Table of Contents

Advertisement

1403-1413 Perf Series Carburetor Owner's Manual.qxd

Your Edelbrock Performer Series carburetor was calibrated using Edelbrock Performer, Performer

RPM, and Torker II Power Packages. The carburetor metering was developed on Edelbrock engine

dynamometers, chassis rolls, and a variety of development vehicles. Although in most applications

you will not need to recalibrate your carburetor, you may wish to change the factory calibration to best

meet any unique needs of your engine. The following manual consists of 2 sections; Theory of

Operation and Tuning Procedure. Upon review of Section 1, Theory of Operation, you will be prepared

to develop your own individualized calibration. Section 2, Tuning Procedures will take you through a

step-by-step procedure that will enable you to achieve a desirable calibration. For added ease of

tuning, a Calibration Reference Chart for your model of carburetor has been included.

SECTION 1:

SECTION 2:

INTRODUCTION

TABLE OF CONTENTS

THEORY OF OPERATION .......................................................................2

BASIC ENGINE REQUIREMENTS ............................................................2

METERING SYSTEMS............................................................................3

1. Idle System ..............................................................................3

2. Primary Main System ................................................................4

3. Secondary Main System............................................................6

TRANSIENT CONTROL SYSTEMS ..........................................................6

1. Secondary Auxiliary System .....................................................6

2. Pump System ...........................................................................7

EXTERNAL DEVICES..............................................................................8

Fuel Pumps and Pressure..............................................................8

Air Cleaners ..................................................................................9

TUNING PROCEDURE ............................................................................9

REVISING THE CALIBRATION.................................................................9

Parts and Equipment ..................................................................10

Changing Components ................................................................11

IDLE MIXTURE ....................................................................................11

Winter Fuel Idle Sets ..................................................................11

Long Duration Camshaft..............................................................12

WIDE-OPEN THROTTLE (WOT) ............................................................12

CALIBRATING THE PART THROTTLE....................................................13

Cruise Mode................................................................................13

Power Mode ...............................................................................14

CALIBRATING THE POWER MODE STAGING.........................................14

CALIBRATING THE PUMP ....................................................................14

FLOAT ADJUSTMENT .........................................................................14

CHOKE ADJUSTMENT.........................................................................15

SPECIAL CALIBRATIONS ....................................................................16

CARBURETOR SPECIFICATIONS ....................................................16, 17

CALIBRATION REFERENCE CHARTS...............................................18-31

APPENDIX .....................................................................................32-38

Exploded View.......................................................................32, 33

Troubleshooting Information. .................................................34-36

WARRANTY .......................................................................................37

EDELBROCK CARBURETOR DATA LOG ...............................................38

1

3/31/2006

12:04 PM

Edelbrock Performer Series Carburetor Owner's Manual 3/00

Page 1

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Edelbrock 1403-1413

-

Page 1: Table Of Contents

1403-1413 Perf Series Carburetor Owner's Manual.qxd Your Edelbrock Performer Series carburetor was calibrated using Edelbrock Performer, Performer RPM, and Torker II Power Packages. The carburetor metering was developed on Edelbrock engine dynamometers, chassis rolls, and a variety of development vehicles. Although in most applications you will not need to recalibrate your carburetor, you may wish to change the factory calibration to best meet any unique needs of your engine. -

Page 2: Section 1: Theory Of Operation

1403-1413 Perf Series Carburetor Owner's Manual.qxd SECTION 1: THEORY OF OPERATION BASIC ENGINE REQUIREMENTS The spark-ignition 4-cycle engine burns a mixture of AIR and FUEL. The air is controlled by the driver’s operation of the throttle. The fuel is mixed with the incoming air by the carburetor. The Ratio of AIR to FUEL is the AIR/FUEL Ratio (A/F). -

Page 3: Metering Systems

1000 2000 3000 4000 5000 6000 7000 8000 9000 METERING SYSTEMS The Edelbrock carburetor has three (3) basic systems that meter fuel to the engine: The Idle System, Primary Main System, and Secondary Main System. By understanding the operation of each you will be better prepared to calibrate your carburetor. -

Page 4: Primary Main System

1403-1413 Perf Series Carburetor Owner's Manual.qxd Fuel is drawn through the Idle System (Figure 2) by the intake manifold vacuum that is communicated at the Idle Screw Port (8) and Transfer Slot (7). Fuel in the bowl passes through the Primary Main Jet and Metering Rod Restriction (1) and into the Primary Well (2). -

Page 5: Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:04 Pm

1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:04 PM Page 5 The fuel flow rate in the Main System is proportional to the air flow rate; as air flow increases - from either an increase in throttle opening or an increase in engine speed at the same throttle opening - the fuel flow also increases by nearly the same degree. -

Page 6: Secondary Main System

1403-1413 Perf Series Carburetor Owner's Manual.qxd Secondary Main System: The Secondary Main System (Figure 5) delivers fuel only when the secondary throttle blades and air valve are open. It ensures that fuel delivery varies with air flow. The Secondary Throttles (1) begin to open when the Primaries are about 65% open. The Primary and Secondary Throttles arrive at the WOT stop at the same time. -

Page 7: Pump System

Regardless of cause, a solution is to temporarily enrichen the A/F Ratio by mechanically pumping a small quantity of fuel into the throat of the carburetor (Figure 7). The Edelbrock carburetor has a piston that draws fuel into the pump cavity past the plunger lip-seal when the throttle is closing (1). -

Page 8: External Devices

If it is more than 6.0 psi at IDLE, it should be reduced through the use of a regulator, such as Edelbrock #8190, or by creating a restricted by-pass bleed to the fuel return line. Edelbrock Street Fuel Pumps are highly recommended for all Edelbrock Performer Series carburetor installations. -

Page 9: Air Cleaners

— A large 14”x3” open element air cleaner, such as Edelbrock Elite Series, Signature Series and Pro-Flo air cleaners, offers almost no resistance to air flow. Flow bench results show virtually no reduction in air flow. -

Page 10: Parts And Equipment

1403-1413 Perf Series Carburetor Owner's Manual.qxd To help you calibrate your carburetor, a CALIBRATION REFERENCE CHART has been designed for each model of the Edelbrock Performer Series carburetor. These charts (pages 18—31) each consist of two sections: A Calibration Table and a Rod/Jet Reference Chart. -

Page 11: Changing Components

IDLE MIXTURE The Edelbrock Performer Series carburetor has conventional Idle Mixture Screws (IMS) that provide a leaner A/F when turned clockwise and richer A/F when turned counter clockwise. The idle air flow is controlled by a conventional screw that opens the Primary Throttles. -

Page 12: Long Duration Camshaft

1403-1413 Perf Series Carburetor Owner's Manual.qxd Long Duration Camshaft If the engine has a fairly radical camshaft it may require an excessive amount of throttle opening for idle and/or have low idle vacuum levels. Either condition can lead to poor levels of adjustability and erratic idles. -

Page 13: Calibrating The Part Throttle

Case 3: Same as base calibration Do not be surprised. Change back to base calibration. CALIBRATING THE PART-THROTTLE The Metering Rod feature used in the Edelbrock Performer allows easy calibration of the part-throttle without change to the WOT metering. •... -

Page 14: Calibrating The Power Mode Staging

Spring Color Staging Vacuum ("Hg) A complete set of these springs is available separately as Edelbrock part #1464. CALIBRATING THE PUMP If you encounter any hesitations or stumbles that do not seem to be related to the basic metering or have not responded to changes in the basic metering, move the pump drive link to one of the holes closer to the carburetor body. - Page 15 Float Level (7/16") Figure 8 7/16” Drill bit (.100") Float Drop (15/16" to 1") Figure 9 (3/64") .026 Wire Slot Piston Cylinder Choke piston linkage Figure 10 Fast idle linkage Figure 11 Edelbrock Performer Series Carburetor Owner’s Manual Rev 9/01...

-

Page 16: Special Calibrations

Although the Edelbrock Performer Series carburetor was not calibrated with hill climbing and other extreme off-road operation in mind, it can be made to perform superbly by substituting Edelbrock #1465 spring loaded needle and seat for the original needle and seat. The spring loaded needle and seat act like a shock absorber, reducing the possibility of flooding during off-road operation. -

Page 17: Carburetor Specifications

Gasahol can be a blend of either ethanol, methanol or other alcohol with gasoline. Methanol blended fuel should not be used in your Edelbrock Performer Series carburetor as it will cause corrosion of the fuel system components. It can also cause rapid failure of seals, gaskets, diaphragms and pump plungers. -

Page 18: Calibration Reference Charts

1403-1413 Perf Series Carburetor Owner's Manual.qxd #1403/ #1404 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%) - Page 19 2 Stages Lean (12%) Lean (8%) JET #1423 JET #1424 (.086) (.089) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1403/#1404 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

- Page 20 1403-1413 Perf Series Carburetor Owner's Manual.qxd #1405 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%) Base...

- Page 21 2 Stages Lean (12%) Lean (8%) JET #1423 JET #1424 (.086) (.089) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1405 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

- Page 22 1403-1413 Perf Series Carburetor Owner's Manual.qxd #1406 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%) Base...

- Page 23 2 Stages Lean (12%) Lean (8%) JET #1423 JET #1424 (.086) (.089) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1406 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

- Page 24 1403-1413 Perf Series Carburetor Owner's Manual.qxd #1407 / #1410 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%)

- Page 25 Lean (12%) Lean (8%) JET #1427 JET #1429 (.098) (.101) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1407 & #1410 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

- Page 26 1403-1413 Perf Series Carburetor Owner's Manual.qxd #1409 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%) Base...

- Page 27 2 Stages Lean (12%) Lean (8%) JET #1425 JET #1426 (.092) (.095) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1409 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

- Page 28 1403-1413 Perf Series Carburetor Owner's Manual.qxd #1411 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%) Base...

- Page 29 2 Stages Lean (12%) Lean (8%) JET #1427 JET #1429 (.098) (.101) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1411 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

- Page 30 1403-1413 Perf Series Carburetor Owner's Manual.qxd #1412 & #1413 Calibration Reference Chart / Primary Metering Power Mode: Low Vacuum/High Power-Rod Up 3 stages 2 stages Lean (12%) Lean (8%) 3 stages Rich (12%) 2 stages Rich (8%) 1 stage Rich (4%)

- Page 31 Lean (12%) Lean (8%) JET #1425 JET #1426 (.092) (.095) Main Jet I.D.—All Edelbrock jets have “120-”prefix. The last three digits minus 300 = actual jet size. Examples: 3/31/2006 Model #1412 & #1413 Rod/Jet Reference Chart METERING ROD CHANGE FROM BASE...

-

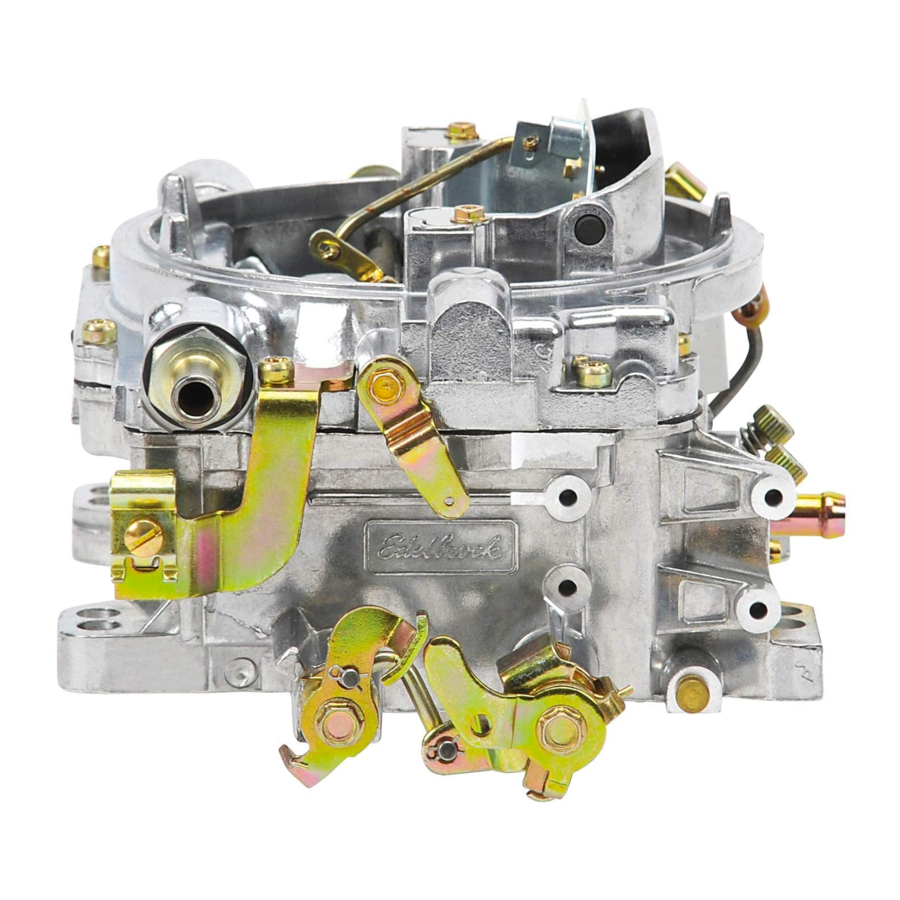

Page 32: Appendix

1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:04 PM Page 32 Exploded View of Edelbrock Performer Series Carburetor Edelbrock Performer Series Carburetor Owner’s Manual 8/94... - Page 33 1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:05 PM Page 33 Edelbrock Performer Series Carburetor Owner’s Manual 8/94...

-

Page 34: Troubleshooting Chart

1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:05 PM Page 34 Troubleshooting Chart Possible Solution (Symptoms on opposite page) Check for air leaks. Make sure carburetor and manifold gaskets seal properly. All outlets must be plugged or connected. Check ignition system. Replace parts as necessary. Adjust timing to proper specifications. - Page 35 1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 Symptoms Edelbrock Performer Series Carburetor Owner’s Manual 8/94 12:05 PM Page 35...

-

Page 36: Troubleshooting Information

Also check to see if the exhaust heat riser is stuck, allowing excessive heat under the carburetor. Use Edelbrock Divided Heat Insulator Gasket #9266 for dual-plane manifolds, Square-Bore Heat Insulator Gasket #9265 for single- plane manifolds, and #9267 Heat Insulator Gaskets for dual-quad manifolds. -

Page 37: Warranty

This warranty covers the replacement or repair at Edelbrock's option of the product only and does not cover the cost of removal or installation of the product. Final warranty determination will be the decision of EDELBROCK. - Page 38 1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:05 PM Page 38 Notes: Edelbrock Performer Series Carburetor Owner’s Manual 8/94...

-

Page 39: Edelbrock Carburetor Data Log

1403-1413 Perf Series Carburetor Owner's Manual.qxd Edelbrock Carburetor Data Log In order to get the most from your Edelbrock carburetor purchase, please complete and mail the enclosed warranty card. Also, you may want to record your calibration settings in the table below and keep it with your vehicle records.

Need help?

Do you have a question about the 1403-1413 and is the answer not in the manual?

Questions and answers