Table of Contents

Advertisement

ENGLISH INSTRUCTION MANUAL

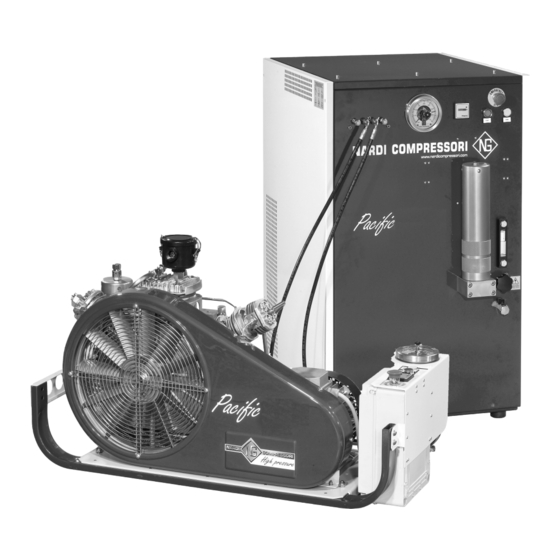

Instruction Manual and Spare Parts Catalogue

Pacific 210

This manual contains operating instructions and maintenance schedules for the high

pressure breathing air compressors. Operators must read and understand all

information inside the manual.

ATTENTION. This machine can be used only after a careful reading of this instruction

manual. The machine may only used to produce compressed air. Other use is strictly

prohibited. The manufacturer and the supplier void all responsibility for damage or injury

resulting from failure to follow these instructions.

1

Advertisement

Table of Contents

Summary of Contents for Nardi Compessori Pacific 210

- Page 1 ENGLISH INSTRUCTION MANUAL Instruction Manual and Spare Parts Catalogue Pacific 210 This manual contains operating instructions and maintenance schedules for the high pressure breathing air compressors. Operators must read and understand all information inside the manual. ATTENTION. This machine can be used only after a careful reading of this instruction manual.

-

Page 2: General Information

INSTRUCTION MANUAL PACIFIC 210 1. GENERAL INFORMATION: Before using the machine please put your attention to this general information: 1. Personnel engaged to operate the machine must have read the instruction manual before beginning work, especially the safety notices chapter. -

Page 3: Compressor Block

3. COMPRESSOR BLOCK The compressor block PACIFIC 210 is used to compress air in the high pressure range up to 420 bar (6000 psi). The compressor block is of a three stage, three cylinders design. The cylinders are arranged in a W form, the 1st stage in the centre, 2nd stage on the right, and 3th stage on the left side looking from the filter side. -

Page 4: Technical Data

Nardi oil High pressure Max permissibile ambient temp. Olio normal Nardi Compressori -5° a +45°C ( +28° a +113°F ) - Olio technical 1 Nardi Compressori –25° a +35°C ( -9° a +95°F ) Max permissibile inclination of compressor 20°... -

Page 5: Safety Measures

Observe switching on and off processes and monitoring indications according to the instructions manual. • Use only Nardi original parts and equipments. • Drain the valve regularly if manual drain valve. Check every ten minutes the valve if automatic drain valve. -

Page 6: Warranty

• Reparation must be made inside Nardi factory and the compressors must always delivered at the buyer’s charges and risks. Otherwise, in case of outside reparation all transport costs will be debted to the buyer (only trained personnel can work with the machine). If the reparation needs of a Nardi technician, all trip charges must be debted to the buyer. -

Page 7: Electrical Installation

INSTRUCTION MANUAL PACIFIC 210 7.4. Electrical installation: For installation of electrical equipment observe the following: In the annex of this instruction manual you will find the standard schematic diagrams valid for the respective compressor unit. • Observe regulations of local electricity supply company. -

Page 8: Filling Procedure

INSTRUCTION MANUAL PACIFIC 210 Units with electric engine with automatic control system: This model is deliverd with an automatic control system. Before starting check point 6.1 and then press ON button.Switch off the machine pressing STOP button. Units with petrol engine: Open condensate drain valves on the filters to release pressure, so that motor start without load. -

Page 9: Maintenance Schedule

INSTRUCTION MANUAL PACIFIC 210 10.2. Maintenance schedule: After fisrt 15 operating hours Date Signature Clean intake filter and intake filter cartridge Check Oil level Check cooler fastening Check tightness of all cooler-pipes and couplings Check tightness of O-rings Check functioning and tightness of filling valve... - Page 10 INSTRUCTION MANUAL PACIFIC 210 Every 1000 operating hours (Nardi technician) Date Signature Valve change Annually or as required Date Signature Perform a breathing air quality check with aerotests Check blow-off pressure of final pressure safety valve After repair work Date...

-

Page 11: Maintenance Work

11.2. Type of oil : Using the correct oil is of vital importance for life and maintenance of the compressor. Nardi has a particular oil studied and tested for the best operation of his machine.Depending on the application of the compressor the requirements placed on the oil are: low deposits •... - Page 12 INSTRUCTION MANUAL PACIFIC 210 11.4. Changing the oil type: To avoid severe damage to the compressor unit when changing the oil type, the following measures should be strictly adhered to: Follow the procedure Chapter 9.3. • Change or clean all parts with old oil.

- Page 13 To avoid any ranger to your health or damage to your unit, change used up cartridges in good time.Never fill used up cartridges yourself. The filter material was chosen specifically by Nardi compressori for each kind of application. Never remove replace- ment cartridge from packaging prior to actual use otherwise highly sensitive molecular sieve will absorb water vapour from surrounding air and cartridge saturated.

- Page 14 INSTRUCTION MANUAL PACIFIC 210 11.10. Lifetime of filter cartridge Lifetime off Cartridge 210 (300 BAR) Temperature °C Little Damp Higt Damp Lifetime off Cartridge 210 (200 BAR) Temperature °C Little Damp Higt Damp...

- Page 15 INSTRUCTION MANUAL PACIFIC 210 11.11. Valves: The valve heads of the individual stages form the top part of the cylinders. The intake and pressure valves are fitted inside the valve heads. Note that the valves are operated by the flow of the medium.

- Page 16 INSTRUCTION MANUAL PACIFIC 210 Changing the valves of the 2rd stage: Please follow the procedure below: Uscrew the intake and pressure linesfrom the cylinder head. • Fix the head. • Unscrew the intake valve body with the special tool. In order to avoid damaging the special tool or •...

- Page 17 Pacific 210 SPARE PARTS Code Description Code Description P A001 Front safety O- ring P A012 Back part safety O- ring P A002 Roller bearing for front shaft P A013 Roller bearing for the back part of the shaft P R003...

- Page 18 Pacific 210 SPARE PARTS Code Description Code Description P B001 Compressor crankcase P B002 Pin flange P B003 Circlip ring P B004 Complete connecting rod assembly P B005 Circlip ring P B006 O-ring closing compressor crankcase P B007 Closing crankcase flange...

- Page 19 Pacific 210 SPARE PARTS Code Description Code Description P D001 Support stirrup tubes high pressure and crankcase P D020 Rilsan tube escape oil 12 mm P D002 Support stirrup tubes cooling lateral external P D021 Plug P D003 Support stirrup tubes cooling lateral internal...

- Page 20 Pacific 210 SPARE PARTS Code Description Code Description P G001 Stud cylinder 1° stage P G012 "L" 1/4 "connection tube 12 mm fast coupling P G002 Piston 1° stage P G013 Male 3/4" connection- 1/2" male P G003 Piston pin 1° stage...

- Page 21 Pacific 210 SPARE PARTS Code Description Code Description P E001 Lower o-ring, cylinder 2°stage P F013 Inferior body valve 2° stage P F002 Piston pin 2°stage P F014 Seal washer valve 2° stage P F003 Stud cylinder 2° stage P F015 Up-right connection 3/8"...

- Page 22 Pacific 210 SPARE PARTS Code Description Code Description P E001 Lower o-ring, cylinder 3°stage P E015 Cylinder's pipe 3° stage P E002 Inferior piston 3°stage P E016 Upper o-ring pipe 3° stage P E003 Stud cylinder 3° stage P E017 Up-right connection 1/4"...

- Page 23 Pacific 210 SPARE PARTS Cod. riferim. Descrizione Articolo Cod. riferim. Descrizione Articolo P L001 Fitting 1/4" P L006 Fixing stirrup intermediate pressure filter P M001 Inferior body filter high pressure P M006 Fixing stirrup high pressure filter P L002 Inferior body filter intermediate pressure P L007 Safety valve 2°...

- Page 24 Pacific 210 SPARE PARTS Code Description Code Description P T004 Connecting tube P T007 2° Stage intercooler P T005 3° Stage intercooler P T006 1° Stage intercooler...

- Page 25 Pacific 210 SPARE PARTS Code Description Code Description P Q001 Support filter system P Q015 nozzle P R001 Black screw of discharge P Q016 O-ring P Q002 Stirrup screw filter system P Q017 base P Q003 Up-right connection 1/4" tube 6 mm...

- Page 26 Pacific 210 SPARE PARTS Code Description Code Description P R001 Black screw of discharge 225 Bar P R016 Closing nut P R002 Red screw of discharge 330 Bar P R017 Rubber pommel P R003 Risan nut P R018 Nut fixing rubber pommel...

- Page 27 Pacific 210 SPARE PARTS Code Description Code Description P S001 water drain pommel P S015 rilsan hose 12 mm - 1/4 fitting P S002 washer P S016 6 mm pipe - fitting 1/4 P S003 Water drain pommel spring P S017...

Need help?

Do you have a question about the Pacific 210 and is the answer not in the manual?

Questions and answers