Table of Contents

Advertisement

Owner's Manual

CRnFTSMnN o

6.0 HP

17 INCH TINE WIDTH

REAR TINE WITH

COUNTER

ROTATING TINES

TILLER

Model No,

917.293400

• Safety

• Assembly

° Operation

° Maintenance

° Repair Parts

CAUTION:

Read and follow all

Safety Rules and Instructions

before operating this equipment

Sears, Roebuck

and Co., Hoffman

Estates,

IL 60179

Advertisement

Table of Contents

Summary of Contents for Craftsman 917.293400

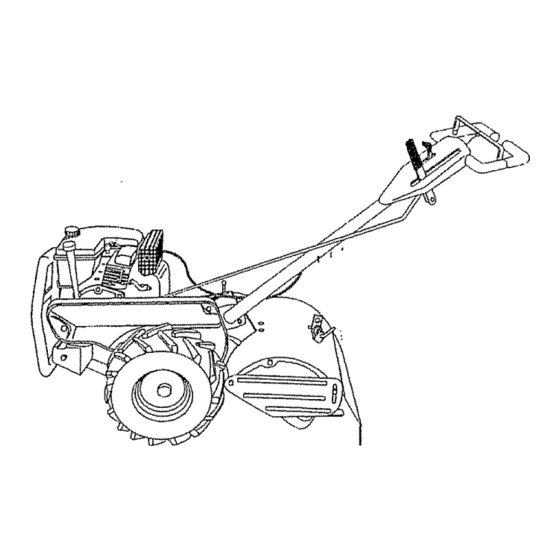

- Page 1 Owner's Manual CRnFTSMnN o 6.0 HP 17 INCH TINE WIDTH REAR TINE WITH COUNTER ROTATING TINES TILLER Model No, 917.293400 • Safety • Assembly ° Operation ° Maintenance ° Repair Parts CAUTION: Read and follow all Safety Rules and Instructions before operating this equipment Sears, Roebuck and Co., Hoffman...

- Page 2 If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies for only thirty _30) days from the date of purchase, Warranty...

- Page 3 OPERATION MAINTENANCE STORAGE • Do not put hands or feet near or under • Keep machine, attachments, accessories in safe working condition. rotating parts. • Exercise extreme caution when operat- ° Check shear pins, engine mounting ing on or crossing gravel drives, walks, bolts, and other bolts at frequent inter-...

- Page 4 This unit is equipped with an Congratulations on your purchase of a internal combustion engine and should not Craftsman Tiller. It has been designed, be used on or near any unimproved forest- gineered and manufacttJred to give you the covered, brush-covered...

- Page 5 Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes, To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper tightness.

- Page 6 UNPACKING CARTON ,,. _ ,,_ Handle Assembly "uP" Posilfoo ,_OAUTION: Be careful of exposed sta- ples when handling or disposing of cartom "::'+:_::_ Tighten handle lock ing material, IMPORTANT:When unpacking assembling tiller, be careful not to stretch or kink cables. Loose__ _.'_,_'_ •...

- Page 7 INSEHT [;ABLI= ULtt _ ° Insert plastic cable clip into hole on the back of handle column Push cables Attach thts end to shift lever -.-,.._ into clip, LL"_,Atlach this End To shift "_'_" Shift Rod Handle Column Lever Indicator Shift Rod Hairpin Clip Shift Lever...

- Page 8 Thesesymbols mayappearon yourTEller or in literature suppliedwitl_the product. Learnandunderstand their meaning. T_,LI#(_ FO;_,Vi_D N_UT_I F_EE CkUT_ON Et,_GIHE 5t',_G_E SLO_ CHOK_ FUEL OR WARNING KNOW YOUR TILLER READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER. Compare the illustrations with your tiller to familiarize yourself with the location of vari-...

- Page 9 The operationol anytillercan resultin foreignobjectsthrownintothe eyes, whichcan resultin severeeye damage.Alwayswear safetyglassesor eye shieldsbeforestartingyourtiller andwhiletilling,We recommenda wide visionsafetymaskoverthe spectaclesor standardsafety glasses. TO USE YOUR TILLER DEPTH STAKE The depth stake ban be raised or lowered Know how to operate all controls before to allow you more versatile tilling and culti-...

- Page 10 TURNING CHECK ENGINE OIL LEVEL • Release tile drive control bar. ,, The engine in your unit has been shipped, from the factory, already filled . Move throttle control to "SLOW" posi- with SAE 30 summer weight oil, tion. . Be sure tiller is level and the area •...

- Page 11 TILLINL_ HINT_ ,_CAUTtON" Fill to within 1/2 inch of top ,_CAUTION: Until you are accustomed of fuel tank to prevent spills and to allow handling your tiller, start actual field use for fuel expansion° If gaso{ine _sacciden- with throttle in slow position (mid-way tally spilled, move machine away from between...

- Page 12 CULTIVATING TINE SHEAR PINS Cultivatingis destroyingthe weeds The fine assemblies on your tiller are betweenrowsto preventthem fromrob- secured to the fine shaft with shear pins bing nourishment a nd moisturefromthe (See 'q'INE REPLACEMENT" In the Service and Adjustments section of this plants,At the sametime, breakingup the upperlayerof soil crustwill help retain manual).

- Page 13 :SERV CE DATES Check Engine Oil Level Change E.glne o, Oil Pivot Points Inspect Spark Attester / Mutfter Inspect Air Screen Clean or Replace Air Cleaner Cartridge Clean Engine Cylinder Fins Replace Spark Plug ! - Ch_flge more often when opersling under a heavy toad a_ in high amblenl temperntures SeatO0 more often when operating In dt_y or dos_ conditions.

- Page 14 After drained completely, Disconnect spark plug wire before per- forming any maintenance (except carbure- replace drain plug tighten tor adjustment) to prevent accidental start_ securely. ing of engine_ Refill engine with oil through oil fIH tube. "CHECK ENGINE Prevent fires] Keep the engine free of grass, leaves, spilled oil, or fue!.

- Page 15 _U_Lr_M L_Ono[ use pressunzuu a. tu u_uan uJ u{y cartridge. Do not operate tiller without muffler Do not Base tamper with exhaust system Damaged Foam Precleaner mufflers or spark arrestors could create a fire hazard, Inspect periodically and re- place if necessary. If your engine is equipped with a spark arrester...

- Page 16 TIRE CARE ._CAUTION: When mounting tires, un- less beads are seated, overinflation cause an explosion_ ° Maintain 20 pounds of tire pressuleo tire pressures are not equal, tiller will pull to one side. • Keep tires free of gasoline or oil which Cap Nut can damage rubber.

- Page 17 Screw - DriveControl Cable ._nsion Transmission Pu!ley TINE REPLACEMENT To maintain the superb tilling perfor- mance of this machine the tines should ,_.CAUTION: Tines are sharp. Wear be checked for sharpness, wear, and gloves or other protection when handling bending, particularly the tines which are tines.

- Page 18 ENGINE TO ADJUST CARBURETOR The carburetor has been preset at the fac- Maintenance, repair, or reRlacement of the tory and adjustment should not be neces- emission control devices af_d systems, sary+ However, engine performance which are being doqe at the customers be affected by differences in fuel, tempera+...

- Page 19 NOTE: Fuel stabilizer is an acceptable Immediately prepare your tiller for storage at the end of the season or if the unit will afternative in minimfzing the formation fuel gum deposits during storage. Add sta- not be used for 30 days or more. bilizer to gasoline in fuel tank or storage ,_,CAUTION:...

- Page 20 CORRECTION CAUSE PROBLEM 1, Fil_fuel tank_ Wt}I not start 1., Out of fuel 2. See "TO START ENGINE" tn,,the 2. Engine not "CHOKED" Operation section,, properly 3. Walt several minutes betore Engine flooded. attempting to start. 4. Clean or replace air cleaner car Dirtyair cleaner tridge°...

- Page 21 PROBLEM CAUSE , CORRECTION 1., check oil level/change oil, Engine overheats 1., Low oil level/dirty oil 2., Dirty engine air screen, Clean engine air screen, 3. Clean cylinder fins, air screen, muf 3, Dirty engine, tier area, 4. Remove and clean muffler. 4.

- Page 22 TILLER - - MODEL NUMBER 917.293400 HANDLES "tt. ",X PART DESCRIPTION PART DESCRIPTION STD541437 *Nut, Cenlefiock 318_16 127o12x Tflrollle, Control 19131611 Washer 13/32 x 1 × 1t Ga 141406 Grip, Handle 109228X Lever. Lock. Handle 110673X G[ommet, Handle 150258 Handle, Assemble 127254X Bar, Drive Conlrol Assembly 121145X...

- Page 23 TILLER - - MODEL NUMBER 917.293400 MAINFRAME, LEFT SIDE "o +" PART DESCRIPTION PART DESCRIPTION STD541431 Nut, Keps 5/16-18 I26875X Rivet, Orllled STD551137 *Washer, Lock 8/8 8TD624003 'Clip, Hairpin STD541037 "Nut, Hex 3/8.t6 131t59X574 Guard, Bell 74930568 Bratt,Hex 5/16-18x4-114 132801 Belt, V 154734 Screw Shift Lever...

- Page 24 Tire Valve 74760512 BoIt, Hex 5/16-18 x 3/4 STD541431 *Nut, Keps 5/16-18 102332X Bracket, Reinforcement ..Engtne, (See Breakdown) Craftsman Model No. 74760532 Bolt, Hex 5/16-18 x 2 I43.976001 I02173X Counter Weight, R H. STD551137 *Washer, Lock 3/8 STANDARD HARDWARE...

-

Page 25: Tiller Model 917.293400 Transmission

TILLER - - MODEL NUMBER 9!7,293400 TRANSMISSION DESCRIPTION PART DESCRIPTION PART 154354 150737 Ground Shatt Assembly Transmission Assembly (Includes Key Nos. 2-52) 143008 Bearing, Shaft, Ground Drive 150698 Gearcase, L H. w/Bearing (fncludes Key No 4} 106388X Spacer 070x 1 O0 x 1 150 106211X Gasket, Gearcase 102121X... - Page 26 TILLER - - MODEL NUMBER 917.293400 TINE SHIELD 2¢ DESCRIPTION PART PART DESCRIPTION 98000129 Nut, Range 5/16d8 162175 NuL Wing Forged 5/16o18 16t415X574 Shield,Side, Outer L.H. STD532512 *Boll, Carriage 1,'4-20 x I-1/4 Gr. 5 8393./ Pin, Stake, Oeplh 120(}0036 Ring, Klip 102701X *Nul, Hex 3/0-10 ST6533107...

- Page 27 TILLER - - MODEL NUMBER 9t 7.293400 TINE ASSEMBLY PAR3 r DESCRIPTION DESCRIPTION PART 4459J Tine, Outer, LH 4460J "line, Outer, R H 132673 Pin, Shear 132728 Assembly. Hub and Pfate. R H '_qne,Inner, L H 6555J 3qne. Inner, R H 6554J STD624008 "Clip.

- Page 28 TILLER --. MODEL NUMBER 917.293400 DECALS DESCRIPTION PAR]' 158095 Decal, Lago 145023 Decal, Logo 157982 Decal, Logo 157983 Decal, Description 137536 Decal, Caution, Ddve Controt 120431X Decal, Hand Placement 102180X Decal, Shift Indicator 157984 Decal, "Fine,Shield, Counter Rotating Tines 120075X Decal, Warning, Rotaling _nes 163094 Decal, "lqneDeplh Stake...

- Page 29 TILLER - - MODEL NUMBER 9t7.293400 ENGINE, TECUMSEH - - MODEL NUMBER 143,976001...

- Page 30 TILLER - - MODEL NUMBER 917,293400 ENGINE, TECUMSEH - - MODEL NUMBER 143.976001 370& ¢ PART PART DESCRIPTION DESCRIPTION 36866 Cylinder (tnoL 2, 20 & 72) 29826 Screw, 10-32 x 3/4" 26727 Dowel Pin 29918 Lock Washer 28277 Washer 29216 Lock Nut, 10-32 30589 Governor Rod...

- Page 31 TILLER - - MODEL NUMBER 9t7.293400 ENGINE, TECUMSEH - - MODEL NUMBER 143.976001 PART PART DESCRIPTION DESCRIPTION Conduit Clip 2038t Piston Pin Retaining _Ring 27793 Screw, 10-32 x 3/8" 32875A Connecting Rod AssOy 28942 Screw, 1/4-20 x 1" (Incl. 46 & 49) 650451 *Intake Pipe Gasket 32610A...

- Page 32 T|LLEH - - ML)IJr_L NUIVI_I::::H f91 [.Z_J;SqUU ENGINE, TECUMSEH - - MODEL NUMBER 143.976001 DESCRIPTION ..640025 Carburetor (Ind 184 or Eng Parts fist) PART "' 631615 Thtotlle Shaft & Lever Assembly 631767 Throttle Return Spdng _!_, ,_ 631184 Dust Seal Washer 631183 Dusl Seat (Throttle) Throtlle Shutter...

- Page 36 For the repair or replacement pads you need deli_'ered directly to your home Call 7 am - 7 pro, 7 days a week 1-800-366-PART (1-800-366-7278) Para ordenar piezas con entrega domicilio - 1-800-659-7084 For in-house major brand repair service Call 24 hours a day, 7 days a week 1-800-4-REPAIR (1-800_473_7274) Para...

Need help?

Do you have a question about the 917.293400 and is the answer not in the manual?

Questions and answers