Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Bacharach MultiZone

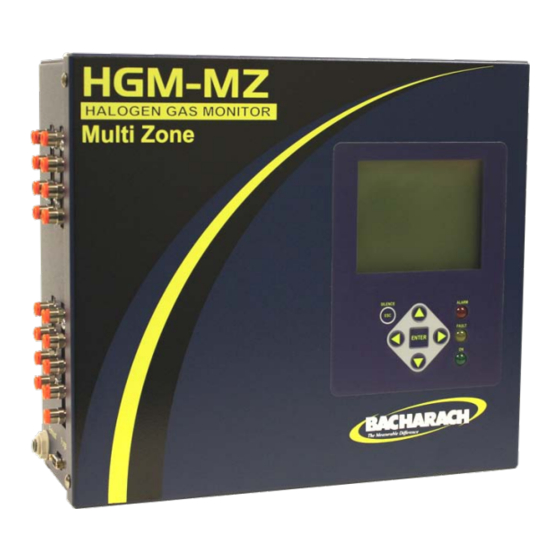

- Page 1 MultiZone Gas Monitors • HGM-MZ (Halogen) • AGM-MZ (Ammonia) • CO2-MZ (Carbon Dioxide) Installation • Operation • Maintenance UL 61010-1 CAN/CSA 22.2 No. 61010.1 EN 14624 Instruction P/N: 3015-5074 Rev. 11 August 2013 Product Leadership • Training • Service • Reliability...

- Page 2 Bacharach Inc.’s reasonable satisfaction to have been defective; provided that written notice of the defect shall have been given by Buyer to Bacharach Inc. within two (2) years after the date of delivery of this Product by Bacharac h, Inc.

-

Page 3: Table Of Contents

Multi-Zone Gas Monitors Table of Contents SECTION 1. INTRODUCTION......................1 1.1. About This Manual ........................1 1.2. Warnings and Cautions ......................1 1.3. Safety Precautions ........................1 1.3.1. Hazardous Areas ......................1 1.3.2. Combustible and Flammable Gases ................2 1.3.3. AC Power Supply ......................2 1.3.4. Protective Grounding .....................2 1.3.5. - Page 4 Multi-Zone Gas Monitors 2.8.2. Saving and Sending Programs ..................20 2.8.3. Trend Data ........................20 2.8.4. Converting the TRE ND Text File to a Microsoft Excel File ..........20 2.8.5. Saving and Printing Screens and Logs ................20 2.8.6. USB Type Laptops .......................20 2.9. Optional Current Loop Interfaces ....................21 2.9.1.

- Page 5 Multi-Zone Gas Monitors 4.4.1. Functional Overview ....................33 4.4.2. Responding to Alarms ....................34 4.4.3. Alarm Detail Screen .....................34 4.4.4. Acknowledging Alarms ....................35 4.4.5. Silencing an Alarm .......................35 4.4.6. Clearing the Alarm E vent Log ..................36 4.5. System Faults .........................36 4.5.1. Functional Overview ....................36 4.5.2.

- Page 6 Multi-Zone Gas Monitors B.3.17. Fault Log Register 0x1900-01 (6400-6401 Dec ) (R, 302 Bytes) ........62 B.3.18. Flow Log Register 0x001F (31 Dec ) (R, 142 Bytes)............62 B.3.19. Alarm Log Register 0x1A 00-02 (6656-58 Dec) (R, 582 Bytes).........62 B.3.20. Service Mode Register 0x001B (27 Dec) (W, 10 Bytes) ..........63 B.3.21.

-

Page 7: Section 1. Introduction

SECTION 1. INTRODUCTION 1.1. About This Manual Thank you for investing in a Bacharach Multi-Zone Gas Monitor. To assure operator safety and the proper use of the monitor please read this manual. It provides important information on the installation, operation, maintenance, and servicing of the monitor and display module. -

Page 8: Combustible And Flammable Gases

Always remove A C power before opening the monitor’s enclosure. WARNI NG: The protection provided by the monitor may be impaired if the monitor is used in a manner not specified by Bacharach, Inc. Modifications to this monitor, not expressly approved, will void the warranty. -

Page 9: Misuse And Modifications To The Instrument

Avoiding significant loss reduces equipment replacement costs, maintains equipment efficiency, promotes safety, and protects the environment. The Bacharach Multi-Zone Monitor provides continuous monitoring of gas levels in up to 16 separate test zones. The instrument is easily programmed to monitor a variety of gases (dependent on particular model) and independent leak (small), spill (medium), and evacuation (large) levels may be designated for each zone. -

Page 10: Communications Options

You can reduce nuisance alarms and needless service calls if the alarm levels are set at practical limits. Bacharach has developed recommended monitoring refrigerant gas levels based on compliance to ANSI/BSR ASHRAE 15-2007 and ASHRAE Safety Code 34-2007. -

Page 11: Locating A Remote Display (Optional)

Multi-Zone Gas Monitors DO NOT block any of the zones. Unused zones may be disabled by setting the distance parameter to zero feet in the zone setup screen. The MZ monitor should be centrally located in the mechanical room and be readily accessible for easy visual monitoring and servicing. -

Page 12: Specifications

Multi-Zone Gas Monitors NOTE: The pickup points located on the floor in the above illustration are examples for refrigerants which are heavier than air. Placement of pickup points should be determined based on characteristics of the gas being monitored and ambient conditions of the sampling area. - Page 13 Multi-Zone Gas Monitors General Multi-Zone Specifications Coverage 4 point standard, expandable to 16 points in 4 point increments Detector Type Infrared Non-Dispersive 3 Indicator lights: • Green Monitor is powered on. LED glows during normal operation; flashes when unit is in warm-up mode Front Panel •...

-

Page 14: Section 2. Installation

Open the enclosure and inspect the interior of the monitor for loose components that may have become dislodged during shipment. If damage is discovered, please contact the nearest Bacharach Service Center for assistance. 2.1.3. -

Page 15: Overview

Multi-Zone Gas Monitors The enclosure utilizes keyhole mounting brackets designed for ¼ inch fasteners. Locate the four screws as shown in the diagram below or by using the provided mounting template (P/N 3015-5109). Allow the screw heads to protrude approximately ¼ inch. Figure 2-1. -

Page 16: Connecting Gas Sample Lines

To connect the air lines to the monitor simply push the tubing firmly onto the connector. To remove a line, press the plastic ring on the connector with one hand, then withdraw the tube with your other hand. See below. The MultiZone monit or uses push- to-connect (PTC) style connectors. To insert sample lines, firmly push... -

Page 17: Connecting P Urge Line

Multi-Zone Gas Monitors with the Halogen Gas Monitor to filter refrigerant from the purge line. It may be mounted adjac ent to the monitor. A line-end filter (P/N 3015-3420) should be attached to the end of the purge line when the charcoal filter is not used. -

Page 18: Installing An Optional Splitter Kit

These kits are designed for use ONLY in confined/defined spaces with high potential for leaks, such as food cases, cold rooms, refrigeration rack rooms, etc. Bacharach’s 2-way (P/N 3015-5404) and 3-way (P/N 3015-5405) splitter kits are available as optional accessories. Refer to instruction 3015-5415 (supplied with the kit) for detailed installation instruction. -

Page 19: Interior Components

NOTE: The plastic cable ties surrounding the air pump are to ensure safe handling during shipping. Please remove before operation. Reinstall a plastic cable around the air pump if the unit is shipped to Bacharach, Inc. for service or repair. This prevents damage during shipping. - Page 20 Multi-Zone Gas Monitors WARNI NG: Copper conductors for connection to supply mains must be made in accordance with NEC/ CEC and local codes. WARNI NG: The AC power ground wire must first be connected to the monitor’s ground stud. Under no circumstances should this monitor be operat ed without a protective ground. Doing so poses a potential shock hazard, and is also a violation of electrical safety standards applicable to this type of equipment.

-

Page 21: Connecting Communications Devices

Multi-Zone Gas Monitors 2.5. Connecting Communications Devices 2.5.1. Remote Display Module (RD) Connection The MZ is connected to the optional RD using a shielded twisted pair instrument cable. The maximum distance between the farthest MZ and RD is 4500 feet. Use any of the remaining service knockouts to gain access to the interior of the monitor. -

Page 22: Changing Terminator Switch Settings

Personal Computer The MZ may be connected to a personal computer using the RS-232 interface on the left side of the enclosure. Software will be provided upon request or as a download from the Bacharach website at http://www.MyBacharach.com/downloads.htm. NOTE: Refer to the “PC Software” section (section 2.8 on page 18) for det ails. -

Page 23: Terminating Multiple Monitors

Multi-Zone Gas Monitors 2.6. Terminating Multiple Monitors Figure 2-8. Termination Settings for a Network of Multiple Monitors and a Remote Display NOTE: For multiple MZs with Remote Display, the last MZ or RD on either end of the network must have its terminator in the “IN” position, and all other units must have their terminat ors in the “OUT”... -

Page 24: Pc Software

Multi-Zone Gas Monitors NOTE: User must have two (2) dedicated ports to successfully complete the required setup. Figure 2-9. Termination Settings for Multiple Monitors Connected to a BMS (Two Trunks) Figure 2-10. Termination Settings for Mul tiple Monitors Connected to a BMS (Daisy Chain) 2.8. - Page 25 Multi-Zone Gas Monitors NOTE: The PC software is not compatible with 64-bit (or newer) computers. NOTE: The PC software uses COM1 by default. Therefore, the interface cable should be connected to the port configured as COM1 on the PC. Also, no other soft ware drivers or devic es in the computer may control COM1 when the MZ software is in use.

-

Page 26: Saving And Sending Programs

Multi-Zone Gas Monitors IMPORTANT: When a modified parameter (zone, system, or calibration) is sent to the MZ monitor, please wait for the computer software to indicate that the download is complete before continuing with any further edits. 2.8.2. Saving and Sending Programs •... -

Page 27: Optional Current Loop Interfaces

Multi-Zone Gas Monitors 2.9. Optional Current Loop Interfaces NOTE: The two-output, current loop interface is an option that MUS T be ordered separately. 2.9.1. Optional 4–20 m A DC Outputs Upon installation of the optional 4–20 mA DC Interface Board (P/N 3015-5152), the MZ has the capability of providing dual 4-20 mA DC scrolling current loop outputs for connection to external monitoring devices (e.g., a local loop-powered display or a building management system [BMS]). -

Page 28: Ma Dc Connections

Figure 2-11. Optional Dual 4-20 m A DC Output Board for the MultiZone CAUTION: The loop outputs have isolated grounds. Therefore the cable shield should be terminat ed at the receiver and not the MZ monitor. -

Page 29: Connecting External Alarms

Multi-Zone Gas Monitors Figure 2-12. Optional Dual 4-20 m A DC Output Board and Connector 2.10. Connecting External Alarms 2.10.1. Overview The MZ monitor includes four SPDT relays whose contacts are rated 2 A at 250 VAC (inductive) and 5 A at 250 VAC (resistive). - Page 30 Multi-Zone Gas Monitors Jumper the “Live/Positive” line of an external power source (DC devices) or the monitor’s AC input (AC devic es) to the “Common” terminal on the relay connector. Connect the “Live/Positive” end of the strobe or horn to the “NO” terminal of whichever level of alarm is appropriate for the application.

-

Page 31: Section 3. Setup Programming

Multi-Zone Gas Monitors SECTION 3. SETUP PROGRAMMING 3.1. Initial Power Up When the MZ monitor is powered up, all front panel LEDs will illuminate and a splash screen will appear, displaying the monitor’s firmware version level. Note that on CO models, a “Clearing Purge Line”... -

Page 32: Location

Multi-Zone Gas Monitors Figure 3-3. HGM System Setup Screen #2 3.4.1. Location This is the name you assign to the MZ monitor to identify its location. It may have up to 12 alphanumeric characters. 1. Press the ENTER key to adjust the setting. 2. -

Page 33: Zone Hold

Multi-Zone Gas Monitors 3.4.5. Zone Hold Sets the length of time a zone will be monitored when the zone hold feature is activated. The default is 15 minutes. The range is 1 to 999 minutes. 1. Press the ENTER key to adjust this setting. 2. -

Page 34: Re-Zero Mode

Multi-Zone Gas Monitors 3.4.9. Re-Zero Mode This parameter defines the frequency at which the instrument re-zeros the optical sensor. 1. Press the ENTER key to adjust the setting. 2. Use the UP/ DOWN cursor keys to toggle bet ween settings. AUTO Sets the instrument to re-zero every 10 minutes. -

Page 35: Additional Service Features

“inactivity” timer that is reset every time a key is pressed. When the timer reaches zero, password access is enabled. To enable password prot ection sooner, cycle power on the MultiZone. When password protected, a password entry is required in order to view screens other than the SYSTEM or ZONE VIEW screen. -

Page 36: Node Address

Multi-Zone Gas Monitors 3.6.3. Node Addre ss Each monitor on the network must has a distinct node address. The node address may be set from 1 to 64. 1. Press the ENTER key to adjust the setting. 2. Use the LEFT/ RIGHT cursor keys to move across the entry field and the UP/DOWN cursor keys to modify the individual numbers. -

Page 37: Section 4. General Operation

Multi-Zone Gas Monitors SECTION 4. GENERAL OPERATION 4.1. Functional Overview Normally each MZ monitor will sequentially perform measurements on its active zones without user input. The total time it takes a MZ monitor to complete a measurement cycle is directly proportional to the number of active zones and the physical length of the air lines. -

Page 38: Distance

Multi-Zone Gas Monitors 4.2.3. Di stance + EXH This parameter defines the combined length of the sample tubing plus any tubing on the exhaust port. Total length should not exceed 1200 ft. 1. Press the ENTER key to adjust the setting. 2. -

Page 39: Leak Level

Multi-Zone Gas Monitors 4.3.1. Leak Level This is the concentration level in PPM that will activate a leak alarm condition. 1. Press the ENTER key to adjust the value. 2. Use the UP/ DOWN cursor keys to modify the setting. 3. -

Page 40: Responding To Alarms

Multi-Zone Gas Monitors 4.4.2. Responding to Alarms An operator can respond to the alarms by accessing the Alarm Summary Screen. Navigate to this screen by selecting ALARM on the first (Data Display) screen. Figure 4-3. Alarm Summary Screen The Alarm Summary Screen displays a list of all alarm conditions pending across the network. The screen is divided into 8 boxes, and each box represents a single alarm. -

Page 41: Acknowledging Alarms

Multi-Zone Gas Monitors This screen provides the following navigation options at the bottom of the display: Using the left arrow key, acknowledges the alarm as described in the next section SETUP Using the right arrow key, navigate to the Zone Setup Screen #1. This enables review of the zone setup paramet ers and access to the Trend Screen. -

Page 42: Clearing The Alarm Event Log

Multi-Zone Gas Monitors 4.4.6. Clearing the Alarm Event Log A data log of the last 20 alarm events is retained in memory. • From the Data Display Screen, press the UP or DOWN arrow key. SETUP will be highlighted in the first box. -

Page 43: Navigating To The Fault Screen

Multi-Zone Gas Monitors 4.5.2. Navigating to the Fault Screen Displayed on the initial Data Display Screen is a Fault option. Scroll down with the cursor key and select this option, which will introduce you to the Fault Screen. Figure 4-7. Fault Screen 4.5.3. -

Page 44: Non Critical Faults

Multi-Zone Gas Monitors 4.5.4. Non Cri tical Faults Fault Code Description / Possible Causes Enclosure’s internal temperature is outside normal range (or IR sensor has BOX TEMP FAULT <0001> failed). Check the installation to verify that the monitor is not being subjected to extreme temperatures. -

Page 45: Viewing Fault Log

Multi-Zone Gas Monitors 4.5.7. Viewing Fault Log A data log of the last 20 fault conditions is retained in memory. On the Fault Screen, select the LOG option to view a display of the fault log. Figure 4-8. Fault Log Screen This screen lists potential fault conditions in the left column and displays a check mark indicating which problems were associated with each fault condition as represented by the vertical cursor bar. -

Page 46: The Trend Screen

Multi-Zone Gas Monitors This screen lists the zones in the left column and displays flow data. Use the UP/DOWN buttons to scroll through the zones and the LEFT/RIGHT to scroll through the log data. As you move the bar horizontally, the date and time of the condition is displayed in the upper right hand corner. -

Page 47: Navigating To The Calibration Screen

Multi-Zone Gas Monitors IMPORTANT: Changing information on CAL FA CTOR will void the factory calibration. Typically, the unit will remain within the factory-calibrated accuracy indefinitely and no calibration is required. Complex soft ware algorithms adjust for temperat ure drift, IR source aging, and pressure changes in order to keep the unit within factory accuracy specifications. -

Page 48: Co 2 Atmospheric Concentration

ENTE R, and use the UP/DOWN arrow keys to enter the calibration factor. The selection of the matching gas and CAL factor is performed by Bacharach by analyzing the new gas. Once the matching gas is determined, field calibration is possible by using the same procedure as for other gases. When the new gas entry is complete simply setup the appropriate zone for CUS TOM. -

Page 49: Zone Hold Mode

2. Select the CUS TOM option. Press ENTER to accept the new entry or ESC to revert to the previous setting. 3. Enter the new CAL Factor as received from Bacharach. 4.8. Zone Hold Mode A zone can be placed on hold and continuously monitored for a length of time determined by the Zone Hold Time value. -

Page 50: The Diagnostic Screen

Multi-Zone Gas Monitors 4.9. The Diagnostic Screen 4.9.1. Navigating to the Diagnostic Screen On the System Setup screen, select the Diagnostic option (DIAG). Figure 4-14. Diagnostic Screen P/N: 3015-5074 Rev 11... -

Page 51: Diagnostic Screen Overview

Multi-Zone Gas Monitors 4.9.2. Diagnostic Screen Overview The Diagnostic Screen contains sensor data and status information useful for trouble shooting various fault conditions. An explanation of the information provided on each line of this screen is listed below, including normal operating ranges. Field Name Description xxxx FEET... - Page 52 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

-

Page 53: Section 5. Maintenance

Multi-Zone Gas Monitors SECTION 5. MAINTENANCE WARNI NG: Shock hazard! Always disconnect AC power before opening the enclosure of the monitor. WARNI NG: The A C power ground wire must first be connected to the monitor’s ground stud. Under no circumstances should this monitor be operated without a protective ground. -

Page 54: Replacement Parts And Optional Accessories

Number Battery: Panasonic CR2032, 3V 0204-0020 Warning: In compliance with agency approvals & safety regulations, the battery must be replaced with the specified Bacharach replacement part. Filter: Charcoal, Zero Air 3015-3125 Filter: Hydrophobic (Internal) 0007-1650 Filter: End of Line – Assembly (Termination/gas sample line) - Page 55 Multi-Zone Gas Monitors Part Item Description Number ¼” to 6 mm Reducer Kit (10) 3015-5389 (10) ¼” to 6 mm Reducer Kit (8) 3015-5390 (8) IR Bench Replacement Kit (HGM) 3015-4572 IR Bench Replacement Kit (AGM) 3015-4492 IR Bench Replacement Kit (CO 3015-4562 Universal Power Supply 3015-5523...

-

Page 56: Troubleshooting

Multi-Zone Gas Monitors Part Item Description Number 12 Zone (13 line end filters, 1 charcoal filter, 1 hydrophobic, 3 end-of-line water stop filters) 3015-5527 16 Zone (17 line end filters, 1 charcoal filter 1 hydrophobic 3 end-of-line water stop filters) 3015-5528 Gases R-22 Gas Cylinder, 100 PPM... - Page 57 Multi-Zone Gas Monitors DIGIP OT= IR VOLT= 4.21 V= 4.7 MA= 96 R= 49 Figure 5-1. Sample DIGIPOT Readings 8. Scroll to “DE T DIGIPOT” option (see above) and press ENTER. 9. Use the UP and DOWN arrows to adjust the IR VOLT reading to 4.20 (or as close as possible). When at the proper value, press ESC once.

- Page 58 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

-

Page 59: Appendix A. Recommended Refrigerant Gas Alarm Settings

Multi-Zone Gas Monitors APPENDIX A. RECOMMENDED REFRIGERANT GAS ALARM SETTINGS Alarm Settings (PPM) Alarm Settings (PPM) Leak Spill Evacuate Leak Spill Evacuate /R-744 1500 2000 3000 R245FA FA188 R401A FC72 R402A H1301 R402B H1211 R404A H2402 R407A H1234YF R408A R407C N1230 R409A /R-717... - Page 60 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

-

Page 61: Appendix B. Rs-485 Communications Protocol

The following instructions are intended as a guide for integrating the MZ network into a Building Management System. If you are unfamiliar with complex systems of this type, it is recommended that you contact Bacharach for technical assistance. B.2. MODBUS RTU Protocol The MZ monitor communicates with master devices (such as the Remote Display or a Building Management System) over the RS-485 serial interface. -

Page 62: Mz Monitor Polling

Multi-Zone Gas Monitors the preset multiple register function. If the transaction is successful, the MZ monitor sends the appropriate MODBUS response. It is the responsibility of the master device, when making modifications, to insure that all parameters transferred are within the working limits of the MZ. IMPORTANT: Each time paramet ers are modified and sent back to the monitor using function 16 (preset multiple registers), the new values are written to the monitor's non- volatile FLASH memory. -

Page 63: Summary Of Registers

Multi-Zone Gas Monitors Parameter Description Stop Bits Default is 1. Can be set for 2 via System data register. 4000 ms when directly accessing the MZ monitor. Ma ximum Response Time 8,000 ms when accessing the MZ monitor through the RD. Error Checking CRC per MODBUS specifications NOTE: All data sent out from the MZ is in “little endian”... -

Page 64: System Data Register 0X0010 (16 Dec) (R/W, 54 Bytes)

Multi-Zone Gas Monitors B.3.7. System Data Register 0x0010 (16 Dec) (R/W, 54 Bytes) Variable Type Length Description Type 2 bytes Indicates EEPROM has been initialized if value = 300 DO NOT MODIFY Float 4 bytes Firmware Rev Level DO NOT MODIFY UNUSED 2 bytes Firmware Serial Number DO NOT MODIFY... -

Page 65: Fault Code Table

Multi-Zone Gas Monitors B.3.9. Fault Code Table Fault Type Code Description CLIPPING FAULT 0x8000 0x8000 Sensor output voltage too high ZERO RANGE FAULT 0x4000 Sensor output voltage outside limits during purge OVER R ANGE FAULT 0x2000 Gas concentration above measurable range PURGE FLOW FAULT 0x1000 No flow detected during purge cycle... -

Page 66: Alarms And Alarm Acknowledge

Multi-Zone Gas Monitors NOTE: Refer to the Recommended Alarm Settings & Gas Enumeration table on page 53. NOTE: Time Structure Format consists of 13 unsigned character types. They are 1 second digit, 10 second digit, 1 minute digit, 10 minute digit, 1 hour digit, 10 hour digit, 1 day digit, 10 day digit, 1 month digit, 10 month digit, 1 year digit, 10 year digit, last byte is unused. -

Page 67: Sensor Data Register 0X0016H (22 Dec) (R, 82 Bytes)

Multi-Zone Gas Monitors B.3.13. Sensor Data Register 0x0016h (22 Dec) (R, 82 Byte s) Variable Type Length Description Pressure Float Manifold Pressure is PSIA P_Volts Float Pressure sensor output Voltage Vacuum_P Float Pressure with all value closed and pump on in PSIA Ambient_P Float Absolute Ambient Pressure in PSIA... -

Page 68: Fault Log Register 0X1900-01 (6400-6401 Dec ) (R, 302 Bytes)

Multi-Zone Gas Monitors 2. Modify the content of the status register to change the MODE parameter to normal mode. Active zone parameter to the zone which you would like to resume normal activity on 3. Send this updated status register structure back to the MZ using PRESE T MULTIPLE REGIS TE R COMMA ND to the RELEASE HOLD REGIS TER (0x0017h). -

Page 69: Service Mode Register 0X001B (27 Dec) (W, 10 Bytes)

Multi-Zone Gas Monitors B.3.20. Service Mode Register 0x001B (27 Dec) (W, 10 Byte s) Variable Type Length Description Rel_Svc_Mode See description of STATUS REGISTER B.3.21. Release Service Mode 0x001C (28 Dec) (W, 10 Byte s) Variable Type Length Description Ent Svc_ Mode See description of STATUS REGISTER B.3.22. -

Page 70: Modb Us Exception Responses

Multi-Zone Gas Monitors Variable Type Length Description Index Point to current reading Time record for each of the 100 log points. The format for the TIM type is Time 1300 defined in note 2 of zone data Last 100 log points (2 byes per point) B.3.25. -

Page 71: Appendix C. System Menu Map

Multi-Zone Gas Monitors APPENDIX C. SYSTEM MENU MAP P/N: 3015-5074 Rev 11... - Page 72 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

-

Page 73: Appendix D. Agency Approvals

Multi-Zone Gas Monitors APPENDIX D. AGENCY APPROVALS P/N: 3015-5074 Rev 11... - Page 74 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

- Page 75 Multi-Zone Gas Monitors European Standard EN14624: 2005 testing wit h R-134a (Halogen Gas Monitor Only). Min. Sensitivity Threshold 1 ppm Max. Sensitivity Threshold (wit hin 1 ppm ± 10% reading accuracy range) 1,000 ppm Max. Sensitivity Threshold within Instrument Reading Range 10,000 ppm Zeroing Time from 1,000 ppm* <12 seconds...

- Page 76 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

-

Page 77: Appendix E. Service Centers

20 Amber Street Unit #7 Markham, Ontario L3R 5P4 Canada Phone: 905-470-8985 Fax: 905-470-8963 Email: support@BachCan.ca Europe Murco Limited – a Bacharach Company 114a Georges Street Lower Dun Laoghaire Co. Dublin Ireland Phone: 353 1 284 6388 Fax: 353 1 284 6389 Email: sales@murco.ie... - Page 78 Multi-Zone Gas Monitors P/N: 3015-5074 Rev 11...

-

Page 79: Index

Multi-Zone Gas Monitors INDEX 3015-5523............48 NUMBERS 3015-5524............49 3015-5525............49 0007-1650..........47, 48 3015-5526............49 0007-1655.........12, 47, 50 3015-5527............49 0007-1656..........12, 50 3015-5528............49 0007-1657..........12, 50 3015-5530............49 0204-0020............48 3015-5542............49 0304-3235............47 4-20 mA DC outputs/loops....... 13, 38 0304-5111............48 Interface Board........21, 48 04-2620 ............47 204-0020............48 3015-2906.......... - Page 80 Multi-Zone Gas Monitors audible alarm......4, 26, 33, 35, 36 current loop ........... 22, 38 board ............4 fault ............22 isolator............22 Bacharach outputs ..........21, 22 service cent er.......... 3, 9 cycle time .............32 website .............16 battery ............48 replacement schedule........48 shelf life ............48 damage......1, 3, 6, 9, 14, 21, 47...

- Page 81 Multi-Zone Gas Monitors screen ..........37, 39 filter(s) ....iii, 4, 5, 11, 12, 37, 47-50, 59 J5 connector..........13 replacement ..........12 J6 connector..........13 termination ..........12 jumper wire ..........22 firmware version ...........25 flammable liquids ........2, 9 flashing box (alarm condition) ....34, 44 knockout(s) ......

- Page 82 Multi-Zone Gas Monitors receive port ..........44 reducer kit ............48 NEC/ CEC compliance ......13, 14 refrigerant ......... 5, 7, 11, 47, 60 network ..16, 17, 28, 30, 31, 34, 35, 38, 55, 56 monitor vs. analyzer........5 neutral ............13 register address ..........44 no flow on purge ...........37 relays ......

- Page 83 Multi-Zone Gas Monitors set points ............5 length ..........32, 44 setup ............25 removing...........11 menu ............27 restrictions ..........5 setup screen #2 ........28, 38 twisted shielded pair ........15 shipping ........... 9, 13 shock hazard ........2, 3, 14 silence mode ..........35 UL classification..........3 smoke test............6 unused zones ..........12...

- Page 84 Headquarters: 621 Hunt Valley Circle, New Kensington, PA 15068-7074 Toll Free: 800-736-4666 • Tel: +1-724-334-5000 • FAX: +1-724-334-5001 Website: www.MyBacharach.com • E-mail: help@MyBacharach.com Printed in U.S.A. ® Registered Trademark of Bacharach Inc.

Need help?

Do you have a question about the MultiZone and is the answer not in the manual?

Questions and answers