Braemar WF2000 Installation Manual

Gas wall furnace

Hide thumbs

Also See for WF2000:

- Owner's manual (2 pages) ,

- Owner operating instructions (2 pages) ,

- User manual

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Braemar WF2000

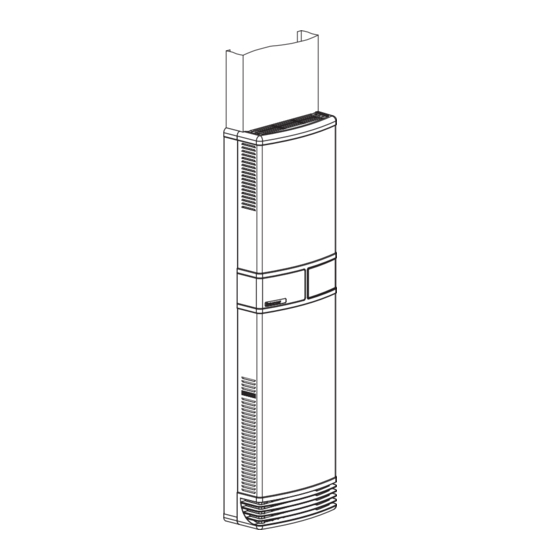

- Page 1 INSTALLATION MANUAL INSTALLATION MANUAL WF2000 GAS WALL FURNACE Inbuilt Console...

- Page 2 Saf et y F ir s t Saf et y F ir s t Employers and Employees Responsibility The installation and maintenance of gas wall furnaces and flue systems, particularly at height, has the potential to create Occupational Health and Safety issues for those involved. Installers are advised to ensure they are familiar with relevant State and Federal legislation, such as Acts, Regulations, approved Codes of Practice and Australian Standards, which offer practical guidance on these health and safety issues.

- Page 3 Introduction and Spec's Introduction and Spec's INTRODUCTION z These installation instructions cover the installation of Braemar WF2000 series gas wall furnaces. They apply to 30 and 40 MJ/hr, natural gas and propane, and inbuilt and console models. z For console installations, one of the following "Console & Flue Cover Kits" is required:...

- Page 4 300mm minimum distance between objects and servicing. z The Braemar flue kit (P/No 077956) is recommended for installation of this heater. z If the heater is replacing an existing unit it must be confirmed that the flue system complies with current requirements of AS5601.

- Page 5 Fit top and bottom mounting brackets as shown - brackets and mounting screws are included with the heater. Header plate Wall top plate (cut between studs) Twin-wall metal flue Braemar top mounting bracket 405 - 415 Wall opening 405 - 430 Wall stud...

- Page 6 Fit the flue cover components in accordance with instructions contained in the console & flue cover kit. The console sides can also be fitted to the front cover at this stage. Twin-wall metal flue Braemar top mounting bracket FOR TIMBER STUD WALLS, THE...

- Page 7 Replacing an existing W/F GENERAL z The Braemar WF2000 wall furnace is suitable for replacement of a wide range of common existing wall furnaces without modification of the wall opening, and with minimal or no modification to the existing flue system (provided the flue system is satisfactory as specified under "Flue System"...

- Page 8 FLUE ADAPTOR KIT (P/No 079981) z The flue adaptor is used to connect between the flue spigot on the top of the Braemar WF2000 and the bottom of the existing flue system to allow the WF2000 to be installed at...

- Page 9 The twin-skin flue extension is used in conjunction with the flue adaptor to connect between the flue spigot on the top of the Braemar WF2000 and the bottom of the existing flue system to allow the WF2000 to be installed at the correct height for some replacement installations, and to enable the use of the existing flue system (note that if the existing flue system is to be used it must comply with the current requirements of AS5601 "Gas installations").

- Page 10 In-fill Panel Kit Installation In-fill Panel Kit Installation IN-FILL PANEL KIT (P/No 085135) z The in-fill panel kit is used to cover the existing wall opening of wall markings when replacing some older and taller heaters. z Fit the in-fill panel after the heater is fitted onto the mounting brackets as shown below. z Attach the in-fill panel to the wall using screws to suit the wall type - screws to suit plaster board, timber or masonry walls are...

- Page 11 Wir i ng diagr am Wir i ng diagr am...

- Page 13 Ins tal lat ion Ch ecklis t Ins tal lat ion Ch ecklis t SELECT SUITABLE LOCATION Room layout Wall stud location/clearance Gas and electricity available Flue clearances OK, no obstructions UNPACK HEATER Remove plastic film Remove 2 transit screws from top rear of cover Remove cover retaining screws from bottom (above top louvre inside air outlet) FIT MOUNTING BRACKETS Remove existing mounting brackets...

- Page 14 FAULT POSSIBLE CAUSES REMEDY Pilot will not light Air in gas line. Purge gas line. Blockage in gas line. Check and clear gas supply line. Insufficient gas supply Check supply pressure at gas valve inlet pressure. pressure test point - increase supply pressure to specified value with main burner running: - Natural Gas: 1.13 kPa...

- Page 15 Seeley International Pty Ltd ACN 23 054 687 035 does not assume any liability for errors and/or omissions. Braemar is a registered trademark of Braemar Industries Pty Ltd. www.seeleyinternational.com Manufacturers and Designers of Technically Advanced Quality Heating and Cooling Products...

Need help?

Do you have a question about the WF2000 and is the answer not in the manual?

Questions and answers