Honda EM650 Owner's Manual

Honda generator owner's manual

Hide thumbs

Also See for EM650:

- Owner's manual (49 pages) ,

- Owner's manual (18 pages) ,

- Shop manual (59 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Honda EM650

- Page 3 This manual contains the information on how to do that; please read it carefully. This owner’s manual describes the operation and maintenance of the EM650 Honda generator. All information in this publication is based on the latest product information available at the time of printing.

-

Page 4: Table Of Contents

CONTENTS SAFETY ... Safety Label Locations ..4 Safety Information ... COMPONENT IDENTIFICATION ..8 CONTROLS Engine Switch ... Recoil Starter Choke Lever ... Pilot Lamp ... Ground Terminal ... Oil Alert System ... AC Circuit Protector ... DC Terminals ... DC Circuit Protector ... - Page 5 MAINTENANCE..Maintenance Schedule ..25 Engine Oil Change ... 26 Air Cleaner Service ..27 Spark Plug Service ... 28 Spark Arrester Maintenance ..31 TRANSPORTING/STORAGE ... 33 TROUBLESHOOTING ... 35 WIRNING DIAGRAM ..37 SPECIFICATIONS..38 CUSTOMER SERVICE INFORMATION ..39 INDEX ...

-

Page 6: Safety

If a label comes off or becomes hard to read, contact your Honda Generator If a label comes off or becomes hard to read, contact your Honda Generator dealer for a replacement. dealer for a replacement. EM650 ‘XONDA . WHEN “SlNG DC OUTPUT. - Page 7 LE PLElN AU OESSUS 0” REPtRE DE NWEA” MAXIMUM. MAS DE LINEA DE CLEANER MAINTENANCE WCLEAN ELEMENT EVERY HOURS (EVERY HOURS UNDER DUSTY CONDITIONS). WASH HIGH FLASH-POINT SOLVENT, SQUEEZE DRY, THEN DIP IN CLEAN ENGINE OIL AND SQUEEZE OUT EXCESS OIL.

-

Page 8: Safety Information

SAFETY INFORMATION Honda generators are designed to give safe and dependable service if operated according to instructions. Read and understand this owner’s manual before operating your generator. You can help prevent accidents by being familiar with your generator’s controls, and by observing safe operating procedures. - Page 9 Fire and Burn Hazards The exhaust system gets hot enough to ignite some materials. Keep the generator at least 1 meter (3 feet) away from buildings and other equipment during operation. Do not enclose the generator in any structure. Keep flammable materials away from the generator. The muffler becomes very hot during operation and remains hot for a while after stopping the engine.

-

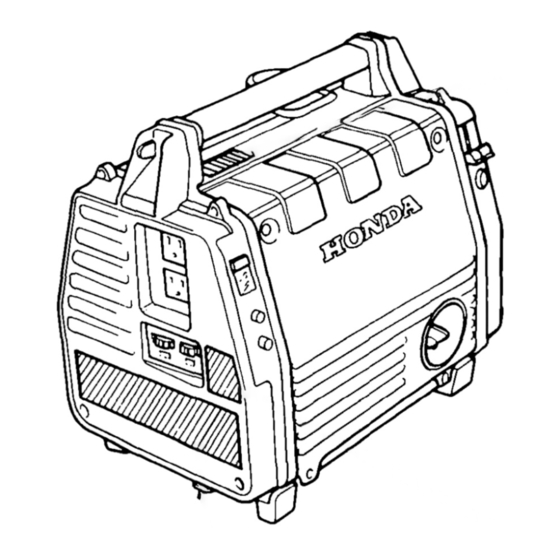

Page 10: Component Identification

COMPONENT IDENTIFICATION ACRECEPTACLES LEFT SIDE COVER DC TERMINALS GROUND TEdMlNAL Record the engine and frame serial numbers for your future reference. Refer to these serial numbers when ordering parts, and when making technical or warranty inquiries (see page 39) Frame serial number: Engine serial number: PILOT LAMP CHOKE LEVER... - Page 11 FUEL TANK CAP CARRYING HANDLE RECOIL OUTLET STARTER GRIP SPARK P\LUG COVER AIR CLEANER...

-

Page 12: Controls

CONTROLS Engine Switch To start and stop the engine. Switch position: OFF: Recoil Starter To start the engine, pull the starter grip lightly until resistance is felt, then pull briskly. Do not allow the starter to snap back against the engine. Return it gently to prevent damage to the starter. -

Page 13: Choke Lever

Choke Lever The choke is used to provide an enriched fuel mixture when starting a cold engine. It can be opened and closed by operating the choke lever manually. Move the lever to the CLOSED position to enrich the mixture. Pilot Lamp The pilot lamp is illuminated when the generator is operating normally. -

Page 14: Ground Terminal

Ground Terminal The generater ground terminal is connected to the frame of the generater, the metal non-current carrying parts of the generator, and the ground terminals of each receptacle. Before using the ground terminal, consult a qualified electrian, electrical inspector or local agency having jurisdiction for local codes or ordinances that apply to the intended use of the generator. -

Page 15: Oil Alert System

Oil Alert System The Oil Alert system is designed to prevent engine damage caused by an insufficient amount of oil in the crankcase. Before the oil level in the crankcase can fall below a safe limit, the Oil Alert system will automatically stop the engine (the engine switch will remain in the ON position). -

Page 16: Dc Terminals

DC Terminals The DC terminals may ONLY be used for charging 12 volt automotive type batteries. The terminals are colored red to identify the positive (+) terminal and black to identify the negative (-) terminal. The battery must be connected to the generator DC terminals with the proper polarity (battery positive to generator red terminal and battery negative to the generator black terminal). -

Page 17: Generator Use

Connections to a Building’s Electrical System Connections for standby power to a building’s electrical system must be made by a qualified electrician. The connection must isolate the generator power from utility power, and must comply with all applicable laws and electrical codes. -

Page 18: Ac Operation

AC Operation 1. Start the engine (refer to page 23) and make sure the pilot lamp comes on. If not, the filament may be burnt out. 2. Plug in the appliance. 1 NOTICE ( Substantial overloading will switch off the circuit protector. Marginal overloading may not switch off the circuit protector, but it will shorten the service life of the generator. -

Page 19: Dc Operation

DC Operation The DC terminals may ONLY be used for charging 12 volt automotive-type batteries. Connecting the battery cables: 1. Before connecting charging cables to a battery that is installed in a vehicle, disconnect the vehicle’s ground cable from the battery. The battery gives off explosive gases;... -

Page 20: Disconnecting The Battery Cables

Disconnecting the battery cables: 1. Stop the engine. 2. Disconnect the negative (-) battery cable from the generator negative (-) terminal. 3. Disconnect the other end of the negative (-) battery cable from the battery negative (-) terminal. 4. Disconnect the positive (+) battery cable from the generator positive (+) terminal. -

Page 21: High Altitude Operation

High Altitude Operation At high altitude, the standard carburetor air-fuel mixture will be excessively rich. Performance will decrease, and fuel consumption will increase. High altitude performance can be improved by installing a smaller diameter main fuel jet in the carburetor and readjusting the pilot screw. If you always operate the engine at altitudes higher than 6,000 feet above sea level, have an authorized Honda generator dealer perform this carburetor modification. -

Page 22: Pre-Operation Check

PRE-OPERATIOIN CHECK Engine Oil Engine oil is a major factor affecting engine performance and service life. Non-detergent and 2-stroke engine oils will damage the engine and are not recommended. Check the oil level BEFORE EACH USE with the generator on a level sur- face with the engine stopped. -

Page 23: Fuel Recommendation

Fuel Recommendation 1. Check the fuel level gauge. 2. Refill the tank if the fuel level is low. Do not fill above the shoulder of the fuel strainer. Gasoline is extremely flammable and is explosive under certain conditions. Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area where the engine is refueled or where gasoline is stored. - Page 24 Occasionally you may hear light “spark knock” or “pinging” (metallic rapping noise) while operating under heavy loads. This is no cause for concern. If spark knock or pinging occurs at a steady engine speed, under normal load, change brands of gasoline. If spark knock or pinging persists, see an authorized Honda generator dealer.

- Page 25 Oxygenated Fuels Some conventional gasolines are being blended with alcohol or an ether compound. These gasolines are collectively referred to as oxygenated fuels. To meet clean air standards, some areas of the United States and Canada use oxygenated fuels to help reduce emissions. If you use an oxygenated fuel, be sure it is unleaded and meets the minimum octane rating requirement.

-

Page 26: Starting/Stopping The Engine

STARTING/STOPPING Starting the engine 1. The generator may be hard to start if a load is connected. 2. Move the choke lever to the CLOSE position. 3. Move the engine switch to the ON position. 4. Pull the starter grip until compression is felt, then pull briskly. NOTICE 1 Do not allow the starter grip to snap back. -

Page 27: Maintenance

Periodic maintenance and adjustment is necessary to keep the generator in good operating condition. Perform the service and inspection at the intervals shown in the Maintenance Schedule below. Exhaust gas contains poisonous carbon monoxide. Shut off the engine before performing any maintenance. If the engine must be run, make sure the area is well ventilated. -

Page 28: Engine Oil Change

Engine Oil Change Drain the oil while the engine is warm to assure complete and rapid draining. 1. Remove the oil filler cap. 2. Turn the engine switch OFF and tilt the generator to drain the oil. 3. Refill with the recommended oil (see page 20 and check the oil level). Oil capacity: 0.35 e (0.37 US qt, 0.31 Imp qt) Please dispose of used motor oil and the oil containers in a manner that is compatible with the environment. -

Page 29: Air Cleaner Service

Air Cleaner Service A dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor malfunction, service the air cleaner regularly. Service more frequently when operating the generator in extremely dusty areas. Using gasoline or flammable solvent to clean the filter element can cause a fire or explosion. -

Page 30: Spark Plug Service

Spark Plug Service Recommended spark plugs: To ensure proper engine operation, the spark plug must be properly gapped and free of deposits. If the engine has been running, the muffler will be very hot. Be careful not to touch the muffler. 1. - Page 31 4. Visually inspect the spark plug. Discard it if the insulator is cracked or chipped. Clean the spark plug with a wire brush if it is to be reused. 5. Measure the plug gap with a feeler gauge. Correct as necessary by carefully bending the side electrode. The gap should be: 0.6-0.7 mm (0.024-0.028 in) 0.6 - 0.7 mm (0.024-0.028...

- Page 32 7. After the spark plug is seated, tighten with a spark plug wrench to compress the washer. If installing a new spark plug, tighten l/2 turn after the spark plug seats to compress the washer. If reinstalling a used spark plug, tighten 1/8-l /4 turn after the spark plug seats to compress the washer.

-

Page 33: Spark Arrester Maintenance

Spark Arrester Maintenance If the generator has been running, the muffler will be very hot. Allow to cool before proceeding. The spark arrester must be serviced every 100 hours to maintain its efficiency. 1. Remove the fuel tank cap. 2. Remove the four 5 mm pan-screws, and then remove the rear cover. Retighten the fuel tank cap. - Page 34 5. Check for carbon deposits around the exhaust port and the spark arrester. Use a brush to remove carbon deposits from the spark arrester screen. Inspect the spark arrester screen for holes or tears. Replace if necessary. NOTE: The spark arrester must be free of breaks and holes. Replace, if necessary.

-

Page 35: Transporting/Storage

When transporting the generator, turn engine switch and the fuel valve OFF. Keep the generator level to prevent fuel spillage. Fuel vapor or spilled fuel may ignite. Contact with a hot engine or exhaust system can cause serious burns or fires. Let the engine cool before transporting or storing the generator. - Page 36 1. Drain the carburetor by loosening the drain screw. Drain the gasoline into a suitable container. Gasoline is extremely flammable and is explosive under certain conditions. Perform this task in a well ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area during this procedure.

-

Page 37: Troubleshooting

When the engine will not start: Is there fuel in the tank? Isthereenoughoilinthe engine? Is there a spark at the spark plug? Be sure there is no spilled fuel around the spark plug. Spilled fuel may ignite. start, take the generator to an authorized HONDA TROUBLESHOOTING Replace the... - Page 38 No electricity at the AC receptacles: Is the AC circuit protec- tor on? Check the electrical ap- pliance or equipment for any defects No electricity at the DC terminals NO DEFECTS DEFECTS Push the AC circuit pro- tector button in. Take the generator w an authorized HONDA...

-

Page 39: Wiring Diagram

WIRING DIAGRAM... -

Page 40: Specifications

SPECIFICATBONS Dimension Power product description code Length x Width x Height Dry Weight Engine Engine Type Displacement [Bore x Stroke] Compression Ratio Engine Speed Cooling System Ignition System Oil Capacity Fuel Tank Capacity Spark Plug Generator AC output Maximum Output DC output NOTE: Specifications... -

Page 41: Customer Service Information

Manager can help. Almost all problems are solved in this way. If you are dissatisfied with the decision made by the dealership’s manage- ment, contact the Honda Power Equipment Customer Service Office. You can writ0 to: American Honda Motor Co.,lnc. -

Page 42: Index

INDEX COMPONENT IDENTIFICATION ... 8 CONTROLS ... AC Circuit Protector..13 Choke Lever ... DC Circuit Protector..14 DC Terminals ... Engine Switch Ground Terminal..Oil Alert System ... Pilot Lamp ... Recoil Starter ... CUSTOMER SERVICE INFORMATION ..39 GENERATOR USE.. - Page 43 PRE-OPERATION CHECK ... 20 Engine Oil ... Fuel Recommendation ... 21 SAFETY ... Safety Information ... Safety Label Locations ... 4 SPECIFICATIONS ... STARTING/STOPPING THE ENGINE ..24 TRANSPORTING/STORAGE ... 33 TROUBLESHOOTING ... 35 WIRING DIAGRAM..37 INDEX...

- Page 44 MEMO...

- Page 45 MEMO...

- Page 46 MEMO...

Need help?

Do you have a question about the EM650 and is the answer not in the manual?

Questions and answers