Scag Power Equipment SWZ Operator's Manual

Swz series

Hide thumbs

Also See for SWZ:

- Operator's manual (67 pages) ,

- Operator's manual (40 pages) ,

- Operator's manual (20 pages)

Table of Contents

Advertisement

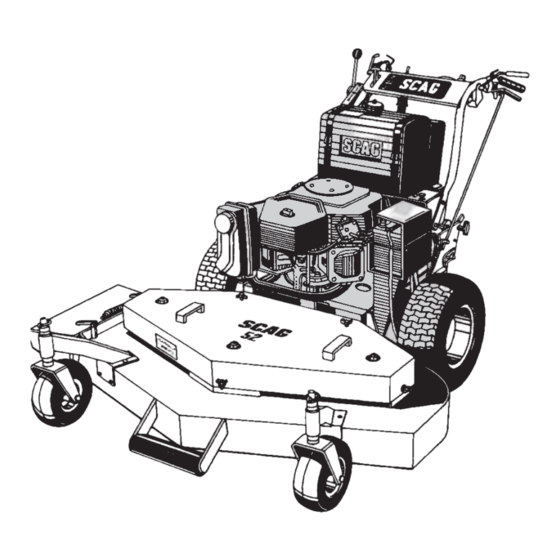

MODEL SWZ

THIS MANUAL CONTAINS THE OPERATING

INSTRUCTIONS AND SAFETY INFORMA-

TION FOR YOUR SCAG MOWER. READING

THIS MANUAL CAN PROVIDE YOU WITH

ASSISTANCE IN MAINTENANCE AND AD-

JUSTMENT PROCEDURES TO KEEP YOUR

MOWER PERFORMING TO MAXIMUM EFFI-

CIENCY. THE SPECIFIC MODELS THAT THIS

BOOK COVERS ARE CONTAINED ON THE

INSIDE COVER. BEFORE OPERATING YOUR

MACHINE, PLEASE READ ALL THE INFOR-

MATION ENCLOSED.

PART NUMBER 03056

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Scag Power Equipment SWZ

- Page 1 MODEL SWZ THIS MANUAL CONTAINS THE OPERATING INSTRUCTIONS AND SAFETY INFORMA- TION FOR YOUR SCAG MOWER. READING THIS MANUAL CAN PROVIDE YOU WITH ASSISTANCE IN MAINTENANCE AND AD- JUSTMENT PROCEDURES TO KEEP YOUR MOWER PERFORMING TO MAXIMUM EFFI- CIENCY. THE SPECIFIC MODELS THAT THIS BOOK COVERS ARE CONTAINED ON THE INSIDE COVER.

- Page 2 4060001-4069999 SWZ48-15KH with a serial number of 4070001-4079999 SWZ48-17KA with a serial number of 4080001-4089999 SWZ-17KA with a serial number of 4100001-4109999 SWM-52E with a serial number of 4110001-4119999 SWM-61E with a serial number of 4120001-4129999...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SUBJECT PAGE Introduction ....................1 General Safety Instructions ................1 Signal Words ....................1 Before Operating ..................2 While Operating ................... 2 Maintenance and Storage ................3 Initial Run-In Procedures ................4 Mower Operation ..................4 Cutter Deck Belt Adjustments ..............5 Cutter Deck Adjustments ................ -

Page 4: Subject Page

TABLE OF CONTENTS (CONTINUED) SUBJECT PAGE Illustrated Parts List SWM-36"Cutter Deck ................ 16-17 SWM-48", 52", 61", 72" Cutter Decks............18-19 Engine Deck....................20-21 Drive And Brake Components..............22-23 Handle Assembly..................24-25 Hydraulic Assembly ................26-27 Hydraulic Pump Assembly ..............28-29 Engine Deck Wire Harness-Kohler (Single Cyl.) &... -

Page 5: Introduction

INTRODUCTION SIGNAL WORDS Your mower was built to the highest standards in the industry. However, the prolonged life and maxi- mum efficiency of your mower depends on you following the operating, maintenance and adjust- ment instructions in this manual. This symbol means “Attention! Become Alert! “Attention! Become Alert! “Attention! Become Alert! “Attention! Become Alert! -

Page 6: Before Operating

WHILE OPERA WHILE OPERA WHILE OPERA WHILE OPERA WHILE OPERATING TING TING TING TING BEFORE OPERATING 1. Start the engine when the neutral latches are in 1. Know the controls and how to stop quickly. the neutral lock position, the cutter blades are disengaged, the parking brake is on and the 2. -

Page 7: Maintenance And Storage

14. Use only Scag approved riding attachments. 9. If the cutting blades should strike a solid object or Scag Approved Riding Attachments: the equipment should start to vibrate abnormally, RS-ZT stop the engine, disconnect the spark plug wire, and Using unapproved attachments, (especially check immediately for the cause. -

Page 8: Initial Run-In Procedures

9. Always store gasoline in a safety-approved, red MOWER OPERATION container. 1. Read and understand the safety instructions before attempting to operate this machine. 10. Be careful when servicing the battery as it contains acid, which is corrosive and could cause 2. -

Page 9: Cutter Deck Belt Adjustments

-NOTE- When PTO is engaged or (possibly) disengaged, a squealing sound from the underside of the machine is normal. It is caused by the electric clutch plates meshing as the mower comes up to speed. For best equipment life, engage the clutch with the engine at 1/2 throttle, not under full load. -

Page 10: Cutter Deck Adjustments

LOW CUT (1 3/4"- 3") -NOTE- Due to initial belt stretch and to prevent the belt from slipping, check this adjustment after the MID RANGE first 2 hours, 4 hours and 8 hours of operation. (2 1/2"- 3 3/4") Adjust the RH blade drive belt using a belt tension gauge. -

Page 11: Cutter Blades

ANGLE BLADE BACK DO NOT CUT IN X MUST NOT EXCEED 1/3 BLADE WIDTH SC4O8G Figure 7. Blade Sharpening NEUTRAL ADJUSTMENT 1. Raise the drive wheels off the ground and block the caster wheels. 2. Remove the speed control spring and the steer- ing control rod from the machine. -

Page 12: Steering Control Rod Adjustment

3. Tighten the bearing securing the speed adjustment STEERING CONTROL ROD bearing lever and repeat on the opposite side. ADJUSTMENT 4. With the machine on a flat level surface, start the -NOTE- engine and place the speed adjustment lever into This adjustment is made to allow the steering the speed that will most often be used. -

Page 13: Lubrication And Maintenance Chart

LUBRICA LUBRICA LUBRICA LUBRICA LUBRICATION & MAINTENANCE TION & MAINTENANCE TION & MAINTENANCE TION & MAINTENANCE TION & MAINTENANCE BREAK-IN BREAK-IN BREAK-IN BREAK-IN BREAK-IN + Grease spindle until grease comes out the relief valve Compatible Greases: Lidok EP #2 (found at industrial shops) 8 HOURS (DAILY) 8 HOURS (DAILY) 8 HOURS (DAILY) -

Page 14: Troubleshooting Cutting Conditions

TROUBLESHOOTING CUTTING CONDITIONS CAUSE CURE CONDITION Stringers - Occasional Low engine RPM Run engine at full 3600 RPM Blades of Uncut Grass Ground speed too fast Slow speed to adjust for conditions Wet grass Cut grass after it has dried out Dull blades, incorrect sharpening Sharpen blades Deck plugged, grass accumulation... -

Page 15: Troubleshooting

TROUBLESHOOTING CAUSE CURE CONDITION Uneven Cut on Flat Lift worn off of blade Replace blade Ground - Wavy High-Low Blade upside down Mount with cutting edge toward Appearance, ground Scalloped Cut, or Rough Contour Deck plugged, grass accumulation Clean underside of deck Too much blade angle (deck pitch) Adjust pitch and level Deck mounted improperly See your authorized SCAG dealer... - Page 16 TROUBLESHOOTING CAUSE CURE CONDITION Scalping - Blades Low tire pressures Check and adjust pressures Hitting Dirt or Cutting Very Close to Ground speed too fast Slow speed to adjust for conditions the Ground Cutting too low May need to reduce ground speed, raise cutting height, change direction of cut, and/or change pitch and level Rough terrain...

-

Page 17: Technical Specifications

TECHNICAL SPECIFICATIONS ENGINES General Type: Heavy duty industrial/commercial Brand: Kohler, Kawasaki, Models: Kohler CV15T, CVE 20;Kaw. FC420V; Horsepower: Kohler 15HP& 20HP; Kaw. 14HP; Kaw. 17HP Type: 4 cycle gas, vertical shaft engines Displacement: Kohler: 15HP = 426cc, 20 HP= 624cc Kawasaki: 14HP = 423cc, 17HP = 494cc Cylinders: Varied - see manufacturer's specifications... -

Page 18: Technical Specifications

TECHNICAL SPECIFICATIONS (CON'T) CUTTER DECKS SWM 36, SWM 48, SWM 52, SWM 61, SWM 72 Type: Out-front design with anti-scalp rollers Construction: SWM36,48: 7-gauge steel with 7-gauge (3/16") steel skirt SWM52,61,72:10-gauge steel with 7-gauge (3/16") steel skirt Cutting Width: 35.5" (90.2 cm), 48.0 (122.0 cm), 52.0 " (132.0 cm), 61.0 "... -

Page 19: Notes

NOTES... -

Page 20: Swm-36"Cutter Deck

32" & 36" CUTTER DECKS SW-SWZ99CD36... - Page 21 36" CUTTER DECKS Ref. Part Ref. Part No. Number Description No. Number Description 04020-09 Hex Nut, 5/8-11 461131 Cutter Deck (Includes Decals) 48204 Belt, Blade Drive 46631 Cutter Spindle Assy. 43077 Spacer 43312 Spacer, Outside 04021-05 Hex Nut, 3/8-16 Center Locknut 48307-08 Tapered Nut, 5/16-24 04019-04...

-

Page 22: Swm-48", 52", 61", 72" Cutter Decks

48", 52", 61", & 72" CUTTER DECKS 56, 56A 62, 62A 55 54 SW-SWZ99CD48"... - Page 23 48, 52, 61, & 72" CUTTER DECKS Ref. Part Ref. Part No. No. Description 48 52 61 72 No. No. Description 48 52 61 72 04001-01 Bolt, 1/4-20 x 3/4" Hex Head 461132 Cutter Deck (Includes decals) 04020-09 Nut, 5/8-11 Hex 461134 Cutter Deck (Includes decals) 48923...

-

Page 24: Engine Deck

ENGINE DECK ELECTRIC START ONLY 030441698... - Page 25 ENGINE DECK Ref. Part Ref. Part Description Description 14KA 15KH 17KA 20CVE 14KA 15KH 17KA 20CVE 48842 Engine 14KA Kawasaki 04001-08 Hex Head Bolt, 5/16-18 x .75" 48844 Engine 15KH Kohler 04040-14 Flat Washer 1/4" 481066 Engine 17KA Kawasaki 04021-10 Nut, 5/16-18 Elastic Stop 48971 Engine 20CVE Kohler Command 04003-04 Carrage Bolt, 5/16-18 x 1"...

-

Page 26: Drive And Brake Components

DRIVE AND BRAKE COMPONENTS 3, 3A 10, 10A SWZ99D&BC... - Page 27 DRIVE AND BRAKE COMPONENTS Ref. Part Ref. Part Description Description 14KA 14KH 17KA 20CVE 14KA 14KH 17KA 20CVE 04002-05 Hex Head Bolt, M10-1.5 x 65 04050-02 Retaining Ring, 3/4 Ext. "E" 04001-149 Hex Head Bolt, 7/16-20 x 2.00" 04001-19 Bolt, 3/8-16 x 1" Hex Head 45842 Brake Shaft Assy.

-

Page 28: Handle Assembly

HANDLE ASSEMBLY REF. SWZ99HA... - Page 29 HANDLE ASSEMBLY Ref. Part Ref. Part Description 14KA 15KH 17KA 20CVE Description 14KA 15KH 17KA 20CVE 461128 Upper Handle Wlmt. W/Decals 04001-69 Hex Head Bolt, 5/16-18 x 1-3/4" 461129 Upper Handle Wlmt. W/Decals 48494-02 Spring, Return 481517-02 Knob, 5/16-18 42675 Quadrant, Speed Control 43308 Bushing...

-

Page 30: Hydraulic Assembly

HYDRAULIC ASSEMBLY 030441798... -

Page 31: Hydraulic Assembly

HYDRAULIC ASSEMBLY Ref. Part Number Description 14KA 15KH 17KA 20CVE 48535 Cap, Oil Reservoir 46618 Oil Reservoir (small Frame) 46619 Oil Reservior (Large Frame) 48484-01 Elbow, 90 deg. Female 1/4 NPT to 1/4 JIC Male 48353-02 Coupling, 7/16-20 SAE Flare Swivel to 1/4" Hose Push On 48482 Hose, 1/4"... -

Page 32: Hydraulic Pump Assembly

HYDRAULIC PUMP ASSEMBLY SC165G... -

Page 33: Hydraulic Pump Assembly

HYDRAULIC PUMP ASSEMBLY Ref. Part Number Description HG 2513017 Housing Kit (Incl. Housing, Journal Bearing) HG 2513016 End Cap HG 9004800-2506 Straight Headless Pin HG 9007314-0810 Socket Head Screw HG 2003067 End Cap Gasket HG 2513027 Charge Pump Kit (Incl. Charge Cover, Gerotor Assy., O-Ring) HG 50273 Gerotor Assembly HG 9004101-1340... -

Page 34: Engine Deck Wire Harness-Kohler (Single Cyl.) & 17Ka

ENGINE DECK BLADE CLUTCH WIRE HARNESS - KOHLER, NEUTRAL (SINGLE CYLINDER) INTERLOCK GROUND & 17 HP Kawasaki PART NO. 481073 BLACK BLACK BLUE WHITE WHITE YELLOW WIRE HARNESS ADAPTER - ENGINE INSTRUMENT SWZ99SC421G PANEL HARNESS TRANSMISSION ENGINE DECK WIRE HARNESS - ENGINE GROUND KOHLER COMMAND... -

Page 35: Handle Wire Harness-Electric Start

HANDLE WIRE HARNESS - ELECTRIC START PART NO. 481681 FUSES MOWER ENGAGE SWITCH BRAKE SWITCH SWITCH BLACK GREEN BLACK W/RED STRIPE BLUE OPERATOR PRESENCE WHITE TO ENGINE SWITCH DECK WIRE YELLOW HARNESS BLACK W/RED STRIPE RED W/ YEL STRIPE HOURMETER HOURMETER SWZ99-481681 WIRE HARNESS WITH RELAY... -

Page 36: Engine Deck Wire Harness-14 Kawasaki

ENGINE DECK WIRE HARNESS - NEUTRAL KAWASAKI INTERLOCK PART NO. 481074 ENGINE REGULATOR BLACK W/RED STRIPE BLACK BLACK BLUE WHITE WHITE BLADE YELLOW CLUTCH INSTRUMENT PANEL HARNESS SWZ99SC417G GROUND HANDLE WIRE HARNESS - BRAKE SWITCH MANUAL START MOWER ENGAGE SWITCH SWITCH PART NO. -

Page 37: Replacement Decals

REPLACEMENT DECALS & INFORMATION HEAVY DUTY COMMERCIAL 48072 48072 48314 WARNING DANGER ROTATING BLADES AND BELTS KEEP HANDS, FEET & CLOTHING CLEAR KEEP ALL GUARDS IN PLACE SPINNING BLADE 36" - 48316 SHUT OFF ENGINE & DISENGAGE BLADE CLUTCH BEFORE SERVICING KEEP CLEAR 48"... - Page 38 REPLACEMENT DECALS & INFORMATION PARKING CHOKE BRAKE FAST SLOW 481415 PARKING BRAKE FAST SLOW 481423 PARKING BRAKE FAST SLOW 481438...

- Page 39 TRACKING ADJUSTMENT FAST CONTROL ROD ADJUSTMENT REVERSE NEUTRAL OPERATOR'S MANUAL ADJUSTMENT 481425 FORWARD 481425 SEE OPERATOR'S MANUAL SPEED 481080 CONTROL SLOW NEUTRAL 481124 481124 48514 - 20" 48555 - 16"...

- Page 40 Scag, are either incompatible with the Scag mower or adversely affect its operation, performance or durability. Scag Power Equipment reserves the right to change or improve the design of any mower without assuming any obliga- tion to modify any mower previously manufactured.

- Page 41 © 1999 PART NO. 03056 SCAG POWER EQUIPMENT PRINTED1/99 DIVISION OF METALCRAFT OF MAYVILLE, INC. PRINTED IN USA...

Need help?

Do you have a question about the SWZ and is the answer not in the manual?

Questions and answers