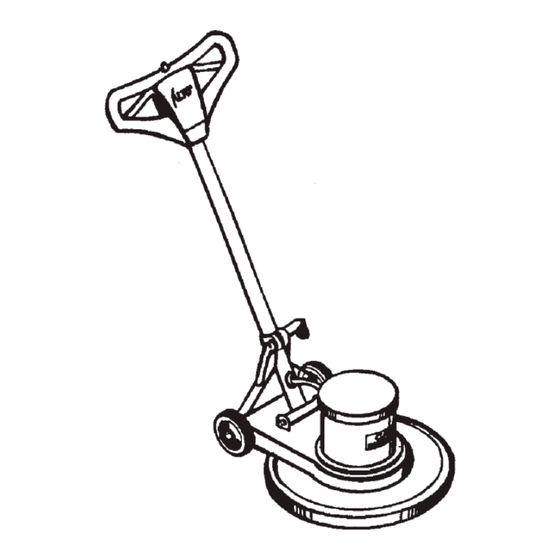

Clarke C2K-16 Operator's Manual

C2k series 230v 50 hz polisher (schuko)

Hide thumbs

Also See for C2K-16:

- Operator's manual (42 pages) ,

- Operator's manual (88 pages) ,

- Operator's manual (26 pages)

Table of Contents

Advertisement

Electronic Service

Manuals

This electronic document is provided as a service to our customers.

We do not create the contents of the information contained in this docu-

ment. Should you have detailed questions pertaining to the information

contained in this document, you may contact Michco, or the manufac-

turer which provided the original information in this electronic deliver-

able. Michco's only part in this electronic deliverable was the electronic

assembly process. By providing this manual on line we are not guaran-

teeing parts availability.

You may contact Michco through the following methods:

Phone (517) 484-9312 or (800) 331-3339

2011 N. High St. -- Lansing, Michigan -- 48906

Fax: (517) 484-9836

Email: CustServe@Michco.com

Web site: www.Michco.Com

Parts Web site: www.FloorMachineParts.Com

Order Parts on Line at:

www.FloorMachineParts.Com

Directly to Parts & Service:

By Email:

Shop@Michco.com

By Fax: (517) 702-2041

By Voice: Use numbers above.

Serving the Cleaning Industry Since 1922

Notice: All copyrighted material remains property of original owners, all trademarks are property of respective owners.

Manuals are subject to Manufacturer's reproduction limitations. Originals or reproductions were provided by manufacturers

through a request. We make no warranty as to the correctness of information provided in this document and you assume

all risk. By placing these manuals on line we are not declaring our corporation to be an manufacturer authorized dealer or

provider, please check our web site for authorized manufacturers we represent.

Advertisement

Table of Contents

Summary of Contents for Clarke C2K-16

- Page 1 Electronic Service Manuals This electronic document is provided as a service to our customers. We do not create the contents of the information contained in this docu- ment. Should you have detailed questions pertaining to the information contained in this document, you may contact Michco, or the manufac- turer which provided the original information in this electronic deliver- able.

-

Page 2: Table Of Contents

All directions given in this book are as seen from the operator’s position at the rear of the machine. For new books write to: ALTO U. S. Inc., 2100 Highway 265, Springdale, Arkansas 72764. Form No. 70225A 5/03 CLARKE TECHNOLOGY Printed in the U.S.A. - Page 3 Dele-og servicehåndbok ........................ 67 ALTO Produkt support avdelinger ....................85 INNEHÅLLET I DENNA BOK Användarhandledning ........................59 Handledning för reservdelar och service ..................67 Avdelningskontor for ALTO produkstöd ..................86 Page -2 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

-

Page 4: Operator's Manual

Read all machine labels before attempting to operate. Make sure all of the labels and instructional information are attached or fastened to the machine. Get replacement labels and decals from your authorized distributor. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 3 -... -

Page 5: Machine Introduction

This appliance is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops, offices and rental businesses. Page -4 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... -

Page 6: Accessories

WARNING: Use only brushes and accessories supplied by the manufacturer. The use of other brushes and accessories may impair safety. Large diameter brushes provided specifically for dry buffing are not intended for general polishing. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 5 -... -

Page 7: Machine Specifications

Brush Diameter (cm) Block Diameter (cm) Brush Speed (rpm) 180/320 180/320 Cord Length (m) Weight (kg) Noise (dBA) <70 <70 <70 <70 <70 Vibration (m/s <2.5 <2.5 <2.5 <2.5 <2.5 Page -6 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... -

Page 8: How To Prepare The Machine For Operation

NOTE: For the best operating position, keep your back straight, bend only your arms. 3. Using your foot, push the locking lever down. 4. Hold the handle against your body for the best control. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 7 -... -

Page 9: Instructions For Connection To Power Supply & Elect. Ground, 230 V

If the receptacle or connector body does not fit the plug, see your Authorized person to make the connection. Page -8 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... -

Page 10: How To Operate The Machine

WARNING: Maintenance must be done by authorized personnel only. Maintenance Instructions Return the machine to a Clarke Technology Authorized Service Location every 12 months for maintenance inspections. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 9 -... - Page 11 Return the machine to the nearest Clarke Technology Service Branch or Clarke Technology Authorized Service Center. For safe operation, and longer life to your Clarke Tech- nology product, use only Clarke Technology parts. NOTE: The grease (503802) for the gear box needs to be changed every year.

-

Page 12: Bedienungsanleitung

Untersuchen Sie das Versorgungskabel regelmäßig auf Schäden wie Risse und Alterung. Verwenden Sie die Maschine nicht, wenn das Versorgungskabel defekt ist. Ersetzen Sie das Versorgungskabel nur mit dem im Anleitungshandbuch angegebenen Kabeltyp. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 11 -... - Page 13 Mit der Shampoobürste kann das Gerät zum Teppichreinigen und mit der Schleifscheibe zum Fußbodenschleifen eingesetzt werden. Dieses Gerät ist geeignet für den kommerziellen Einsatz wie z.B. in Hotels, Schulen, Krankenhäusern, Fabriken, Geschäften, Büros und Mietagenturen. Page -12 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 14 Die Verwendung anderer Bürsten und anderen Zubehörs kann die Sicherheit beeinträchtigen. Bürsten mit großem Durchmesser, die speziell zum Trockenschleifen geliefert werden, sind nicht für das allgemeine Schleifen bestimmt. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 13 -...

- Page 15 Leistung (kW) Bürstendurchmesser (cm) Blockdurchmesser (cm) Bürstengeschwindigkeit (Drehzahl) 204 180/320 180/320 Kabellänge (m) Gewicht (pounds) Lärm (dBA) <70 <70 <70 <70 <70 Vibration (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -14 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 16 Sie den Rücken gerade und biegen Sie nur Ihre Arme. 3. Drücken Sie den Sperrhebel mit dem Fuß hinunter. 4. Halten Sie für eine optimale Kontrolle den Griff gegen Ihren Körper. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 15 -...

- Page 17 Steckdose oder ein Anschlußstück zu stecken, das nicht zum Stecker paßt. Falls die Steckdose oder das Anschlußstück nicht zum Stecker paßt, veranlassen Sie Ihre befugte Person, den Anschluß herzustellen. Page -16 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 18 WARNUNG: Die Instandhaltung darf nur von befugtem Personal durchgeführt werden. Anleitungen zur Instandhaltung Geben Sie alle 12 Monate die Maschine in eine Clarke Vertragsstelle zum Kundendienst zurück. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 17 -...

- Page 19 Personal durchgeführt werden. VORSICHT: Führen Sie alle Einstellungen gemäß der Angaben durch. Anleitungen zur Instandhaltung Geben Sie alle 12 Monate die Maschine in eine Clarke Vertragsstelle zum Kundendienst zurück. Schalter WARNUNG: Alle elektrischen Reparaturen dürfen nur von befugtem Personal durchgeführt werden.

-

Page 20: Brugervejledning

Forsyningsledningen skal regelmæssigt efterses for skade såsom revner eller slid. Maskinen må ikke anvendes med en beskadiget forsyningsledning. Forsyningsledningen må kun udskiftes med den ledningstype, som er angivet i instruktionshåndbogen. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 19 -... - Page 21 MASKININTRODUKTION Clarke Technology C2K Series Clarke Technology modeller C2K series er maskiner til gulvvedligeholdelse, som kan bruges til pudsning, sprøjtning, polering, afsyring og vask med vaskemidler. Maskinerne kan bruges på træ-, vinyl-, flise- eller cementgulve. Med vaskemiddelbørsterne kan maskinerne bruges til at rense tæpper, og med slibeskiven kan de bruges til at slibe gulve.

- Page 22 ADVARSEL: Brug kun børster og tilbør, som forsynes af fabrikanten. Brug af andre børster og andet tilbehør kan hæmme sikkerheden. Børster med større diametre, som er specielt egnet til tørpolering, er ikke beregnet til almen polering. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 21 -...

- Page 23 Effekt (kW) Børstediameter (cm) Blokdiameter (cm) Børstehastighed (o/m) 180/320 180/320 Ledningslængde (m) Vægt (kg) Støj (dBA) <70 <70 <70 <70 <70 Vibration (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -22 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 24 1. Øksene opnå den bedste betjeningsposition. 2. Driverens adapteråbninger 3. Skub låsegrebet ned med foden. 4. Hold håndtaget mod kroppen for at opretholde bedst mulig kontrol over maskinen. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 23 -...

- Page 25 Hvis kontakten eller forbindelsesdelen ikke passer til kontakten, kan du få en autoriseret person til at foretage forbindelsen. Page -24 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V...

- Page 26 Maskinen flyttes til højre ved at løfte håndtaget en smule. VEDLIGEHOLDELSE ADVARSEL: Vedligeholdelse må udelukkende udføres af autoriseret personale. Vedligeholdelsesinstruktioner Maskinen skal returneres til et Clarke Technology autoriseret servicested hver 12. måned for vedligeholdelse-sinspektioner. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Page - 25 -...

- Page 27 Clarke Technology produktet. BEMÆRK: Smørefedtet (503802) til gearkassen skal udskiftes årligt. C2K-1600, C2K-1800 og C2K-2000, kræver 8 oz. Alle andre C2K Series gearkasser kræver 9 oz. smørefedt. Page -26 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

-

Page 28: Libro De Instrucciones

No utilizar la maquina si el cable de alimentación está dañado. Utilizar solamente el cable de recambio que se indica en este manual de instrucciones. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 27 -... - Page 29 Este aparato es adapto para usos comerciales como por ejemplo, hoteles, escuelas, hospitales, fábricas, tiendas, oficinas y en el sector del alquiler. Page -28 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 30 El uso de otros cepillos y accesorios podría ser peligroso. Los cepillos de diámetro grande son específicos para lustrar en seco y no son adecuados para el pulimentado en general. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 29 -...

- Page 31 Velocidad del cepillo (rpm) 180/320 180/320 Longitud del cable de añadido (m) Peso (kg) Ruido (dBA) <70 <70 <70 <70 <70 Vibración (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -30 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 32 1. Espigas Con el pie baje la palanca de bloqueo. 2. Aberturas del acoplamiento Para controlar mejor la máquina, tenga el mango cerca del cuerpo mientras trabaja. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 31 -...

- Page 33 Si la caja de enchufe o el conector no corresponde al enchufe, acude a un electricista o un técnico autorizado. Page -32 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 34 AVISO : El mantenimiento debe ser efectuado por untécnico autorizado. Instrucciones para el mantenimiento Cada 12 meses, la máquina debe ser mandada a un centro técnico autorizado CLARKE TECHNOLOGY para ser comprobada. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 33 -...

- Page 35 (503802) debe ser cambiada cada año. Los modelos C2K-1600, C2K-1800 y C2K-2000 y necesitan 236 cm³ de grasa. Todos los demás sistemas de accionamiento de la serie C2K necesitan 266 cm³ de grasa. Page -34 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

-

Page 36: Manuel D'utilisation

électrocution. Vérifiez régulièrement l'absence de dommages, tels qu'une fissure ou une usure du cordon. Ne remplacer le cordon d'alimentation qu'avec le type spécifié dans le manuel d'utilisation. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 35 -... - Page 37 PRÉSENTATION DE LA MACHINE Modèles Série C2K CLARKE TECHNOLOGY Les appareils Série C2K de la société Clarke Technology sont des machines d’entretien des sols intérieurs pouvant être utilisées pour shampooiner, arroser, poncer, décaper et polir. Elles peuvent être employées sur des surfaces en bois, en linoléum, en granito et en ciment. Lorsqu’elles sont équipées d’une brosse à...

- Page 38 AVERTISSEMENT: N'utiliser que les brosses et accessoires fournis par le fabricant. L'utilisation d'autres brosses ou accessoires peut compromettre la sécurité. Les brosses de grand diamètre conviennent uniquement au polissage à sec et ne conviennent pas au polissage général. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 37 -...

- Page 39 Diamètre du bloc (cm) Vitesse de la brosse (tr/min) 180/320 180/320 Longueur du cordon (m) Poids (kg) Bruit (dBA) <70 <70 <70 <70 <70 Vibrations (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -38 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 40 3. Avec votre pied, abaissez le levier de verrouillage. 4. Pour mieux contrôler la machine, tenez le manche contre votre corps. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 39 -...

- Page 41 à la fiche. Si la fiche ne s’ajuste pas à la prise ou au connecteur de rallonge, demandez à un technicien qualifié d’établir la connexion. Page -40 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 42 Directives d’entretien Tous les 12 mois, retournez la machine à un centre de service après-vente Clarke Technology pour une inspection générale d’entretien. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 41 -...

- Page 43 Assurez-vous que toutes les connexions sont serrées. Les tests et les réparations électriques doivent être confiés à un centre de service après-vente Clarke Tech- nology. Entretien du moteur Les moteurs à induction ne nécessitent pas l'utilisation de balais.

-

Page 44: Bedieningshandleiding

Controleer de voedingskabel regelmatig op beschadigingen, zoals scheurtjes of veroudering. Gebruik het apparaat niet als de voedingskabel is beschadigd. Vervang de voedingskabel uitsluitend door het type dat is gespecificeerd in de instructiehandleiding. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 43 -... - Page 45 De shampooborstel wordt gebruikt om een tapijt te reinigen en de schuurschijf wordt gebruikt om vloeren te schuren. Dit apparaat is geschikt voor commercieel gebruik, bijvoorbeeld in hotels, scholen, ziekenhuizen, fabrieken, werkplaatsen, kantoren en verhuurbedrijven. Page -44 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 46 Borstels met grote diameter die special worden geleverd voor droog wrijven, zijn niet bedoeld voor algemene polijstwerkzaamheden. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 45 -...

- Page 47 Diameter borstel (cm) Diameter blok (cm) Toerental borstel (tpm) 180/320 180/320 Snoerlengte (m) Gewicht (kg) Geluid (dBA) <70 <70 <70 <70 <70 Trilling (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -46 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 48 2. De plaataandrijvingsadapter 3. Duw de hefboom met uw voet omlaag. openingen. 4. Het apparaat wordt het beste bestuurd als u de handgreep tegen uw lichaam houdt. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 47 -...

- Page 49 Clarke Technology dealer op te nemen om de aansluiting door een bevoegde persoon te laten uitvoeren. Page -48 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 50 ONDERHOUD WAARSCHUWING: Onderhoud mag alleen door bevoegd personeel worden uitgevoerd. U.S. Onderhoudsinstructies Breng het apparaat om de 12 maanden naar een erkend Clarke Technology servicecentrum voor onderhoudsinspecties. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 49 -...

- Page 51 Voor de C2K-1600, C2K-1800, en C2K-2000 is 227 ml (8 oz.) smeervet . De versnellingsbakken van alle overige modellen in de C2K-serie vereisen 255 ml (9 oz.) Page -50 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

-

Page 52: Brukerhåndbok

ADVARSEL: Vedlikehold og reparasjon som utføres av personale som ikke er autorisert kan føre til ødeleggelse eller skade. Vedlikehold og reparasjoner må kun utføres av autorisert personell. Hold alle fester godt tilskrudd. Gjør justeringer i følge spesifikasjonene. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 51 -... - Page 53 å rense tepper og med slipeskiven kan de brukes til å slipe gulv. Dette apparatet er egnet til kommersiell bruk, for eksempel i hoteller, på skoler, sykehus, fabrikker, butikker, kontorer og utleiesteder. Page -52 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 54 Bruk kun børster og tilleggsutstyr levert av produsenten. Bruk av andre børster og tilbehør kan svekke sikkerheten. Børster med stor diameter som er spesielt egnet for tørre anvendelser. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 53 -...

- Page 55 Energi (kw) Børstediameter (cm) Blokkdiameter (cm) Børstehastighet (o/MIN) 180/320 180/320 Ledningslengde (m) Vekt (kg) Støy (dBA) <70 <70 <70 <70 <70 Vibrasjon (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -54 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 56 MERK: For mest bekvemmelige posisjon for brukeren, hold ryggen rett og bare bøy armene. 3. Trykk låsespaken ned ved hjelp av foten. 4. Hold håndtaket mot kroppen for best kontroll. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 55 -...

- Page 57 Hvis stikkontakten eller koplingen ikke passer støpselet, kontakt en autorisert leverandør av Clarke Technology-produkter for å få en autorisert person til å gjøre koplingen. Page -56 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 58 Løft håndtaket noe for å bevege maskinen til høyre. VEDLIKEHOLD ADVARSEL: Vedlikehold må kun gjøres av autorisert personell. Vedlikeholdsinstrukser Returner maskinen til et servicesenter autorisert av ALTO hver 12. måned for vedlikehold. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 57 -...

- Page 59 MERK: Smørefettet til gearkassen må skiftes hvert år. C-2K-1600, C2K-1800 og C2K-2000 trenger 224 g (8 oz.) med smørefett. Alle andre girkasser i C2K- seriene trenger 252 g (9 oz.) smørefett. Page -58 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

-

Page 60: Användarhandledning

VARNING! Om underhåll och reparation utförs av obehörig personal kan detta orsaka skada på operatör eller utrustning. Underhåll och reparationer får endast utföras av behörig personal. Dra åt alla fästen. Utför alla justeringar i enlighet med maskinspecifikationerna. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 59 -... - Page 61 När maskinen är försedd med schamponeringsborste kan den användas vid mattrengöring. När den är försedd med slipskiva kan den användas vid golvslipning. Denna maskin är lämplig för kommersiellt bruk, t.ex. i hotell, skolor, sjukhus, fabriker, butiker, kontor och i uthyrningsverksamhet. Page -60 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 62 Använd endast borstar och tillbehör som tillhandahålls av tilverkaren. Användning av andra borstar och tillbehör kan medföra minskad säkerhet. Borstar med stor diameter som tillhandahålls särskilt för torr polering är inte avsedda för allmän polering. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 61 -...

- Page 63 Borstens diameter (cm) Blockets diameter (cm) Borsthastighet (rpm) 180/230 180/230 Längd på elkabel (m) Vikt (kg) Ljudstyrka (dBA) <70 <70 <70 <70 <70 Vibrationer (m/s/s) <2.5 <2.5 <2.5 <2.5 <2.5 Page -62 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 64 3. Tryck ned låsspaken med foten. Figur 3 1. Tapparna 4. Håll handtaget nära kroppen för största kontroll. 2. Öppningarna på drivenhetens adapter CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 63 -...

- Page 65 Försök inte sätta in en trestiftskontakt i ett uttag som inte passar kontakten. Kontakta en behörig elektriker som kan göra anslutningen. Page -64 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

- Page 66 åt höger genom att lyfta upp handtaget en aning. UNDERHÅLL VARNING! Underhåll får endast utföras av godkänd personal. Underhållsinstruktioner Skicka maskinen till ett av ALTO godkänt servicecenter var 12:e månad för underhåll. CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 65 -...

- Page 67 OBS! Fettet (503802) i växellådan måste bytas varje år. C2K-1600, C2K-1800, C2K-1800HS och C2K- 2000 kräver 240 g. fett. Alla andra växellådor i C2K- serien kräver 270 g fett. Page -66 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko...

-

Page 68: Section Ii Parts And Service Manual

C2K Series 230V 50 Hz Polisher (Schuko) Section II Parts and Service Manual (70225A) CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 67 -... -

Page 69: Assembly Drawing 2/01

CLARKE TECHNOLOGY C2K-16, C2K-18, C2K-160, C2K-180, C2K-200, C2K-1600, C2K-1800, C2K-2000, C2K-1600HS, C2K-1800HS, C2K-2000HS, C2K-1800HSV Assembly Drawing 2/01 23 1 Page -68 - CLARKE TECHNOLOGY Operator's Manual - C2K Series... -

Page 70: Assembly Parts List

80098A Screw, -18 x 2 50796A Bushing, Cord 50795A Tube, Handle 50931A Cord, Power 441401 Cam Asm. (includes #14, 15 and 16) 747553 Strain Relief 77378A Label 82100A Locknut CLARKE TECHNOLOGY Operator's Manual - C2K Series Page - 69 -... -

Page 71: Assembly Drawing 2/01

CLARKE TECHNOLOGY C2K-1600DS and C2K-2000DS Assembly Drawing 2/01 21 22 23 1 Page -70 - CLARKE TECHNOLOGY Operator's Manual - C2K Series... -

Page 72: Assembly Parts List

70218A Label, (High - Low) 77378A Label 441401 Cam Asm. (includes #14, 15 &16) 30605A Baffle 50931A Cord, Power 47201A Filter 98458A Bushing 962957 Screw 82100A Locknut 51058A Baffle CLARKE TECHNOLOGY Operator's Manual - C2K Series Page - 71 -... -

Page 73: Motor Assembly Drawing & Parts List

CLARKE TECHNOLOGY C2K-16, C2K-18, C2K-160, C2K-180 and C2K-200 230V - 50 Hz Motor Assembly Drawing & Parts List 2/01 Note: If your machine has motor #44638A refer to this drawing for service part replacement. Ref. Part No. Description Qty. Ref. -

Page 74: Gearbox Assembly Drawing & Parts List 5/03

CLARKE TECHNOLOGY C2K-16, C2K-18, C2K-160, C2K-180 and C2K-200 Gearbox Assembly Drawing & Parts List 5/03 Note: If your machine has gearbox #50872A refer to this drawing for service part replacement. Ref. Part No. Description Qty. 80141A Screw, Socket Hd. Cap... -

Page 75: Motor Assembly Drawing & Parts List 1/02

"HS" machines 50880A 50879A Ref. Part No. Part No. Description 50861A 50861A Ball Bearing 40153A 51054A Centrifugal and Switch 40154A 51055A Rotor 40155A 50862A Capacitor, Start 40156A 50863A Capacitor, Run Page -74 - CLARKE TECHNOLOGY Operator's Manual - C2K Series... -

Page 76: Gearbox Assembly Drawing & Parts List 1/02

902736 Bearing 58314A Retainer 442473 Coupling Gear, Pinion 902737 Bearing, Needle Cage Gear, Idler 58312A Shaft 902573 Bearing, Ball Housing, Drive 50851A Gearbox Asm., Complete 51344A Gearbox Asm., Complete CLARKE TECHNOLOGY Operator's Manual - C2K Series Page - 75 -... -

Page 77: Motor Assembly Drawing And Parts List

Armature Asm. (Includes #12) 58056A Strain Relief 831102 Bushing 55648A Red Lead (included w/ #8) 980076 Wave Washer 55647A Yellow Lead (included w/ #8) 59607A Varistor (Included w/#8) 46736A Speed Control 51343A Gearbox Page -76 - CLARKE TECHNOLOGY Operator's Manual - C2K Series... -

Page 78: Gearbox Assembly Drawing And Parts List

Screw 10-24" x 1" 54858A Cover, Housing 902736 Bearing 58314A Retainer 442473 Coupling 58313A Gear, Pinion 902737 Bearing, Needle 52020A Cage 54408A Gear, Idler 58312A Shaft 902573 Bearing, Ball 54856A Housing, Drive CLARKE TECHNOLOGY Operator's Manual - C2K Series Page - 77 -... -

Page 79: Wiring Diagrams

Wiring Diagram 230V 11/99 WARNING: All electrical repairs must be performed by qualified personnel only. CLARKE TECHNOLOGY C2K-1800HSV Wiring Diagram 230V 2/01 WARNING: All electrical repairs must be performed by qualified personnel only. Page -78 - CLARKE TECHNOLOGY Operator's Manual - C2K Series... - Page 80 1355 West Oak Common Lane Stuartweg 4C (770) 973-5225 NL-4131 NJ Vianen +31 347 324000 ALTO Sverige AB, Molndal (Sweden) CLARKE TECHNOLOGY Aminogatan 18 AMERICAN SANDERS TECHNOLOGY Box 4029 A.L. COOK TECHNOLOGY S-431 04 Molndal Customer Service Headquarters and Factory...

-

Page 81: Alto Produktbetreuungs-Niederlassungen

Kundendienst-Hauptbüro und Werk +46 3127 1600 2100 Highway 265 Springdale, Arkansas 72764 ALTO Norge A/S, Oslo (Norwegen) (479) 750-1000 Bjornerudveien 24 N-1266 Technischer Dienst +47 2275 1770 1-800-356-7274 Page -80 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... -

Page 82: Alto Produktsupportafdelinger

+46 3127 1600 Kundeservice hovedkvarter og fabrik 2100 Highway 265 ALTO Norge A/S, Oslo (Norge) Springdale, Arkansas 72764 Bjornerudveien 24 (479) 750-1000 N-1266 +47 2275 1770 Teknisk service 1-800-356-7274 CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 81 -... -

Page 83: Sucursales De Servicio De Productos Alto

Oficina central de servicio al cliente y fábrica 2100 Highway 265 ALTO Norge A/S, Oslo (Noruega) Springdale, Arkansas 72764 Bjornerudveien 24 (479) 750-1000 N-1266 +47 2275 1770 Servicio técnico 1-800-356-7274 Page -82 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... -

Page 84: Centres De Service Apres-Vente Alto

Service clientèle - Siège social et usine +46 3127 1600 2100 Highway 265 Springdale, Arkansas 72764 ALTO Norge A/S, Oslo (Norvège) (479) 750-1000 Bjornerudveien 24 N-1266 Service technique +47 2275 1770 1-800-356-7274 CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 83 -... -

Page 85: Alto Afdelingen Voor Productondersteuning

+46 3127 1600 Hoofdkwartier Klantenservice en Fabriek 2100 Highway 265 ALTO Norge A/S, Oslo (Noorwegen) Springdale, Arkansas 72764 Bjornerudveien 24 (479) 750-1000 N-1266 +47 2275 1770 Technische dienst 1-800-356-7274 Page -84 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... -

Page 86: Alto Produkt Support Avdelinger

+46 3127 1600 Kundeservice Hovedkvarter og fabrikk ALTO Norge A/S, Oslo 2100 Highway 265 Bjornerudveien 24 Springdale, Arkansas 72764 N-1266 (479) 750-1000 +47 2275 1770 Teknisk Service 1-800-356-7274 CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 85 -... -

Page 87: Avdelningskontor For Alto Produkstöd

+46 3127 1600 Customer Service Headquarters and Factory 2100 Highway 265 ALTO Norge A/S, Oslo (Norge) Springdale, Arkansas 72764 Bjornerudveien 24 (479) 750-1000 N-1266 +47 2275 1770 Technical Service 1-800-356-7274 Page -86 - CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko... - Page 88 CLARKE TECHNOLOGY Operator's Manual - C2K Series 230V Schuko Page - 87 -...

- Page 89 WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY, SHALL BE IMPLIED. A warranty registration card is provided with your Clarke Technology floor machine. Return the card to assist Clarke Technology in providing the performance you expect from your new floor machine.

Need help?

Do you have a question about the C2K-16 and is the answer not in the manual?

Questions and answers