Table of Contents

Advertisement

Congratulations,

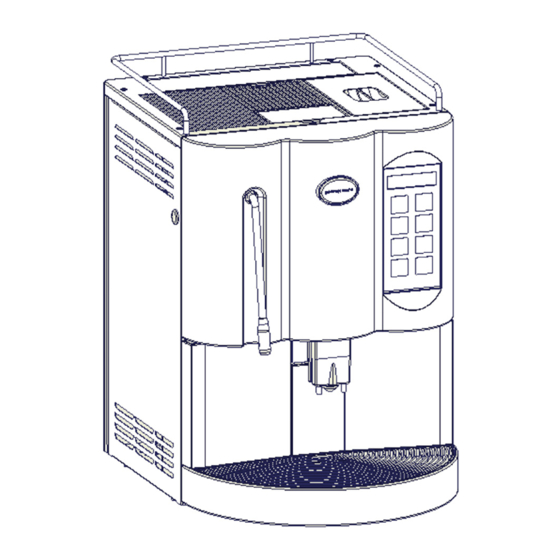

upon the wise choice you have made by purchasing the MICROBAR model.

In fact, you are now the owner of not just a simple coffee dispenser, but a true espresso coffee-making machine which is fully automatic and comple-

tely controlled by a microprocessor. This means absolute reliability and simple to use.

We are certain that our MICROBAR model will increase your confidence in Nuova Simonelli and that you will undoubtedly recommend others to pur-

chase this coffee-making machine, since the MICROBAR model has been chosen to increase the profitability of the coffee shop, thus fully optimising

running costs.

This machine has been manufactured in compliance with the EEC directives 89/392, 89/336, 73/23, 89/109 and subsequent modifications.

With best wishes

Nuova Simonelli s.r.l.

TECHNICAL CHARACTERISTICS

NET WEIGHT

GROS WEIGHT

POWER

A 320 mm A 12

DIMENSIONS

B 200 mm B 7

C 480 mm C 18

D 260 mm D 10

E 400 mm E 15

Rel. 02 - 2003

30 Kg

66 Lb

33 Kg

72 Lb

2000 W

2000 W

1/4

inc

3/8

inc

3/8

inc

1/16

inc

5/16

inc

C

B

A

D

E

29

Advertisement

Chapters

Table of Contents

Summary of Contents for Nuova MICROBAR

-

Page 1: Technical Characteristics

This means absolute reliability and simple to use. We are certain that our MICROBAR model will increase your confidence in Nuova Simonelli and that you will undoubtedly recommend others to pur- chase this coffee-making machine, since the MICROBAR model has been chosen to increase the profitability of the coffee shop, thus fully optimising running costs. -

Page 2: Table Of Contents

....31 KEYBOARD DESCRIPTION (Standard configuration) . .32 MICROBAR INTERNAL DESCRIPTION ... . .32 CLEANING AND MAINTENANCE . -

Page 3: Description

DESCRIPTION Fig. 1 LEGENDA 7 Coffee nozzles 12 Milk flow adjusting tap 1 Coffee bean holder cap 8 Milk/Cappuccino nozzle (Cappuccino version only) 2 Control panel (Cappuccino version only) 13 Water tank opening 3 Front door 9 Control panel hatch opening / locking key 14 Main switch (ON / OFF) 4 Steam pipe / Hot water pipe 10 Ground coffee conveyor hatch... -

Page 4: Keyboard Description (Standard Configuration)

KEYBOARD MICROBAR INTERNAL DESCRIPTION DESCRIPTION (Standard configuration) Fig. 2 Fig. 3 LEGENDA LEGENDA 1 Ground coffee conveyor 1 Espresso key 2 Coffee bean holder 2 Espressos key 3 Coffee grinder adjusting screw 1 Coffee key 2 Coffees key 4 Delivery unit... -

Page 5: Safety Instructions

SAFETY INSTRUCTIONS ☞ This book is an integral and essential RISK OF POLLUTION part of the product and must be given to the user. Read this book carefully. It provides important information concerning safety of installation, use and maintenance. Save it carefully for future reference. - Page 6 ☞ ☞ • do not leave the appliance expo- For installation, the qualified electri- Basic rules must be observed when sed to atmospheric agents (rain, cian must fit an omnipolar switch in using any electric appliance. sun, etc.); accordance with the safety regula- •...

- Page 7 CAUTION CAUTION RISK OF POLLUTION RISK OF BURNS OR SCALDING ☞ ☞ Do not dispose of the machine in the We remind you that before carrying environment: to dispose of the out any installation, maintenance, machine, use an authorised centre, unloading or adjustment operations, or contact the manufacturer for relati- the qualified operator must put on...

-

Page 8: Transport And Handling

MACHINE HANDLING IDENTIFICATION Always quote the machine serial number in all CAUTION CAUTION communications to the manufacturer, Nuova RISK OF POLLUTION Simonelli. RISK OF IMPACT OR CRASHING During all handling operations, the operator must ensure that there are no persons, objects or property in the handling area. -

Page 9: Installation And Preliminary Operations

INSTALLATION AND PRELIMINARY OPERATIONS Once the machine has been withdrawn from CAUTION WARNING the packaging, carry out the following instruc- RISK OF POLLUTION tions: Pour ONLY toasted coffee beans into the Do not dispose of packaging in the environ- 1 Position the unit on a horizontal surface. coffee bean holder. -

Page 10: Adjustments To Be Made By A Qualified Technician

NOTE: in case the following procedure should- ADJUSTMENTS TO BE MADE n't take effect, see the chapter on BY A QUALIFIED TECHNICIAN ONLY "Problems and Solutions". After the preliminary operations: GRINDING MILK FOAMER ADJUSTMENT ADJUSTMENT 1 Press the main switch so that the LCD dis- NOTE: the procedure is possible also with the play turns on showing the message: WARNING... -

Page 11: Milk Flow Adjustment

MILK FLOW ADJUSTMENT Before starting usage of the appliance, the ope- STANDARD rator must read and fully understand the safety CONFIGURATION instructions in this handbook. KEYS LEGENDA (Standard Configuration) START UP: By pressing the ON / OFF key, the machine will begin to carry out a self-diagnostic check at the end of which (if the machi- 1 Espresso... -

Page 12: Selection Configuration

NOTE: The nozzles can be adjusted to fit all SELECTIONS HOW TO MAKE THE kinds of cups. CONFIGURATION COFFEE’ Set the desired function on keyboard keys n. 1- Position the nozzles carefully in such a way as 2-3-4-6 (see 'DISPLAY' chapter), by following to limit the space between cup and nozzles. -

Page 13: How To Make Caffelatte

• According to the kind of coffee selected the • The display will read as follows: HOW TO MAKE DECAF- display will read. FEINATED COFFEE • Open the ground coffee conveyor hatch. WARNING Pour only ground coffee into the coffee Lasciare la tazza sotto gli erogatori fino a bean holder. -

Page 14: How To Make Short Espresso

6.11 6.12 • The display will read: HOT WATER STEAM WARNING WARNING Before proceeding with the following opera- During steam delivery, never touch the steam pipe with any part of you body or tions, ensure that the water tank has water place your hands underneath it. -

Page 15: Programming

PROGRAMMING LIST OF PROGRAMMABLE PROGRAMMING LEGENDA FUNCTIONS For accessing the programming sites proceed as follows: 1. CUMULATIVE TOTAL NOTE: can be performed with machine on. 2. PRODUCT NAME 3. WATER VOLUME • Insert the key into the appropriate lock. 4. GRIND TIME •... -

Page 16: Exiting Programming

2. PRODUCT NAME: EXITING PROGRAMMING CYCLE By pressing the ENTER key, the subme- PROGRAMMING nus can be accessed. 1. CUMULATIVE TOTAL A beverage is assigned to each key. To exit programming sites, proceed as follows: The submenus can be entered by pus- NOTE: can be performed with machine on and hing the ENTER key. - Page 17 3. WATER VOLUME CC 10 Grind Time s. Cappuccino 1 Pre-Brewing Ristretto 11 Grind Time s. Big Cappuccino 2 Pre-Brewing 2 Ristretto By pressing the ENTER key the subme- 3 Pre-Brewing Espresso nus can be accessed. The arrow keys ▲▼ allow you to 4 Pre-Brewing 2 Espresso The doses of water to be used for each...

-

Page 18: 15. Water Filter

Press the ENTER key to scroll all the items on This allows you to program the number of 13. COFFEE TEMPERAT. the submenu and see confirmation of the tam- cycles after which the group clean war- Press the ENTER key to access the sub- ping programmed. -

Page 19: Special Machine Scaling Functions

SPECIAL MACHINE SCALING FUNCTIONS until the display reads: HANDLING MANUAL RESETTING THE CLEA- COFFEE DELIVERY NING FILTER LITRE GROUP COUNTER This function makes it possible to activate the This function allows you to reset the total motor manually forming the automation of the amount of water used. -

Page 20: Cleaning And Maintenance

CLEANING AND MAINTENANCE sists of hot water deliveries alternated with pau- Cleaning the work area: remove the worktop, SWITCHING OFF THE lifting it up from the front and sliding it out. ses. The whole cycle lasts approximately 4 MACHINE minutes. Remove the water collection dish underneath To switch the machine off the main switch must We recommend that you carry out a WAS-... -

Page 21: Reinstating An Interrupted Washing Cycle

5. Keep pressing down on the key for about 5 • Afterwards the rinsing procedure will begin COFFEE HOLDER AND seconds until the display reads: and the display will read: COFFEE DELIVERY UNIT CLEANING CAUTION RISK OF BURNS OR SCALDING Reposition a container only with water in it. -

Page 22: Cleaning The Steam Nozzle

9.10 CLEANING THE STEAM CLEANING THE WATER CLEANING THE NOZZLE COLLECTING TRAY GASKET Clean the steam nozzle each time it is used to • Clean the water collecting tray with hot • Use a small brush to clean any deposits or warm up drinks. -

Page 23: Cleaning The Milk Foamer

9.11 IMPORTANT: Proceed with caution NOTE:To make the reassembling procedure CLEANING THE MILK easier, an explanatory label has been FOAMER • Extract the whole delivery unit including the attached to the front door. NOTE:Follow the instructions applied on the milk foamer, pulling it towards you. label on the inside of the front door too. -

Page 24: Standard Setting Table

STANDARD SETTING TABLE BEVERAGE WATER VOLUME GRINDING TIME MILK TIME PRE-BREWING TAMPING NUMBER (cc) (sec) (sec) [in 3 ] Ristretto 40 [2.44] 2 Ristretto 80 [4.88] Espresso 50 [3.05] 2 Espresso 100 [6.1] 10,5 Caffè 60 [3.66] 2 Caffè 120 [7.32] 10,5 Caffe Creme 100 [6.1]... -

Page 25: Machine Functions Messages

MACHINE FUNCTIONS MESSAGES DISPLAY CAUSE EFFECT SOLUTION NOTE GROUNDS DRAWER FULL Grounds drawer full. The Keys delivering coffee based Pull out the grounds drawer number of coffee grounds in drinks are blocked. and empty it into a garbage the drawer has reached the bag. - Page 26 DISPLAY CAUSE EFFECT SOLUTION NOTE WASHING CYCLE The set number of cycles pro- The message will appear on Do a washing cycle (see para- graph WASHING THE DELI- IS NEEDED grammed before washing, has the display but the machine VERY UNIT AND MILK FOA- been exceeded.

-

Page 27: Machine Block Alarm Messages

MACHINE BLOCK ALARM MESSAGES DISPLAY CAUSE EFFECT SOLUTION NOTE UPPER PISTON MOTOR During the group handling The control unit will halt wha- Open and close the machine If the xxxxx reappears GROUP ALARM phase, the upper piston tever cycle is on by turning off door. - Page 28 DISPLAY CAUSE EFFECT SOLUTION NOTE CLEANING FILTER The volume counter has rea- Coffee will not be delivered; Regenerate cleaning filter This alarm will not halt ALARM ched the number of litres of the dose will not be halted or it salts.

Need help?

Do you have a question about the MICROBAR and is the answer not in the manual?

Questions and answers