Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Invacare Compressor

- Page 1 User Manual HomeFill Compressor ® User: Before using the product, read this manual and save for future reference. Dealer: This manual must be given to the end user. For more information regarding Invacare products, parts, and services, please visit www.invacare.com...

-

Page 2: Accessories Warning

ACCESSORIES WARNING Invacare products are specifically designed and manufactured for use in conjunction with Invacare accessories. Accessories designed by other manufacturers have not been tested by Invacare and are not recommended for use with Invacare products. NOTE: Updated versions of this manual are available on www.invacare.com. HomeFill... -

Page 3: Table Of Contents

Compressor Initial Setup Checklist... 16 Choosing a location... 16 Transporting the Compressor... 17 Installing the Power Cord... 17 Connecting the Compressor to the Concentrator... 18 SECTION 4—CHECKLIST AND CYLINDER INSPEC- TION ... 20 Compressor Operation Checklist... 20 Cylinder Prefill Inspection ... 20 The Hydrostatic Testing Date ... - Page 4 TABLE OF CONTENTS Connecting/Disconnecting the Cylinder to/from the Compressor ... 23 Connecting the Cylinder to the Compressor... 23 Disconnecting the Cylinder from the Compressor... 26 Turning the Compressor On ... 28 SECTION 6—INDICATOR LIGHTS ... 30 SECTION 7—TROUBLESHOOTING ... 31 SECTION 8—MAINTENANCE ...

-

Page 5: Special Notes

Caution indicates a potentially hazardous situation which, if not avoided, may result in property damage or minor injury or both. ACCESSORIES CAUTION SPECIAL NOTES MEANING HomeFill Compressor ®... - Page 6 Textiles and other materials that normally would not burn are easily ignited and burn with great intensity in oxygen enriched air. Failure to observe this warning can result in severe fire, property damage and cause physical injury or death. HomeFill Compressor Part No 1100873 ®...

-

Page 7: Typical Product Parameters

TYPICAL PRODUCT PARAMETERS Standard Listing: TYPICAL PRODUCT PARAMETERS - COMPRESSOR IPX0 Electrical Requirements: Rated Current Input: Operating Temperature: Storage Temperature: Part No 1100873 TYPICAL PRODUCT PARAMETERS Double Insulated Product ETL Certified as Complying with UL60601-1, First Edition ETL Certified Complying with CAN/CSA C22.2 No. - Page 8 No AP/APG: Electrical: Placement: Tubing: Time of Operation: Recommended Storage and Shipping Temperature: Environment: Minimum Operating Time: HomeFill Compressor ® 14 - 21 psi 2 L/min >90% O 20 ¼ inches 15 inches 16 inches 33 lbs 39 lbs Not suitable for use in the presence of a flammable anaesthetic mixture.

-

Page 9: Label Location

See Owner’s Manual before cleaning. Never oil or lubricate coupling. Cylinders filled on this unit MUST be labeled “Contents of this cylinder are the product of an oxygen concentrator.” DEALER INFORMATION NOTE: Invacare recommends leaving a full cylinder of oxygen with the patient after setting up the HomeFill compressor. Before leaving a HomeFill Compressor with a user, the following checklist MUST be completed: ❑ Make sure the pressure test on cylinder has not expired. ❑ Instruct the user on the safe operation of the concentrator and review all warnings. -

Page 10: Homefill Information

HOMEFILL INFORMATION HOMEFILL INFORMATION HomeFill is an accessory device to the oxygen concentrator that enables the patient to refill custom portable oxygen cylinders for personal use. NOTICE The HomeFill compressor is for use with specially designed Invacare Platinum™5, 10, XL and Perfecto ™ HomeFill compatible oxygen concentrators. The oxygen concentrator can be set to the following maximum flowrates when operating with HomeFill compressor: Platinum 5, XL and Perfecto : 3 L/min or less. Platinum 10: 5 L/min or less. To determine if your oxygen concentrator is HomeFill compatible, examine the lower right corner of the rear of the oxygen concentrator for an outlet fitting. Refer to the illustration below. TOP VIEW Power Cord Outlet Fitting Concentrator HomeFill Compressor Part No 1100873 ®... -

Page 11: Section 1-Important Safety Instructions

No user serviceable parts. TO REDUCE THE RISK OF BURNS, ELECTROCUTION, FIRE, OR INJURY TO PERSONS NEVER use near any type of flame or flammable/explosive substances, vapors or atmosphere. Operating Information DO NOT allow oil from your hands or other sources to come into contact with the compressor coupling or bottle fittings. These substances may become flammable in the presence of oxygen and cause injury. Avoid touching the bottle fitting whenever possible. Example of items to avoid are hand creams or lotions, cooking oils, suntan oils or sunblocks and similar oily products. If you use these types of products, wash your hands prior to using the HomeFill unit. If the bottle fitting should come in contact with such substances it should ... - Page 12 SECTION 1—IMPORTANT SAFETY INSTRUCTIONS NEVER oil or lubricate the compressor coupler or bottle fittings. NEVER use any penetrating oil or lubricant such as WD‐40 ® or 3‐in‐1 oil ® . If connection difficulty is experienced verify that the bottle fitting is being inserted straight down into the compressor coupler. If continued difficulty is experienced contact your supplier for assistance. Before moving or repositioning either the compressor or concentrator, ALWAYS push the power switch to the Off (O) position, disconnect the AC power cord and the interconnect hose between the compressor and concentrator. Failure to do so may result in damage to the unit or personal injury. Children should ALWAYS be supervised around the HomeFill unit. When used with the HomeFill table or similar elevated support surfaces, a child could pull over any such table causing the unit to fall. Failure to observe this warning may result in personal injury or product damage. Use extreme care when handling and filling an oxygen cylinder. Full oxygen cylinders are under pressure and can become a projectile if dropped or mishandled. DO NOT store filled oxygen cylinders near a furnace, hot water tank, in the trunk of a car or other high temperature area. Storage in areas such as this can result in bursting of the cylinder or fire. The use of this device is limited to the oxygen patient. Cylinders MUST be used ONLY by the oxygen patient and are not to be distributed to any other individual for any purpose. DO NOT use outdoors. The maximum patient flow while filling a cylinder with the IOH200 is 3 L/min for Platinum 5, XL and Perfecto concentrators and 5 L/min for Platinum 10 concentrators. Patients with a higher prescribed flow should not fill a ...

-

Page 13: Maintenance

SECTION 1—IMPORTANT SAFETY INSTRUCTIONS NEVER block the air openings of the product or place it on a soft surface, such as a bed or couch, where the air opening may be blocked. Keep the openings free from lint, hair and the like. If the compressor has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or submersed in water, call a qualified technician for examination and repair. If any leakage of the oxygen cylinder is detected DO NOT attempt to use the cylinder. Turn the flow selector knob on the regulator to Off. If leakage persists, place the cylinder outdoors and notify your Home Health Care Provider or Service Representative of this condition. The HomeFill is equipped with a high pressure relief valve to ensure the user’s safety. When activated, this safety feature will make an extremely loud noise. If this noise occurs, turn the unit Off and contact your Home Health Care Provider or Service Representative. Unplug unit from outlet when not in use and before cleaning. Maintenance DO NOT disassemble. The unit is provided with double insulation and has no serviceable parts. If any service is required, contact Invacare Technical Service. Double-Insulated Products In a double‐insulated product, two systems of insulation are provided instead of grounding. No grounding means is required on a double‐insulated product, nor is a means for grounding to be added to the product. A double‐insulated product is marked with the words “DOUBLE INSULATION” or “DOUBLE INSULATED” or the symbol ( ). Part No 1100873 HomeFill Compressor... -

Page 14: Disposal Of Equipment And Accessories

Disposal of Equipment and Accessories Follow local governing ordinance and recycling plans regarding disposal of device components. Radio Frequency Interference This equipment has been tested and found to comply with EMC limits specified by IEC/EN 60601‐1‐2. These limits are designed to provide a reasonable protection against electromagnetic interference in a typical medical installation. Other devices may experience interference from even the low levels of electromagnetic emissions permitted by the above standards. To determine if the emissions from the Perfecto causing the interference, turn the Perfecto interference with the other device(s) stops, then the Perfecto is causing the interference. In such rare cases, interference may be reduced or corrected by one of the following measures: • Reposition, relocate, or increase the separation between the equipment. • Connect the equipment into an outlet on a circuit different from that to which the other device(s) is connected. Avoid creation of any spark near medical oxygen equipment. This includes sparks from static electricity created by any type of friction. SAVE THESE INSTRUCTIONS HomeFill Compressor ® Off. If the Part No 1100873 is ... -

Page 15: Section 2-Technical Description

SECTION 2—TECHNICAL DESCRIPTION SECTION 2—TECHNICAL DESCRIPTION The HomeFill Oxygen System (IOH200) is an electro‐mechanical prescription system for use in the home. Its intended function and use is to supply pressurized oxygen to fill Invacare proprietary gas cylinders for ambulatory use while the patient receives therapeutic oxygen from an accessory oxygen concentrator. The IOH200 gas system is designed for use with an Invacare Platinum oxygen concentrator with an integral HF2 accessory port that can supply a gas concentration greater than 90% O around 2 L/min. while supplying a patient therapy flow rate up to 2.5 L/min. for Platinum 5 and 5 L/min. for Platinum 9. The HomeFill Oxygen system consists of IOH200 gas compressor, connection tubing, and the Invacare supplied portable gas cylinders with the integral flow regulator and interlocking fill fitting. The IOH200 compressor consists of a multistage compressor, internal reservoir, control electronics with an integral oxygen concentration sensor, interlocking fill fitting, inlet fitting, and drive motor. The compressor operation is controlled by the electronics assembly. The motor/compressor is allowed to fill a cylinder only when the oxygen concentration of the inlet gas stream is greater than 90%. The motor/compressor fill operation is completed when the gas in a cylinder reaches the maximum fill pressure of 2000 PSI (13786 kPa). The IOH200 compressor can fill cylinders for portable use by ambulatory patients. The Invacare supplied portable gas cylinders have an interlocking fill fitting that mates only with the Invacare IOH200 compressor assembly. The gas cylinder also contains an integral flow regulator with fixed, selectable flow settings. Part No 1100873... -

Page 16: Section 3-Initial Setup

SECTION 3—INITIAL SETUP SECTION 3—INITIAL SETUP NOTE: Dealers Only ‐ Refer to Dealer Information on page 9 before performing this procedure. Initial Set Up of Compressor Compressor Initial Setup Checklist Before operating the HomeFill Compressor for the first time, complete the following checklist: ❑ Choose a location for the compressor. ❑ Transport the compressor to the desired location. ❑ Connect the power cord to the compressor. ❑ Connect the compressor to the concentrator. Choosing a location The compressor should be at least three inches away from walls, draperies or furniture to ensure sufficient air flow. Avoid placing the compressor next to heaters, radiators or hot air registers. DO NOT use in a closet. The compressor should sit on a hard flat stable surface, such as a table or the Ready Rack. WARNING NEVER use near any type of flame or flammable/explosive ... -

Page 17: Transporting The Compressor

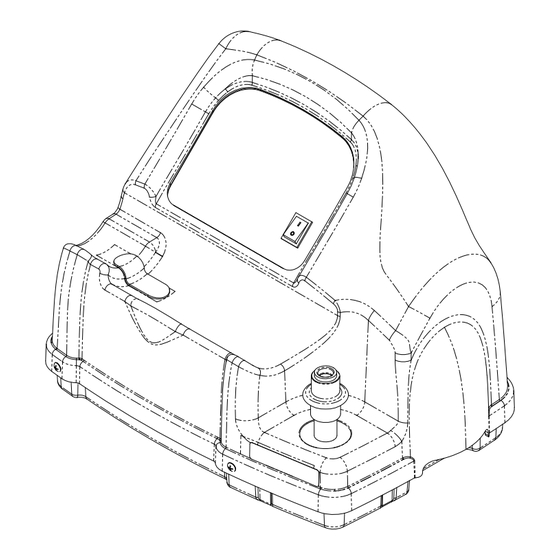

Transporting the Compressor NEVER transport a compressor with a cylinder connected to or stored on the compressor, otherwise injury or damage can occur. When transporting the compressor, be careful not to bump the compressor or the connectors into obstacles. Otherwise, damage to the compressor may occur. NOTE: For this procedure, refer to FIGURE 3.1. 1. There are two methods to safely transport the compressor: • One Hand ‐ Grasp the hand grip at the bottom rear of the compressor. • Two Hands ‐ Grasp the hand grips on the sides of compressor. Installing the Power Cord NOTE: For this procedure, refer to FIGURE 3.2 on page 18. 1. Choose a proper location. Refer to Choosing a location on page 16. 2. Make sure the power switch is in the Off (O) position 3. Plug the power cord into the electric connector in the back of the compressor. 4. Plug the opposite end of the power cord into the wall outlet. Part No 1100873 SECTION 3—INITIAL SETUP... -

Page 18: Connecting The Compressor To The Concentrator

SECTION 3—INITIAL SETUP Wall Outlet Power Cord NOTE: This product may come with a polarized plug (one blade is wider than the other). As a safety feature, this plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician. DO NOT attempt to defeat this safety feature. FIGURE 3.2 Installing the Power Cord Connecting the Compressor to the Concentrator NOTE: For this procedure, refer to FIGURE 3.3 on page 19. 1. Insert one end of the interconnect hose into the outlet fitting on the back of the concentrator (Detail “A”). 2. Insert the opposite end of the interconnect hose into the inlet fitting on the side of the compressor (Detail “B”). NOTE: The metal tabs on the concentrator outlet fitting and the compressor inlet fitting will pop out with an audible “click” when the end of the interconnect hose is properly installed (Detail “C”). HomeFill Compressor ® Compressor (REAR) - Page 19 DETAIL “A” Insert End of Interconnect Hose Inlet/Outlet Fitting Interconnect Hose into Inlet/Outlet Fitting Metal DETAIL “B” CONCENTRATOR TOP VIEW Power Cord Compressor Outlet Fitting Inlet Fitting FIGURE 3.3 Connecting the Compressor to the Concentrator Part No 1100873 HomeFill Compressor ®...

-

Page 20: Section 4-Checklist And Cylinder Inspection

SECTION 4—CHECKLIST AND CYLINDER INSPECTION SECTION 4—CHECKLIST AND CYLINDER INSPECTION Compressor Operation Checklist Each time the HomeFill Compressor is used to fill a cylinder, complete the following checklist: ❑ Ensure the concentrator has been On for at least thirty minutes. Refer to the concentrator Owner’s Manual. ❑ Perform the prefill inspection on the cylinder. ❑ Connect the cylinder to the compressor. ❑ Push the compressor power switch to the On ( ) position. ❑ Examine the indicator lights on the control panel. ❑ Disconnect and remove the full cylinder. ❑ Push the compressor power switch to the Off (O) position. ❑ If filling another cylinder, repeat this checklist. Cylinder Prefill Inspection WARNING ONLY use cylinders that have the Invacare HomeFill connection and HomeFill label. All cylinders MUST be inspected before attempting to fill. ... - Page 21 Secure cylinder during storage and use. No smoking in cylinder area. Keep away from heat, flame and spark. Keep out of reach of children. DO NOT drop. Filling of this gas is performed by Invacare HomeFill oxygen system Only. Cylinders that have been refinished and/or exposed to elevated temperatures must be hydrostatically tested before filling.

-

Page 22: The Hydrostatic Testing Date

Contact your dealer for replacement. External Examination 1. Examine the outside of the cylinder for the following conditions, and replace the cylinder if they exist: • Dents or dings • Arc burns • Oil or grease • Any other signs of damage that might cause a cylinder to be unacceptable or unsafe for use. 2. Examine the cylinder for evidence of fire or thermal damage. Evidence includes charring or blistering of the paint, or other protective coating or heat sensitive indicator. If fire or thermal damage is found, replace the cylinder. 3. Inspect the cylinder/regulator assembly for the following and replace if found: • Debris, oil or grease • Noticeable signs of damage • Signs of corrosion inside the valve • Signs of excessive heat or fire damage HomeFill Compressor ® WARNING Part No 1100873... -

Page 23: Section 5-Compressor Operation

SECTION 5—COMPRESSOR OPERATION Connecting/Disconnecting the Cylinder to/from the Compressor NEVER use tools of any kind to connect/disconnect the cylinder and the compressor. Otherwise, severe injury and/or damage may occur. Connecting the Cylinder to the Compressor DO NOT drop oxygen cylinders. Use two hands when handling/transporting oxygen cylinders. Otherwise, injury or damage may occur. DO NOT use a liquid leak detector to test for leaks. NOTE: For this procedure, refer to FIGURE 5.1 on page 24 and FIGURE 5.2 on page 25. 1. Examine the cylinder gauge. If the cylinder pressure is less than 1500 psig, proceed to STEP 2. NOTE: For location of the cylinder gauge, refer to the cylinder’s manual. NOTE: If the cylinder pressure is greater than 1500 psig, DO NOT attempt to top off this cylinder. It may not fill. 2. Set the regulator flow dial on the cylinder to Off. Refer to the cylinder’s manual. 3. Remove the cylinder and connector fillport covers (if present). Part No 1100873 SECTION 5—COMPRESSOR OPERATION... - Page 24 SECTION 5—COMPRESSOR OPERATION 4. Momentarily push DOWN on the outer ring (sleeve) of the connector fillport until GREEN dots are visible to reset the connector (FIGURE 5.1). NOTE: If the outer ring (sleeve) is in the UP position (GREEN dots not visible), the connector fillport will not be able to accept the cylinder fillport. Pushing DOWN momentarily will reset the connector fillport (GREEN dots visible) to accept the cylinder fillport. PUSH DOWN GREEN Dots FIGURE 5.1 Resetting Connector Fillport 5. Grasp the cylinder in the area behind the cylinder fillport (FIGURE 5.2). 6. Position the cylinder in the compressor cradle (FIGURE 5.2). 7. Align the cylinder fillport with the connector fillport (FIGURE 5.2). 8. Pull UP on the outer ring (sleeve) of the connector fillport while pushing DOWN on the cylinder to couple the cylinder fillport into the connector fillport (FIGURE 5.2). NOTE: The cylinder is properly connected when an audible “click” is heard. HomeFill Compressor ® Outer Ring (Sleeve)

- Page 25 Cylinder NOTE: Fillport covers not shown for clarity. Compressor Cradle Compressor Cylinder FIGURE 5.2 Connecting the Cylinder to the Compressor Part No 1100873 SECTION 5—COMPRESSOR OPERATION PULL UP Cylinder Fillport Power Switch Connector Fillport Outer Ring (Sleeve) Cylinder Fillport Connector Fillport Outer Ring (Sleeve)

-

Page 26: Disconnecting The Cylinder From The Compressor

Disconnecting the Cylinder from the Compressor NOTE: For this procedure, refer to FIGURE 5.3. 1. Press the compressor power switch to the Off (O) position. 2. Grasp the cylinder in the area behind the cylinder fillport. 3. With the other hand, grasp the outer ring (sleeve) of the connector fillport and push DOWN. 4. Lift up on the cylinder to remove from the connector fillport. Cylinder Compressor Connector Fillport FIGURE 5.3 Disconnecting the Cylinder from the Compressor 5. When the cylinder fillport is disconnected from the connector fillport, release the outer ring (sleeve) of the connector fillport and use two hands to remove the cylinder from the compressor cradle. HomeFill Compressor ® PUSH DOWN Cylinder Fillport... - Page 27 The fillport cover on the connector fillport and the cylinder fillport MUST be replaced after filling and whenever not in use. If either of the fillport covers are missing contact your healthcare provider before using. 6. Place the fillport covers onto the connector fillport and cylinder fillport. NOTE: When using the post valve type cylinder, attach an oxygen regulator per manufacturers instructions. 7. Examine the cylinder gauge to ensure cylinder is full (needle pointing into GREEN area). If the cylinder is not full, perform the following: A. Repeat Connecting the Cylinder to the Compressor on page 23. B. If cylinder is not full after second attempt to fill, contact the provider. Cylinder Fillport FIGURE 5.4 Fillport Covers Part No 1100873 SECTION 5—COMPRESSOR OPERATION WARNING Cover Connector Fillport Cover HomeFill Compressor ®...

-

Page 28: Turning The Compressor On

SECTION 5—COMPRESSOR OPERATION Turning the Compressor On NOTE: For this procedure, refer to FIGURE 5.5 on page 29. 1. Make sure the concentrator is On. Refer to the concentrator Owner’s Manual. The concentrator flow rate to the patient MUST be set at maximum: 3 L/min or less for Platinum 5, XL, and Perfecto 5 L/min for Platinum 10. Otherwise, the oxygen level to the compressor will be <90% and the compressor will not fill the cylinder. 2. Set the concentrator flow rate to the patient to 3 L/min or less for Platinum 5, XL, and Perfecto2 and 5 L/min for Platinum 10. Refer to the concentrator Owner’s Manual. 3. Make sure the cylinder is connected to the compressor. Refer to Connecting the Cylinder to the Compressor on page 23. 4. Push the power switch on the control panel to the On ( ) position. 5. Examine the control panel. The following sequence of events should occur: A. 0‐3 minutes ‐ The O be lit while the compressor warms up. B. After three minutes ‐ The FILLING (GREEN) light will be on while the cylinder is filling. C. The FULL (GREEN) light will be on when the cylinder is ... -

Page 29: Control Panel

31. NOTE: If the ATTENTION (RED) light and audible alarm are on. Refer to Troubleshooting on page 31. Control Panel Filling (GREEN Light) FIGURE 5.5 Turning the Compressor On Part No 1100873 SECTION 5—COMPRESSOR OPERATION Attention (RED light and HOMEFILL® ATTENTION O2 BELOW NORMAL FILLING FULL DANGER - RISK OF ELECTRICAL SHOCK DO NOT remove cover, refer servicing to qualified service personnel. -

Page 30: Section 6-Indicator Lights

ATTENTION - RED (Audible Alarm) HomeFill Compressor ® COMPRESSOR STATUS Compressor is Off. Compressor is On and warming up (0-3 minutes after power is On). from concentrator is < 90% (any time after three minute warmup). Compressor is On and cylinder is filling. -

Page 31: Section 7-Troubleshooting

2. Check that the cylinder is connected properly. 3. Turn the compressor Off. 4. Remove the cylinder and reinstall. 5. Turn the compressor On. If cylinder is not full and is connected properly, the compressor may have internal failure. Contact your home health care provider or Invacare. -

Page 32: Troubleshooting

• If damaged, replace. • If pinched, straighten tubing. Turn the compressor Off for at least 10 seconds. Turn the compressor On. If the YELLOW light still remains on after 10 minutes, proceed to STEP 3. -

Page 33: Section 8-Maintenance

Push the power switch to the Off (O) position and unplug the compressor before cleaning. DO NOT operate the compressor without the filter installed. DO NOT unplug by pulling on cord. To unplug, grasp the plug not the cord, otherwise damage may occur. NOTE: For this procedure, refer to FIGURE 8.1. NOTE: All compressors have one filter on the back of the cabinet. NOTE: Perform this procedure at least once a week. 1. Unplug the compressor. Grasp the plug not the cord. 2. Remove the filter. 3. Clean the filter with a vacuum cleaner or wash in warm soapy water and rinse thoroughly. 4. Dry the filter thoroughly before reinstallation. Filter FIGURE 8.1 Cleaning the Compressor Filter Cabinet To avoid electrical shock, DO NOT remove cabinet. 1. Clean the cabinet with a mild household cleaner and non‐abrasive cloth or sponge. Part No 1100873 SECTION 8—MAINTENANCE WARNING CAUTION WARNING HomeFill Compressor ®... - Page 34 NOTES NOTES HomeFill Compressor Part No 1100873 ®...

-

Page 35: Limited Warranty

Invacare or a dealer, with a copy of the seller’s invoice required for coverage under this warranty, or 5,000 hours, whichever comes first. - Page 36 (INCLUDING, BUT NOT LIMITED TO, MODIFICATION THROUGH THE USE OF UNAUTHORIZED PARTS OR ATTACHMENTS) OR TO PRODUCTS DAMAGED BY REASON OF REPAIRS MADE TO ANY COMPONENT WITHOUT THE SPECIFIC CONSENT OF INVACARE CORPORATION OR TO PRODUCTS DAMAGED BY CIRCUMSTANCES BEYOND INVACARE CORPORATION'S CONTROL.

Need help?

Do you have a question about the Compressor and is the answer not in the manual?

Questions and answers