Table of Contents

Advertisement

OPERATOR'S MANUAL

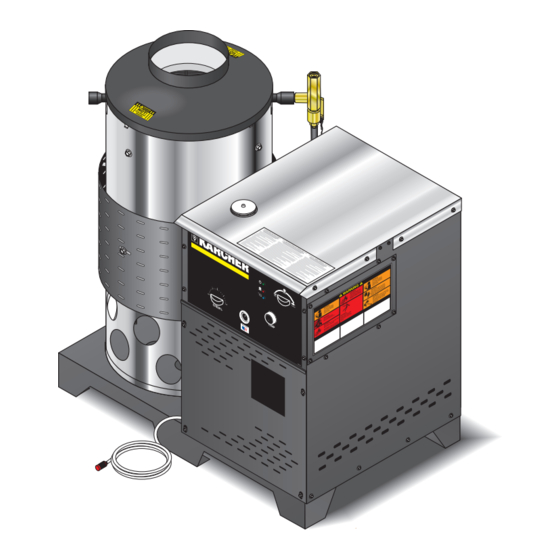

HDS NG 4.5/22 Ea St - 1.575-715.0

HDS NG 5.0/30 Eb St - 1.575-717.0

To locate your local Kärcher Commercial Pressure Washer Dealer nearest you,

visit our web page at www.karchercommercial.com

98001600-2

HDS NG 3.5/30 Ea St - 1.575-719.0

HDS NG 5.0/30 Ec ST - 1.575-721.0

®

9.800-160.0

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the HDS NG 4.5/22 Ea St - 1.575-715.0 and is the answer not in the manual?

Questions and answers