Table of Contents

Advertisement

S

C

U

S

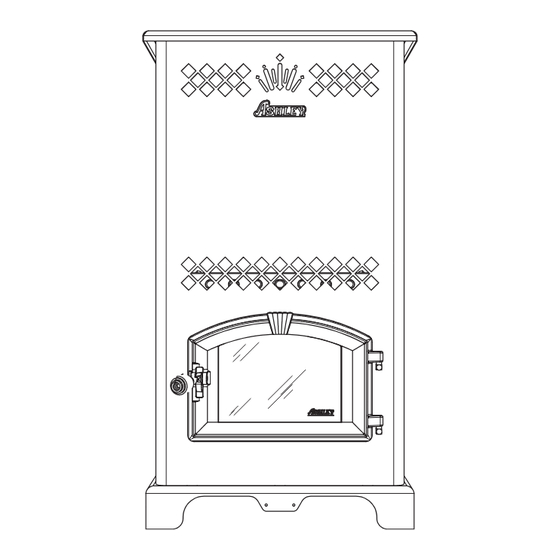

King/Ashley Pellet Stove

5500

Please read this entire manual before installation and use of this appliance. Failure to follow

these instructions could result in property damage, bodily injury, or even death.

Contact your local building or fire officials about obtaining permits, restrictions and installation

inspection requirements in your area.

Save these instructions.

French version is available for download from the U. S. Stove website: http://www.usstove.com/

UNITED STATES STOVE COMPANY • 227 INDUSTRIAL PARK ROAD • SOUTH PITTSBURG, TENNESSEE 37380 • WWW.USSTOVE.COM

FOR TECHNICAL ASSISTANCE:

UNITED STATES STOVE COMPANY

"Keeping North America Warm Since 1869"

Owner's Manual

TESTED &

LISTED BY

Report #: 215-S-05b-2

PHONE: (800) 750-2723

5500XL

PORTLAND,

OREGON, USA

FAX: (423) 837-2109

models 5500/5500M/5500XL

5500M

851641 Rev H

Advertisement

Table of Contents

Summary of Contents for United States Stove Company 5500

- Page 1 French version is available for download from the U. S. Stove website: http://www.usstove.com/ TESTED & PORTLAND, LISTED BY OREGON, USA Report #: 215-S-05b-2 UNITED STATES STOVE COMPANY • 227 INDUSTRIAL PARK ROAD • SOUTH PITTSBURG, TENNESSEE 37380 • WWW.USSTOVE.COM FOR TECHNICAL ASSISTANCE: PHONE: (800) 750-2723 FAX: (423) 837-2109 851641 Rev H...

-

Page 2: Table Of Contents

Table of Contents TABLE OF CONTENTS ....................2 WARRANTY REGISTRATION ................3-4 SAFETY PRECAUTIONS ................... 5 SPECIFICATIONS ....................... 6 Heating Specifications ..................6 Dimensions ...................... 6 Electrical Specifications ................... 6 Fuel Considerations ..................6 Safety and EPA Compliance ................6 INSTALLATION ......................7 Installation Options ..................7 Floor Protection ....................7 Clearances ...................... -

Page 3: Warranty Registration

WARRANTY INFORMATION CARD Name__________________________________________ Telephone #: (_____)_____________ City____________________________________________ State_______ Zip_________________ Email Address __________________________________________________________________ Model # of Unit________________________________ Serial #___________________________ Fuel Type: qWood qOther _________________________ qCoal qPellet qGas Place of Purchase (Retailer)______________________________________________________ City____________________________________________ State_______ Zip_________________ If internet purchase, please list website address___________________________________ Date of Purchase _______________________________________________________________ Reason for Purchase: qAlternative Heat... - Page 4 Ê É Fold Here Fold Here Fold Here PLACE STAMP HERE United States Stove Company P.O. Box 151 South Pittsburg, TN 37380...

-

Page 5: Safety Precautions

Safety Precautions IMPORTANT: Read this entire manual before installing Allow the stove to cool before performing any and operating this product. Failure to do so may maintenance or cleaning. Ashes must be disposed result in property damage, bodily injury, or even death. in a metal container with a tight fitting lid. The closed Proper installation of this stove is crucial for safe and container of ashes should be placed on a non- efficient operation. -

Page 6: Specifications

Specifications Heating Specifications Fuel Burn Rate* 2.0 - 6.0 lbs./hr. (0.9 - 2.7 kg/hr) Burn Time (lowest setting) 5500/5500M - 60 hrs. 5500XL - 160 hrs. Hopper Capacity 5500/5500M - 120lbs. (55kg) 5500XL - 320lbs.(146kg) * Pellet size may effect the actual rate of fuel feed and burn times. Fuel feed rates may vary by as much as 20%. Use PFI listed fuel for best results. Dimensions 5500/5500M 5500XL Height 34 in. (864mm) 47 1/4 in. (1200mm) Width 26 in. (660mm) 26 in. (660mm) Depth 27 in. (686mm) 27 in. (686mm) Weight 210 lbs. (95.5kg) 275 lbs. (125kg) Electrical Specifications Electrical Rating 110-120 volts, 60 HZ, 3.0 Amps Watts (operational) 175 (approx.) Watts (igniter running) 425 (approx.) FUEL CONSIDERATIONS Your pellet stove is designed to burn premium hardwood pellets that comply with Association of Pellet Fuel Industries standards. (Minimum of 40 lbs density per cubic ft, 1/4” to 5/16” diameter, length no greater than 1.5”, not less than... -

Page 7: Installation

Installation INSTALLATION OPTIONS Read this entire manual before you install and use your pellet stove. Failure to follow instructions may result in property damage, bodily injury, or even death! (See specific installation details for clearances and other installation requirements) A Freestanding Unit—supported by pedestal/legs and placed on a non-combustible floor surface in compliance with clearance requirements for a freestanding stove installation. -

Page 8: Clearances

FIGURE 3 FIGURE 4 SIDEWALL CLEARANCES SIDEWALL CLEARANCES PARALLEL INSTALATION CORNER INSTALATION PARALLEL A - Backwall to unit 2.00 / 50mm B - Sidewall to flue 13.00 / 330mm C - Sidewall to top edge of unit 8.00 / 203mm CORNER D - Adjacent wall to unit 8.00 / 203mm ALCOVE E - Alcove depth 36.00 - 914mm F - Alcove height 60.00 - 1520mm (5500(M) only) TABLE 1 CLEARANCES ALCOVE INSTALLATION THIS INSTALLATION IS NOT APPLICABLE FOR MODEL 5500XL. FIGURE 5 ALCOVE CLEARANCES USSC... -

Page 9: Venting Requirements

Installation VENTING REQUIREMENTS Install vent at clearances specified by the vent manufacturer. Do not connect the pellet vent to a vent serving any other appliance or stove. Do not install a flue damper in the exhaust venting system of this unit. ... -

Page 10: Vent Termination Clearances

Installation VENT TERMINATION CLEARANCES: Minimum 4-foot (1.22m) clearance below or beside any door or window that opens. Minimum 1-foot (0.3m) clearance above any door or window that opens. Minimum 3-foot (0.91m) clearance from any adjacent building. Minimum 7-foot (2.13m) clearance from any grade when adjacent to public walkways. Minimum 2-foot (0.61m) clearance above any grass, plants, or other combustible materials. Minimum 3-foot (0.91m) clearance from an forced air intake of any appliance. Minimum 2-foot (0.61m) clearance below eves or overhang. Minimum 1-foot (0.3m) clearance horizontally from combustible wall. Must be a minimum of 3 foot (0.91m) above the roof and 2 foot (0.61m) above the highest point or the roof within 10 feet (3.05m). FIGURE 6 VENT TERMINATION CLEARANCES USSC... -

Page 11: Through The Wall Installation

Installation THROUGH THE WALL INSTALLATION (RECOMMENDED INSTALLATION) Canadian installations must conform to CAN/CSA-B365. To vent the unit through the wall, connect the pipe adapter to the exhaust motor adapter. If the exhaust adapter is at least 18 in.(457mm) above ground level, a straight section of pellet vent pipe can be used through the wall. Your heater dealer should be able to provide you with a kit that will handle most of this installation, which will include a wall thimble that will allow the proper clearance through a combustible wall. Once outside the structure, a 3 in.(76mm) clearance should be maintained from the outside wall and a clean out tee should be placed on the pipe with a 90-degree turn away from the house. At this... -

Page 12: Outside Air Supply

Installation OUTSIDE AIR SUPPLY (optional, unless installing in a mobile home) Depending on your location and home construction, outside air may be necessary for optimal performance. Metal pipe (solid or flexible) must be used for the outside air installation. PVC pipe is NOT approved and should NEVER be used. A wind shield over the termination of the outside air pipe or a 90-degree elbow or bend away from the prevailing winds MUST be used when an outside air pipe is installed through the side of a building. The outside air termination MUST be at least 1ft (0.305m) away from the exhaust system termination. The outside air pipe on your heater is 2” (50.8mm) OD. The outside air connecting pipe must be at least 2” (50.8mm) ID. The outside air connection used MUST NOT restrict the amount of air available to your heater. The outside air connecting pipe must be as short and free of bends as possible, and it must fit over, not inside, the outside air connection to the heater. FIGURE 9 TYPICAL FRESH AIR TERMINATION NOTE: Dimensions from the floor to your stoves FIGURE 8 inlet/exhaust pipes are approximate and may vary EXHAUST/INLET LOCATIONS depending on your installation. SPECIAL MOBILE HOME REQUIREMENTS ... -

Page 13: Understanding Your Stove

Understanding your stove How your stove works Your pellet stove utilizes a inclined auger fuel feed system that is operated by a microprocessor controlled digital circuit board. The digital circuit board allows the inclined auger fuel feed system to run in a timer-based, non-continuous cycle; this cycling allows the auger to run for a predetermined period of seconds. The auger pushes pellets up a chute located at the front/bottom of the hopper which in turn falls through another chute into the burnpot. Your stove is equipped with an automatic ignition system that should ignite the fuel within 5-10 minutes from pressing the ON button. As pellets enter the burn pot and ignite, outside air is drawn across the fuel and heated during the combustion process which is then pulled through the heat exchanger by the exhaust motor or draft fan. As the stove heats up, room air is circulated around the heat exchanger by means of a room air blower, distributing warm air into the room. The amount of heat produced by the stove is proportional to the rate of the fuel that is burned, and this rate is controlled by the “HEAT RANGE” setting. In order to maintain combustion of the fuel at a desired rate, the air provided to the burn chamber by the exhaust or draft fan must be maintained precisely. Too little air will result in a flame that is non-energetic or lazy. If the fuel continues to flow with too little air for long enough, the burn pot will fill with too much fuel and the fire will smother out. To much air will result in a flame that is overactive or aggressive. The flame in this situation is typically very blue at the bottom and resembles a blow torch. If this situation continues, the fuel in the burn pot will be consumed and the fire will go out. Matching the amount of air required for proper combustion to the fuel rate is the primary objective in effectively burning pellets of various brands and qualities in your stove. The air to fuel ratio can be adjusted to allow almost any fuel quality to burn effectively by following the procedures detailed in the remainder of this manual. Because a forced draft pressure is required for the combustion process inside your stove, it is extremely important that the exhaust system be properly installed and maintained. And, that when operating your stove, you make sure that the viewing door is properly sealed. 4 Digit Display FIGURE 10 DIGITAL CONTROL PANEL Up / Down Buttons : Heat Range Room Fan Auto Mode Draft Fan... -

Page 14: Control Panel Overview

Control Panel Overview Turning the heater ON/OFF, as well as adjustments for the fuel feed rate and room fan speed are performed by pressing the appropriate button(s) on the control panel which is located on the lower left-hand side of your heater. This unit can be changed between an automatic operation or a manual operation. The controller comes default in the automatic mode. • ON/OFF Pressing the “ON” button on the control panel will begin the start-up sequence for the heater. Fuel will begin to feed through the auger feed system then ignite after approximately 5 minutes. Pressing the “OFF” button on the control panel will cause the heater to enter its shut-down sequence. The fuel feed system will stop pulling fuel from the hopper and, once the fire goes out and the heater cools down, the fans will stop running. • HEAT RANGE Pressing the “Heat Range” arrows, up or down, will adjust the amount of fuel being delivered to the burnpot. • DRAFT FAN The draft fan (exhaust) will come on as soon as the “ON” button is pressed. The fan will automatically adjust its speed in accordance to the heat range setting. However, this speed can be manually operated by pressing the “Draft Fan” arrows up or down. “Draft Fan” when pressed, the display will show “Df-A”, which is automatic. Press the arrows again to adjust fan speed. When the heater is in the manual mode, the optional thermostat will not properly control the unit. When adjusting the Draft Fan setting, try only 1 setting above or below the heat setting. It is better to leave the stove in the automatic mode. • ROOM FAN The room fan will come on once the unit has reached operating temperature. By pressing the “Room Fan” buttons, the display will show “Rf-A” which is automatic or “Rf-1” through “Rf-9” for manual settings. In auto mode, the room fan’s speed will automatically be adjusted in accordance with the heat range setting. By pressing the “Room Fan” up arrow, you can adjust the fan speed setting up to “Rf-9”. The room fan must operate at a level greater than or equal to the heat range setting. • AUX - USED TO RETURN THE STOVE TO THE FACTORY SETTINGS To return the stove to it’s original factory settings, press and hold the AUX UP and AUX DOWN buttons simultaneously for 3 seconds. • AUGER DELAY The “Auger Delay” button can be used to pause rotation of the Auger for approximately 1 minute. This can be cancelled by pressing the “ON” button. The “Auger Delay” is normally used only during the start up cycle to slow... -

Page 15: Operation

Operation UNIT PREPARATION After carefully unpacking and reading the instructions for installing your stove, you will need to perform the following steps: • Attach the included spring handle to the door handle by screwing it on in a respective location. • Attach the electrical cord to the back of the stove first; then plug it into a 110-volt outlet (an outlet surge protector is highly recommended). PERFORMING AN INITIAL TEST This test is used at the factory where the stoves are assembled to test the functionality of the control and the stove before the unit is shipped. To perform this test, press and hold the OFF and AUGER DELAY buttons simultaneously for 3 seconds. To advance through the test, press any key unless otherwise noted in the test step. 1.) Exhaust Fan Output Test – The display will show “drft”. The exhaust fan is turned on full then reduced to a level just above the typical minimum pressure switch setting. The ON LED indicates whether the pressure sensor is detected. If the pressure switch is not detected, the fan ramps to full on for two seconds then returns to the previously established level if the pressure switch closes. If the Draft Fan Fuse is not blown and the fuse detection circuit is functioning, the Draft Fan LED will be lit and the other three top row LEDs will be off. 2.) Room Fan Output Test - The display will show “rfan”. The room fan is turned on full. If the Room Fan Fuse is not blown and the fuse detection circuit is functioning, the Room Fan LED will be lit and the other three top row LEDs will be off. 3.) Ignitor Output Test - The display will show “ignt”. The ignitor motor is turned on full. If the Ignitor (AUX) Fuse is not blown and the fuse detection circuit is functioning, the Aux LED will be lit and the other three top row LEDs will be off. 4.) Auger Output Test - The display will show “augr”. The auger motor is turned on full. If the Auger Fuse is not blown and the fuse detection circuit is functioning, the Heat Range LED will be lit and the other three top row LEDs will be off. 5.) Hopper Switch Test – The display will show “hppr”. The “ON” LED is lit. If the hopper switch is open (lid is open), the “HEAT RANGE” LED will turn on. If the lid is closed, the “HEAT RANGE” LED will be off. 6.) Thermostat Input Test – The display will show “stat”. If the thermostat input is closed, the ON LED will turn on, otherwise it will be off. 7.) Flue gas Thermistor Test – The display will show the flue gas temperature in degrees F. -

Page 16: Start-Up Procedure

Operation START-UP PROCEDURE DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE - Never use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid, or similar liquids to start or “freshen up” a fire in this stove. Keep all such liquids well away from the stove while it is in use. -

Page 17: Daily Operation

Operation DAILY OPERATION The hopper and stove top will be hot during operation; therefore, you should always use some type of hand protection when refueling your stove. Never place your hand near the auger while the stove is in operation. This unit should be filled when the hopper level drops below 3-inches. -

Page 18: Maintenance

Maintenance INTERIOR CHAMBERS Periodically remove and clean the burnpot and the area inside the burnpot housing. In particular it is advisable to clean out the holes in the burnpot to remove any build up that may prevent air from moving through the burn pot freely. Remove the two(2) plates on each side of the burnpot housing and clean out that rear chamber. If a vacuum is used to clean your stove, we suggest using a vacuum designed for ash removal. Some regular vacuum cleaner (i.e. shop vacs) may leak ash into the room. ASH DISPOSAL Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes should be placed on a noncombustible floor or on the ground, well away from all combustible materials, pending final disposal. If the ashes are disposed of by burial in soil or otherwise locally dispersed, they should be retained in the closed container until all cinders have been thoroughly cooled. The container shall not be used for other trash or waste disposal. CHECK AND CLEAN THE HOPPER Check the hopper periodically to determine if there is any sawdust or pellets that are sticking to the hopper surface. Clean as needed. DOOR AND GLASS GASKETS Inspect the main door and glass window gaskets periodically. The main door may need to be removed to have frayed, broken, or compacted gaskets replaced by your authorized dealer. The glass gasket has a gap at the bottom for the airwash. BLOWER MOTORS Clean the air holes on the motors of both the exhaust and distribution blowers annually. Remove the exhaust blower from the exhaust duct and clean out the internal fan blades as part of your fall start-up. PAINTED SURFACES Painted surfaces may be wiped down with a damp cloth. If scratches appear, or you wish to renew your paint, contact your authorized dealer to obtain a can of suitable high-temperature paint. GLASS - Cleaning, Removal and Replacement of Broken Door Glass Cleaning - We recommend using a high quality glass cleaner. Should a build up of creosote or carbon accumulate, you may wish to use 000 steel wool and water to clean the glass. DO NOT use abrasive cleaners. DO NOT perform the cleaning while the glass is HOT. ,... -

Page 19: Trouble Shooting

Trouble Shooting Disconnect the power cord before performing any maintenance! NOTE: Turning the ON/OFF Switch to ”OFF” does not disconnect all power to the electrical components of the stove. Never try to repair or replace any part of the stove unless instructions for doing so are given in this manual. All other work should be done by a trained technician. -

Page 20: Error Codes & Display Indicators

Error Codes and Display Indicators Error Error Possible Code Descrption Causes Err1 The high limit temperature sensor • Inadequate ventilation. has tripped. • Room fan failure. • Exhaust Blockage. • Electrical Open in wiring. Err2 Stove ran out of fuel during normal • Hopper Empty. operation. • Auger output failure or jam. • Flame of fuel quality caused fire to burn too slowly or go out. • Electrical Open in wiring. Err3 The stove was unable to reach the • Flame or Fuel quality caused the fire to burn too slowly or go Room Fan On temperature within the out. -

Page 21: Repair Parts Diagram/List

Parts Diagram/List models 5500, 5500M & 5500XL Model 5500 PARTS LIST Item Part No. Title Qty. Item Part No. Title Qty. 25490 Door Weldment 88087 Glass Gasket 3.75 ft 891166 Ceramic Glass 83297 8-32 Hex Nut 891188 Glass Retainer, Top 83547 Washer 891186 Glass Retainer, Bottom 83903 Spring 25517 Handle, Door 83546... - Page 22 Parts Diagram model 5500, 5500M and 5500XL Note: All repair parts (other than Cabinet Sides, Hopper Assy., and Door Assy.) are same for models 5500, 5500M and 5500XL. USSC...

- Page 23 Parts List model 5500/5500M/5500XL PARTS LIST Item Part No. Title Qty. Item Part No. Title Qty. 86624 Burnpot Assembly 80473 Blower, Exhaust 86625 Housing Assy, Burnpot 88118 Gasket, Igniter Flange 86628 Weldment, Exhaust Duct 891169 Hose, Heater 1.5in 86633 Weldment, Igniter Tube 891141 Auger 80481 Igniter Cartridge 80488 Drive Motor 25506 Weldment, Door Hinge 83529 Hairpin...

-

Page 24: Wiring Diagram

ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN IN THIS LIST: 1. THE PART NUMBER 2. THE PART DESCRIPTION 3. THE MODEL NUMBER:____________________ 4. THE SERIAL NUMBER:____________________ United States Stove Company 227 Industrial Park Road P.O. Box 151 South Pittsburg, TN 37380 (800) 750-2723 WWW.USSTOVE.COM...

Need help?

Do you have a question about the 5500 and is the answer not in the manual?

Questions and answers