recommend that you install a sediment trap/drip leg in supply line as shown in Figure INSTALLATION 32. Locate sediment trap/drip leg where it is Continued within reach for cleaning. Install in piping sys- tem between fuel supply and fireplace. Locate CAUTION: Use only new, sediment trap/drip leg where trapped matter black iron or steel pipe. - Page 23 FIREPLACE 4. Check all joints of gas supply piping sys- tem. Apply noncorrosive leak detection INSTALLATION fluid to all joints. Bubbles forming show a Continued leak. Correct all leaks at once. 5. Reconnect fireplace and equipment To Gas Supply shutoff valve to gas supply. Check recon- (Natural) Equipment nected fittings for leaks.

- Page 24 FIREPLACE INSTALLING OPTIONAL WIRELESS HAND-HELD REMOTE CONTROL INSTALLATION TRC AND MRC SERIES Continued NOTICE: Use only alkaline bat- PRESSURE TESTING FIREPLACE GAS teries (not included). CONNECTIONS 1. Open equipment shutoff valve (see Figure 34, page 23). Installing Remote Receiver 1. Open bottom louver (KC42 series) or 2.

- Page 25 FIREPLACE INSTALLATION Continued Removing Louver Panels Press in on the bottom of door screen until Remove top and bottom louver panels by magnetic door latch is pushed in. simultaneously pulling both top end spring Removing Glass Door latches towards center of appliance until If replacement of glass is necessary, entire they are disengaged from locating holes assembly, glass and frame, must be replaced.

-

Page 26: Brick Panels

FIREPLACE INSTALLATION Continued INSTALLING LAVA ROCK AND Andiron GLOWING EMBERS Plenum It is very important to keep logs exactly as installed. Do not modify logs. Only use log set designed for this fireplace. WARNING: Logs are unitized and not attached to the burner. Do not handle log assembly by Ember Material top logs. -

Page 27: Operation

FIREPLACE OPERATION INSTALLATION FOR YOUR SAFETY Continued READ BEFORE LIGHTING 10. Install right brick panel using the same WARNING: If you do not fol- method described in step 6 for left brick low these instructions exactly, panel. a fire or explosion may result 11. - Page 28 OPERATION MANUAL LIGHTING PROCEDURE Continued 1. Remove glass door (see Removing/Re- 6. The pilot is located by the main burner and placing Glass Door, page 24). should not require accessing for lighting. 2. Follow steps 1 through 8 under Lighting 7.

-

Page 29: Inspecting Burners

OPERATION Continued OPERATING OPTIONAL OPERATING OPTIONAL GWMT1 - WALL MOUNTED BLOWER ACCESSORY THERMOSTAT Locate blower controls by opening lower louver panel on fireplace. Blower controls are WARNING: Do not con- located on right side of switch bracket to the left just inside louver panel. nect the thermostat to a power The BK manual blower and BKT thermostati- source. -

Page 30: Cleaning And Maintenance

INSPECTING bURNERS Continued BURNER FLAME PATTERN Burner flames will be steady, not lifting or float- ing. Flame patterns will be different from unit to unit and will vary depending on installation type and weather conditions. If vent configuration is installed incorrectly, flames will lift or "ghost". -

Page 31: Cleaning And Maintenance

CLEANING AND MAINTENANCE Continued If glass has been broken, carefully remove LOGS glass door (see Removing/Replacing Glass • If you remove logs for cleaning, refer to Door, page 24). Vacuum all glass pieces with Installing Lava Rock and Glowing Embers, a shop vac. -

Page 32: Troubleshooting

TROUbLEShOOTING WARNING: Turn off heater and let cool before servicing. Only a qualified service person should service and repair heater. CAUTION: Never use a wire, needle or similar object to clean pilot. This can damage pilot unit. Note: All troubleshooting items are listed in order of operation. OBSERVED PROBLEM POSSIBLE CAUSE REMEDY... -

Page 33: Cleaning And Maintenance

TROUbLEShOOTING Continued OBSERVED PROBLEM POSSIBLE CAUSE REMEDY Pilot lights but flame goes 1. Gas control knob not fully 1. Press in gas control knob out when control knob is pressed in fully released 2. Gas control knob not 2. After pilot lights, keep gas pressed in long enough control knob pressed in 30 seconds... - Page 34 TROUbLEShOOTING Continued OBSERVED PROBLEM POSSIBLE CAUSE REMEDY Heater produces a whistling 1. Turning gas control knob to 1. Turn gas control knob to LO noise when burner is lit HI position when burner is position and let warm up for cold a minute 2.

- Page 35 TROUbLEShOOTING Continued WARNING: If you smell gas • Shut off gas supply. • Do not try to light any appliance. • Do not touch any electrical switch; do not use any phone in your building. • Immediately call your gas supplier from a neighbor’s phone. Fol- low the gas supplier’s instructions.

-

Page 36: Specifications

• propane/LP gas supply might be low (pro- pane/LP units only) You can also visit FMI PRODUCTS, LLC’s web site at www.fmiproducts.com. You may feel your gas pressure is too low. If so, contact your local gas supplier. -

Page 37: Accessories

Purchase these accessories from your local dealer. If they can not supply these accessories call FMI PRODUCTS, LLC at 1-866-328-4537 for information. You can also write to the ad- THERMOSTATICALLY- dress listed on the back page of this manual. -

Page 38: Parts

PARTS MODELS (V)KC42(N)(P) AND (V)KCC42(N)(P) SERIES www.fmiproducts.com 116239-01M... - Page 39 PARTS This list contains replaceable parts used in your fireplace. When ordering parts, follow the instructions listed under Replacement Parts on page 36 of this manual. NO. PART NO. DESCRIPTION QTY. Firebox Assembly • • Face Weldment • • 108328-01 Door Assembly •...

- Page 40 PARTS BURNER ASSEMBLY MODELS (V)KC42(N)(P) AND (V)KCC42(N)(P) SERIES www.fmiproducts.com 116239-01M...

- Page 41 PARTS BURNER ASSEMBLY MODELS (V)KC42(N)(P) AND (V)KCC42(N)(P) SERIES This list contains replaceable parts used in your fireplace. When ordering parts, follow the instructions listed under Replacement Parts on page 36 of this manual. NO. PART NO. DESCRIPTION QTY. Burner Pan Assembly Base Grate Firebox Base Bottom 26808...

- Page 42 NOTES _____________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ _____________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ _____________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ www.fmiproducts.com 116239-01M...

- Page 43 NOTES _____________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ _____________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ _____________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ ______________________________________________________ 116239-01M www.fmiproducts.com...

-

Page 44: Warranty

FMI PRODUCTS, LLC’s liability is limited to the purchase price of the product, and FMI PRODUCTS, LLC shall not be liable for any other damages whatsoever under any circumstances including indirect, incidental, or consequential damages.

Need help?

Do you have a question about the KC42N series and is the answer not in the manual?

Questions and answers