Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Hoffrichter CARAT I

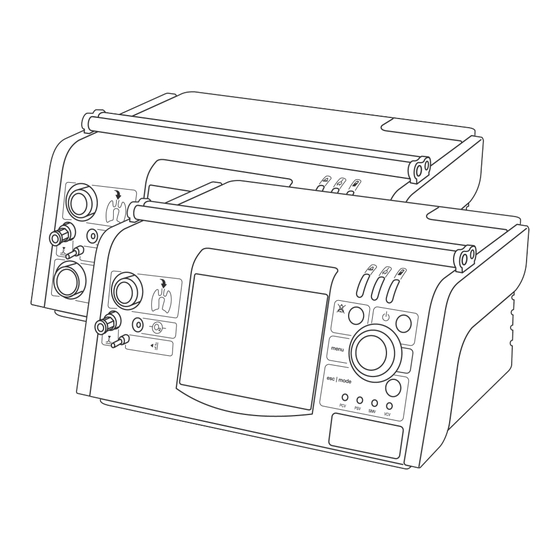

- Page 1 Service Manual Ventilator valid for devices of the types 9LV102 and 9LV202...

-

Page 2: Table Of Contents

Reprocessing Procedure 1....................5 Reprocessing Procedure 2....................5 Reprocessing Procedure 3....................6 Block Diagrams .......................6 Block Diagram – Pneumatic (CARAT I) ................6 Block Diagram – Pneumatic (CARAT II) ................7 Block Diagram – Complete Machine .................7 Block Diagram – Controller Board ..................8 Block Diagram – Power Management Circuit Board ............8 Assemblies ........................9... - Page 3 Safety-Related Check .....................23 Check the Electrical Safety of the External Power Supply ..........23 Exploded Views ......................24 10.1 Exploded View C – Inner Casing CARAT I ...............24 10.2 Exploded View C – Inner Casing CARAT II...............25 10.3 Exploded View C – Inner Casing CARAT II...............26 10.4...

-

Page 4: Symbols In This Service Manual

symbols in This serviCe manual In this Service Manual, the most important notes for users are indicated by symbols. Please make sure to follow these hints in order to avoid personal injury or property damage. Furthermore, all local accident prevention and general safety rules applicable to the intended use should be followed. -

Page 5: Preparing The Device When Changing Patient

PreParing The DeviCe when Changing PaTienT Before using the ventilator on a different patient, clean and disinfect it to such an extent that it is free from any human pathogens. Please ensure that all tools used, such as measuring instruments and test lung, are free from human pathogens. If MRSA contamination is suspected, the device must be packaged, with the appropriate label- ing, and disinfected accordingly. If the accessories (e.g., tube system, mask, fi lter, humidifier, etc.) are intended for repeated use, the manufacturer's provisions must be followed. The reprocessing of the device acc. to procedure 1 and 2 must be documented. 3.1 REPROCESSIng PROCEDuRE 1 The following measures may only be carried out by companies with a QM system and appropriately qualified, authorized and experienced specialist personnel. To reprocess the device, carry out the following steps: •... -

Page 6: Reprocessing Procedure 3

Air Inlet for Inspiration Blower Valvemembrane 1 Flow Sensor 1 Pressure Connector Sensor 1 Measuring Tube Pressure Sensor 2 Connector Control Tube Air Outlet Mechan. Valve Proportionalvalve (in the port) Figure 1: Block Diagram – Pneumatic CARAT I - 6 -... -

Page 7: Block Diagram - Pneumatic (Carat Ii)

4.2 BLOCk DIAgRAM – PnEuMATIC (CARAT II) Oxygen Outlet Control Unit Oxygen Connection Port Mechan. Valve - Valve (in the port) Tube Connector Inspiration Air Inlet Blower Valve Membran 1 Flow Sensor 1 Pressure Sensor 1 Connector Measuring Tube Pressure Sensor 2 Connector Mechan. Valve Control Tube Proportional Valve (in the port) -

Page 8: Block Diagram - Controller Board

4.4 BLOCk DIAgRAM – COnTROLLER BOARD Figure 4: Block Diagram – Controller Board 4.5 BLOCk DIAgRAM – POwER MAnAgEMEnT CIRCuIT BOARD Figure 5: Block Diagram – Power Management Circuit Board - 8 -... -

Page 9: Assemblies

assemblies 5.1 COnTROL CIRCuIT BOARD The control circuit board facilitates the operation and control of the artificial respiratory machine. The machine is divided into two main function groups, the operating section and the control sec- tion. 5.1.1 OPERATIng SECTIOn Functions: Selection of the respiratory mode and display by the Light Emitting Diode (LED) Input of the respiratory parameters using the Multi-Function Knob (MFK) and display in the Liq- uid Crystal Display (LCD) Start the respiratory mode... -

Page 10: Control Section

to 6.) The real-time clock is, foremost, to indicate the time for an occurrence of an alarm. Furthermore, the operator date and time is shown on the display. to 7.) The communication with the external peripherals (e.g. Windows computer) is through an isolated RS232 interface. -

Page 11: Power Management Circuit Board

5.2 POwER MAnAgEMEnT CIRCuIT BOARD Functions: Current measurement and allocation of the available current according to the priority Display of the operating condition Determining the capacitance and state of charge of the internal battery Charge the internal battery Transmission of the “battery-data” to the processor to be shown on the display 5.3 InTERnAL BATTERy The internal battery comprises of two Lithium-Ion batteries (Pana CRg 18650 CF) that are con- nected to a 28.8 V, 2.25 Ah manifold. -

Page 12: Tube Connection

5.5.4 TUBE COnnECTIOn The tube connection completes the manifold. It comprises of the connection for the inspiration tube (22M), the connection for the expiration tube (22F), the connection for the pressure tube (Ø 3.5 mm) and the connection for the control tube (subminiature coupling with bayonet connection [for one- line circuit]). -

Page 13: Tools, Metering Devices

• Soft underlay • Disposable gloves • Airflow Pressure Meter (APM) (0 - 100 hPa, e.g. HOFFRICHTER APM Art. no.: 00004832) • Blanking caps, with T-piece and silicon tubes (Art. no.: 00004831) • Flow meter (0 - 200 l/min e.g. HOFFRICHTER APM Part no.: 00004832) •... -

Page 14: Maintenance Hardware

mainTenanCe harDware 8.1 CLEAnIng AnD DISInFECTIOn Use a brush and vacuum cleaner and carefully clean the bottom cover and inner mounting. Use compressed air to clean inaccessible areas and subsequently use a vacuum cleaner to gather loose particles. Use a cloth, moist with normal concentrated soap solution, to remove stubborn contamination on the inside and outside of the top and bottom covers. -

Page 15: Check Attachment Of Printed Circuit Boards

8.5 CHECk ATTACHMEnT OF PRInTED CIRCuIT BOARDS The controller circuit board is attached to the inner mounting. Subsequently check the attachment of all PCBs: • Controller circuit board: 2 screws • RS232 circuit board: 2 screws • Power management circuit board: 3 screws • O metering cell circuit board: 1 screw 8.6 CHECk AIR OuTLET Check the air outlet (on the rear of the valve manifold) for correct seating, and attention must be... - Page 16 Figure 6: Measurement setup pressure sensor calibration CARAT I and CARAT II 2. Flow Sensor Calibration 2.1. For the CARAT I, attach the respiration tube, with pressure metering tube, to the inspiration connection and connect the pressure metering tube. The measurement of the flow is taken at the open side of the tube.

- Page 17 3.2. For the CARAT I, connect the respiration tube with pressure metering tube to the inspiration connection and the metering tube with the pressure metering connection of the device. Install a blanking cap in the open side of the respiration tube.

-

Page 18: Carry Out Battery Test

8.10 CARRy OuT BATTERy TEST During the test of the internal battery, the machine remains connected to the mains, is switched on at the main switch, and must not be disconnected from the mains during the test. no line circuit or other accessories must be used during the test procedure. To start the test procedure, press and hold the MFK until the service screen appears. -

Page 19: Maintenance And Replacement Kits

8.12 MAInTEnAnCE AnD REPLACEMEnT kITS Use the following kits for the various replacement and maintenance cycles (chapter 9.2): Diaphragm replacement kit (art. no.: 00004983) Quantity nomenclature Valve diaphragm O-Ring Cable tie maintenance kit 1 (art. no.: 00004984) anzahl / length nomenclature Valve diaphragm O-Ring Coarse filter Fine filter... -

Page 20: Check The Alarms

8.13 CHECk THE ALARMS You must adhere to the procedure given in chapter “Functional Check” of the User's Manual. 8.14 DATA BACkuP If it is proposed to change the set parameters during a SRC or maintenance, the contents of the device memory must be read and saved. If necessary, the data is to be analyzed. no maintenance is necessary to the PC software. - Page 21 Parameter Psv 20.0 hPa PEEP 5.0 hPa Frequency 12 bpm Apnoea limit AUTO Chute Inspiration trigger Expiration trigger 30 % Min. Volume Additional pressure 5.0 hPa (not active, Min. volume is set to OFF) Max. Volume 1.00 l Min. Volume 0.20 l Max.

-

Page 22: Safety-Related Check And Maintenance

safeTy-relaTeD CheCk anD mainTenanCe 9.1 MAInTEnAnCE The respiratory machine must be serviced by an authorised specialist every 12 months. 9.2 RECOMMEnDED MAInTEnAnCE SCHEDuLE operating hours required maintenance Before and during Carry out battery test (see chapter 8.10) storage: every 6 months Weekly Clean the air filters (coarse filter) Before return to ser- Alarm test (leakage, power failure),... -

Page 23: Safety-Related Check

9.3 SAFETy-RELATED CHECk The safety-related check must be carried out at intervals of no more than 6 months. This consists • A visual inspection of the machine (for external damage) • A functional check (acc. to User's Manual) • A visual inspection of the accessories, in accordance with the manufacturer’s instructions (respi- ratory tubes, oxygen sensor, etc.) The safety-related check carried out must be documented. -

Page 24: Exploded Views

10 exPloDeD views 10.1 ExPLODED VIEw C – InnER CASIng CARAT I - 24 -... -

Page 25: Exploded View C - Inner Casing Carat Ii

10.2 ExPLODED VIEw C – InnER CASIng CARAT II - 25 -... -

Page 26: Exploded View C - Inner Casing Carat Ii

10.3 ExPLODED VIEw C – InnER CASIng CARAT II - 26 -... -

Page 27: Exploded View A - Top Cover Carat I

10.4 ExPLODED VIEw A – TOP COVER CARAT I - 27 -... -

Page 28: Exploded View A - Top Cover Carat Ii

10.5 ExPLODED VIEw A – TOP COVER CARAT II - 28 -... -

Page 29: Exploded View E - Sensor Manifold Carat I

10.6 ExplodEd ViEw E – SEnSor Manifold CaraT i - 29 -... -

Page 30: Exploded View E - Sensor Manifold Carat Ii

10.7 ExplodEd ViEw E – SEnSor Manifold CaraT ii - 30 -... -

Page 31: Exploded View B - Lower Cover Carat (Rear View)

10.8 ExplodEd ViEw B – lowEr CoVEr CaraT (rEar ViEw) - 31 -... -

Page 32: Exploded View B - Lower Cover Carat (Front View)

10.9 ExplodEd ViEw B – lowEr CoVEr CaraT (fronT ViEw) - 32 -... -

Page 33: Exploded View - Assembling Carat I

10.10 ExplodEd ViEw – aSSEMBling CaraT i - 33 -... -

Page 34: Exploded View - Assembling Carat I

10.11 ExplodEd ViEw – aSSEMBling CaraT i - 34 -... -

Page 35: Exploded View - Assembling Carat Ii

10.12 ExplodEd ViEw – aSSEMBling CaraT ii - 35 -... -

Page 36: Exploded View - Assembling Carat Ii

10.13 ExplodEd ViEw – aSSEMBling CaraT ii - 36 -... -

Page 37: Spare Parts List

11 sPare ParTs lisT Pos. nomenclature order no. Top Cover CARAT Top Cover CARAT I plus 00004645 A-II Top Cover CARAT II plus 00004646 Cover Adjustment Knob CARAT MFK with Cover 00004956 Spring Circlip Design A8 DIn7993 Intake Adjustment Knob, lower part CARAT... - Page 38 00004272 Support O Metering Cell Seal Flow Sensor Spacer long, nickel-plated Flow Sensor 23000023 Flow Sensor Cable CARAT I, assembled 00004121 Flow Sensor Cable CARAT II, assembled 00004101 Spacer short, nickel-plated Tie-Rod M3, nickel-plated Sensor Manifold for Replacement of Diaphragm...

-

Page 39: Disposal

12 DisPosal Proper disposal saves natural resources and prevents harmful substances being released into the environment. 12.1 DEVICE The ventilator must not be disposed of with the household waste. Please contact the manufacturer to find out how to dispose of the device properly. 12.2 PACkAgIng The packaging is taken back by the distributor but it can alternatively be disposed of separately in the normal household waste. -

Page 40: Shipping Instructions For Contaminated Medical Technology

13 shiPPing insTruCTions for ConTaminaTeD meDiCal TeChnology The following shipping instructions apply to contaminated medical technology which is delivered to HOFFRICHTER gmbH for processing. 13.1 PICk-uP The dealer, medical technician or authorised personnel picks up the contaminated medical technol- ogy from the patient. A local surface disinfection of the equipment and accessories with microcide liquid spray (MRSA active) takes place followed by carefully placing the objects in bags with the use of disposable gloves, mask and disposable apron. - Page 41 HOFFRICHTER gmbH Mettenheimer Straße 12 / 14 19061 Schwerin germany Phone: +49 385 39925 - 0 Fax: +49 385 39925 - 25 E-Mail: info@hoffrichter.de www.hoffrichter.de CARAT FL-service-eng-070911-06...

Need help?

Do you have a question about the CARAT I and is the answer not in the manual?

Questions and answers