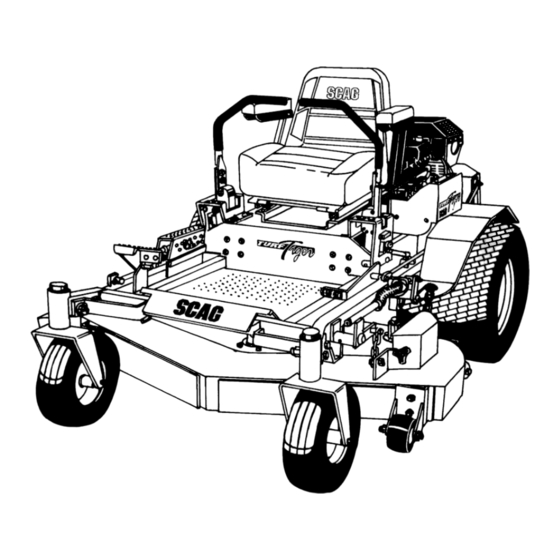

Scag Power Equipment STT Operator's Manual

Stt series

Hide thumbs

Also See for STT:

- Operator's manual (129 pages) ,

- Operator's manual (66 pages) ,

- Operator's manual (76 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Scag Power Equipment STT

- Page 1 MODEL STT PART NUMBER 03092...

- Page 2 WARNING: REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR! Hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper training of the personnel involved in the operation, transport, maintenance, and storage of the equipment.

- Page 3 TABLE OF CONTENTS SUBJECT PAGE Section 1 - General Information Section 2 - Safety Information Section 3 - Specifications ....................... Section 4 - Operating Instructions Section 5 - Troubleshooting Cutting Conditions.............

- Page 4 TABLE OF CONTENTS (CONT'D) SUBJECT PAGE Section 6 - Adjustments Section 7 - Maintenance Section 8 - Replacement Parts...

-

Page 5: General Information

Section 1 GENERAL INFORMATION 1.1 INTRODUCTION 1.2 DIRECTION REFERENCE 1.3 SERVICING THE ENGINE AND DRIVE TRAIN COMPONENTS SERIAL NUMBER PLATE LOCATION 390S0137A Figure 1-1 Tractor Serial Number Plate Location... - Page 6 SYMBOL DESCRIPTION SYMBOL DESCRIPTION 48071S WARNING FALLING HAZARD USE ONLY SCAG APPROVED RIDING ATTACHMENTS SEE OPERATOR'S MANUAL 481109...

- Page 7 SYMBOL DESCRIPTION SYMBOL DESCRIPTION 481039S...

-

Page 8: Safety Information

Section 2 SAFETY INFORMATION 2.1 INTRODUCTION WARNING: CAUTION: 2.2 SIGNAL WORDS 2.3 BEFORE OPERATION CONSIDERATIONS... - Page 9 Section 2 2.3 BEFORE OPERATION CONSIDERATIONS (CONT'D) -NOTE- WARNING: This machine is equipped with an interlock system intended to protect the operator and others from injury. This is accomplished by preventing the engine from starting unless the deck drive is disengaged, the parking brake is on, 2.4 OPERATION CONSIDERATIONS the steering control levers are in the neutral position and the operator is in the seat.

- Page 10 Section 2 2.4 OPERATION CONSIDERATIONS (CONT'D) 2.5 MAINTENANCE CONSIDERATIONS WARNING:...

-

Page 11: Safety And Instructional Decals

Section 2 2.6 SAFETY AND INSTRUCTIONAL DECALS WARNING INSTALL BELT COVER BEFORE OPERATING MACHINE READ OPERATOR'S MANUAL 481039 FORWARD REVERSE 481568 IMPORTANT ADJUSTMENT PROCEDURES READ OPERATOR'S MANUAL FOR MORE DETAILS Check tire pressure- (Drive tires - 12 psi, Caster tires - 25 psi) NEUTRAL ADJUSTMENT Loosen jam nuts Rotate turnbuckle... -

Page 12: Specifications

Section 3 SPECIFICATIONS 3.1 ENGINE 3.2 ELECTRICAL 3.3 TRACTOR... - Page 13 Section 3 3.3 TRACTOR (CONT'D) 3.4 CUTTER DECK 3.6 HYDRAULIC SYSTEM 3.7 WEIGHTS AND DIMENSIONS SMT52A SMT61A SMT72A 3.8 PRODUCTIVITY...

-

Page 14: Operating Instructions

Section 4 OPERATING INSTRUCTIONS CAUTION: Do not attempt to operate this mower unless you have read this manual. Learn the location and purpose of all controls and instruments before you operate this mower. 4.1 CONTROLS AND INSTRUMENT IDENTIFICATION DECK LIFT RIGHT STEERING LEFT STEERING CONTROL... - Page 15 Section 4 DUMP VALVE CONTROL LEVER 390S0141 Figure 4-2 Dump Valve Control 4.2 SAFETY INTERLOCK SYSTEM WARNING: Never operate the mower with the interlock system disconnected or malfunctioning. Do not disengage or bypass any switch; injury to yourself and others or property damage could result.

- Page 16 Section 4 4.5 GROUND TRAVEL AND STEERING -IMPORTANT- 4.4 STARTING THE ENGINE CAUTION: DO NOT USE STARTING FLUIDS. Use of starting fluids in the air intake system may be potentially explosive or cause a “runaway” engine condition that could result in engine damage and/or personal Forward Travel injury.

- Page 17 Section 4 4.6 ENGAGING THE DECK DRIVE (CUTTER BLADES) Reverse Travel CAUTION: Disengage power to the mower before backing up. Do not mow in reverse unless absolutely necessary and then only after observation of the entire area behind the mower. CAUTION: Before backing up, observe behind the mower for persons and obstructions.

- Page 18 Section 4 4.7 HILLSIDE OPERATION WARNING: DO NOT operate on steep slopes. To check a slope, attempt to back up it (with the cutter deck down). If the machine can back up the slope without the wheels slipping, reduce speed and use extreme caution.

- Page 19 Section 4 4.10 REMOVING CLOGGED MATERIAL ROTATING BLADES NEVER PUT YOUR HANDS INTO THE DISCHARGE CHUTE FOR ANY REASON! Shut off the engine and remove the key and only then use a stick or similar object to remove material if clogging has occurred. 4.11 MOVING MOWER WITH ENGINE STOPPED 4.12 RECOMMENDATIONS FOR MOWING...

- Page 20 Section 4 4.13 ADJUSTING CUTTING HEIGHT DECK RELEASE LEVER WARNING: Do not adjust the cutting height with the mower blades rotating. Disengage the power to the cutter blades and then adjust cutting height. 390S0151 Figure 4-7 Deck Release Lever LANYARD PIN HEIGHT ADJUSTMENT PEDAL 390S0140 Figure 4-6 Adjusting Cutting Height...

-

Page 21: Troubleshooting Cutting Conditions

Section 5 TROUBLESHOOTING CUTTING CONDITIONS CAUSE CURE CONDITION Stringers - Occasional Blades of Uncut Grass Width of Deck SGB020 Streaking - Strips of Uncut Grass in Cutting Path Width of Deck SGB018 Streaking - Strips of Uncut Grass Between Cutting Paths Width Width Deck... - Page 22 Section 5 TROUBLESHOOTING (CONT'D) CAUSE CURE CONDITION Uneven Cut on Flat Ground - Wavy High-Low Appearance, Scalloped Cut, or Rough Contour Width of Deck SGB020 Uneven Cut on Uneven Ground - Wavy Appearance, High-LowScalloped Cut, or Rough Contour Width of Deck SGB021 Sloping Ridge Across Width of Cutting Path...

- Page 23 Section 5 TROUBLESHOOTING (CONT'D) CAUSE CURE CONDITION Scalping - Blades Hitting Dirt or Cutting Very Close to the Ground Width of Deck SGB022 Step Cut - Ridge in Center of Cutting path Width of Deck SGB024 Slope Cut - Sloping Ridges Across Width of Cutting Path Width of Deck...

- Page 24 Section 6 ADJUSTMENTS 6.1 PARKING BRAKE ADJUSTMENT WARNING: Do not operate the mower if the parking brake is not operable. Possible severe injury could result. LOOSEN HERE LOOSEN HERE 2" TO 2 1/4" 390S0152 Figure 6-1. Brake Adjustment LOOSEN HERE 1/8"...

-

Page 25: Neutral Adjustment

Section 6 Neutral Adjustment CONTROL LOOSEN HERE LOOSEN HERE 390S0147 390S0149 LOOSEN HERE LOOSEN HERE ADJUST HERE STT99RHCRA ADJUST HERE 390S0146 Figure 6-3. RH Steering Control Rod Adjustment Figure 6-4. LH Steering Control Rod Adjustment... - Page 26 Section 6 Tracking Adjustment CAUTION: Stop the engine and remove the key from the ignition before making any adjustments. Wait for all moving parts to come to a complete stop before beginning work. CAUTION: The engine and drive unit can get hot during operation causing burn injuries.

- Page 27 Section 6 6.6 CUTTER DECK ADJUSTMENTS Cutter Deck Pitch Cutter Deck Level JAM NUT ADJUST HERE CUTTER DECK ADJUSTING BOLT 390S0174 Figure 6-5. Cutter Deck Adjustment...

- Page 28 Section 6 Cutter Deck Height LANYARD PIN CONTROL ROD LOOSEN HERE HEIGHT ADJUSTMENT PEDAL 390S014A Figure 6-6. Cutter Deck Height Adjustment 1/4" DECK STOP 390S0175 Figure 6-7. Cutter Deck Stop...

- Page 29 Section 7 MAINTENANCE 7.1 MAINTENANCE CHART - RECOMMENDED SERVICE INTERVALS HOURS Break-In 40 100 200 500 Procedure Comments (First 10)

- Page 30 Section 7 MAINTENANCE CHART - RECOMMENDED SERVICE INTERVALS (CONT'D) HOURS Break-In 40 100 200 500 Procedure Comments (First 10) 7.2 LUBRICATION - GREASE FITTING LUBRICATION CHART (SEE FIGURE 7-1, PAGE 27) LUBRICATION NO. OF LOCATION INTERVAL LUBRICANT PLACES...

- Page 31 Section 7 GREASE FITTING LUBRICATION LUBRICANT / INTERVAL LITHIUM MP WHITE GREASE 2125 ( 40 HOURS / WEEKLY ) CHASSIS GREASE ( 100 HOURS / BI-MONTHLY ) CHASSIS GREASE ( 200 HOURS / MONTHLY ) CHASSIS GREASE ( 500 HOURS / YEARLY ) 390S0145 Figure 7.1 Lubrication Fitting Points...

- Page 32 Section 7 7.3 HYDRAULIC SYSTEM A. Checking Hydraulic Oil Level B. Changing Hydraulic Oil HYDRAULIC OIL RESERVOIR STT99HOR...

- Page 33 Section 7 C. Changing Hydraulic Oil Filter Element A. Checking Engine Crankcase Oil Level B. Changing Engine Crankcase Oil HYDRAULIC OIL FILTER 390S0155 ENGINE OIL FILTER Figure 7-3 Hydraulic Oil Filter DRAIN PLUG STT99CEC Figure 7-5 Drain Plug and Oil FilterLocation C.

- Page 34 Section 7 7.5 ENGINE FUEL SYSTEM 7.6 ENGINE AIR CLEANER A. Cleaning and/or Replacing Air Cleaner Element To avoid injury from burns, allow the mower to cool before removing the fuel tank cap and refueling. A. Filling the Fuel Tank FUEL FILTER HOSE...

- Page 35 Section 7 7.7 BATTERY WARNING: A. Checking Electrolyte Level and Cleaning Electric storage battery fluid contains Battery sulfuric acid which is POISON and can cause SEVERE CHEMICAL BURNS. Avoid contact of fluid with eyes, skin, or clothing. Use proper protective gear when handling batteries.

- Page 36 Section 7 WARNING: WARNING: BATTERIES PRODUCE EXPLOSIVE GASES. Always wear proper hand and eye protection Charge the battery in a well ventilated when working with cutter blades. space so gases produced while charging can dissipate. WARNING: Do not attempt to straighten a bent blade, and never weld a broken or cracked blade.

- Page 37 Section 7 HEX NUT-TORQUE TO 75 LB-FT ANGLE BLADE BACK DO NOT CUT IN SPINDLE CUTTER SHAFT DECK X MUST NOT EXCEED 1/3 BLADE WIDTH 390S0139 Figure 7-7 Blade Sharpening HEX HEAD BOLT / NUT SPINDLE ASSEMBLY CUTTER BLADE SPACER C.

- Page 38 Section 7 7.11 CUTTER DECK GEARBOX A. Checking Lubricant Level CAUTION: The cutter deck gearbox can reach high operating temperatures. Allow the cutter deck gearbox to cool before servicing. 7.12 KAWASAKI COOLING SYSTEM WARNING: To avoid burns, always allow the engine to cool before removing the radiator cap.

- Page 39 Section 7 7.13 BODY, DECK, AND UPHOLSTERY CAUTION: Do not wash any portion of the equipment while it is hot. Do not wash the engine; use compressed air. B. Cleaning the Radiator Debris Screen CAUTION: To avoid personal injury, always wear safety glasses when using compressed air.

- Page 40 Section 8 52A & 61A CUTTER DECKS 44 61 63 23 68 STT 2001 CD...

- Page 41 Section 8 52A & 61A CUTTER DECKS Ref. Part Ref. Part No. No. Description 52 61 No. No. Description 52 61 43312 Spacer, Outside 461377 Cutter Deck Advantage 43296 Spacer, Inside 461382 Cutter Deck Advantage 481025 Seal, Bottom 04003-04 Bolt, Carriage 5/16-18 x 1" 43297 Spindle Bushing, Bottom 04019-04...

-

Page 42: A Cutter Deck

Section 8 72A CUTTER DECK 44 61 63 23 68 STT-BSG-2001CD... - Page 43 Section 8 72A CUTTER DECK Ref. Part Ref. Part No. No. Description No. No. Description 481025 Seal, Bottom 461384 Cutter Deck, 72” Advantage (Includes Decals) 43297 Spindle Bushing, Bottom 04003-04 Bolt, Carriage 5/16-18 x 1" 481035 Nut, Special 1 - 1/16-18 04019-04 Nut, Hex Serrated Flange 3/8-16 48114-04...

-

Page 44: Cutter Deck Controls

Section 8 CUTTER DECK CONTROLS 37 28 CUTTER DECK STT99CDC... - Page 45 Section 8 CUTTER DECK CONTROLS Ref. Part Description 481549 Spring, Deck Lift 481764 Link, Deck Lift 481765 Rod End, Female - 1/2-20 RH 481766 Rod End, Female - 1/2-20 LH 04020-27 Nut, Jam 1/2-20 RH 04020-28 Nut, Jam 1/2-20 LH 422800 Flatwasher, Spring Stop 481560...

-

Page 46: Sheet Metal Components

Section 8 SHEET METAL COMPONENTS STT 2001 SMC... - Page 47 Section 8 SHEET METAL COMPONENTS Ref. Part Ref. Part Description Description 451079 Fender Weldment, RH 481025 Seal, 2.00 OD. x 1.625 Bore 04001-63 Bolt, Hex Head 5/16-18 x 3-1/2" 04021-07 Nut, Hex Elastic Stop 1/2-13 04017-16 Screw, Hex Serrated Flange 5/16-18 x 3/4" 45934 Yoke Weldment, Caster 04041-11...

- Page 48 Section 8 DECK DRIVE COMPONENTS FRAME STT 2001 DDC...

- Page 49 Section 8 DECK DRIVE COMPONENTS Ref. Part Ref. Part No. No. Description No. No. Description 422594 Belt Guard 481309 Latch, Hood 481531 Hinge, Belt Guard 04010-01 Screw, Phillips Washer Head #10-32 x 1/2" 04003-07 Bolt, Carriage 1/4-20 x 1/2" 04031-01 Lockwasher, #10-32 External Tooth 04019-02 Nut, Hex Serrated Flange 1/4-20...

- Page 50 Section 8 ENGINE AND ATTACHING PARTS - KOHLER ENGINE AND ATTACHING PARTS - KOHLER REF. PUMP MTG. WELDMENT FRAME STT 2K EAP-KH...

- Page 51 Section 8 ENGINE AND ATTACHING PARTS - KOHLER Ref. Part Description 422593 Muffler Guard 04017-05 Screw, Hex Serrated Flange 1/4-20 x 3/4" Muffler, Part Of Engine (Available only through Kohler) 04011-09 Screw, #10-16 x 1/2" 04110-01 U-Nut, 1/4-20 481584 Exhaust Elbow 43421 Spacer, Engine (Kohler) 481758...

- Page 52 Section 8 ENGINE AND ATTACHING PARTS - 22HP KAWASAKI REF. PUMP MTG. WELDMENT FRAME STT 2001 EAP-K...

- Page 53 Section 8 ENGINE AND ATTACHING PARTS - 22HP KAWASAKI Ref. Part Description 451127 Muffler Guard 04017-05 Screw, Hex Serrated Flange 1/4-20 x 3/4" 481982 Muffler 482346 Extension, Oil Drain 04110-01 U-Nut, 1/4-20 43498 Spacer, Engine Bolt 43420 Spacer, Engine (Kawasaki) 481574 Engine, Kawasaki 22KA (Available only through Kawasaki) 04002-03...

- Page 54 Section 8 ENGINE AND ATTACHING PARTS - 23HP &27HP KAWASAKI REF. PUMP MTG. WELDMENT FRAME STT 2001 EAP-23&27KA...

- Page 55 Section 8 ENGINE AND ATTACHING PARTS - 23HP & 27HP KAWASAKI Ref. Part Description 451378 Muffler Guard 04017-05 Screw, Hex Serrated Flange 1/4-20 x 3/4" 482310 Muffler 482351 Extension, Oil Drain 04110-01 U-Nut, 1/4-20 43498 Spacer, Engine Bolt 43420 Spacer, Engine (Kawasaki) 482410 Engine, Kawasaki 23KA (Available only through Kawasaki) 482271...

- Page 56 Section 8 BRAKE AND STEERING COMPONENTS TO RH PUMP TO LH PUMP 61 59 STT99B&SC...

- Page 57 Section 8 BRAKE AND STEERING COMPONENTS Ref. Part Ref. Part No. No. Description No. No. Description 48796 Bushing, Self Align 481599 Grip, Handle Bar 461037 Handle Bar (Includes item 1) 04001-08 Bolt, Hex Head 5/16-18 x 3/4" 04001-32 Bolt, Hex Head 3/8-16 x 1-1/4" 04001-147 Bolt, Hex Head 3/8-24 x 5-1/4", 2-3/4"...

- Page 58 Section 8 KOHLER & KAWASAKI (52” & 61”) FUEL AND HYDRAULIC SYSTEM Dump Valve ENGINE STT99F&HS390S0166...

- Page 59 Section 8 KOHLER & KAWASAKI (52” & 61”) FUEL AND HYDRAULIC SYSTEM Ref. Part Ref. Part No. No. Description No. No. Description 48811 Hose, 3/8" ID. Pushlock-16.0" (order by inch) 48551 Pump, Sunstrand BDP-10L117 481507 Insert, Filler Neck 48811 Hose, 3/8" ID. Pushlock-38.0" (order by the inch) 04001-01 Bolt, Hex Head 1/4-20 x 3/4"...

- Page 60 Section 8 27KA - 72” CUTTER DECK, FUEL AND HYDRAULIC SYSTEM TO "G" TO "H" TO "F" TO "I" 50 49 TO "E" CARB. TO "D" 50 48 TO "G" TO "F" TO "H" TO "B" TO "C" TO "I" To A 2001- STT2727KA-FHS...

- Page 61 Section 8 27KA - 72” CUTTER DECK, FUEL AND HYDRAULIC SYSTEM Ref. Part Ref. Part No. No. Description No. No. Description 48657 Pad, Rubber 422475 Rear Cover 48350-05 Elbow, 90 Degree, 7/8-14 THD 04003-12 Bolt, Carraige 5/16-18 x .75” 48938-02 Bushing, 7/8-14 JIC x 3/4-16 O-Ring 04001-03 Bolt, Hex Head 1/4-20 x 2.0”...

- Page 62 Section 8 ELECTRICAL SYSTEM (KOHLER) STT 2001 ESKH...

- Page 63 Screw, Phillips Washer Head #10-32 x 1-1/2" 04031-03 Lockwasher, 5/16" External Tooth 04002-12 Bolt, Hex Head M8-1.25 x 20 482313 Electronic Module 481751 Wire Harness, STT * Common hardware which should be purchased locally. All bolts Grade 5 plated, all other fasteners zinc plated.

- Page 64 Section 8 ELECTRICAL SYSTEM (22HP KAWASAKI) ELECTRICAL SYSTEM (KAWASAKI) STT99ESKA...

- Page 65 Electronic Module 481752 Wire Harness, STT-KA 481670 Sending Unit, Water Temp. 48030-11 Clamp, Cable 481183 Water Temp. Gauge (STT - KA Only) * Common hardware which should be purchased locally. All bolts Grade 5 plated, all other fasteners zinc plated.

- Page 66 Section 8 ELECTRICAL SYSTEM (23HP & 27HP KAWASAKI) STT2001 23 & 27 ESKA...

- Page 67 Wire Harness, STT-23KA & 27KA Only 481670 Sending Unit, Water Temp. 48030-11 Clamp, Cable 481183 Water Temp. Gauge (STT - KA Only) * Common hardware which should be purchased locally. All bolts Grade 5 plated, all other fasteners zinc plated.

- Page 68 Section 8 BDP-10L HYDRAULIC PUMP ASSEMBLY FOR HYDRAULIC PUMP ASSEMBLY STT-22KA, STT-23CH, STT-23KA, STT-25CH, STT61A-27KA 390S0167...

- Page 69 Section 8 BDP-10L HYDRAULIC PUMP ASSEMBLY FOR STT-22KA, STT-23CH, STT-23KA, STT-25CH, STT61A-27KA Ref. Part Description HG 2513017 Housing Kit (Includes Housing, Journal Bearing) HG 2513016 End Cap HG 9004800-2506 Straight Headless Pin HG 9007314 Hex Head Screw 5/16-18x1.0 HG 2003067...

- Page 70 Section 8 REPLACEMENT DECALS AND INFORMATION PLATES MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING PATENTS: 4, 487, 006 4, 991, 382 5, 832, 708 4, 885, 903 4, 998, 948 5, 865, 018 4, 920, 733 5, 118, 617 4, 967, 543 5, 826, 416 PATENTS PENDING...

-

Page 71: Replacement Decals And Information Plates

Section 8 REPLACEMENT DECALS AND INFORMATION PLATES Ref. Part Description 482285 Decal, Danger-Spining Blades 482286 Decal, Warning-Rotating Blades 481954 Decal, 52 Advantage 481955 Decal, 61 Advantage 481956 Decal, 72 Advantage 482290 Decal, Fuel Tank 48656 Decal, Patents 481568 Decal, Traction Control 48072 Decal, Heavy Duty Commercial 48404... - Page 72 Section 8 ELECTRICAL SCHEMATIC (KOHLER) GROUND SOLENOID STARTER RED/YEL ENGINE ENGINE HARNESS GRN/ LH NEUTRAL SWITCH RH NEUTRAL RED/WHT RED/WHT SWITCH SEAT SWITCH BRAKE INTERLOCK INSTRUMENT PANEL SWITCH HOURMETER PINK LT/BLU MODULE PLUG MOWER BLUE ENGAGE ELECTRIC LITE/BLUE SWITCH CLUTCH RED/YEL SWITCH GRN/BLK...

- Page 73 Section 8 ELECTRICAL SCHEMATIC (22HP KAWASAKI) GROUND STARTER RED/YEL GRN/WHT ENGINE SOLENOID ENGINE HARNESS LH NEUTRAL SWITCH WHT/ RH NEUTRAL RED/WHT RED/WHT SWITCH SEAT SWITCH INSTRUMENT PANEL BRAKE INTERLOCK SWITCH WATER WHT/BLK TEMP PINK HOURMETER LT/BLU FUEL PUMP MODULE PLUG MOWER ENGAGE LT/BLU...

- Page 74 Section 8 ELECTRICAL SCHEMATIC (23HP &27HP KAWASAKI) GROUND STARTER RED/YEL GRN/WHT ENGINE SOLENOID ENGINE HARNESS LH NEUTRAL SWITCH WHT/ RH NEUTRAL RED/WHT RED/WHT SWITCH SEAT SWITCH INSTRUMENT PANEL BRAKE INTERLOCK SWITCH WATER WHT/BLK TEMP PINK HOURMETER LT/BLU FUEL PUMP MODULE PLUG MOWER ENGAGE...

- Page 75 Section 8 NOTES...

- Page 76 LIMITED WARRANTY - COMMERCIAL EQUIPMENT...

Need help?

Do you have a question about the STT and is the answer not in the manual?

Questions and answers