Summary of Contents for Ninja 411-22AMO

- Page 1 PORTABLE EXTRACTOR Operating Instructions MODELS: 411-22AMO 10070340 411-221MO 10070280 411-221HMO 10070270 411-2X1MO 10070360 411-22AHMO 10070330 Read these instructions before using the machine 86037520 05/01/07 PRV NO. 980181...

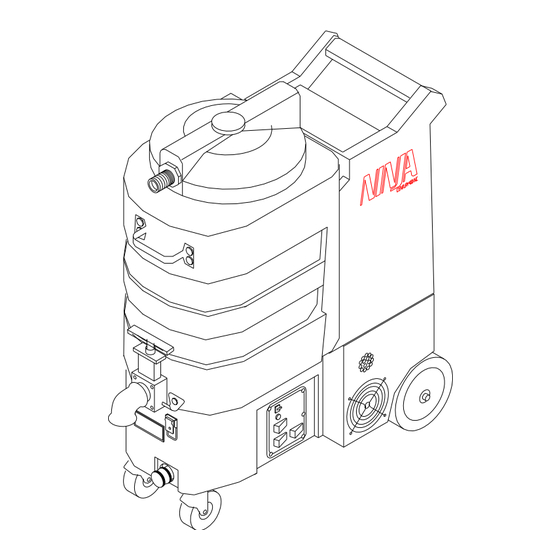

- Page 2 Phone Number: _________________________________________________________________________________________ OVERVIEW The Ninja is an electric powered carpet extractor intended for commercial use. This appliance applies a cleaning solution to the carpet and then vacuums the soiled water back into the recovery tank. 411- X X X XXX...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Machine Data Log/Overview........2 GROUP PARTS LIST Table of Contents..........3 Frame Group (2 Stg)............5-1 HOW TO USE THIS MANUAL Frame Group (3 Stg)............5-3 Frame Group (w/ heat)............5-5 How to use this Manual........1-1 Pump Group (no heat)............5-7 Pump Group (w/ heat)............5-9 SAFETY Recovery and Solution Tank Group........5-11 Vacuum Motor Group (2 Stg)..........5-13... -

Page 4: How To Use This Manual

HOW TO USE THIS MANUAL The SAFETY section contains important information This manual contains the following sections: regarding hazard or unsafe practices of the machine. Levels of hazards are identified that could HOW TO USE THIS MANUAL result in product or personal injury, or severe injury SAFETY resulting in death. -

Page 5: Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic precaution must always be followed, including the following: READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE. This machine is for commercial use. To reduce the risk of fire, electric shock, or injury: Connect to a properly grounded outlet. -

Page 6: Hazard Intensity Level

HAZARD INTENSITY LEVEL The following symbols are used throughout this guide as indicated in their descriptions: HAZARD INTENSITY LEVEL There are three levels of hazard intensity identified by signal words - WARNING and CAUTION and FOR SAFETY. The level of hazard intensity is determined by the following definitions: WARNING WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death. -

Page 7: Safety Label Location

SAFETY LABEL LOCATION NOTE: These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible, promptly replace them. LABEL, WARNING 86242230 PRV NO. 500009 LABEL CIRCUIT INTERRUPTER 86200570 PRV NO. 170-41 86037520 05/01/07... -

Page 8: Grounding Instructions

GROUNDING INSTRUCTIONS THIS PRODUCT IS FOR COMMERCIAL USE ONLY. ELECTRICAL: In the USA this machine operates on a standard 15 amp 115V, 60 hz, A.C. power circuit. The amp, hertz, and voltage are listed on the data label found on each machine. Using voltages above or below those indicated on the data label will cause serious damage to the motors. -

Page 9: Technical Specifications

TECHNICAL SPECIFICATIONS ITEM MEASURE ELECTRICAL 115 Volt, 60 hz Vacuum Motor Dual 3 stage Solution Pump 100 psi 150 psi Solution Capacity 10 gal (38 L) Recovery Capacity 8 gal (240 kg) Weight- Empty 110 lbs (240 kg) Weight-Full Solution 200 lbs (440 kg) Height 36 inches (91.44 cm) -

Page 10: Controls

CONTROLS CENTURY 400 Pump Switch Vacuum #1 Switch Vacuum #2 Switch 86037520 05/01/07... -

Page 11: Machine Operation

MACHINE OPERATION PRE-RUN INSPECTION EMPTYING AND CLEANING 1. Check all fittings and connectors for proper assembly. Always use defoamer if foaming occurs. Foam 2. Check all hoses for leaks. Repair or replace any will suspend large particles that may damage damaged hoses. -

Page 12: Maintenance

MAINTENANCE DAILY MAINTENANCE Unplug power cord(s) before servicing or making DO NOT attempt to repair hose! Repairing high- any repairs. pressure hoses may result in severe burns and serious injury. 1. Flush the entire system, including floor tool, hand tool, etc., with 1 to 3 gallons of clean, hot water. PERIODIC MAINTENANCE 2. -

Page 13: Vacuum Motor Replacement

MAINTENANCE Only qualified Vacuum Motor Carbon Brushes Replacement (Ametek) maintenance personnel End Cap are to perform the following repairs. WARNING: The green VACUUM MOTOR REPLACEMENT Carbon ground wire must be Brushes 1. Turn off all switches and unplug machine. attached for safe operation. See wiring diagram. -

Page 14: Pump Replacement Kits

MAINTENANCE FLOJET 100 PSI (86251110 – PRV NO. 65219) PUMP REPLACEMENT KITS DIAPHRAM 86235120 PRV NO. 29219 86258860 86247360 PRV NO.84166 PRV NO. 29219 86251090 VALVE ASM MOTOR PRV NO. 65204 PUMP HEAD SHURFLO 100 PSI (86201430 – PRV NO. 250-64A) PUMP REPLACEMENT KITS 86161980 PRV NO. -

Page 15: Troubleshooting

TROUBLESHOOTING PROBLEM CAUSE SOLUTION Dead electrical circuit Check building circuit breaker or fuse box. Loss of Power Faulty power cord Replace Equipment not grounding Follow grounding instructions exactly Receptacle not grounded Contact an electrician to check building’s wiring Electrical shock Have a trained service technician check machine’s Internal wiring problem wiring... -

Page 16: Frame Group (2 Stg)

FRAME GROUP (2 STG) 86037520 05/01/07... - Page 17 SCR, 1/4-20 X 1/2 HHCS SS NP 86200710 040-03 CASTER SWIVEL 4” SWIVEL 86002450 22015 COUPLER, 1/4 QD 86200670 500359 LABEL, NINJA 3 SWITCH NO HEAT 86091030 62900 PLATE, NINJA 3 SWITCH NO HEAT 86256960 72142 SWITCH, SPST 15A EURO ROCKER 86271380 57196...

-

Page 18: Frame Group (3 Stg)

FRAME GROUP (3 STG) 86037520 05/01/07... - Page 19 86199430 040-03 CASTER SWIVEL 4” SWIVEL 86273830 70020 SCR, 1/4-20 X 1/2 HHCS SS NP 86200670 500359 LABEL, NINJA 3 SWITCH NO HEAT 86091030 62900 PLATE, NINJA 3 SWITCH NO HEAT 86256960 72142 SWITCH, SPST 15A EURO ROCKER 86199650 070-08...

-

Page 20: Frame Group (W/ Heat)

FRAME GROUP (W/ HEAT) 86037520 05/01/07... - Page 21 NUT, 1/2 PUSH-ON DOME CAP 86202250 040-06 WHEEL 8” BLK CENTERED HUB 86273810 70018 SCR, 1/4-20 X 1 HHCS SS 86199200 010-04B AXLE SINGLE NINJA 86064960 08061 BASE, NJA 100 PSI 2ST W/H 86005670 57040 NUT, 1/2 NPT CONDUIT 86256200 73200...

-

Page 22: Pump Group (No Heat)

PUMP GROUP 86037520 05/01/07... - Page 23 WASHER, 1/4 ID X 5/8 OD SS 86005810 57245 NUT, 1/4-20 HEX NYLOCK SS OPEN 411-221MO 86201430 250-64A SHURFLO 100 PSI PUMP DEMAND ONLY 411-221MO 86251110 65219 PUMP, 115V 100PSI BYPASS W/SW ONLY 411-22AMO 86161940 41-809155 PUMP, SHURFLO 150PSI ONLY 86037520 05/01/07...

-

Page 24: Pump Group (W/ Heat)

PUMP GROUP (W/ HEAT) 86037520 05/01/07... - Page 25 CHECK VALVE 86200120 151-36C HOSE, 60.0 RED 3/8 1/4 MPT X 1/4 MPT 86200110 151-36B HOSE, 28.0 RED 3/8 1/4 MPT X 1/4 MPT 86033590 41516 HEATER ASM, NINJA COMPLT *INCLUDED 86005590 56014 NIPPLE, 1/4 CLOSE IN ASM *INCLUDED 86197370 31017...

-

Page 26: Recovery And Solution Tank Group

RECOVERY & SOLUTION TANK GROUP 86037520 05/01/07 5-11... - Page 27 LID, NJA DLX LT GRY ALL 86200290 260-33 HOSEBARB, 1.5MPT X 1.5 86199840 090-12A FLOAT CAGE ASSY COMPLETE SLIP 86033240 090-17 NINJA STAND PIPE ASSY 86064760 31082 ELBOW, 1.5FS X 1.5FPT PVC MCHD 86090850 065-42 FLOOD MACHINE BAFFLE 86279610 87190...

-

Page 28: Vacuum Motor Group (2 Stg)

VACUUM MOTOR GROUP (2 STG) 86037520 05/01/07 5-13... - Page 29 VACUUM MOTOR GROUP (2 STG) SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES: FROM 86201510 390-26 SPACER NYLON 1/4ID X 1/2OD 86199910 110-26B GASKET, VAC BRACKET WAS 35168 86090960 360-23A PLATE, VAC 86003760 35166 GASKET, VAC MTR 86201970 065-92 VAC SPACER 2 1/4 II STAGE 86010630 87013 WASHER, 1/4ID X 5/8OD SS...

-

Page 30: Vacuum Motor Group (3 Stg)

VACUUM MOTOR GROUP (3 STG) 86037520 05/01/07 5-15... - Page 31 VACUUM MOTOR GROUP (3 STG) SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES: FROM 86201510 390-26 SPACER NYLON 1/4ID X 1/2OD 86199910 110-26B GASKET, VAC BRACKET WAS 35168 86090960 360-23A PLATE, VAC 86003760 35166 GASKET, VAC MTR 86201950 065-24E VAC SPACER 3-1/8 86020630 87013 WASHER, 1/4ID X 5/8OD SS...

-

Page 32: Wiring Group (2 Stg No Heat)

WIRING GROUP (2 STG) 86037520 05/01/07 5-17... -

Page 33: Wiring Group (3 Stg No Heat)

WIRING GROUP (3 STG) 86037520 05/01/07 5-18... -

Page 34: Wiring Group (2 Stg W/ Heat)

WIRING GROUP (W/ HEAT) 86037520 05/01/07 5-19... -

Page 35: Notes

NOTES 86037520 05/01/07 5-20...

Need help?

Do you have a question about the 411-22AMO and is the answer not in the manual?

Questions and answers