Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Neptronic SK VAP

- Page 1 SK VAP Evaporative Humidifier / Cooling System Manual Installation, Commissioning, Operation and Maintenance. SK VAP Version 1.00 (SK VAP) 12-12-28 Neptronic® 400 boul. Lebeau Montreal, Quebec H4N 1R6 (CANADA) TEL: (514) 333-1433 FAX: (514) 333-3163 www.neptronic.com...

- Page 2 This installation and operation manual has been developed to facilitate the installation and the ope- ration of the SK VAP Humidification System. The strict application of these instructions will ensure the conformity of the installation and operation to the manufacturer's recommendations.

-

Page 3: Table Of Contents

Stage 4 - Install Drain Pipework..Page 14 Stage 5 - Position the SK VAP Control panel..Page 15 Stage 6 - Connect Power Supply to SK VAP Control panel..Page 16 Stage 7 - Connect SK VAP Module..Page 16 Stage 8 - Connect Controls... - Page 4 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

-

Page 5: Delivery And Storage

It is the customer's responsibility to ensure that operators are trained in handling heavy goods and to enforce the relevant lifting regulations. The packaged SK VAP unit may be carried by fork lift from the underside, but caution should be exercised to ensure that the load is balanced before lifting. Refer to weights and measures section for system weight. - Page 6 At the heart of the SK VAP is the evaporative module, which is installed in an AHU or duct. Water is supplied to the top of a highly efficient bonded matrix, which is impregnated with silver for added hygiene. Dry air passes through this moist material picking up water vapour, raising the humidity as it does so.

-

Page 7: Sk Vap Overview

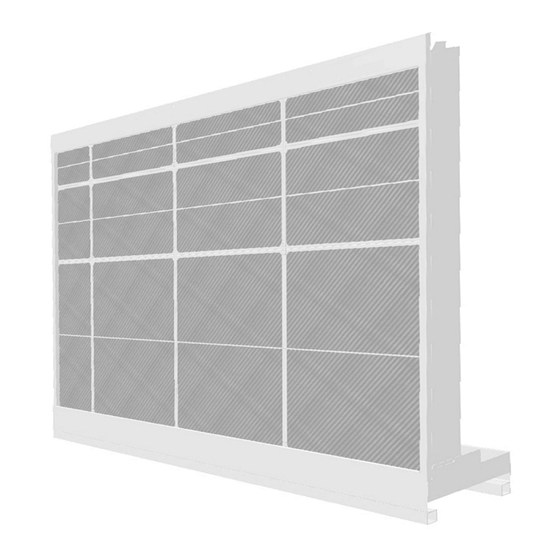

2 - SK VAP Evaporative Module The SK VAP evaporative module is available in a range of widths (24” (600mm) - 118” (3000mm)) and heights (30” (750mm)) - 106” (2750mm)) to match the requirements of individual applications. The evaporative matrix consists of modular cassettes with low pressure drop which are available in a range of sizes and efficiencies. - Page 8 Evaporative Humidification / Cooling System When designing or installing an air handling system that incorporates an ‘SK VAP’, appropriate micro-organism and bacterial control methods MUST be considered and this should only be undertak en by suitably qualified persons. A risk assessment MUST also be undertaken in relation to control of micro-organisms and bacterial growth, especially Legionnaires disease.

- Page 9 I = ON O = OFF II = Drain Additional wiring connections Cable entry SK VAP Control panel Specification Description Specification Dimensions 12” (300mm) wide x 17” (420mm) high x 6” (140mm) deep Weight 14.5 lb (6.5 kg) Required Power Supply 110 V AC fused at 10 Amps in the US.

-

Page 10: Control Panel Specification

Step 4 - Connect to open drain Step 5 - Position and mount Control panel Step 6 - Connect power supply to Control panel Step 7 - Connect Control panel to Evaporative Module Step 8 - Connect Controls wiring Neptronic ® www.neptronic.com... - Page 11 Step 1 - Position the SK VAP Evaporative Module Installation should only take place after careful consideration of final position of the SK VAP Evaporative module and SK VAP Control panel and should be in accordance with AHU/duct-work installation diagram below.

- Page 12 Step 2 - Install Blanking Plates Once the SK VAP Evaporative Module has been positioned in the waterproof section of air handling unit, non corrosive blanking plates (not supplied) must be installed to prevent air bypass around the Module in the AHU.

- Page 13 1/2” BSP female threaded connection of the filling hose. The PureFlo Ag+ assembly should be positioned as close to the SK VAP Evaporative Module inlet as possible, via two 1/2” (15mm) compression fittings. It is advisable to mount the PureFlo Ag+ outside the AHU for ease of access.

- Page 14 Step 4 - Install Drain Pipework The SK VAP Evaporative Module features an integrated drain and overflow which must be connected to the main building drain with 3/4” (20mm) copper or stainless pipework. The drain assembly can be reversed to face in the opposite direction to suit either left or right feed pipe-work.

- Page 15 Evaporative Humidification / Cooling System Step 5 - Position the SK VAP Control panel The SK VAP Control panel should ideally be positioned as close to the Evaporative Module as possible for ease of servicing and maintenance. Use a 9-core electrical inter-connecting cable with a maximum length of 33ft (10m) for connection between the SK VAP Evaporative Module and the SK VAP Control Panel (see “Wiring Diagram”...

- Page 16 The electrical power cable to SK VAP Control panel should be suitably rated for a 120Vac / 10 Amp load in the US. The power supply should be connected to the G, L and N terminals as shown in “wiring diagram” on page 17.

-

Page 17: Wiring Diagram

Evaporative Humidification / Cooling System Wiring Diagram Neptronic ® www.neptronic.com... - Page 18 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

- Page 19 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

- Page 20 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

- Page 21 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

- Page 22 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

-

Page 23: Pre-Commissioning Checklist

The use of mains water fed tanks and reservoirs is only permitted as part of a managed water treatment system. Check that the SK VAP Evaporative Module has a feed water supply in excess of 29 psi (2 bar) connected to the supplied filling hose. - Page 24 18. 4. Final Checks - Ensure that the system is operating correctly. Check for any leaks from the SK VAP evaporative module, and verify that the air supply is evenly distributed, and matches the design conditions for the system.

-

Page 25: Maintenance Schedule

In the event that the humidifier contains any residual water or has remained damp, and the temperature exceeded 68°F (20°C), the SK VAP should be cleaned and disinfected. Refer to the cleaning, disinfection and descaling instructions in this manual. -

Page 26: Maintenance Guide

“The control of Legionella bacteria in water systems”. Your water sampling / testing and disinfection regime must be based on details in the O&M manual and from results of a site specific risk assessment. For this type of Evaporative Humidifier, Neptronic recommend that disinfection is undertaken at least twice a year. Operations... -

Page 27: Routine Water Sampling And Testing

The SK VAP system MUST be connected to a clean, potable mains water supply. It is the responsibility of the user to ensure that the water system complies with local regulations and bylaws, particularly those for the control of Legionella bacteria. -

Page 28: Recommended Spares List

Evaporative Humidification / Cooling System Recommended Spares List Description SK VAP Evaporative Matrix Cassette Box of 5 Disfin tablets Sediment filter Antimicrobial filter Float valve Drain valve Inlet valve Stage Control Solenoid Valve Optional Re-circulating Pump 6K Re-circulating Pump 8K... -

Page 29: Trouble Shooting

16 ft/s (5.0 m/s) dependant on its position relative to the fan. 2. The air velocity might be uneven. Fit a perforated plate before the SK VAP. 3. The humidifier matrix might be incorrectly fitted. Check the humidifier cassettes have been fitted correctly. -

Page 30: Cleaning And Disinfection

Before commencing cleaning and disinfection: Risk assess the situation. This should include but is not limited to observance of COSHH, L8 and the use of PPE, working from heights and ensuring a full understanding of the SK VAP System. Coordinate with relevant responsible persons. - Page 31 • Check for and complete maintenance requirements as per manufacturers instructions. • Always leave work area clean, dry and tidy. Step 8 - Recommission the system • Refer to the commissioning section of this manual. Neptronic ® www.neptronic.com...

-

Page 32: Descaling

• Reassemble the individual cassettes into the SK VAP evaporative Module. Step 8 - Flush the SK VAP to remove traces of acid • Before normal operation of the SK VAP the matrix must be flushed and drained several times to ensure no acid is left on the cassettes. -

Page 33: System Code Identification

Product Identification Product Identification HE = HumEvap HumEvap System Efficiency (Matrix Depth) SK VAP System Efficiency (Matrix Depth) A = 75% Eficiente - 4” (100mm) A = 75% Efficient - 100mm (4") B =85% Eficiente - 6” (150mm) B = 85% Efficient - 150mm (6") C =95% Eficiente - 8”... - Page 34 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

- Page 35 Evaporative Humidification / Cooling System Neptronic ® www.neptronic.com...

-

Page 36: Neptronic

Neptronic® 400 boul. Lebeau Montreal, Quebec H4N 1R6 (CANADA) TEL: (514) 333-1433 FAX: (514) 333-3163 www.neptronic.com...

Need help?

Do you have a question about the SK VAP and is the answer not in the manual?

Questions and answers