Table of Contents

Advertisement

Quick Links

SERVICE MANUAL

MOBILE GENERATORS

Sdg25S-6A7, SDG45S-6A6,

Sdg65S-6A6, SDG100S-6A6,

Sdg125S-6A6, SDG150S-6A6

MMD Equipment Inc.

121 High Hill Road

Swedesboro, NJ 08085

Tel: (800) 433-1382

Fax: (856) 467-5235

www.mmdequipment.com

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for MMD Equipment SDG25S-6A7

- Page 1 SERVICE MANUAL MOBILE GENERATORS SDG25S-6A7, SDG45S-6A6, SDG65S-6A6, SDG100S-6A6, SDG125S-6A6, SDG150S-6A6 MMD Equipment Inc. 121 High Hill Road Swedesboro, NJ 08085 Tel: (800) 433-1382 Fax: (856) 467-5235 www.mmdequipment.com...

-

Page 2: Table Of Contents

Table of Contents Specifications ............................1-1 Specifications............................ 1-1 Outline Drawing ..........................1-7 Internal Components......................... 1-10 Overhauling ............................. 2-1 Cautions for Overhauling ........................2-1 Tightening Torque..........................2-3 Disassembly/Reassembly of Generator Main Unit and Connection of Generator Main Unit and Engine............. 2-5 Engine Maintenance Standards...................... -

Page 3: Specifications

1. Specifications Specifications Model SDG25S-6A7 Brushless Exciting system Star with Neutral ZigZag Armature connection Phase number Three Single Power factor Frequency Rated output 14.4 Rated output 14.4 Voltage 240/120 Current Model ISUZU AA-4LE1 4-cycle, water-cooled, swirl chamber type Type Number of cylinders Total displacement cu. - Page 4 1. Specifications Model SDG45S-6A6 Brushless Exciting system Star with Neutral ZigZag Armature connection Phase number Three Single Power factor Frequency Rated output Rated output Voltage 240/120 Current Model NISSAN DIESEL 2A-BD30T 4-cycle, water-cooled, direct injection type with turbo Type charged Number of cylinders Total displacement cu.

- Page 5 1. Specifications Model SDG65S-6A6 Brushless Exciting system Star with Neutral ZigZag Armature connection Phase number Three Single Power factor Frequency Rated output 36.5 Rated output 36.5 Voltage 240/120 Current Model ISUZU EE-4BG1T 4-cycle, water-cooled, direct injection type with turbo Type charged Number of cylinders Total displacement...

- Page 6 1. Specifications Model SDG100S-6A6 Brushless Exciting system Star with Neutral ZigZag Armature connection Phase number Three Single Power factor Frequency Rated output Rated output Voltage 240/120 Current Model ISUZU EE-6BG1T 4-cycle, water-cooled, direct injection, turbo charged, Type intercooled Number of cylinders Total displacement cu.

- Page 7 1. Specifications Model SDG125S-6A6 Brushless Exciting system Star with Neutral ZigZag Armature connection Phase number Three Single Power factor Frequency Rated output Rated output Voltage 240/120 Current Model VOLVO TAD720GE 4-cycle, water-cooled, direct injection, turbo charged, Type intercooled Number of cylinders Total displacement cu.

- Page 8 1. Specifications Model SDG150S-6A6 Brushless Exciting system Star with Neutral ZigZag Armature connection Phase number Three Single Power factor Frequency Rated output Rated output Voltage 240/120 Current Model VOLVO TAD720GE 4-cycle, water-cooled, direct injection, turbo charged, Type intercooled Number of cylinders Total displacement cu.

-

Page 9: Outline Drawing

1. Specifications Outline Drawing SDG25S-6A7 Unit : in. (mm) SG06052 SDG45S-6A6 SG06053... - Page 10 1. Specifications SDG65S-6A6 Unit : in. (mm) SG06054 SDG100S-6A6 SG06055...

- Page 11 1. Specifications SDG125S-6A6 Unit : in. (mm) SG06056 SDG150S-6A6 SG06057...

-

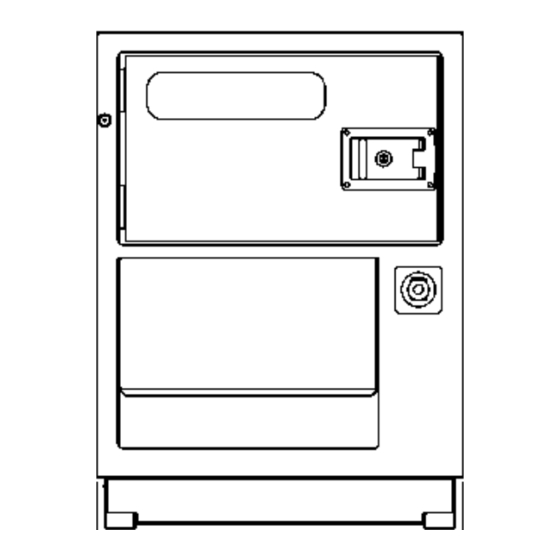

Page 12: Internal Components

1. Specifications Internal Components SDG25S-6A7 A040574 1. Control panel 8. Battery 2. Engine 9. Engine oil level gauge 3. Air filter 10. Sedimenter 4. Engine oil filler port 11. Fuel filter 5. Reserve tank 12. Generator main unit 6. Radiator 13. - Page 13 1. Specifications SDG45S-6A6 A040575 1. Control panel 9. Filter for electromagnetic pump 2. Engine 10. Fuel air-bleeding electromagnetic pump 3. Air filter 11. Battery 4. Reserve tank 12. Fuel filter 5. Engine oil filler port 13. Engine oil level gauge 6.

- Page 14 1. Specifications SDG65S-6A6 12 11 A040576 1. Control panel 9. Fuel tank 2. Air filter 10. Engine oil filler port 3. Engine oil level gauge 11. Fuel air-bleeding electromagnetic pump 4. Reserve tank 12. Engine oil filter 5. Engine 13. Battery • ¦ 6.

- Page 15 1. Specifications SDG100S-6A6 A050016 1. Control panel 9. Intercooler 2. Air filter 10. Fuel filter 3. Engine 11. Sedimenter 4. Engine oil level gauge • ¦ 12. Engine oil filter 5. Engine oil filler port • ¦ 13. Battery • ¦ 6.

- Page 16 1. Specifications SDG125S-6A6 13 12 A050157-1 1. Control panel 10. Intercooler 2. Air filter 11. Fuel filter 3. Engine 12. Engine oil filter 4. Reserve tank 13. Fuel pump 5. Engine oil level gauge 14. Fuel pre- filter 6. Engine oil filler port 15.

- Page 17 1. Specifications SDG150S-6A6 13 12 A050585 1. Control panel 10. Intercooler 2. Air filter 11. Fuel filter 3. Engine 12. Engine oil filter 4. Reserve tank 13. Fuel pump 5. Engine oil level gauge 14. Fuel pre- filter 6. Engine oil filler port 15.

-

Page 18: Overhauling

2. Overhauling 2.1 Cautions for Overhauling 2.1.1 Precautions before starting work (1) Work to be performed It is very important to always plan in advance what facilities, tools, instruments, materials, oil, etc. you will need to use; the exact locations and methods of performing inspection, adjustment, or disassembly;... - Page 19 2. Overhauling 2.1.2 Disassembly and assembly (1) Wash dirt, dust and grime off vinyl tube and fuel hose before removing it, and take necessary steps to cover or tape the openings of vinyl tubes or fuel hoses to prevent any dirt from entering them.

-

Page 20: Tightening Torque

2. Overhauling 2.2 Tightening Torque 2.2.1 General tightening torque of bolts and nuts Fasten all the bolts and nuts with the specified tightening torque when assembling. Type Low or medium carbon steel bolt High strength steel bolt (SCM435, etc.) (SS400B, etc.) Strength, 8.8•... - Page 21 2. Overhauling 2.2.2 Tightening torque for terminal plate When connecting the output terminals of the generator, it is important to tighten the screws, according to the designated torque. Since the terminal is so small, it could be burned or damaged without the proper torque.

-

Page 22: Disassembly/Reassembly Of Generator Main Unit And Connection Of Generator Main Unit And Engine

2. Overhauling 2.3 Disassembly/Reassembly of Generator Main Unit and Connection of Generator Main Unit and Engine 2.3.1 Disassembly of generator main unit The generator main unit is unilaterally mounted and the clearance is small, so it must be handled with extreme care to avoid the possibility of damage to the rotor or stator. Use hoisting equipment of sufficient capacity when it is necessary to lift up the engine and the generator main unit. - Page 23 2. Overhauling (1) Procedures of disassembly 1. Remove cables from battery (-) terminal. 2. Remove brackets (or fittings for muffler, air filter and etc.) equipped on the bonnet. 3. Remove top cover and dismantle such parts on the bonnet so that generator main unit can be pulled out.

- Page 24 2. Overhauling 2.3.2 Measuring center deviation and surface deviation Measure them with a dial gauge pressed to the flywheel. (1) Measuring the center deviation, turn the rotor with the dial gauge pressed to the circumference of the coupling flange. If the biggest value measured on the same circumference exceeds 0.008in. (0.2mm), it is necessary to repair it.

- Page 25 The coupling connecting bolts shall be high tensile bolts 7T or more. (Use 2 guide bolts for this job.) Size of guide bolt SG05047 (mm) SDG25S-6A7 SDG45S-6A6 SDG65S-6A6 SDG100S-6A6 SDG125S-6A6 SDG150S-6A6 ‚ c ƒ Ó • © • © • © • ©...

- Page 26 2. Overhauling 2.3.4 Assembly of flywheel housing and generator main unit frame (stator) Handle the stator with care after fastening the engine flywheel and generator coupling, to avoid damage to either the rotor or stator. Tighten the connections to the specified torque. For connection of flywheel housing and generator main unit frame (stator), coat anti-corrosion agent “...

- Page 27 2. Overhauling 2.3.5 Mounting of generator main unit and engine on frame Perform centering carefully, to avoid deviation in the horizontal leveling caused by distortion of the frame or inaccurate mounting of the generator main unit and engine. Running the machine without accurate centering may cause abnormal vibrations. ‡...

- Page 28 2. Overhauling (1) Centering method 1. Mount the brackets on the engine secured to the generator main unit. (Use only genuine fastening bolts.) 2. Place four assembly level plates • ¦ on the points for mounting the engine and the generator main unit onto the frame.

- Page 29 2. Overhauling (2) Check the gap between the cooling fan and fan shroud Maintain an adequate gap in both the vertical and horizontal directions. If the fan is mounted incorrectly so that it leans toward one side wall of the shroud, leading to a smaller gap in one direction, the fan may produce abnormal noise due to rubbing against the shroud during starting or stopping and may also overheat.

- Page 30 2. Overhauling 2.3.6 Changing the bearings in the generator main unit Use guide bolts to avoid the danger of dropping the bearing shield and to prevent the rotor and stator from rubbing against each other. (Use the guide bolts used to mount the generator main unit.) Do not hit the bearing outer race when installing or the bearing may be damaged.

- Page 31 2. Overhauling 2.3.7 Changing the rotary rectifier Care must be taken not to damage the rotary rectifier when mounting it on the conductive plate. When a soldering iron must be used on the rotary rectifier, make the contact time as short as possible.

-

Page 32: Engine Maintenance Standards

2. Overhauling 2.4 Engine Maintenance Standards SDG25S-6A7 Engine model ISUZU AA-4LE1 DA-05 Tighten M12 bolt according to the tightening torque of 61.5• ` 68.7lbw¥ ft [83.4• ` 93.2N¥ m(850• ` 950kgf¥ cm)] lbw¥ ft and further turn the bolt by 60• ` 90•... - Page 33 2. Overhauling SDG65S-6A6 Engine model ISUZU EE-4BG1TRD-02 First time 50.6 [69 (700)] lbw¥ ft Tightening torque of head bolts Second time 65.1 [88 (900)] [N¥ m(kgf¥ cm)] Third time 90°• ` 120° (Angle tightening) Air intake in. (mm) 0.016 (0.4) [normal temperature] Valve clearance Discharge in.

- Page 34 2. Overhauling SDG125S/150S-6A6 Engine model VOLVO TAD-720GE First time 37 [ 50 ( 510)] lbw¥ ft Tightening torque of head bolts Second time 96 [130 (1326)] [N¥ m(kgf¥ cm)] Third time 90° (Angle tightening) Air intake in. (mm) 0.014 (0.35) Valve clearance Discharge in.

-

Page 35: Electrical Parts

3. Electrical Parts 3.1 Installation Positions of Electrical Appliances SDG25S-6A7 VIEW-A VIEW-B SG06008 1. Thermal relay 8. Safety relay 2. Automatic voltage regulator (AVR) 9. Solenoid relay 3. Starter relay 10. Voltage selector switch 4. Charge relay 11. Three-phase circuit breaker 5. - Page 36 3. Electrical Parts SDG45S-6A6 SG06009 1. Current transformer 7. Safety relay 2. Thermal relay 8. Solenoid relay 3. Automatic operation unit 9. Automatic voltage regulator (AVR) 4. Time relay 10. Terminal plate 5. Charge relay 11. Voltage selector switch 6. Heater relay 12.

- Page 37 3. Electrical Parts SDG65S-6A6 SG06010 1. Current transformer 7. Time relay 2. Thermal relay 8. Motor stopper relay 3. Automatic operation unit 9. Automatic voltage regulator (AVR) 4. Magnetic switch 10. Terminal plate 5. Glow relay 11. Voltage selector switch 6.

- Page 38 3. Electrical Parts SDG100S-6A6 SG06011 1. Current transformer 7. Motor stopper relay 2. Thermal relay 8. Glow relay 3. Automatic voltage regulator (AVR) 9. Magnetic switch 4. Automatic operation unit 10. Terminal plate 5. Safety relay 11. Voltage selector switch 6.

- Page 39 3. Electrical Parts SDG125S/150S-6A6 SG06012 1. Automatic voltage regulator (AVR) 7. Terminal plate 2. Automatic operation unit 8. Voltage selector switch • ¦ 3. Magnetic switch 9. Three-phase circuit breaker 4. Glow relay 10. Current transformer 5. Starter relay 11. Thermal relay 6.

-

Page 40: Electrical Parts Of Generator

3. Electrical Parts 3.2 Electrical Parts of Generator 3.2.1 Rotary rectifier 1.Silicon rectifier 2.Varistor 3.Conductive plate 4.Insulating plate 5.Lead wire (alternator) 6.Lead wire (Exciter) AS-016 cathode anode • œ • œ How to check whether silicon rectifier (diode element) functions correctly or not Check the silicon rectifier (diode element) according to the resistance range of circuit meter. - Page 41 3. Electrical Parts 3.2.2 AS (Ammeter change-over switch) SG06014 Diagram: AS for SDG25S-6A7,SDG100S/125S-6A6 SG06015 Interior cable connection 3.2.3 Voltage selector switch SG06016...

- Page 43 3. Electrical Parts 3.2.4 AVR (Automatic voltage regulator) SDG25S-6A7,SDG45S• | 150S-6A6(AVR model : DST-100-2FA/2FA4) ( 4) ( 2) ( 3) 9 Pin(female) 6 Pin(female) 1:Brown 4:Yellow 7:Purple 1:Brown 4:Yellow 2:Red 5:Green 8:Gray 2:Red 5:Green 3:Orange 6: • ^ • ^ 3:Orange 6: •...

- Page 44 3. Electrical Parts AVR is adjusted and set prior to delivery from factory. Accordingly, it is not necessary to adjust it unless the machine equipped with a new AVR functions abnormally. If upon test operation, there is any trouble such as voltage hunting, adjust it according to the following procedures. Adjustment of AVR 1.Start engine, and adjust the frequency to 62.5Hz at no load operation.

- Page 45 3. Electrical Parts Adjusting V/Hz characteristic If at the start stage of engine, voltage adjustment and stability adjustment have been already done, it is not necessary to adjust the V/Hz characteristic. But if at no load operation any trouble of voltage adjustment function occurs, or voltage disappears, adjust V/Hz characteristics, according the following procedures.

- Page 46 3.2.5 Thermal relay SETTING DIAL AUTO-RESET BUTTON TERMINALS FOR TEST BUTTON INSTRUMENT CIRCUIT TERMINALS FOR MAIN CIRCUIT Thermal relay set value unit SDG25S-6A7 SDG45S-6A6 SDG65S-6A6 Rated voltage Rated current Detected current at rated operation CT ratio 5/100 5/75 5/100 Wound rolls (Rolls...

- Page 47 3. Electrical Parts 3.3 Electric Parts of Engine 3.3.1 Alternator SDG25S-6A7 AS-006 AS-017 Voltage • | Current 12‚ u • | 20‚ ` Regulator adjusted voltage 13.8‚ u • } 0.5‚ u 3-13...

- Page 48 3. Electrical Parts SDG45S-6A6 Interior cable connection SG06044E (1) List of functions Line Pin No. Connection Explanation of function color Charge relay 2nd terminal Power for charging voltage Detect output voltage from alternator and adjust Fuse 10A the current flowing to rotor coil Tachometer with hour meter Power for hour meter functioning CN6-1 terminal...

- Page 49 3. Electrical Parts SDG65S-6A6 AS-011 SDG-005 Voltage • | Current 24‚ u • | 20‚ ` Regulator adjusted voltage 28.5‚ u • } 0.5‚ u SDG100S-6A6 SDG-004 AS-018 Voltage • | Current 24‚ u • | 25‚ ` Regulator adjusted voltage 28.5‚...

- Page 50 3. Electrical Parts 3.3.2 Controller SG06045E SDG25S-6A7,45S• ` 100S-6A6(Emergency controller) List of functions Line Connection Function color During normal operation the interior contact is ON between No.1 terminal and No.8 terminal. • ¦ 1 • ¦ 2 When emergency stop device functions, the interior Solenoid (motor stopper) relay contact will be OFF between No.1 terminal and...

- Page 51 3. Electrical Parts Line Connection Function color During normal operation, engine water temperature switch is kept ON. The contact between No.1 and No.8 terminals becomes OFF at the condition OFF of engine water temperature switch, it cuts electric Engine water temperature supply to solenoid (motor stopper) relay so that switch for emergency stop...

- Page 52 3. Electrical Parts SG06063 SDG125S/150S-6A6(Control unit EDC 4) List of functions Line Connection Function color Glow relay No.2 terminal When pre-heating is done, the contact between M-3 terminal and F-1 terminal is ON, and electrically Emergency indicator CN16-5 conducted. terminal Fuel temperature sensor No.1 Detect fuel temperature between M-5 and M-8 terminal...

- Page 53 3. Electrical Parts Line Connection Function color ‚ f rounding When engine water temperature rises, the interior contact between F-3 and F-1 terminals becomes ON and electrically conducted. Then warning lamp engine water Emergency indicator CN16-7 temperature rise goes on. terminal •...

- Page 54 3. Electrical Parts Line Connection Function color Speed control knob (Engine F-23 Grounding speed potentiometer) (-) terminal Speed control knob (Engine Engine speed can be adjusted minutely by F-24 speed potentiometer) signal changing resistance between F-24 and F-23 input terminal terminals.

- Page 55 3. Electrical Parts 3.3.3 Emergency indicator SG06064 SDG125S/150S-6A6 List of functions Line Pin No. Connection Function color Put in the engine revolution pulse converted for tachometer by PLC unit of auto start unit. CN15-1 Auto start unit CN7-6 terminal • œ Revolution ratio (pulse type): 2 revolutions per 1 pulse Output the engine revolution pulse to tachometer No.4 terminal.

- Page 56 3. Electrical Parts Line Pin No. Connection Function color When engine water temperature rises, it is CN16-7 G/W Controller F-3 terminal electrically conducted to make warning lamp glow. Auto start unit CN7-9 terminal CN16-8 Grounding Air filter differential pressure indicator Power supply (DC24V...

- Page 57 3. Electrical Parts 3.3.4 Auto start unit (Automatic operation unit) CONNECTOR SG06026 SDG25S-6A7,45S• ` 100S-6A6 List of functions Line Connection Function color Power for auto start unit. • ¦ 1 With No.1 terminal of auto start unit electrically Manual-Auto selector switch...

- Page 58 3. Electrical Parts Line Connection Function color Remote start/stop switch connection terminal. When the remote start/stop switch is switched ON with No.1 terminal of auto start unit conducted electrically, XO relay begins to function. Consequently, the relay is put in order and power is supplied to PLC unit through •...

- Page 59 3. Electrical Parts CONNECTOR SG06027 SDG125S/150S-6A6- List of functions Line Pin No. Connection Function color Power for XO relay of remote start /stop switch. With auto start unit No.1 terminal electrically CN6-1 Manual-Auto selector switch conducted, when remote start/stop switch (exterior output terminal plate between A1-A2 terminals) is switched ON, XO relay begins to function.

- Page 60 3. Electrical Parts Line Pin No. Connection Function color CN6-6 15A fuse Power supply for auto start unit. • œ Manual starting operation Power supply for auto start unit. During manual operation, power is supplied to Starter switch ACC terminal hour meter functioning signal output, engine revolution speed...

- Page 61 3. Electrical Parts List of functions Line Pin No. Connection Function color Power supply (DC24V) for output of engine Emergency indicator CN16-9 CN7-1 revolution pulse outputted between emergency terminal indicator CN16-1 and CN16-8 terminals. Air filter differential pressure Detection of air filter differential pressure indicator CN7-2 indicator clogging.

- Page 62 3. Electrical Parts 3.3.5 Glow timer SDG25S-6A7,SDG65S-6A6(QOS‡ V timer) (1) List of functions Line Connection Function color Grounding For exciting glow relay For pre-heating function, it forms excitation circuit with connection of No.1 terminal (grounding). When starter switch is switched ON, pre-heat lamp Glow relay goes on and pre-heating starts.

- Page 63 3. Electrical Parts (2) Characteristics of water temperature and glowing time (Key OFF• ¨ ON) SDG25S-6A7 Water temperature Lamp glows¥ Glowing time t1 (seconds) [°F (• Ž )] 5 (-15) 68 (20) 122 (50) SDG65S-6A6 Water temperature Lamp glows¥ Glowing time t1 (seconds) [°F (•...

- Page 64 3. Electrical Parts SDG45S-6A6 (QHS controller) SG06065 (1) List of functions Line Connection Function color 10A fuse Power supply Detection of generation signal In case that no start signal is sent to No.3 terminal Alternator L terminal after No.8 terminal detects start signal, it cuts the output of No.4 terminal, and it will not perform after heating.

- Page 65 3. Electrical Parts (2) Water temperature and glow time characteristics (Key OFF• ¨ ON) Water temperature Lamp glows and glowing time t1 Time of afterheating t2 [°F (• Ž )] (seconds) (seconds) 5 (-15) 32 ( 0 ) 50 (10) (3) Chart of function (st) •...

- Page 66 3. Electrical Parts SDG100S-6A6(QOS‡ U ) SG06046E (1) List of functions Line Connection Function color 10A fuse Power supply Water temperature switch Detection of water temperature Safety relay C terminal Detection of start signal Power supply for excitation of glow relay Glow relay When start signal is inputted to No.3 terminal, it preheats irrespective of water temperature.

- Page 67 3. Electrical Parts (2) Water temperature and glow time characteristics (Key OFF• ¨ ON) Lamp lighting time t1 Pre-glow time t2 After glow time t3 Water temperature (seconds) (seconds) (seconds) Within 50• } 37°F (10• } 3• Ž ) More than 50•...

- Page 68 3. Electrical Parts 3.3.6 Safety relay SDG45S-6A6 SG06023E SG06024 List of functions Line Connection Function color Starter motor B terminal Power supply for starting of starter motor Battery (+) When voltage is applied to No.1 terminal, the Starter motor S terminal contact between B-S terminals turns ON, it applies voltage to starter terminal.

- Page 69 3. Electrical Parts SDG65S/100S-6A6 SG06025E The R in the parenthesis shows connection point of SDG100S. Function 1) Starting operation while stopping • When voltage is applied to S terminal from starter switch or auto start unit No.8 terminal, the input from B terminal will be outputted from C terminal , and starter begins to rotate and then engine starts.

- Page 70 3. Electrical Parts 3.3.7 Tachosensor SDG65S-6A6 (1) Checking whether voltage generated between terminals is proper or not With the clearance of 0.0295in. (0.75mm) between feed During pump cam and the extreme end operation at of tachosensor, it is proper if the the rated voltage generated...

- Page 71 3. Electrical Parts 3.3.8 Tachometer (with hour meter) SDG25S-6A7,SDG45S• ` 150S-6A6 SG06028 The figure shows the tachometer at of SDG25S/45S/125S/150S (1) Specifications SDG25S/45S/125S/150S SDG65S/100S Operation voltage 10• ` 16V 20• ` 30V Operation temperature -4• ` 140°F (-20• ` 60• Ž )

- Page 72 3. Electrical Parts 3.3.9 Stop solenoid SDG25S-6A7 SDG-006 (37.2ƒ ¶ ) (0.537ƒ ¶ ) SG06029E SDG45S-6A6 SG06030E (1) Specifications Suction coil Holding coil 0.75A SG06031E (2) Function Turning starter switch ON, voltage is applied to plus (+) terminal, and current flows to parallel circuit of suction coil and holding coil to pull the plunger for stop solenoid at once.

- Page 73 3. Electrical Parts 3.3.10 Motor stopper SDG65S/100S-6A6 SG06032E (1) List of functions Pin No. Line color Connection Function L/B (L/W) Motor stopper relay No.5 terminal (NO) G/L (L) Motor stopper relay No.3 terminal (COM) Grounding Y/R (L/Y) Motor stopper relay No.6 terminal (NC) W/G (L/R) 10A(20A) fuse For power supply The line colors in parenthesis show those of SDG100S.

- Page 74 3. Electrical Parts 2. Engine starts SG06034E 1) When closing ACC contact (“operation” position) for starting engine by handling starter switch, the following circuit will be formed ; controller interior contact → motor stopper relay No.1 terminal → excitation coil → motor stopper relay No.2 terminal → grounding and then the excitation coil of motor stopper relay will be excited.

- Page 75 3. Electrical Parts 3. Rotation of contact plate SG06035E 1) When motor begins to rotate, the worm fitted to the motor shaft rotates and at the same time worm wheel rotates. 2) The worm wheel and contact plate are interconnected and so it continues to rotate as shown in Fig 4.

- Page 76 3. Electrical Parts 5. Engine stops (normal stop) SG06037E 1) To stop engine, handle starter switch to open BR contact (“Stop” position) so that excitation circuit of motor stopper relay may be released to move the contact point as shown in Fig e. 2) As battery voltage is applied to motor stopper relay No.6 terminal, the following circuit is formed: motor stopper relay No.3 terminal →...

- Page 77 4.6 (17.5) 32.5 9.9 (37.5) • ¦ approx. 17.0 (64.5) • ¦ marked : The figures of the remaining fuel in the table are for model SDG25S-6A7. (2) List of functions Pin No. Line color Connection Function Grounding Panel light switch...

- Page 78 3. Electrical Parts 3.3.12 Sending unit SDG25S-6A7 (equipped with thermistor sensor) SG06066 (1) Position of meter pointer for resistance value Pointer position Resistance value (ƒ ¶ ) Remaining fuel [gal. (L)] 4.6 (17.5) 32.5 9.9 (37.5) 17.0(64.5) (2) Specification of thermistor (for warning lamp indicating the shortage of remaining fuel)

- Page 79 3. Electrical Parts SDG45S• ` 150S-6A6 Meter indicates F (Full) from this position Meter indicates E (Empty) from this position Diagram: Sending unit for SDG100S to SDG150S SG06039 Remaining fuel [gal. (L)] Pointer position Resistance value (ƒ ¶ ) SDG45S SDG65S SDG100S SDG125S...

- Page 80 3. Electrical Parts 3.3.13 Electro-magnetic pump for bleeding air from fuel line 1. Type without filter SDG25S-6A7,SDG45S-6A6 2. Type with built-in filter SDG65S/100S-6A6 3. Specifications Model SDG25S-6A7 SDG45S-6A6 SDG65S/100S-6A6 Rated voltage Operating current 1.5A (Max) 1.5A (Max) 1.5A (Max) More than...

- Page 81 3. Electrical Parts 3.3.14 Coolant water temperature gauge SDG25S-6A7,SDG45S• ` 150S-6A6 SG06040 (1) List of functions Pin No. Line color Connection Function Grounding Panel light switch Power source for lighting W/B (Y) Water temperature sensor Detector for water temp 10A fuse Power source for water temperature gauge ( ) marked indicates the line color for SDG45S.

- Page 82 3. Electrical Parts 3.3.15 Thermo-sensor for water temperature gauge SDG25S-6A7,SDG125S/150S-6A6 Characteristic of temperature resistance SDG25S-6A7,SDG125S/150S-6A6 SDG45S/65S/100S-6A6 Temperature Resistance Permissible Temperature Resistance Permissible [°F (• Ž )] value (ƒ ¶ ) value [°F (• Ž )] value (ƒ ¶ ) value 122 (50) (153.9)

- Page 83 3. Electrical Parts 3.3.16 Oil pressure gauge SDG25S-6A7,SDG45S• ` 150S-6A6 SG06041E (1) Indicated pressure and Standard current value Indicated pressure [psi (kPa)] 56.8 (392) 113.8 (785) Resistance value (ƒ ¶ ) 12.3 (2) List of functions Pin No. Line color...

- Page 84 3. Electrical Parts 3.3.17 Oil pressure sensor for oil pressure gauge SDG25S-6A7,SDG45S• ` 150S-6A6 SG06042 Standard pressure and Standard resistance value STD pressure [psi (kPa)] 56.8 (392) 113.7 (784) resistance value (ƒ ¶ ) 3.3.18 Others (1) Engine oil pressure switch (for emergency stop)

-

Page 85: Generator Wiring Diagram

3. Electrical Parts Generator Wiring Diagram Molded case circuit breaker SDG25S -6A7 (three-phase) Terminal plate Molded case circuit breaker MCB1• | (single-phase) Shunt coil Ammeter Voltmeter Frequency meter Illumination lamp Current transformer Thermal relay Automatic voltage regulator Hand trimmer (voltage regulator) Ammeter change-over switch Voltage selector sw. - Page 86 3. Electrical Parts Molded case circuit breaker SDG45S/65S-6A6 (three-phase) Terminal plate Molded case circuit breaker MCB1• | (single-phase) Shunt coil Ammeter Voltmeter Frequency meter Illumination lamp Current transformer Thermal relay Automatic voltage regulator Hand trimmer (voltage regulator) Ammeter change-over switch Voltage selector sw.

- Page 87 3. Electrical Parts Molded case circuit breaker SDG100S-6A6 (three-phase) Terminal plate Molded case circuit breaker MCB1• | (single-phase) Shunt coil Ammeter Voltmeter Frequency meter Illumination lamp Current transformer Thermal relay Automatic voltage regulator Hand trimmer (voltage regulator) Ammeter change-over switch To Battery To Monitor lamp A.C.Generator...

- Page 88 3. Electrical Parts Molded case circuit breaker SDG125S-6A6 (three-phase) Terminal plate Molded case circuit breaker MCB1• | (single-phase) Shunt coil Ammeter Voltmeter Frequency meter Illumination lamp Current transformer Thermal relay Automatic voltage regulator Hand trimmer (voltage regulator) Ammeter change-over switch To Battery To Monitor lamp A.C.Generator...

- Page 89 3. Electrical Parts Molded case circuit breaker SDG150S-6A6 (three-phase) Molded case circuit breaker MCB1• | Terminal plate (single-phase) Shunt coil Ammeter Voltmeter Frequency meter Illumination lamp Current transformer Thermal relay Automatic voltage regulator Hand trimmer (voltage regulator) Ammeter change-over switch To Battery To Monitor lamp A.C.Generator...

-

Page 90: Engine Wiring Diagram

3. Electrical Parts Engine Wiring Diagram SDG25S-6A7 An Example Black White Yellow Brown Blue Orange Wire of Red/White Line Green Pink Wire size (mm Gray SG06047 3-56... - Page 91 3. Electrical Parts SDG45S-6A6 An Example Black White Yellow Brown Blue Orange Wire of Red/White Line Green Pink Wire size (mm Gray SG06048 3-57...

- Page 92 3. Electrical Parts SDG65S-6A6 An Example Black White Yellow Brown Blue Orange Wire of Red/White Line Green Pink Wire size (mm Gray SG06049 3-58...

- Page 93 3. Electrical Parts SDG100S-6A6 An Example Black White Yellow Brown Blue Orange Wire of Red/White Line Green Pink Wire size (mm Gray SG06050 3-59...

- Page 94 3. Electrical Parts SDG125S/150S-6A6 An Example Black White Yellow Brown Blue Orange Wire of Red/White Line Green Pink Wire size (mm Gray SG06051 3-60...

-

Page 95: Troubleshooting

4. Troubleshooting 4.1 Repairing Procedures When performing failure diagnosis, pay special attention to the followings, observing general cautions. 4.1.1 Safety caution (1) Removing such cap and/or plug for receiver tank, fuel tanks and pipes where pressure is loaded, stop the machine and relieve all the interior pressure. Install measuring instruments connected firmly. - Page 96 4. Troubleshooting 4.1.3 How to use the failure diagnosis Standard H igh Possible Impossible Abnormal Normal 1.In the troubleshooting column something abnormal is mentioned in lined parenthesis. 2.In the troubleshooting column the cause of the said trouble is mentioned in dotted parenthesis. 3.In the troubleshooting column the countermeasures or treatment are mentioned in the double lined parenthesis.

-

Page 97: Generator Troubleshooting

4. Troubleshooting 4.2 Generator Troubleshooting 4.2.1 No voltage is generated or voltage too low Raise the speed to the Check the frequency meter No speed Refer to "Engine Lower specified value, and confirm that engine increases speed manual". watching the speed during no-load frequency meter. - Page 98 4. Troubleshooting 4.2.2 Voltage is very high or it cannot be adjusted Adjust the speed to Speed should be about 1,875 the specified speed for 62.5 Hz during NO (Higher) with the speed no-load operation. adjusting bolt. Check resistance in AVR Defective resistor resistor hand trimmer? Is AC voltage at AVR input...

- Page 99 4. Troubleshooting 4.2.4 Load cannot be operated Generated voltage and Adjust. frequency are normal? If it cannot be adjusted at all, please refer to troubleshooting "4.2.1 No voltage is generated or voltage too low". Circuit breaker (MCB) is Turn MCB on. "ON"? Immediately the circuit breaks...

-

Page 100: Emergency Switch Functions

4. Troubleshooting 4.3 Emergency Switch Functions 4.3.1 Engine oil pressure drop is shown in monitor and it stops Check engine oil Shortag Shortage of oil. Replenish or replace. quantity. Proper Faulty Check oil filter. Filter clogging. Replace it. Normal Faulty Check engine oil Defective oil pressure Replace it. -

Page 101: Engine Troubleshooting

4. Troubleshooting 4.4 Engine Troubleshooting 4.4.1 Anything abnormal is not shown, but it sometimes stops without its cause shown (Excluding the cases of faulty contact of starter switch and fuse broken) Check cable connection Disconnected Faulty cable to emergency stop Repair. - Page 102 4. Troubleshooting 4.4.3 It will not speed up to rated speed Filter clogging Check air filter. Faulty filter. Clean or replace it. Normal Filter clogging Check fuel filter. Fuel filter faulty. Replace it. Normal Malfunction of fuel feed Check how fuel Replace feed pump.

- Page 103 4. Troubleshooting 4.5 How to Check • m A• n Checking for Disconnection of Voltage Adjusting Resistor Hand Trimmer Turn the knob right and left, and check if the resistance changes. It is normal if the resistance value is within the following ranges.

- Page 104 4. Troubleshooting (2) Generator field winding wire Disconnect the wires leading to the rotary rectifier, then measure the resistance between the wires. 6-15-2 (3) Exciter armature winding wires Disconnect the wires leading to the rotary rectifier, and measure the resistance between the wires.

- Page 105 4. Troubleshooting • m C• n Measurement of Insulation Resistance of Generator Winding Wires Measurement is performed with a 500V megger. The situation is considered to be satisfactory if the measurement produces a result of 1M or more, while a result of less than that value indicates failure.

- Page 106 4. Troubleshooting • œ Disconnect wires leading from generator to the control panel terminals and short-circuit them, then measure insulation resistance between the wires and the generator body. 6-18-1 (2) Generator field winding wire Disconnect the wires leading to the rotary rectifier, then measure the insulation resistance between the disconnected wires and the shaft.

- Page 107 4. Troubleshooting • m D• n Checking Rotary Rectifier (Diode) Remove the silicon rectifiers (diode) of rotary rectifier, and then measure them with a tester. Normal part Defective part SG06013 Note: Rotary rectifier has 3 pieces of silicon rectifiers of forward polarity at K side and 3 pieces of silicon rectifier of reverse polarity at J side.

-

Page 108: References

(J and K wires). It is dangerous that the wire may be overheating, if the wire is too small in thickness. Generated voltage from forced excitation (at 480V) Voltage generated (V) [at the temperature of 104°F(40• Ž Battery 12V Battery 24V SDG25S-6A7 SDG45S-6A6 SDG65S-6A6 SDG100S-6A6 SDG125S-6A6 SDG150S-6A6 * The generating voltage is only for reference because it will change due to the ambient temperature.

Need help?

Do you have a question about the SDG25S-6A7 and is the answer not in the manual?

Questions and answers

Where is the fuse box location