Table of Contents

Advertisement

Quick Links

Safety Instructions

& Operator's Manual for

REAR ENGINE RIDING MOWER

SERIES 18

MODEL

421618BVE

MODEL

NUMBER

EXPLANATION

CUTTING WIDTH

ENGINE HP

SERIES DESIGNATION

ENGINE OPTIONS

ENGINE TYPE

ENGINE MODEL

42 - 42" Cutting Deck

I 16-1G.0HPEngine

118-Series

Desi_jnation

IB-BriggsEngine

I V - Over Head Valve

I E-ElectricStart

Thank you for buying a SNAPPER Product!

Before operating your REAR ENGINE RIDER, read this manual

carefully and pay particular attention to the "IMPORTANT

SAFETY INSTRUCTIONS"

on Pages 2 & 3. Remember

that all power equipment can be dangerous if used improperly.

Also keep in mind that SAFETY requires careful

use in accordance with the operating instructions and common sense!

5NAPPERMcDonough,

GA., 30253

U.S.A.

COPYRIGHT

© 1999

SNAPPER

INC.

ALL RIGHTS RESERVED

MANUAL No. 4-7042 (REV. 1, 8/20/99)

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Snapper 421618BVE

- Page 1 IB-BriggsEngine I V - Over Head Valve I E-ElectricStart Desi_jnation Thank you for buying a SNAPPER Product! Before operating your REAR ENGINE RIDER, read this manual carefully and pay particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all power equipment can be dangerous if used improperly.

-

Page 2: Important Safety Instructions

If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN... - Page 3 Inspect machine repair SNAPPER dealer at least once a year and have damage before resuming operation. the dealer install any new safety devices. 12. Operate machine only in daylight or with good 15. Use only genuine SNAPPER replacement parts artificial light.

-

Page 4: Table Of Contents

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ................. TABLE OF CONTENTS ...................... SECTION 1 - FAMILIARIZATION ..................SECTION 2 - OPERATING INSTRUCTIONS ..............6-11 Pre-start Checklist ......................Operator's Seat Adjustment ..................Starting & Stopping Engine, Blades & Wheel Drive ..........7-10 Starting &... -

Page 5: Section 1 - Familiarization

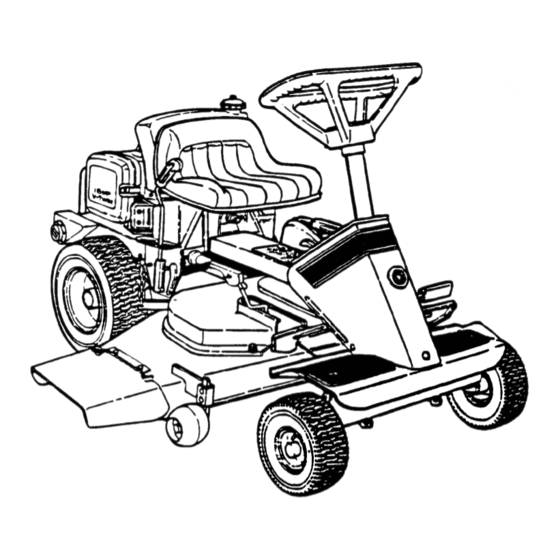

This manual has been prepared for the operator's of the The nomenclature drawing above, Figure 1.1, shows the SNAPPER Rear Engine Rider. Its purpose, aside from essential parts of the SNAPPER Rear Engine Rider. It is recommending standard operating procedures... -

Page 6: Section 2 - Operating Instructions

Section 2 - OPERATING INSTRUCTIONS PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 2.1.1. Check tires and add or release air as needed to bring pressure to 12 psi in front and 12 psi in rear tires. - Page 7 Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION TO APPLY ..2.3.1. ENGINE (ELECTRIC START) BRAKES, PUSH IMPORTANT: When the ignition key is turned to CLUTCH/BRAKE "START", the engine will turn over, but will not start PEDAL ALL THE unless the Clutch/Brake pedal is pressed all the way WAY DOWN.

-

Page 8: Parking Brake

Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION 4. Open vent fuel filler turning 2.3.1. ENGINE (ELECTRIC START) (Continued) counterclockwise. NOTE: Failure to open vent on 8. Should the battery be too weak to start the engine, the fuel filler cap can cause engine to stall. See Refer to Section "ENGINE (MANUAL START)"... - Page 9 3 seconds, the blade brake and hazards before and while backing. must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return DEPRESS machine an authorized SNAPPER dealer CLUTCH/BRAKE adjustment. DO NOT CONTINUE to operate machine PEDAL until blade brake adjusted functioning properly.

- Page 10 3 seconds, the blade brake must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return FIGURE 2.15 machine an authorized SNAPPER dealer adjustment. DO NOT CONTINUE to operate machine until blade brake adjusted functioning (Continued on Next Page) properly.

- Page 11 Section 2 - OPERATING INSTRUCTIONS 2.5. CUTTING HEIGHT ADJUSTMENT STOPPING - ENGINE, WHEEL DRIVE, BLADE 2.4.4. PARK BRAKE 1. Adjust cutting height as desired to any one of six positions using deck lift lever. When in desired 1. Engage park brake by pushing clutch/brake pedal "DOWN"...

-

Page 12: Section 3 - Maintenance Instructions

Both the foam pre-cleaner and cartridge require service. Refer to Engine Owner's Manual for INTRODUCTION recommended service procedures. To retain the quality of the Rear Engine Rider, use genuine SNAPPER replacement parts only. Contact a local SNAPPER dealer parts service 3.2.3. -

Page 13: Check Blade Drive Belt

Exercise extreme caution• Clear area of loose parts & tools first• Only operate blades when seated in the operator's seat• DO NOT operate machine if interlock system WARNING functioning properly, Contact your SNAPPER immediately for assistance,... -

Page 14: Lubrication - Grease Fittings

Section 3- MAINTENANCE 3.2.8. LUBRICATION - GREASE FITTINGS IMPORTANT: If the Rear Engine Rider will be on its rear bumper for longer than two hours, remove the battery. Refer The following components on the Rear Engine to Section "BATTERY REMOVAL". Rider are equipped with grease fittings and require periodic lubrication. -

Page 15: Differential /Chain Case-Lubrication

See Figure 3.8. 4. To check lubricant in chain case, remove fill/level plug look lubricant internal components of the chain case. If no lubricant is visible, add "SNAPPER Transmission" grease as needed. See Figure 3.8. FIGURE 3.9... -

Page 16: Every Two Years

SNAPPER dealer. Holding the fuel tank, remove the fuel filler cap and pour remaining fuel in an approved container. See 3.5.1. All bushings and pivot areas. -

Page 17: Section 4-Adjustments And Repair

1/8", rotate eye bolt swivel CLOCKWISE additional turn and re-check clearance. adjustments and repairs, it is recommended that 5. Once the 1/16" to 1/8" clearance has been these repairs be made by an authorized SNAPPER dealer. attained, reinstall swivel onto deck rail. -

Page 18: Mower Deck Adjustment (Side To Side Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2.4. MOWER DECK ADJUSTMENT WARNING (Side To Side Levelness) DO NOT attempt adjustments, maintenance, Before making deck leveling adjustments, check service or repairs with the engine running. STOP the tire pressure. Front tires 12 psi, rear tires 12 psi. engine. -

Page 19: Mower Deck Adjustment (Front To Rear Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2 MOWER DECK & COMPONENT ADJUSTMENTS WARNING 4.2.6. CUTTING HEIGHT ADJUSTMENT DO NOT attempt adjustments, maintenance, cutting height range of the mower can be adjusted. service or repairs with the engine running. STOP Place the Rear Engine Rider on a smooth, level engine. -

Page 20: Rear Engine Rider Drive Components

However, it is recommended that all the park brake. See Figure 4.8. adjustments to the Rear Engine Rider be made by an authorized SNAPPER dealer. PUSH CLUTCH/BRAKE PEDAL 4.3.1. CLUTCH - STARTING MOTION ADJUSTMENT ALL THE WAY DOWN... -

Page 21: Mower Blade Replacement

Section 4 - ADJUSTMENTS & REPAIR WARNING BRAKE CABLE CASE DO NOT attempt adjustments, maintenance, service or repairs with the engine running. STOP engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. -

Page 22: Blade Sharpening

Section 4 - ADJUSTMENTS & REPAIR WARNING DO NOT attempt adjustments, maintenance, lades are extremely sharp and can cause severe l service or repairs with the engine running. STOP injuries. Wear heavy leather gloves when working on or handling blades. DO NOT use blades that show signs engine. - Page 23 Section 4 - ADJUSTMENTS & REPAIR WARNING REMOVE DO NOT attempt adjustments, maintenance, STATIONARY service or repairs with the engine running. STOP IDLER engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT.

- Page 24 Section 4 - ADJUSTMENTS & REPAIR POSITIVE TERMINAL WARNING POSITIVE INSULATOR DO NOT attempt adjustments, maintenance, (+) CABLE service or repairs with the engine running. Stop engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and BLACK secure away from plug.

- Page 25 Section 4 - ADJUSTMENTS & REPAIR WARNING The electrolyte (acid) produces a highly explosive gas. DO NOT attempt to charge battery while installed on Keep all sparks, flame and fire away from area when WARNING Riding Mower. DO NOT use "BOOST" chargers on charging battery or when...

-

Page 26: Accessories

Two Balls Floating 1.120 11.90v 25% Charged One Ball Floating Less than 1.100 Less than 11.80v 0% Charged Zero Balls Floating SNAPPER REAR ENGINE RIDER ACCESSORIES PART NO. DESCRIPTION OF KIT MODELS USED ON 6-0517 ......Wheel Weight (8" Wheels) ...... -

Page 27: Troubleshooting

5. Engage park brake. Blown Fuse. 6. Replace with new 20 AMP fuse. Faulty interlock module. 7. Contact authorized SNAPPER dealer. 8. Ignition is in the OFF position. Turn ignition switch to the START position. 9. Battery is weak or dead. - Page 28 2. Rubber drive disc is not tracking properly on Adjust rubber drive disc. drive disc. 3. Tapered axle bolt and nut missing. Replace with SNAPPER tapered bolt & nut. Contact authorized SNAPPER dealer. 4. Axle bearing seized. 5. Insufficient lubrication in chain case or Contact authorized SNAPPER dealer.

-

Page 29: Maintenance Schedule

MAINTENANCE SCHEDULE EACH EACH SUBJECT SERVICE REFERENCE HOURS HOURS HOURS HOURS SEASON TO BE PERFORMED PAGES Check Oil Level Engine Page 6 Tires Check Pressures Page 6 Engine Initial Oil Change Page 12 Engine Periodic Oil Change Page 13 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element... -

Page 30: Warranty

For three (3) years from purchase date for the original purchaser's residential, non-commercial use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both. - Page 31 & how reasonable maintenance can protect it! Snapper uses the best avail- able engines and components in their products in order to provide long, satisfactory service. However, proper care is essential In prolonging engine life.

-

Page 32: Primary Maintenance

Because of Its working environ- ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, Damage caused by a poorly serviced air... - Page 33 PRIMARY MAINTENANCE Air is also needed to keep your engine cool. Dirt, dust & debris build up to restrict and clog cooling air Intake screens and fins. Clean screens and fins at frequent Intervals. The engine blower housing and shrouds should be removed at least once each season or more often under dry, dusty conditions...

- Page 34 2-cycle engine fuel, be sure the containers are clearly marked to avoid mix-up. Snapper 2-cycle engines require a 32 to 1 mixture of gasoline and BIA certified TC-W oil such as Snapper's 2-cycle engine o11. Many of the 2-cycle engine oils on the...

- Page 35 SERVICE NOTES...

- Page 36 Safety Instructions & Operator's Manual for REAR ENGINE RIDING MOWER SERIES 18 IMPORTANT Snapper products are built using engines that meet or exceed all applicable emissions requirements on the date manufactured. The labels on those engines contain very important emissions...

- Page 37 IB-BriggsEngine I V - Over Head Valve I E-ElectricStart Desi_jnation Thank you for buying a SNAPPER Product! Before operating your REAR ENGINE RIDER, read this manual carefully and pay particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all power equipment can be dangerous if used improperly.

- Page 38 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN...

- Page 39 Inspect machine repair SNAPPER dealer at least once a year and have damage before resuming operation. the dealer install any new safety devices. 12. Operate machine only in daylight or with good 15. Use only genuine SNAPPER replacement parts artificial light.

-

Page 40: Starting & Stopping Engine, Blades & Wheel Drive

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ................. TABLE OF CONTENTS ...................... SECTION 1 - FAMILIARIZATION ..................SECTION 2 - OPERATING INSTRUCTIONS ..............6-11 Pre-start Checklist ......................Operator's Seat Adjustment ..................Starting & Stopping Engine, Blades & Wheel Drive ..........7-10 Starting &... -

Page 41: Important Safety Instructions

This manual has been prepared for the operator's of the The nomenclature drawing above, Figure 1.1, shows the SNAPPER Rear Engine Rider. Its purpose, aside from essential parts of the SNAPPER Rear Engine Rider. It is recommending standard operating procedures... -

Page 42: Section 2 - Operating Instructions

Section 2 - OPERATING INSTRUCTIONS PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 2.1.1. Check tires and add or release air as needed to bring pressure to 12 psi in front and 12 psi in rear tires. - Page 43 Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION TO APPLY ..2.3.1. ENGINE (ELECTRIC START) BRAKES, PUSH IMPORTANT: When the ignition key is turned to CLUTCH/BRAKE "START", the engine will turn over, but will not start PEDAL ALL THE unless the Clutch/Brake pedal is pressed all the way WAY DOWN.

-

Page 44: Parking Brake

Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION 4. Open vent fuel filler turning 2.3.1. ENGINE (ELECTRIC START) (Continued) counterclockwise. NOTE: Failure to open vent on 8. Should the battery be too weak to start the engine, the fuel filler cap can cause engine to stall. See Refer to Section "ENGINE (MANUAL START)"... - Page 45 3 seconds, the blade brake and hazards before and while backing. must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return DEPRESS machine an authorized SNAPPER dealer CLUTCH/BRAKE adjustment. DO NOT CONTINUE to operate machine PEDAL until blade brake adjusted functioning properly.

- Page 46 3 seconds, the blade brake must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return FIGURE 2.15 machine an authorized SNAPPER dealer adjustment. DO NOT CONTINUE to operate machine until blade brake adjusted functioning (Continued on Next Page) properly.

-

Page 47: 2.5. Cutting Height Adjustment

Section 2 - OPERATING INSTRUCTIONS 2.5. CUTTING HEIGHT ADJUSTMENT STOPPING - ENGINE, WHEEL DRIVE, BLADE 2.4.4. PARK BRAKE 1. Adjust cutting height as desired to any one of six positions using deck lift lever. When in desired 1. Engage park brake by pushing clutch/brake pedal "DOWN"... -

Page 48: Section 3 - Maintenance Instructions

Both the foam pre-cleaner and cartridge require service. Refer to Engine Owner's Manual for INTRODUCTION recommended service procedures. To retain the quality of the Rear Engine Rider, use genuine SNAPPER replacement parts only. Contact a local SNAPPER dealer parts service 3.2.3. -

Page 49: Blade Brake

Exercise extreme caution• Clear area of loose parts & tools first• Only operate blades when seated in the operator's seat• DO NOT operate machine if interlock system WARNING functioning properly, Contact your SNAPPER immediately for assistance,... -

Page 50: Lubrication - Grease Fittings

Section 3- MAINTENANCE 3.2.8. LUBRICATION - GREASE FITTINGS IMPORTANT: If the Rear Engine Rider will be on its rear bumper for longer than two hours, remove the battery. Refer The following components on the Rear Engine to Section "BATTERY REMOVAL". Rider are equipped with grease fittings and require periodic lubrication. -

Page 51: Differential /Chain Case-Lubrication

See Figure 3.8. 4. To check lubricant in chain case, remove fill/level plug look lubricant internal components of the chain case. If no lubricant is visible, add "SNAPPER Transmission" grease as needed. See Figure 3.8. FIGURE 3.9... -

Page 52: Every Two Years

SNAPPER dealer. Holding the fuel tank, remove the fuel filler cap and pour remaining fuel in an approved container. See 3.5.1. All bushings and pivot areas. -

Page 53: Section 4-Adjustments And Repair

1/8", rotate eye bolt swivel CLOCKWISE additional turn and re-check clearance. adjustments and repairs, it is recommended that 5. Once the 1/16" to 1/8" clearance has been these repairs be made by an authorized SNAPPER dealer. attained, reinstall swivel onto deck rail. -

Page 54: Mower Deck Adjustment (Side To Side Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2.4. MOWER DECK ADJUSTMENT WARNING (Side To Side Levelness) DO NOT attempt adjustments, maintenance, Before making deck leveling adjustments, check service or repairs with the engine running. STOP the tire pressure. Front tires 12 psi, rear tires 12 psi. engine. -

Page 55: Mower Deck Adjustment (Front To Rear Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2 MOWER DECK & COMPONENT ADJUSTMENTS WARNING 4.2.6. CUTTING HEIGHT ADJUSTMENT DO NOT attempt adjustments, maintenance, cutting height range of the mower can be adjusted. service or repairs with the engine running. STOP Place the Rear Engine Rider on a smooth, level engine. -

Page 56: Rear Engine Rider Drive Components

However, it is recommended that all the park brake. See Figure 4.8. adjustments to the Rear Engine Rider be made by an authorized SNAPPER dealer. PUSH CLUTCH/BRAKE PEDAL 4.3.1. CLUTCH - STARTING MOTION ADJUSTMENT ALL THE WAY DOWN... -

Page 57: Mower Blade Replacement

Section 4 - ADJUSTMENTS & REPAIR WARNING BRAKE CABLE CASE DO NOT attempt adjustments, maintenance, service or repairs with the engine running. STOP engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. -

Page 58: Blade Sharpening

Section 4 - ADJUSTMENTS & REPAIR WARNING DO NOT attempt adjustments, maintenance, lades are extremely sharp and can cause severe l service or repairs with the engine running. STOP injuries. Wear heavy leather gloves when working on or handling blades. DO NOT use blades that show signs engine. - Page 59 Section 4 - ADJUSTMENTS & REPAIR WARNING REMOVE DO NOT attempt adjustments, maintenance, STATIONARY service or repairs with the engine running. STOP IDLER engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT.

- Page 60 Section 4 - ADJUSTMENTS & REPAIR POSITIVE TERMINAL WARNING POSITIVE INSULATOR DO NOT attempt adjustments, maintenance, (+) CABLE service or repairs with the engine running. Stop engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and BLACK secure away from plug.

- Page 61 Section 4 - ADJUSTMENTS & REPAIR WARNING The electrolyte (acid) produces a highly explosive gas. DO NOT attempt to charge battery while installed on Keep all sparks, flame and fire away from area when WARNING Riding Mower. DO NOT use "BOOST" chargers on charging battery or when...

- Page 62 Two Balls Floating 1.120 11.90v 25% Charged One Ball Floating Less than 1.100 Less than 11.80v 0% Charged Zero Balls Floating SNAPPER REAR ENGINE RIDER ACCESSORIES PART NO. DESCRIPTION OF KIT MODELS USED ON 6-0517 ......Wheel Weight (8" Wheels) ......

- Page 63 5. Engage park brake. Blown Fuse. 6. Replace with new 20 AMP fuse. Faulty interlock module. 7. Contact authorized SNAPPER dealer. 8. Ignition is in the OFF position. Turn ignition switch to the START position. 9. Battery is weak or dead.

- Page 64 2. Rubber drive disc is not tracking properly on Adjust rubber drive disc. drive disc. 3. Tapered axle bolt and nut missing. Replace with SNAPPER tapered bolt & nut. Contact authorized SNAPPER dealer. 4. Axle bearing seized. 5. Insufficient lubrication in chain case or Contact authorized SNAPPER dealer.

- Page 65 MAINTENANCE SCHEDULE EACH EACH SUBJECT SERVICE REFERENCE HOURS HOURS HOURS HOURS SEASON TO BE PERFORMED PAGES Check Oil Level Engine Page 6 Tires Check Pressures Page 6 Engine Initial Oil Change Page 12 Engine Periodic Oil Change Page 13 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element...

- Page 66 For three (3) years from purchase date for the original purchaser's residential, non-commercial use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 67 & how reasonable maintenance can protect it! Snapper uses the best avail- able engines and components in their products in order to provide long, satisfactory service. However, proper care is essential In prolonging engine life.

- Page 68 Because of Its working environ- ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, Damage caused by a poorly serviced air...

- Page 69 PRIMARY MAINTENANCE Air is also needed to keep your engine cool. Dirt, dust & debris build up to restrict and clog cooling air Intake screens and fins. Clean screens and fins at frequent Intervals. The engine blower housing and shrouds should be removed at least once each season or more often under dry, dusty conditions...

- Page 70 2-cycle engine fuel, be sure the containers are clearly marked to avoid mix-up. Snapper 2-cycle engines require a 32 to 1 mixture of gasoline and BIA certified TC-W oil such as Snapper's 2-cycle engine o11. Many of the 2-cycle engine oils on the...

- Page 71 SERVICE NOTES...

- Page 72 Safety Instructions & Operator's Manual for REAR ENGINE RIDING MOWER SERIES 18 IMPORTANT Snapper products are built using engines that meet or exceed all applicable emissions requirements on the date manufactured. The labels on those engines contain very important emissions...

- Page 73 IB-BriggsEngine I V - Over Head Valve I E-ElectricStart Desi_jnation Thank you for buying a SNAPPER Product! Before operating your REAR ENGINE RIDER, read this manual carefully and pay particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all power equipment can be dangerous if used improperly.

- Page 74 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN...

- Page 75 Inspect machine repair SNAPPER dealer at least once a year and have damage before resuming operation. the dealer install any new safety devices. 12. Operate machine only in daylight or with good 15. Use only genuine SNAPPER replacement parts artificial light.

- Page 76 TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ................. TABLE OF CONTENTS ...................... SECTION 1 - FAMILIARIZATION ..................SECTION 2 - OPERATING INSTRUCTIONS ..............6-11 Pre-start Checklist ......................Operator's Seat Adjustment ..................Starting & Stopping Engine, Blades & Wheel Drive ..........7-10 Starting &...

-

Page 77: Important Safety Instructions

This manual has been prepared for the operator's of the The nomenclature drawing above, Figure 1.1, shows the SNAPPER Rear Engine Rider. Its purpose, aside from essential parts of the SNAPPER Rear Engine Rider. It is recommending standard operating procedures... -

Page 78: Section 2 - Operating Instructions

Section 2 - OPERATING INSTRUCTIONS PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 2.1.1. Check tires and add or release air as needed to bring pressure to 12 psi in front and 12 psi in rear tires. - Page 79 Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION TO APPLY ..2.3.1. ENGINE (ELECTRIC START) BRAKES, PUSH IMPORTANT: When the ignition key is turned to CLUTCH/BRAKE "START", the engine will turn over, but will not start PEDAL ALL THE unless the Clutch/Brake pedal is pressed all the way WAY DOWN.

- Page 80 Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION 4. Open vent fuel filler turning 2.3.1. ENGINE (ELECTRIC START) (Continued) counterclockwise. NOTE: Failure to open vent on 8. Should the battery be too weak to start the engine, the fuel filler cap can cause engine to stall. See Refer to Section "ENGINE (MANUAL START)"...

- Page 81 3 seconds, the blade brake and hazards before and while backing. must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return DEPRESS machine an authorized SNAPPER dealer CLUTCH/BRAKE adjustment. DO NOT CONTINUE to operate machine PEDAL until blade brake adjusted functioning properly.

- Page 82 3 seconds, the blade brake must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return FIGURE 2.15 machine an authorized SNAPPER dealer adjustment. DO NOT CONTINUE to operate machine until blade brake adjusted functioning (Continued on Next Page) properly.

-

Page 83: 2.5. Cutting Height Adjustment

Section 2 - OPERATING INSTRUCTIONS 2.5. CUTTING HEIGHT ADJUSTMENT STOPPING - ENGINE, WHEEL DRIVE, BLADE 2.4.4. PARK BRAKE 1. Adjust cutting height as desired to any one of six positions using deck lift lever. When in desired 1. Engage park brake by pushing clutch/brake pedal "DOWN"... -

Page 84: Section 3 - Maintenance Instructions

Both the foam pre-cleaner and cartridge require service. Refer to Engine Owner's Manual for INTRODUCTION recommended service procedures. To retain the quality of the Rear Engine Rider, use genuine SNAPPER replacement parts only. Contact a local SNAPPER dealer parts service 3.2.3. -

Page 85: Blade Brake

Exercise extreme caution• Clear area of loose parts & tools first• Only operate blades when seated in the operator's seat• DO NOT operate machine if interlock system WARNING functioning properly, Contact your SNAPPER immediately for assistance,... -

Page 86: Lubrication - Grease Fittings

Section 3- MAINTENANCE 3.2.8. LUBRICATION - GREASE FITTINGS IMPORTANT: If the Rear Engine Rider will be on its rear bumper for longer than two hours, remove the battery. Refer The following components on the Rear Engine to Section "BATTERY REMOVAL". Rider are equipped with grease fittings and require periodic lubrication. -

Page 87: Differential /Chain Case-Lubrication

See Figure 3.8. 4. To check lubricant in chain case, remove fill/level plug look lubricant internal components of the chain case. If no lubricant is visible, add "SNAPPER Transmission" grease as needed. See Figure 3.8. FIGURE 3.9... -

Page 88: Every Two Years

SNAPPER dealer. Holding the fuel tank, remove the fuel filler cap and pour remaining fuel in an approved container. See 3.5.1. All bushings and pivot areas. -

Page 89: Section 4-Adjustments And Repair

1/8", rotate eye bolt swivel CLOCKWISE additional turn and re-check clearance. adjustments and repairs, it is recommended that 5. Once the 1/16" to 1/8" clearance has been these repairs be made by an authorized SNAPPER dealer. attained, reinstall swivel onto deck rail. -

Page 90: Mower Deck Adjustment (Side To Side Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2.4. MOWER DECK ADJUSTMENT WARNING (Side To Side Levelness) DO NOT attempt adjustments, maintenance, Before making deck leveling adjustments, check service or repairs with the engine running. STOP the tire pressure. Front tires 12 psi, rear tires 12 psi. engine. -

Page 91: Mower Deck Adjustment (Front To Rear Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2 MOWER DECK & COMPONENT ADJUSTMENTS WARNING 4.2.6. CUTTING HEIGHT ADJUSTMENT DO NOT attempt adjustments, maintenance, cutting height range of the mower can be adjusted. service or repairs with the engine running. STOP Place the Rear Engine Rider on a smooth, level engine. -

Page 92: Rear Engine Rider Drive Components

However, it is recommended that all the park brake. See Figure 4.8. adjustments to the Rear Engine Rider be made by an authorized SNAPPER dealer. PUSH CLUTCH/BRAKE PEDAL 4.3.1. CLUTCH - STARTING MOTION ADJUSTMENT ALL THE WAY DOWN... -

Page 93: Mower Blade Replacement

Section 4 - ADJUSTMENTS & REPAIR WARNING BRAKE CABLE CASE DO NOT attempt adjustments, maintenance, service or repairs with the engine running. STOP engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. -

Page 94: Blade Sharpening

Section 4 - ADJUSTMENTS & REPAIR WARNING DO NOT attempt adjustments, maintenance, lades are extremely sharp and can cause severe l service or repairs with the engine running. STOP injuries. Wear heavy leather gloves when working on or handling blades. DO NOT use blades that show signs engine. - Page 95 Section 4 - ADJUSTMENTS & REPAIR WARNING REMOVE DO NOT attempt adjustments, maintenance, STATIONARY service or repairs with the engine running. STOP IDLER engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT.

- Page 96 Section 4 - ADJUSTMENTS & REPAIR POSITIVE TERMINAL WARNING POSITIVE INSULATOR DO NOT attempt adjustments, maintenance, (+) CABLE service or repairs with the engine running. Stop engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and BLACK secure away from plug.

- Page 97 Section 4 - ADJUSTMENTS & REPAIR WARNING The electrolyte (acid) produces a highly explosive gas. DO NOT attempt to charge battery while installed on Keep all sparks, flame and fire away from area when WARNING Riding Mower. DO NOT use "BOOST" chargers on charging battery or when...

- Page 98 Two Balls Floating 1.120 11.90v 25% Charged One Ball Floating Less than 1.100 Less than 11.80v 0% Charged Zero Balls Floating SNAPPER REAR ENGINE RIDER ACCESSORIES PART NO. DESCRIPTION OF KIT MODELS USED ON 6-0517 ......Wheel Weight (8" Wheels) ......

- Page 99 5. Engage park brake. Blown Fuse. 6. Replace with new 20 AMP fuse. Faulty interlock module. 7. Contact authorized SNAPPER dealer. 8. Ignition is in the OFF position. Turn ignition switch to the START position. 9. Battery is weak or dead.

- Page 100 2. Rubber drive disc is not tracking properly on Adjust rubber drive disc. drive disc. 3. Tapered axle bolt and nut missing. Replace with SNAPPER tapered bolt & nut. Contact authorized SNAPPER dealer. 4. Axle bearing seized. 5. Insufficient lubrication in chain case or Contact authorized SNAPPER dealer.

- Page 101 MAINTENANCE SCHEDULE EACH EACH SUBJECT SERVICE REFERENCE HOURS HOURS HOURS HOURS SEASON TO BE PERFORMED PAGES Check Oil Level Engine Page 6 Tires Check Pressures Page 6 Engine Initial Oil Change Page 12 Engine Periodic Oil Change Page 13 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element...

- Page 102 For three (3) years from purchase date for the original purchaser's residential, non-commercial use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 103 & how reasonable maintenance can protect it! Snapper uses the best avail- able engines and components in their products in order to provide long, satisfactory service. However, proper care is essential In prolonging engine life.

- Page 104 Because of Its working environ- ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, Damage caused by a poorly serviced air...

- Page 105 PRIMARY MAINTENANCE Air is also needed to keep your engine cool. Dirt, dust & debris build up to restrict and clog cooling air Intake screens and fins. Clean screens and fins at frequent Intervals. The engine blower housing and shrouds should be removed at least once each season or more often under dry, dusty conditions...

- Page 106 2-cycle engine fuel, be sure the containers are clearly marked to avoid mix-up. Snapper 2-cycle engines require a 32 to 1 mixture of gasoline and BIA certified TC-W oil such as Snapper's 2-cycle engine o11. Many of the 2-cycle engine oils on the...

- Page 107 SERVICE NOTES...

- Page 108 Safety Instructions & Operator's Manual for REAR ENGINE RIDING MOWER SERIES 18 IMPORTANT Snapper products are built using engines that meet or exceed all applicable emissions requirements on the date manufactured. The labels on those engines contain very important emissions...

- Page 109 IB-BriggsEngine I V - Over Head Valve I E-ElectricStart Desi_jnation Thank you for buying a SNAPPER Product! Before operating your REAR ENGINE RIDER, read this manual carefully and pay particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all power equipment can be dangerous if used improperly.

- Page 110 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN...

- Page 111 Inspect machine repair SNAPPER dealer at least once a year and have damage before resuming operation. the dealer install any new safety devices. 12. Operate machine only in daylight or with good 15. Use only genuine SNAPPER replacement parts artificial light.

- Page 112 TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ................. TABLE OF CONTENTS ...................... SECTION 1 - FAMILIARIZATION ..................SECTION 2 - OPERATING INSTRUCTIONS ..............6-11 Pre-start Checklist ......................Operator's Seat Adjustment ..................Starting & Stopping Engine, Blades & Wheel Drive ..........7-10 Starting &...

-

Page 113: Important Safety Instructions

This manual has been prepared for the operator's of the The nomenclature drawing above, Figure 1.1, shows the SNAPPER Rear Engine Rider. Its purpose, aside from essential parts of the SNAPPER Rear Engine Rider. It is recommending standard operating procedures... -

Page 114: Section 2 - Operating Instructions

Section 2 - OPERATING INSTRUCTIONS PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 2.1.1. Check tires and add or release air as needed to bring pressure to 12 psi in front and 12 psi in rear tires. - Page 115 Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION TO APPLY ..2.3.1. ENGINE (ELECTRIC START) BRAKES, PUSH IMPORTANT: When the ignition key is turned to CLUTCH/BRAKE "START", the engine will turn over, but will not start PEDAL ALL THE unless the Clutch/Brake pedal is pressed all the way WAY DOWN.

-

Page 116: Parking Brake

Section 2 - OPERATING INSTRUCTIONS STARTING & OPERATION 4. Open vent fuel filler turning 2.3.1. ENGINE (ELECTRIC START) (Continued) counterclockwise. NOTE: Failure to open vent on 8. Should the battery be too weak to start the engine, the fuel filler cap can cause engine to stall. See Refer to Section "ENGINE (MANUAL START)"... - Page 117 3 seconds, the blade brake and hazards before and while backing. must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return DEPRESS machine an authorized SNAPPER dealer CLUTCH/BRAKE adjustment. DO NOT CONTINUE to operate machine PEDAL until blade brake adjusted functioning properly.

- Page 118 3 seconds, the blade brake must be adjusted. Refer to Section "BLADE BRAKE ADJUSTMENT" for adjustment procedures or return FIGURE 2.15 machine an authorized SNAPPER dealer adjustment. DO NOT CONTINUE to operate machine until blade brake adjusted functioning (Continued on Next Page) properly.

-

Page 119: 2.5. Cutting Height Adjustment

Section 2 - OPERATING INSTRUCTIONS 2.5. CUTTING HEIGHT ADJUSTMENT STOPPING - ENGINE, WHEEL DRIVE, BLADE 2.4.4. PARK BRAKE 1. Adjust cutting height as desired to any one of six positions using deck lift lever. When in desired 1. Engage park brake by pushing clutch/brake pedal "DOWN"... -

Page 120: Section 3 - Maintenance Instructions

Both the foam pre-cleaner and cartridge require service. Refer to Engine Owner's Manual for INTRODUCTION recommended service procedures. To retain the quality of the Rear Engine Rider, use genuine SNAPPER replacement parts only. Contact a local SNAPPER dealer parts service 3.2.3. -

Page 121: Blade Brake

Exercise extreme caution• Clear area of loose parts & tools first• Only operate blades when seated in the operator's seat• DO NOT operate machine if interlock system WARNING functioning properly, Contact your SNAPPER immediately for assistance,... -

Page 122: Lubrication - Grease Fittings

Section 3- MAINTENANCE 3.2.8. LUBRICATION - GREASE FITTINGS IMPORTANT: If the Rear Engine Rider will be on its rear bumper for longer than two hours, remove the battery. Refer The following components on the Rear Engine to Section "BATTERY REMOVAL". Rider are equipped with grease fittings and require periodic lubrication. -

Page 123: Differential /Chain Case-Lubrication

See Figure 3.8. 4. To check lubricant in chain case, remove fill/level plug look lubricant internal components of the chain case. If no lubricant is visible, add "SNAPPER Transmission" grease as needed. See Figure 3.8. FIGURE 3.9... -

Page 124: Every Two Years

SNAPPER dealer. Holding the fuel tank, remove the fuel filler cap and pour remaining fuel in an approved container. See 3.5.1. All bushings and pivot areas. -

Page 125: Section 4-Adjustments And Repair

1/8", rotate eye bolt swivel CLOCKWISE additional turn and re-check clearance. adjustments and repairs, it is recommended that 5. Once the 1/16" to 1/8" clearance has been these repairs be made by an authorized SNAPPER dealer. attained, reinstall swivel onto deck rail. -

Page 126: Mower Deck Adjustment (Side To Side Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2.4. MOWER DECK ADJUSTMENT WARNING (Side To Side Levelness) DO NOT attempt adjustments, maintenance, Before making deck leveling adjustments, check service or repairs with the engine running. STOP the tire pressure. Front tires 12 psi, rear tires 12 psi. engine. -

Page 127: Mower Deck Adjustment (Front To Rear Levelness)

Section 4 - ADJUSTMENTS & REPAIR 4.2 MOWER DECK & COMPONENT ADJUSTMENTS WARNING 4.2.6. CUTTING HEIGHT ADJUSTMENT DO NOT attempt adjustments, maintenance, cutting height range of the mower can be adjusted. service or repairs with the engine running. STOP Place the Rear Engine Rider on a smooth, level engine. -

Page 128: Rear Engine Rider Drive Components

However, it is recommended that all the park brake. See Figure 4.8. adjustments to the Rear Engine Rider be made by an authorized SNAPPER dealer. PUSH CLUTCH/BRAKE PEDAL 4.3.1. CLUTCH - STARTING MOTION ADJUSTMENT ALL THE WAY DOWN... -

Page 129: Mower Blade Replacement

Section 4 - ADJUSTMENTS & REPAIR WARNING BRAKE CABLE CASE DO NOT attempt adjustments, maintenance, service or repairs with the engine running. STOP engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. -

Page 130: Blade Sharpening

Section 4 - ADJUSTMENTS & REPAIR WARNING DO NOT attempt adjustments, maintenance, lades are extremely sharp and can cause severe l service or repairs with the engine running. STOP injuries. Wear heavy leather gloves when working on or handling blades. DO NOT use blades that show signs engine. - Page 131 Section 4 - ADJUSTMENTS & REPAIR WARNING REMOVE DO NOT attempt adjustments, maintenance, STATIONARY service or repairs with the engine running. STOP IDLER engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT.

- Page 132 Section 4 - ADJUSTMENTS & REPAIR POSITIVE TERMINAL WARNING POSITIVE INSULATOR DO NOT attempt adjustments, maintenance, (+) CABLE service or repairs with the engine running. Stop engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and BLACK secure away from plug.

- Page 133 Section 4 - ADJUSTMENTS & REPAIR WARNING The electrolyte (acid) produces a highly explosive gas. DO NOT attempt to charge battery while installed on Keep all sparks, flame and fire away from area when WARNING Riding Mower. DO NOT use "BOOST" chargers on charging battery or when...

- Page 134 Two Balls Floating 1.120 11.90v 25% Charged One Ball Floating Less than 1.100 Less than 11.80v 0% Charged Zero Balls Floating SNAPPER REAR ENGINE RIDER ACCESSORIES PART NO. DESCRIPTION OF KIT MODELS USED ON 6-0517 ......Wheel Weight (8" Wheels) ......

-

Page 135: Troubleshooting

5. Engage park brake. Blown Fuse. 6. Replace with new 20 AMP fuse. Faulty interlock module. 7. Contact authorized SNAPPER dealer. 8. Ignition is in the OFF position. Turn ignition switch to the START position. 9. Battery is weak or dead. - Page 136 2. Rubber drive disc is not tracking properly on Adjust rubber drive disc. drive disc. 3. Tapered axle bolt and nut missing. Replace with SNAPPER tapered bolt & nut. Contact authorized SNAPPER dealer. 4. Axle bearing seized. 5. Insufficient lubrication in chain case or Contact authorized SNAPPER dealer.

-

Page 137: Maintenance Schedule

MAINTENANCE SCHEDULE EACH EACH SUBJECT SERVICE REFERENCE HOURS HOURS HOURS HOURS SEASON TO BE PERFORMED PAGES Check Oil Level Engine Page 6 Tires Check Pressures Page 6 Engine Initial Oil Change Page 12 Engine Periodic Oil Change Page 13 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element... - Page 138 For three (3) years from purchase date for the original purchaser's residential, non-commercial use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 139 & how reasonable maintenance can protect it! Snapper uses the best avail- able engines and components in their products in order to provide long, satisfactory service. However, proper care is essential In prolonging engine life.

-

Page 140: Primary Maintenance

Because of Its working environ- ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, Damage caused by a poorly serviced air... - Page 141 PRIMARY MAINTENANCE Air is also needed to keep your engine cool. Dirt, dust & debris build up to restrict and clog cooling air Intake screens and fins. Clean screens and fins at frequent Intervals. The engine blower housing and shrouds should be removed at least once each season or more often under dry, dusty conditions...

- Page 142 2-cycle engine fuel, be sure the containers are clearly marked to avoid mix-up. Snapper 2-cycle engines require a 32 to 1 mixture of gasoline and BIA certified TC-W oil such as Snapper's 2-cycle engine o11. Many of the 2-cycle engine oils on the...

- Page 143 SERVICE NOTES...

- Page 144 Safety Instructions & Operator's Manual for REAR ENGINE RIDING MOWER SERIES 18 IMPORTANT Snapper products are built using engines that meet or exceed all applicable emissions requirements on the date manufactured. The labels on those engines contain very important emissions...

Need help?

Do you have a question about the 421618BVE and is the answer not in the manual?

Questions and answers