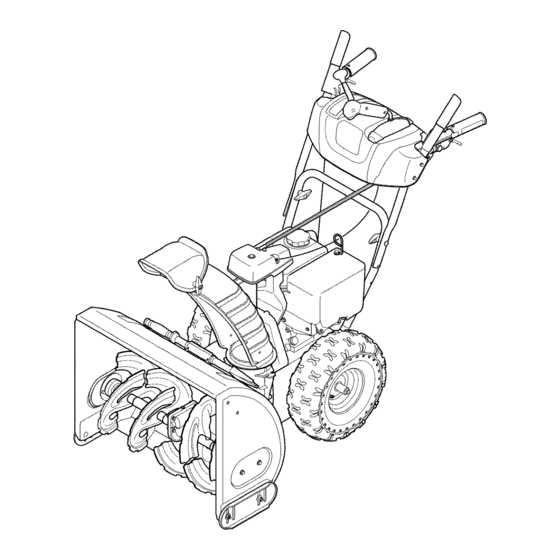

MTD 600 Series Operator's Manual

K style snow thrower

Hide thumbs

Also See for 600 Series:

- Illustrated parts manual (68 pages) ,

- Operator's manual (48 pages) ,

- Owner's manual (35 pages)

Table of Contents

Summary of Contents for MTD 600 Series

- Page 1 Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty 600-Series Snow Thrower m K Style MTD LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019 PrintedIn USA FormNo.769-05082A (August5, 2009)

-

Page 2: Customer Support

Choose from the options below: Visit us on the web at www.mtdproducts.com Call a Customer Support Representative at (800) 800-7310 or (330) 220-4683 Write us at MTD LLC • EO. Box 361131 • Cleveland, OH • 44136-0019... -

Page 3: Important Safe Operation Practices

ImportantSafeOperation Practices WARNING! This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. -

Page 4: Safe Handling Of Gasoline

Never run an engine indoors or in a poorly ventilated area. SafeHandling of Gasoline Engine exhaust contains carbon monoxide, an odorless To avoid personal injury or property damage use extreme care and deadly gas. in handling gasoline. Gasoline is extremely flammable and the Do not operate... -

Page 5: Clearing A Clogged Discharge Chute

According to the Consumer Products Safety Commission Clearinga CloggedDischarge Chute (CPSC) and the U.S. Environmental Protection Agency (EPA), Hand contact with the rotating impeller inside the discharge this product has an Average Useful Life of seven (7) years, chute is the most common cause of injury associated with snow or 60 hours of operation. -

Page 6: Safety Symbols

Safety Symbols This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate. READ THE OPERATOR'S MANUAL(S) Read, understand, and follow all instructions in the manual(s) before attempting assemble and operate... -

Page 7: Assembly And Setup

Assembly & Set-Up Contentsof Carton One Snow Thrower Two Replacement Auger Shear Pins One Product Registration Card Hex Rod One Snow Thrower Operator's Chute Assembly Manual ChuteAssembly Assembly Remove cotter pin, wing nut and hex screw from chute Remove all loose parts before assembling. control head and clevis pin and bow-tie cotter... -

Page 8: Top View

Place chute onto chute base and ensure hex rod is Rotate the joystick to the one o'clock position so that the positioned under the handle panel. Install hex bolt silver indicator arrow on the pinion gear below the control previously removed but do not secure with wing nut at this panel faces upward. - Page 9 Push the hex rod toward the control panel until the hole Set-Up in the hex rod lines up with the hole in the chute control ShearPins input closest to the chute control head and insert the cotter pin. See Fig. 3-8. A pair of replacement auger shear pins and bow tie cotter pins...

-

Page 10: Fuel Recommendations

Fuel Recommendations Checking 0il Level Use automotive gasoline (unleaded or low leaded to minimize combustion chamber deposits) with a minimum of 87 octane. engine. You must, however, check the oil level prior Gasoline with up to 10% ethanol or 15% MTBE (Methyl Tertiary AUTION"... - Page 11 ChuteAssembly Adjustments The distance snow is thrown can be adjusted by changing SkidShoes angle of the chute assembly. To do so: The snow thrower skid shoes are adjusted upward at the factory Stop the engine by removing the ignition key and loosen for shipping purposes.

- Page 12 Auger Control carefully read and follow all instructions below. WARNING! Prior to operating your snow thrower, Perform all adjustments to verify your snow thrower is operating safely and properly. Check the adjustment of the auger control as follows: When the auger control is released and in the disengaged "up"...

-

Page 13: Controls And Features

Controls a nd Features Shift Lever Drive Directional Control )_====== Auger Control Heated Grips Gas Cap, Chute Assembly Clean Out Tool Primer K_ y J o_ Electric Starter Outlet Choke _Electric Starter Button Throttle Augers Recoil Starter Oil Drain Shoe Handle Figure 4=1 Snow thrower... -

Page 14: Auger Control

ThrottleControl AugerControl AUGER CONTROL The throttle control is located on the rear of the engine. regulates the speed of the engine and will shut offthe engine when moved into the STOP position. Primer The auger control is located on the left handle. Squeeze the control grip against the handle to engage the augers and start snow throwing... -

Page 15: Chuteclean-Outtool

Chute Directional Control ChuteClean-OutTool [PUSH BUTTONi clogged chute assembly. Shut off engine and remain CHUTE ROTATE LEFT ARNING! Never use your hands to clear a behind handles until all moving parts have stopped before unclogging. The chute clean-out tool is conveniently fastened to the rear of the auger housing... -

Page 16: Operation

Operation Plug the extension cord into the electric outlet located Starting the Engine on the engine. Plug the other end of extension cord into a three-prong 120-volt, grounded, AC outlet in a well- ventilated area. See Fig. 5-2. moving parts. Do not use a pressurized starting l_lhllL ARNING! -

Page 17: Replacing Shearpins

RecoilStarter ToEngageDrive With the throttle control in the Fast(rabbit) position, move engine running. shift lever into one of the six forward (F) positions or two CAUTION: Do not pull the starter handle while the reverse (R) positions. Select a speed appropriate for the snow conditions and a pace you're comfortable with. -

Page 18: Maintenance And Adjustments

Maintenance& Adjustments Maintenance Lubrication GearShaft Engine Refer to the Engine Maintenance section. The gear (hex) shaft should be lubricated at least once a season or after every twenty-five (25) hours of operation. ShavePlate and Skid Shoes Allow the engine to run until it is out of fuel. The shave plate and skid shoes on the bottom of the snow Carefully... - Page 19 Auger Shaft Adjustments At least once a season, remove the shear pins from the auger Shift Cable shaft. Spray lubricant inside the shaft and around the spacers and the flange bearings found at either end of the shaft. If the full range of speeds (forward and reverse) cannot be See Fig.

-

Page 20: Off-Season Storage

DriveControl ChuteControl Rod When the drive control is released and in the disengaged "up" To adjust the chute control rod, proceed as follows: position, the cable should have very little slack. It should NOT be Remove the cotter pin from the hole closest to the chute tight. -

Page 21: Engine Maintenance

Engine Maintenance WARNING! To prevent accidental start-up, shut off Periodic inspection and adjustment of the engine is essential high level performance is to be maintained. Regular maintenance the engine and remove the key before performing will also ensure a long service life. The required service intervals any type of engine maintenance. -

Page 22: Spark Plug

Refill with the recommended oil and check the oil level; Measure the plug gap with a feeler gauge. Correct as necessary by bending side electrode, Figure 7-4. The gap refer to Operation section for instructions. should be set to .02-.03 inches (0.60-0.80 ram). -

Page 23: Cleaning The Engine

Cleaning the Engine If the engine has been running, allow it to cool for at least half an hour before cleaning. Periodically remove dirt build-up from engine. because water could contaminate fuel. Using a CAUTION: Do not spray engine with water to clean garden hose or pressure washing equipment also force water into the muffler... -

Page 24: Belt Replacement

Service Carefully pivot the snow thrower up and forward so that it Belt Replacement rests on the auger housing. Auger Belt Remove the frame cover from the underside of the snow thrower by removing the self-tapping screws which secure To remove and replace your snow thrower's auger belt, proceed it. -

Page 25: Drive Belt

Drive Belt Remove the belt from around the auger pulley, and slip the belt between the support bracket and the auger pulley. To remove and replace your snow thrower's drive belt, proceed See Fig. 8-5. as follows: To prevent spillage, remove all fuel from tank by running engine until it stops. - Page 26 FrictionWheelRemoval Back out the stop bolt to increase the clearance between the friction wheel disc and friction wheel. See Fig. 8-7. If the snow thrower fails to drive with the drive control engaged, and performing the drive control cable adjustment fails to correct the problem,...

- Page 27 Carefully remove the hex nut which secures the hex shaft Follow the previous steps in reverse order to reassemble to the snow thrower frame and lightly tap the shaft's end to components. If you're disassembling the friction wheel and dislodge the ball bearing from the right side of the frame.

-

Page 28: Troubleshooting

Troubleshooting Problem Cause Remedy Engine fails to start 1. Choke notin CHOKE position. 1. Move choke to CHOKE position. 2. Spark plug wire disconnected. 2. Connect wire to spark plug. 3. Fuel tank empty or stale fuel. 3. Fill tank with clean, fresh gasoline. 4. -

Page 29: Replacement Parts

Replacement P arts Component Part Number and Description 929-0071 Extension Cord, 110V 954-04050 Auger Drive Belt 954-0367 Wheel Drive Belt 684-04153 Friction Wheel Assembly 935-04054 Friction Wheel Rubber 725-1629 Lamp 738-04124A Shear Pin, 1.50 714-04040 Bow-tie Cotter Pin 784-5580 Slide Shoe, Standard (Steel) 731-06439 Slide Shoe, Standard (Polymer) 790-00091... -

Page 30: Attachments & Accessories

Attachments & Accessories The following attachments and accessories are available for your snow thrower. Phone (800) 800-7310 for information regarding compatibility, price and availability (have your full model number and serial number ready). Model Number Description 753-05762A Heated Grips _- 0EM-390-679 Drift Cutter 0EM-390-674... - Page 32 SECTION 12-- NOTES...

- Page 33 SECTION 12 -- NOTES...

- Page 34 MTD. OWNER'S WARRANTY RESPONSIBILITIES: As the smalloff-roadengineowner,youare responsible forthe performance of the requiredmaintenance listed in your Owner'sManual.MTD recommends that you retainall yourreceiptscoveringmaintenances on yoursmall off-roadengine,but MTDcan not denywarrantysolelyfor the lack of receiptsor foryour failureto ensurethe performanceto all scheduledmaintenance. As the smalloff-roadengineowner,youshouldhoweverbe awarethat MTDmaydenyyour warrantycoverageif yoursmall off-roadengine or part hasfaileddue toabuse, neglect,impropermaintenance or unapprovedmodifications.

- Page 35 (8)Throughout the engine's warranty period defined inSubsection (a)(2), MTD will m aintain a supply ofwarranted parts s ufficient tomeet the expected demand forsuch parts. (9)Any replacement part m ay b eused i ntheperformance...

-

Page 36: Limited Warranty

MANUFACTURER'S LiMiTED WARRANTY The limited warranty set forth below is given by MTD LLC with c. Service completed by someone other than an authorized service dealer. respect to new merchandise purchased and used in the United States and/or its territories and possessions, and by MTD Products Limited d.

Need help?

Do you have a question about the 600 Series and is the answer not in the manual?

Questions and answers