Table of Contents

Advertisement

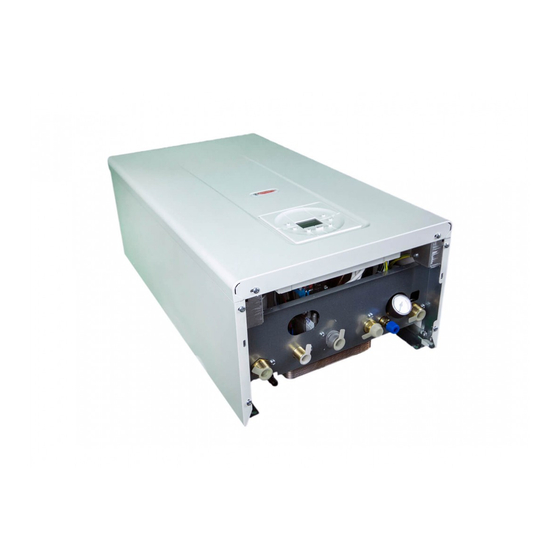

Wall mounted instantaneous combi boiler

CE

0694

RKR 24_28_34 - RAD - ING - MAN.INST - 1104A - DIGITECH 2 - REGNO UNITO - EXTRAHEAT

Technical specification RADIANT BRUCIATORI S.p.A. Montelabbate (PU) ITALY

Instruction Manual

Installation, operating, commissioning and maintenance instructions

premix condensing boiler

for model

RKR 24

RKR 28

RKR 34

- CBD

ENGLISH

Advertisement

Table of Contents

Need help?

Do you have a question about the RKR 24 and is the answer not in the manual?

Questions and answers