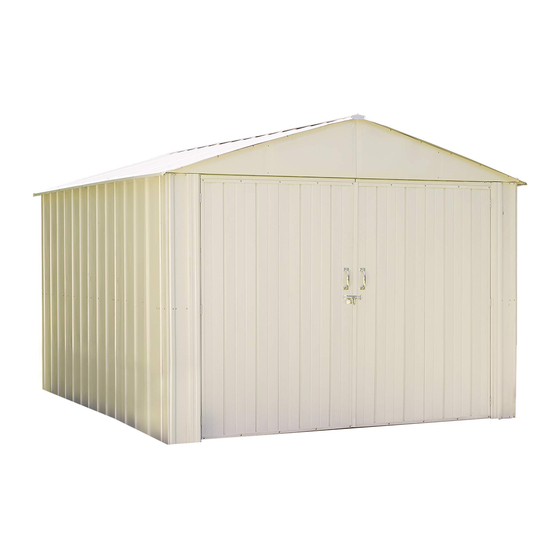

Arrow Storage Products Commander series Owner's Manual & Assembly Manual

Hide thumbs

Also See for Commander series:

- Owner's manual & assembly manual (48 pages) ,

- Owner's manual & assembly manual (48 pages)

Advertisement

Quick Links

717740813

Owner's Manual

& Assembly Guide

Gloves must be worn

at all times to reduce

risk of injury!

* See Inside for Detailed Safety Information.

Customer Service:

1-800-851-1085

assist@arrowsheds.com

BASE BUILDING DIMENSIONS

†

Approx.

Storage

Size

10' x 10'

101 Sq. Ft. 697 Cu. Ft.

2

3,0 m x 3,1 m

9,4 m

Each Module adds an additional 57 1/2" (146,1 cm) in length, 47.2 Sq. Ft. (4,4

additional storage area, and 324 Cu. Ft. (9,2

COMMANDER

MOUNTAINEER

or

†

Size rounded off to the nearest foot

Exterior Dimensions

(Roof Edge to Roof Edge)

Area

Width

Depth

123 1/4"

128 3/4"

19,7 m 3

313,1 cm

327,0 cm

m 3

) additional storage volume.

10x10

Base Size

Additional

per Module

Interior Dimensions

(Wall to Wall)

Height

Width

Depth

92 1/2"

118 1/4"

123 1/2"

235,0 cm

300,4 cm

313,7 cm

2

)

m

SERIES

™

SERIES

™

122 1/4" x 127 1/2"

310,5 cm x 323,9 cm

122 1/4" x 57 1/2"

310,5 cm x 146,1 cm

For proper base construction see page 5

Door

Opening

Height

Width

Height

91 1/4"

98 1/4"

72 3/4"

231,8 cm

249,6 cm

184,8 cm

www.arrowsheds.com

01H

R

TM

All Sizes

Advertisement

Summary of Contents for Arrow Storage Products Commander series

- Page 1 717740813 Owner’s Manual & Assembly Guide COMMANDER SERIES ™ Gloves must be worn MOUNTAINEER SERIES ™ at all times to reduce risk of injury! * See Inside for Detailed Safety Information. All Sizes 10x10 122 1/4” x 127 1/2” Customer Service: Base Size 310,5 cm x 323,9 cm 1-800-851-1085...

- Page 2 SAFETY PRECAUTIONS... Safety precautions MUST be followed at all times throughout the construction of your building! Practice caution with the tools being used in the Care must be taken when handling various pieces assembly of this building. Be especially familiar with of your building since many contain sharp edges.

-

Page 3: What You Need

ASSEMBLY TIPS & TOOLS Watch the Weather Closely: Be sure the day you choose to install your building is dry and calm. Do NOT attempt to assemble your building on a windy day. Be careful on wet or muddy ground. Use Teamwork: Two or more people are required to assemble your building. - Page 4 BEFORE YOU BEGIN... Your Commander™ / Mountaineer™ Shed has a Modular Design. This means your shed can be extended to virtually any length with the addition of Extension Modules. Extension Modules can be installed when you fi rst construct your building, or they can be added to it later.

- Page 5 CONSTRUCTING A BASE... Before you assemble your building, you must construct a base. The length of your base, shown as “L” in the diagrams below, will depend on the length of your building. See below. For each additional module beyond the Nominal Size # of Modules Length “L”...

- Page 6 HARDWARE - C1GA C1GA Hardware Key Part Part Qty. Description List 65103 Hex Nut (#8-32) #2 Phillips 11/32 Hex. 65923 Small Bolt (#8-32 x 3/8) (10 mm) 65004 Small Screw (#8AB x 5/16) (8 mm) 66611 Large Screw (#10AB x 1/2) (13 mm) 66625 Long Bolt (#10-32 x 3/4) (19 mm) 66783...

- Page 7 HARDWARE - C2GA / GA5M *Packed loose in carton C2GA Hardware Key Part Part Qty. Description List 10651 Latch Plate 7003 Shear Plate LT 7004 Shear Plate RT 66779 Slide Bolt 66780 Cane Bolt 66782 Door Handle GA5M Hardware Key Part Part Qty.

- Page 12 Step 1: Trusses You will need for this page: 10641 10642 10643 10644 7003 Truss Post Upper Chord Lower Chord Left Shear Truss Post (QTY: 12) (QTY: 24) Insert Truss Truss Plate 7004 Washers are to be used on painted parts only. Washers are not necessary on unpainted parts and there are Right Shear not enough to use on every Screw and Bolt.

- Page 13 Step 1: Continued You will need for this page: 10645 10646 Assemblies from previous page: • Truss Post Assembly (2) • Chord Truss Assembly (2) Truss Splice Knee Brace (QTY: 12) (QTY: 14) Next, insert the Upper/Lower Chord Truss Assembly into the Truss Post Assembly as shown.

-

Page 14: Step 2: Rear Wall

Step 2: Rear Wall You will need for this page: 10629 10630 10631 10640 Rear Wall Rear Wall Rear Frame Wall Post (QTY: 8) (QTY: 15) Channel Diagonal Lay out the parts and position them as shown. Overlap the Rear Frames by 4”... - Page 15 Step 2: Continued You will need for this page: 7822 10619 Wall Panel Corner Panel (QTY: 30) 10619 10619 INSIDE 7822 7822 10619 7822 10630 7822 LEAVE HOLES OPEN ALONG SIDE OF WALL OUTSIDE Place Washers on all Bolts and Screws used on painted parts.

-

Page 16: Step 3: Front Wall

Step 3: Front Wall You will need for this page: 10640 10652 10627 10628 10673 Wall Post Front Wall Front Wall Wall Post Front Frame (QTY: 34) (Hinge) Channel Diagonal (QTY: 24) 10638 10639 Left Front Wall Assembly Right Front Wall Assembly 10640 10652 Long Fascia... - Page 17 Step 3: Continued You will need for this page: Assemblies from previous page: 10618 10619 • Left Front Wall Assembly • Right Front Wall Assembly Front Wall • Door Header Assembly (QTY: 12) (QTY: 8) Corner Panel Panel Slide the Door Header Assembly down onto the Front Wall Assemblies as shown and secure with Small Bolts and Nuts.

-

Page 18: Step 4: Truss Installation

Step 4: Truss Installation You will need for this page: 10632 10634 Assemblies from Step 1: • Truss Assemblies (2) Side Wall Side Frame (QTY: 8) Channel (QTY: 4) 10632 Overlap Length 10632 8 1/4” 21,0 cm 10632 Assemble two sets of Side Frames by overlapping them by 8 1/4”... - Page 19 Step 4: Continued Side of Beams with small holes must face up. You will need for this page: 10650 Main Outer Outer Roof Beam (QTY: 14) End View of Double Beam 10650 Outer Main 10650 Outer Main Roof Beam 10650 10650 10650 Remove Bolts holding Truss peaks together (from...

- Page 20 Step 4: Continued for Extension Modules You will need for this page: 10632 10634 10650 Assemblies from Step 1: • All remaining Truss Side Wall Assemblies Side Frame (QTY: 6+) Roof Beam Channel (QTY: 18+) If you are erecting a 10x10 (3,0 m x 3,1 m) building, skip this page and move on to page 21.

- Page 21 Step 5: Rear Wall Install You will need for this page: 10633 Assemblies from Step 2: • Rear Wall Assembly Side Wall (QTY: 2) (QTY: 4) Channel 10633 10633 10’x10’ (3,0 m x 3,1 m) building shown. Carefully position the Rear Wall Assembly in place at the rear of the building and secure to Side Frame with one Large Screw per side as shown.

- Page 22 Step 6: Front Wall Install You will need for this page: 10633 10622 80037 Assemblies from Step 3: • Front Wall Assembly Right Door Left Door Side Wall (QTY: 2) (QTY: 4) Jamb Jamb Channel (QTY: 6) 10633 10633 10’x10’ (3,0 m x 3,1 m) building shown.

- Page 23 Step 7: Wall Angles You will need for this page: 10625 10625 (QTY: 4+) (QTY: 4) (QTY: 4+) Side Angle Starting at the front and rear of the building, attach Side Wall Angles to the front and rear wall of the building with Large Screws as shown.

- Page 24 Step 8: Wall Panels IMPORTANT: At this time, take a moment to ensure the building is level and square. Measure EQUAL MEASUREMENTS diagonally across the building from opposite corners; when these measurements match, the building is square. For the remainder of assembly it will be important that the building is both level and square.

- Page 25 Step 8: Continued You will need for this page: 7822 (QTY: 150+) Wall Panel (QTY: 9+) 10’x10’ (3,0 m x 3,1 m) building shown. Working one side at a time, lift the Panels into place and secure with three Small Screws in the top of the Panel, three Small Screws in the middle of the Panel, and three Small Screws in the bottom of the Panel.

- Page 26 Step 9: Gables You will need for this page: 8577 8576 6635 69835 (QTY: 8) Left Gable Right Gable Bracket Edge Trim GABLES ARE STACKED TOGETHER DURING SHIPPING AND MAY BE MIS- TAKEN FOR ONE GABLE! SEPARATE GABLES BEFORE CONTINUING. Edge Trim (Plastic) 69835 Edge Trim MUST cover Gable edge.

- Page 27 Step 9: Continued You will need for this page: 9009 6228 (QTY: 16) (QTY: 2) Gable Brace Track Sup. Gable must fi t UNDER Side Wall Angle at corner. 8576 8577 Working with one Gable at a time, attach the Gables to the top Rear Frame with Small Screws.

- Page 28 Step 9: Continued 10649 You will need for this page: 10649 10649 10649 (QTY: 13) Roof Beam 10649 Leave Hole Open 10’x10’ (3,0 m x 3,1 m) building shown. 10649 Top View of Gables Seal the gap between the Gables using the Tape should wrap around Weather Stripping Tape as shown.

- Page 29 Step 9: Continued You will need for this page: 9204 9204 Beam Brace (QTY: 2) 10’x10’ (3,0 m x 3,1 m) building shown. Attach the Roof Beam Brace to the Tab end attaches to Roof Beam. Track Support with one Small Bolt and Nut as shown.

- Page 30 Roof Install Prep Page Read thru all of Roof Assembly before beginning Step 10. IMPORTANT: At this time, take a moment to ensure the building is level and square. Measure the building diagonally again to make sure the building is square.

-

Page 31: Step 10: End Panels

Step 10: End Panels You will need for this page: 8578 8579 Right End Left End (QTY: 8) (QTY: 24) Secure the End Panel to the Main Roof Beam An Awl may be used to help by placing a Small Screw in hole #1 (from the align holes that are only slightly diagram below). - Page 32 Roof Assembly Chart 10’x10’ EP = End Panel (8578 / 8579) (3,0 m x 3,1 m) RP = Roof Panel (7743) RC - F/R = Front and Rear Ridge Cap (10621) No Extension RC - MID = Mid Ridge Cap (10680) RC - F/R RC - F/R Modules.

-

Page 33: Step 11: Roof Assembly

Step 11: Roof Assembly You will need for this page: 7743 • Starting with rib #5 below, every rib that is over Roof Panel (QTY: 48) (QTY: 8) a Truss should be secured with a Small Bolt and Nut, and then sealed with a strip of Tape. Begin weather stripping the roof ridge. - Page 34 Step 11: Continued For 10’x10’ (3,0 m x 3,1 m) ONLY. DO NOT fully tighten Ridge Cap Bolts until you have both Ridge Cap Bolts in place. This will ease Overlap two Front and Rear Ridge Caps assembly. Bolts must be fully tightened before moving on to as shown and secure with two Small the next page.

- Page 35 Step 11: Continued for Extension Modules You will need for this page: 7743 10621 10680 Ridge Cap - Ridge Cap - (QTY: 32+) Roof Panel (QTY: 8+) Continue to apply Weather Stripping. If you are erecting a 10’x10’ (3,0 m x 3,1 m) building, skip this page and move on to page 36.

- Page 36 Step 11: Continued You will need for this page: 7743 • Bolts under Ridge Cap pass thru slots where (QTY: 52+) Roof Panel (QTY: 6) the End Roof Panel is overlapped by the Panel next to it (labeled rib 5 below). Continue to apply Weather Stripping.

- Page 37 Step 12: Roof Trim You will need for this page: 80017 10620 6015 (QTY: 4) (QTY: 16+) (QTY: 8) Left Trim Right Trim Mid Trim Trim Cap (L) Slide Peak Cap legs under Ridge Cap and secure Ridge Cap ends with four Small Bolts and Nuts on each end as shown.

-

Page 38: Step 13: Door Assembly

Step 13: Door Assembly You will need for this page: 10623 10624 80051 Door Panel Right Door Left Door (QTY: 10) (Hinge) Panel Panel Refer to page 11 for Door assembly overview. Position Door Panels as shown and secure using Small Bolts and The best way to assemble the Nuts. - Page 39 Step 13: Door Assembly You will need for this page: 10635 10637 10678 [ NO HARDWARE NEEDED 10635 FOR THIS STEP ] Vert. Door Vert. Door Horiz. Door Brace (Hinge) Brace (Latch) Brace Extra hole along Position Horizontal Door Braces, and INSIDE of Door.

- Page 40 Step 13: Continued You will need for this page: 10636 Vert. Door (QTY: 12) Open ends of Vertical Door Braces Brace must face edge of Doors. Slide Vertical Door Braces into position with ends inside Horizontal Door Braces. Double check that the open ends of the Vertical Door Braces face the edges of the Door (see image to right) and secure with Large Screws in each Door.

- Page 41 Step 13: Continued You will need for this page: Plastic Washer 10651 66781 10626 Diagonal (QTY: 13) (QTY: 2) Latch Plate Spring Latch (QTY: 2) Brace (QTY: 3) A: Position parts as shown and secure to upper inside corner of left Door with Large Screws.

- Page 42 Step 13: Continued You will need for this page: The Cane Bolt, Door Handles 10675 66780 and Slide Bolt are pre-packaged with thier own hardware. This hardware is not used when assembling Cane Bolt the building. Instead, use the (QTY: 26) Cane Bolt Bracket hardware indicated in each step.

- Page 43 Step 13: Continued You will need for this page: 66778 10648 10647 Astragal Top Trim Lock Eyelet (QTY: 20) (QTY: 20) (QTY: 2) Secure the Horizontal Door Brace to the Door with Large Screws. If holes do not align, insert Screw Position Door Trim and Astragals as at an angle.

- Page 44 Step 13: Continued You will need for this page: 66782 66779 10651 Door Handle Slide Bolt Latch Plate (QTY: 8) (QTY: 4) Slide Latch Plate into position on the Left Do not use hardware supplied Door. Next, position the Slide Bolt on the with Door Handle and Slide Bolt.

- Page 45 Step 13: Continued Slide Bolt may need adjustment If Slide Bolt does not align properly, you may need to insert plastic washers between the to align properly. door and the Slide Bolt to ensure proper fi t. Adjust number of plastic washers until desired fi...

- Page 46 ANCHORING OPTIONS... IMPORTANT: • Doors must hang and swing level before anchoring building. • Anchor your building at this time. See below for details on anchoring. • After anchoring, drill a 5/8” (1,6 cm) hole at least 2” (5,1 cm) into your base to receive the left-side Cane Bolt and hold the Door (left side only) closed.

- Page 47 CARE & MAINTENANCE... Exterior Care: For a long lasting fi nish clean and wax the exterior surface. We recommend washing with a mild soap solution. DO NOT use power washing to clean your shed. Using a spray automotive type wax periodically on the exterior is highly recommended if you are in a high humidity or coastal climate region.

-

Page 48: How To Order

ARROW ACCESSORIES... ATTIC KIT / WORKBENCH KIT ANCHOR KITS Model No. AK4 Model No. AT101 Anchor Kit contains heavy-duty steel Heavy-duty galvanized steel bars that augers, 60' (18 m) of steel cable and fi t all 10' (3,0 m) wide Arrow buildings. 4 cable clamps.

Need help?

Do you have a question about the Commander series and is the answer not in the manual?

Questions and answers